Abstract

Eu3+-doped Ba3Al2O6 red phosphors were synthesized by high-temperature solid-state reaction. The crystal structure, morphology and luminescence properties were investigated by XRD, TEM and photoluminescence spectroscopy. The effect of calcination temperature, Eu3+ concentration as well as charge compensators on the luminescence properties was also investigated. Characteristic orange-red emission at 589 nm was detected under 394 nm excitation. The best performance could be derived for the sample calcined at 1450 °C. With the increase of Eu3+ concentration, the emission intensities increased gradually up to the Eu3+ concentration of 12 %. The emission intensities could be enhanced with Li+, Na+ and K+ introduced as charge compensators. The results showed that Ba3Al2O6:Eu3+ phosphors with charge compensator had potential application in the fields of near-UV-excited WLEDs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recently, white light-emitting diodes (WLEDs) have attracted much attentions due to its compactness, high efficiency, long operational lifetime, energy saving and environment protection [1–4]. However, the commercial WLEDs fabricated using yellow-emitting YAG:Ce3+ phosphors with blue LED chips have a notable deficiency because of the scarcity of red emission, restricting their applications in some important fields, especially in lighting markets [5]. Nowadays, near-UV LED chips coated with red, green and blue phosphors are considered as a potential system to produce better properties in emission efficiency, colour temperature and colour rendering index [6, 7]. Comparing with the blue and green phosphors, the commonly used red phosphors for WLEDs show lower chemical stabilities and fluorescence efficiencies. Therefore, stable and high-efficient red phosphors suitable for near-UV chips are necessary for the development of WLEDs.

Among all the host materials used in WLEDs, rare earth-doped Alkaline earth aluminates M3Al2O6 (M = Ca, Sr, Ba) possess many advantages, such as high chemical stability, high luminescence intensity, high quantum efficiency, nontoxic, low cost and so on [8]. The structure of M3Al2O6 belongs to the cubic system with space group Pa3 [9–11]. M has six independent crystallographic sites in M3Al2O6 lattices [12]. Recently, it is reported that Eu3+- or Dy3+-doped Ca3Al2O6 and Eu2+-doped Sr3Al2O6 can be used as promising phosphors for fabrication of warm WLED [13–15]. In addition, Ca3Al2O6 and Sr3Al2O6 are popular hosts in M3Al2O6 system and the luminescence properties of rare earth ions doped in these two hosts have been investigated [8, 16, 17]. But to our best knowledge, there are few reports on the photoluminescence properties of rare earth-doped Ba3Al2O6. In this work, the Eu3+-doped Ba3Al2O6 phosphors are prepared by the method of high-temperature solid-state reaction. The luminescence properties of Ba3Al2O6:Eu3+ are investigated, and the effect of calcinations temperature, Eu3+ concentration as well as charge compensations on the luminescence properties is also discussed.

Experiment

Ba3Al2O6:Eu3+ phosphor was synthesized by high-temperature solid-state method using Eu2O3 (99.99 %), BaCO3 (AR), Al2O3 (AR), Li2CO3 (AR), Na2CO3 (AR) and K2CO3 (AR) as reagents. Two types of samples were prepared: Ba3Al2O6:xEu3+(x = 0.02, 0.04,…, 0.16), Ba3Al2O6:0.06Eu3+, 0.06Z (Z = Li+, Na+, K+). According to the formula above, stoichiometric amounts of starting materials were weighed and then mixed thoroughly in the agate mortar. The mixture was calcined at different temperatures (1300, 1350, 1400 and 1450 °C) in a muffle furnace in air atmosphere for about 6 h. After cooling down to room temperature, white powder samples were obtained and then reground.

X-ray diffraction patterns of the samples in the range of 10° ≤ 2θ ≤ 90° were recorded on a Bruker D8 Advance X-ray diffractometer with Cu K α radiation (λ = 1.54178 Å). Transmission electron microscopy (TEM) micrographs were taken with a Tecnai G2 F20 field-emission transmission electron microscope. The excitation and emission spectra of the samples were detected by Hitachi F-7000 fluorescence spectrometer. The light source was xenon lamp and resolution was 0.5 nm. The light emitted from the Xe lamp entered the excitation side monochromator and then incident on the sample. Luminescence signal emitted from the sample directed into the emission side monochromator and was condensed onto the photomultiplier tube by concave mirror, whereby its intensity was measured. To ensure the identical measurement conditions of photoluminescence spectra for the different samples, the slit width, scan speed and high voltage of photomultiplier tube were kept unchanged for each measurement. All measurements were carried out at room temperature and the spectra had been corrected.

Results and discussion

Photoluminescence characteristics

The photoluminescence spectra of Ba3Al2O6:0.06Eu3+ calcined at 1450 °C are presented in Fig. 1. In the excitation spectrum found in Fig. 1a, there are broadband centred at about 270 nm associated with the charge transfer (CT) transition from 2p orbital of O2− ions to 4f orbital of Eu3+ ions and narrower bands arising from intraconfigurational 4f–4f transitions (assignment is given in Figure). The emission spectrum of Ba3Al2O6:0.06Eu3+ sample under 394 nm excitation (Fig. 1b) consists of two emission bands with peaks at 589 and 612 nm, corresponding to the 5D0 → 7F1 and 5D0 → 7F2 transitions. The most intense peak located at 589 nm confirms that Eu3+ ion occupies the lattice site with inversion centre of symmetry [18, 19].

The effect of calcination temperature on the photoluminescence properties of Ba3Al2O6:0.06Eu3+

The XRD patterns of Ba3Al2O6:0.06Eu3+ calcined at four different temperatures are shown in Fig. 2. It can be seen from the figure that all the diffraction peaks of samples show very similar profiles and they are in agreement with that of the standard card (JCPDS No. 25-0075), which means that cubic phase Ba3Al2O6 is predominant in the samples. Some additional peaks at about 22.5° and 36.2° are observed for the samples with calcination temperature 1300 and 1350 °C in Fig. 2. These additional peaks maybe attributed to the diffraction of BaCO3 (JCPDS No.52-1528). The decomposition temperature of BaCO3 is 1300 °C, so it may not be decomposed completely at 1300 and 1350 °C because of the temperature fluctuation in the furnace. The intensities of diffraction peaks increase when the calcination temperature increases from 1300 to 1450 °C, which indicates that higher crystalline is obtained at higher calcination temperature.

Figure 3 shows the TEM images of Ba3Al2O6:0.06Eu3+ calcined at different temperatures. It is found that the morphology of the sample depends on the calcination temperature heavily. The particles of sample calcined at 1300 °C are irregular with sizes in the range of 40–60 nm and aggregated evidently, as shown in Fig. 3a and b. The high-resolution TEM (HRTEM) image exposes the crystalline nature of the sample. In Fig. 3c, lattice fringes can be observed and the interplanar spacing is 0.375 nm, indexed to be (331) planes. However, most of the fringes cannot be observed clearly in the detected region, which means that amorphous phase is predominant in this sample and the crystallinity is poor. With the increase of calcinations temperature, whole of the samples are converted into nanorods and the nanorods are straight in nature. What is more, lattice fringes become clearer. The formation of these varying morphologies is not yet well understood. As can be seen from Fig. 3d and e, the nanorods calcined at 1350 °C have the range of diameter 40–80 nm and length in the range from 2 to 8μm. HRTEM image shows very clear lattice fringes and the amorphous phase has disappeared (see Fig. 3f). The obvious lattice fringes confirm the high crystallinity of the sample calcined at 1350 °C. The interplanar spacing of lattice fringes is 0.317 nm, ascribed to (511) planes of Ba3Al2O6. However, a part of lattice sites are not aligned or go right through the entire array, indicating the presence of defects in the crystal. For the samples calcined at 1400 and 1450 °C, the length of nanorods decreases to about 2–6μm and the diameter increases to 50–110 nm (see Fig. 3g, h, j, k). Further, HRTEM analysis reveals that the lattice fringes with the interplanar spacing of 0.333 and 0.441 nm are present and assigned to the (442) and (321) planes for the sample calcined at 1400 °C (see Fig. 3i). The orientations in different directions show the polycrystalline nature of sample [20]. While, as for the sample calcined at 1450 °C, only lattice fringes of (422) planes can be observed (see Fig. 3l), which means the sample is of single-crystalline nature. Therefore, it is concluded that the crystallinity increases with the increase of calcinations temperature, which is consistent with the XRD results. In general, all experimental results discussed above confirm that morphology and crystallinity of Ba3Al2O6 are heavily affected by the calcination temperature.

Figure 4 shows the emission spectra excited at 394 nm for Ba3Al2O6:0.06Eu3+ calcined at different temperatures. The emission intensity increases with the increase of calcination temperature. The reason may be due to the better crystallinity at higher calcination temperature, just as discussed above.

The effect of Eu3+ concentration on the photoluminescence properties of Ba3Al2O6:Eu3+ samples

The XRD patterns of Ba3Al2O6 samples doped with different Eu3+ concentrations are presented in Fig. 5. It is found that all the diffraction peaks of samples are in agreement with that of the standard card (JCPDS No. 25-0075) when the Eu3+ concentration (x) is lower than 0.04. Then the impurity phase BaAl2O4 (JCPDS No. 17-0306) appears when x exceeds 0.04 and the amounts of BaAl2O4 increase with the increase of Eu3+ concentration. Similar results are observed in rare earth-doped Ca3Al2O6 phosphors [12]. This indicates that Eu3+ concentration has strong influence on the phase of synthesized Ba3Al2O6 samples. Since the ionic radius of Eu3+ (0.095 nm) is smaller than that of Ba2+ (0.136 nm), the structure of Ba3Al2O6 will be distorted when Eu3+ ions occupy the Ba2+ sites. According to the ratio of raw materials of Ba3Al2O6:xEu, if Eu3+ replaces Ba2+, it will lead to an excess of BaO and Al2O3 and the Al2O3 will react with Ba3Al2O6 to form BaAl2O4 [16, 21]. Usually, the diffraction peaks will move to the larger angles with increasing Eu3+ concentration when Ba2+ are replaced by the Eu3+ ions with smaller ionic radius. However, the diffraction peaks of samples move very slightly to the low-angle side with increase of Eu3+ concentration, demonstrating the increase of lattice constant in the samples [22, 23]. The reason may be that some Eu3+ ions are incorporated into the interstitial sites of crystal.

Figure 6 presents emission spectra of different Eu3+ concentration-doped Ba3Al2O6 samples calcined at 1450 °C under 394 nm excitation. It can be seen that photoluminescence intensity of 5D0 → 7F1 transition (589 nm) grows with increasing Eu3+ concentration up to x = 0.12. Further increase of Eu3+ concentration leads to intensity reduction because of concentration quenching. This quenching process is often attributed to energy migration among the Eu3+ ions. As the Eu3+ concentration increases, the distance between Eu3+ ions become shorter which may lead to growing energy migration between activator centres and thus enhanced probability of reaching a luminescence-killing defect [24, 25]. This optimal concentration of Eu3+ ions in Ba3Al2O6 samples is lower than those in other aluminate hosts, such as YAG and SrAl2O4 [26, 27]. Eu3+ ion is known as a sensitive probe for the site symmetry. The red emission 5D0 → 7F2 transition is highly sensitive to the environment symmetry and a larger probability of this transition will be increased due to a decrease in symmetry. However, 5D0 → 7F1 transition hardly varies with the crystal field strength around Eu3+ ions and can be taken as a Ref. [28]. Therefore, the ratio of emission intensity of 5D0 → 7F2 transition to that of 5D0 → 7F1 transition, known as asymmetry factor R, is used to be a criterion for the site symmetries of Eu3+ ions. Generally, R is <1.0 for symmetric and >1.0 for noncentrosymmetric surroundings [29]. Figure 7 shows the dependence of asymmetry factor R on the Eu3+ concentration under 394 nm excitation wavelength in Ba3Al2O6 samples. The R value is <1.0 and decreases with increase of Eu3+ concentration when x is lower than 0.12, which confirms that the Eu3+ ions are located in a symmetric environment, while the R values show an increasing tendency when Eu3+ concentration x exceeds 0.12, which means the decrease of local symmetry of Eu3+ ions. The reason is possible that the ion radius of Eu3+ is much smaller than that of Ba2+ ion. When Eu3+ ions enter the host lattice and substitute Ba2+ ions, barium vacancies are produced in order to keep charge balance in the materials, \( {\text{Eu}}_{2} {\text{O}}_{3} \mathop{\longrightarrow}\limits{{{\text{Ba}}_{3} {\text{Al}}_{2} {\text{O}}_{6} }}2{\text{Eu}}_{\text{Ba}}^{.} + {\text{V}}_{\text{Ba}}^{{\prime \prime }} + 3{\text{O}}_{0} \). These defects will lead to the distortion of local environment symmetries of Eu3+ ions [30]. With the increase of Eu3+ concentration, more barium vacancies are induced, leading to lowering the symmetry of the surrounding Eu3+ ions [31]. For the sample in which Eu3+ concentration x = 0.16, the R value increases abruptly and is found to be 1.06, so the Eu3+ ions located in asymmetric environment are predominant. We think that impurity phase BaAl2O4 makes a great contribution to the R value. With the increase of Eu3+ concentration, the impurity phase cannot be negligible and Eu3+ ions may incorporate into BaAl2O4 host, so the real Eu3+ concentration doped into Ba3Al2O6 samples maybe lower than that expected. On the other hand, the red emission of 5D0 → 7F2 transition is predominant in the Eu3+-doped BaAl2O4 phosphors because the Eu3+ ions occupy the barium sites with low symmetry [28]. Therefore, emission intensity of 5D0 → 7F1 transition (589 nm) decreases and that of 5D0 → 7F2 transition (612 nm) increases in high Eu3+ concentration-doped samples, and then intensity ratio of 5D0 → 7F2 transition to that of 5D0 → 7F1 transition increases according to the analysis above. This assumption can be proved by the emission spectrum of the sample in which Eu3+ concentration x = 0.16. It can be seen that the profile of the emission spectrum is different than those in other Eu3+ concentration-doped samples and the peak of 5D0 → 7F2 transition shifts from 612 to 613 nm. So we think the emission spectrum is an overlap of those in Ba3Al2O6 and BaAl2O4 hosts.

The effect of charge compensators on the photoluminescence properties of Ba3Al2O6:0.06Eu3+

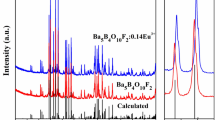

The replacement of divalent Ba2+ ion by trivalent Eu3+ ion will produce defects in the crystal lattice, so Li+, Na+ and K+ are often introduced as charge compensator to reduce the distortion of local environment symmetries of optical centres caused by the defects and enhance the overall photoluminescence intensity [30]. Figure 8 shows the XRD patterns for Ba3Al2O6:0.06Eu3+ calcined at 1450 °C and its charge compensated (with Li+, Na+, K+ ions) counterparts. The XRD patterns show that Ba3Al2O6 is predominant in the samples. However, the impurity phase BaAl2O4 will increase in the charge compensator co-doped samples comparing with those without charge compensators.

Figure 9 shows the emission spectra of the samples under 394 nm excitation. The shapes of the emission spectra of all the samples are very similar, indicating that the introduction of charge compensators (Li+, Na+, K+ ions) does not change the sub-lattice structure around the luminescent centre of Eu3+ ions [32]. However, the emission intensities of 5D0 → 7F1 transition are significantly enhanced by the addition of charge compensators. In the Eu3+-doped Ba3Al2O6 host, not all Eu3+ ions go into the lattice and occupy Ba2+ sites, instead impurity phases Eu2O3 or BaO may exist in the samples because of the charge imbalance caused by the substitution of divalent Ba2+ ion with trivalent Eu3+ ion. The existence of Eu2O3 or BaO could restrain the Ba3Al2O6 grains growth during the sintering process, leading to the decrease in emission intensity [32]. The addition of charge compensator can help to incorporate Eu3+ ions into Ba2+ sites by compensating the different charges between Eu3+ and Ba2+ ions. So the emission intensity can be enhanced. Furthermore, the emission intensity depended on the type of charge compensator. The inset in Fig. 9 shows the dependence of integral intensity of 5D0 → 7F1 transition on the type of charge compensator. The emission intensity of the sample with Li+ as the charge compensator is higher than those of samples co-doped with Na+, Eu3+ and K+, Eu3+. The reason is that Li+ ions are easier to enter into the interstitial site of Ba3Al2O6 crystal lattice than the others and introduces the smaller lattice distortions, because the ionic radius of Li+ (0.076 nm) is smaller than those of Na+ (0.102 nm) and K+ (0.138 nm) [5, 33]. However, the emission intensity of the sample co-doped with Na+, Eu3+ is lower than that co-doped with K+, Eu3+, which is contrary to the results obtained in ZnMoO4 and CaBO3Cl hosts [32, 33]. The reason is possible that the ionic radius of K+ is similar to that of Ba2+ (0.136 nm), so K+ ion is easier to substitute Ba2+ ion than Na+ ion.

Conclusions

Eu3+-doped Ba3Al2O6 phosphors are synthesized by high-temperature solid-state method. The influence of calcinations temperature, Eu3+ concentration as well as charge compensators on the crystal structure, morphology and photoluminescence properties is investigated. The XRD analysis confirms that cubic phase Ba3Al2O6 is predominant in the as-prepared samples. The crystal structure is not changed in the four samples calcined at different calcination temperatures and those co-doped with charge compensators. However, the impurity phase BaAl2O4 is obtained in the high Eu3+ concentration-doped samples. The morphology of the sample depends on the calcination temperature heavily. The particles are converted into nanorods when the calcination temperature exceeds 1350 °C. The photoluminescence spectra studies reveal a strong peak at 589 nm due to 5D0 → 7F1 transition of Eu3+ ions, when excited at 394 nm. The emission shows an increase in intensity with increasing calcinations temperature from 1300 to 1450 °C. The optimum Eu3+ concentration is about 12 % for the sample calcined at 1450 °C. The emission intensity can be significantly enhanced by the addition of charge compensators. The sample doped with Li+ as charge compensator exhibits the strongest emission intensity. Therefore, Ba3Al2O6:Eu3+ phosphors with charge compensator are potential candidates for UV-excited WLEDs.

References

Li H, Jia Y, Sun W, Zhao R, Fu J, Jiang L, Zhang S, Pang R, Li C (2014) Novel energy transfer mechanism in single-phased color-tunable Sr2CeO4:Eu3+ phosphors for WLEDs. Opt Mater 36:1883–1889

Zhu H, Lin CC, Luo W, Shu S, Liu Z, Liu Y, Kong J, Ma E, Cao Y, Liu R, Chen X (2014) Highly efficient non-rare-earth red emitting phosphor for warm white light-emitting diodes. Nat Commun 5:4312

Mao Z, Zhu Y, Wang Y, Gan L (2014) Ca2SiO4:Ln (Ln = Ce3+, Eu2+, Sm3+) tricolor emission phosphors and their application for near-UV white light-emitting diode. J Mater Sci 49:4439–4444. doi:10.1007/s10853-014-8140-4

Bandi VR, Grandhe BK, Jang K, Lee HS, Shin DS, Yi SS, Jeong JH (2012) Citric based sol-gel synthesis and luminescence characteristics of CaLa2ZnO5:Eu3+ phosphors for blue LED excited white LEDs. J. Alloys Compd 512:264–269

Wang T, Xu X, Zhou D, Qiu J, Yu X (2014) Red phosphor Ca2Ge7O16:Eu3+ for potential application in field emission displays and white light-emitting diodes. Mater Res Bull 60:876–881

Salimi R, Sameie H, Sabbagh Alvani AA, Sarabi AA, Moztarzadeh F, Eivaz Mohammadloo H, Nargesian F, Tahriri M (2012) Sol–gel synthesis, structural and optical characteristics of Sr1−xZn2Si2yO7+δ:xEu2+ as a potential nanocrystalline phosphor for near-ultraviolet white light-emitting diodes. J Mater Sci 47:2658–2664. doi:10.1007/s10853-011-6091-6

Suresh K, Poornachandra Rao NV, Murthy KVR (2014) Photoluminescent properties of Sr2CeO4:Eu3+ and Sr2CeO4:Eu2+ phosphors suitable for near ultraviolet excitation. Bull Mater Sci 37:1191–1195

Chen W, Wang Y, Xu X, Zeng W, Gong Y (2012) A new long-lasting phosphor Ce3+ doped Ca3Al2O6. ECS Sol State Lett 1:R17–R19

Lazic B, Kahlenberg V, Kaindl R, Kremenovic A (2009) On the symmetry of Ba3Al2O6—X-ray diffraction and Raman spectroscopy studies. Sol State Sci 11:77–84

Chang C, Li W, Huang X, Wang Z, Chen X, Qian X, Guo R, Ding Y, Mao D (2010) Photoluminescence and afterglow behavior of Eu2+, Dy3+ and Eu3+, Dy3+ in Sr3Al2O6 matrix. J Lumin 130:347–350

Ju H, Deng W, Wang B, Liu J, Tao X, Xu S (2012) The structure and luminescence properties of green Ca3Al2O6:Bi3+ phosphors. J Alloys Compd 516:153–156

Zhang J, He Y, Qiu Z et al (2014) Site-sensitive energy transfer modes in Ca3Al2O6:Ce3+/Tb3+/Mn2+ phosphors. Dalton Trans 43:18134–18145

Guo X, Lei L, Lv C, Sun Y, Zheng H, Cui Y (2008) Preparation and photoluminescence property of a loose powder, Ca3Al2O6:Eu3+ by calcination of a layered double hydroxide precursor. J Sol State Chem 181:1776–1781

Yerpude AN, Dhoble SJ (2012) Luminescence properties of micro Ca3Al2O6:Dy3+ phosphor. Micro Nano Lett 7:268–270

Zhang J, Zhang X, Shi J, Gong M (2011) Luminescent properties of green- or red-emitting Eu2+-doped Sr3Al2O6 for LED. J Lumin 131:2463–2467

Li G, Lai Y, Cui T, Yu H, Liu D, Gan S (2010) Luminescence properties and charge compensation of Sr3Al2O6 doped with Ce3+ and alkali metal ions. Mater Chem Phys 124:1094–1099

Wang L, Guo H, Wei Y, Noh HM, Jeong JH (2015) White luminescence and energy transfer process in Bi3+, Sm3+ co-doped Ca3Al2O6 phosphors. Opt Mater 42:233–236

Wani JA, Dhoble NS, Kokode NS, Deva Prasad Raju B, Dhoble SJ (2014) Synthesis and luminescence property of Li2BaP2O7:Ln3+ (Ln = Eu, Sm) phosphors. J Lumin 147:223–228

Kolesnikov IE, Tolstikova DV, Kurochkin AV, Pulkin SA, Manshina AA, Mikhailov MD (2015) Concentration effect on photoluminescence of Eu3+-doped nanocrystalline YVO4. J Lumin 158:469–474

Nagabhushana H, Sunitha DV, Sharma SC, Daruka Prasad B, Nagabhushana BM, Chakradhar RPS (2014) Enhanced luminescence by monovalent alkali metal ions in Sr2SiO4:Eu3+ nanophosphor prepared by low temperature solution combustion method. J Alloys Compd 595:192–199

Jiang W, Fu R, Gu X, Zhang P, Cosgun A (2015) A red-emitting phosphor LaSr2AlO5:Eu3+/Eu2+ prepared under oxidative and reductive atmospheres. J Lumin 157:46–52

Song X, Fu R, Agathopoulos S, He H, Zhao X, Zhang S (2009) Photoluminescence properties of Eu2+-activated CaSi2O2N2 Redshift and concentration quenching. J Appl Phys 106:033103-1–033103-5

Shimokawa Y, Sakaida S, Iwata S, Inoue K, Honda S, Iwamoto Y (2015) Synthesis and characterization of Eu3+ doped CaZrO3-based perovskite type phosphors. Part II: PL properties related to the two different dominant Eu3+ substitution sites. J Lumin 157:113–118

Huang J, Yi S, Deng Y, Xian J, Zhang L (2015) A novel red emitting phosphor of Eu3+ doped Sr2La2MgW2O12 for white light emitting diodes, Spectrochim. Acta Part A 148:324–327

Sheetal Taxak VB, Arora R, Dayawati Khatkar SP (2014) Synthesis, structural and optical properties of SrZrO3:Eu3+ phosphor. J Rare Earths 32:293–297

Kolesnikov IE, Tolstikova DV, Kurochkin AV, Manshina AA, Mikhailov MD (2014) Eu3+ concentration effect on luminescence properties of YAG:Eu3+ nanoparticles. Opt Mater 37:306–310

Fu Z, Ma L, Sahi S, Hall R, Chen W (2013) Influence of doping concentration on valence states of europium in SrAl2O4 Eu phosphors. J Lumin 143:657–662

Bandi VR, Jayasimhadri M, Jeong J, Jang K, Lee HS, Yi SS, Jeong JH (2010) Host sensitized novel red phosphor CaZrSi2O7:Eu3+ for near UV and blue LED-based white LEDs. J Phys D 43:395103-1–395103-7

Chengaiah T, Jamalaiah BC, Rama Moorthy L (2014) Luminescence properties of Eu3+-doped Na3Gd(PO4)2 red-emitting nanophosphors for LEDs, Spectrochim. Acta Part A 133:495–500

Puchalska M, Zych E, Sobczyk M, Watras A, Deren P (2014) Effect of charge compensation on up-conversion and UV excited luminescence of Eu3+ in Yb3+–Eu3+ doped calcium aluminate CaAl4O7. Mater Chem Phys 147:304–310

Suresh Kumar A, Arun Kumar R, Balasundaraprabhu R, Senthil K, Ramesh Kumar S, Gunasekaran V (2015) Influence of calcination temperature on the luminescent properties of Eu3+ doped CaAl4O7 phosphor prepared by Pechini method, Spectrochim. Acta Part A 134:283–287

Xie A, Yuan X, Wang F, Shi Y, Mu Z (2010) Enhanced red emission in ZnMoO4:Eu3+ by charge compensation. J Phys D 43:055101-1–055101-5

Yang F, Liang Y, Liu M, Li X, Wang N, Xia Z (2012) Enhanced red-emitting by charge compensation in Eu3+-activated Ca2BO3Cl phosphors. Ceram Int 38:6197–6201

Acknowledgements

This work has been supported by Natural Science Foundation of China (51304086), pilot funding of rare earth development and application of Ganzhou, the Leading Academic Discipline Project of Jiangxi University of Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

You, W., Xiao, Z., Lai, F. et al. Synthesis and photoluminescence properties of Ba3Al2O6:Eu3+ red phosphor. J Mater Sci 51, 5403–5411 (2016). https://doi.org/10.1007/s10853-016-9843-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-9843-5