Abstract

Poly(lactic acid)/poly(trimethylene carbonate) (PLA/PTMC) films incorporated with cinnamaldehyde (0, 3, 6, 9, and 12 wt%) were prepared by solvent casting and characterized by physical, mechanical, and antimicrobial properties. SEM analysis revealed that the surface of film became rougher with certain porosity when cinnamaldehyde was incorporated into the PLA/PTMC blends. Cinnamaldehyde acted as plasticizers which reduce the intermolecular forces of polymer chains, thus improving the flexibility and extensibility of the films. Differential scanning calorimetry showed that the crystallinity of PLA phase decreased by the presence of cinnamaldehyde in the composite films. Water vapor permeability of films increased with the increase of cinnamaldehyde loading. However, the active PLA/PTMC/cinnamaldehyde composite films showed adequate barrier properties for food packaging application. Incorporation of cinnamaldehyde to the PLA/PTMC polymer matrix improved the antimicrobial activity of active packaging films. These results indicated that the best compromise between mechanical, barrier, thermal, and antimicrobial properties could be achieved by the addition of 9 wt% cinnamaldehyde into PLA/PTMC blends.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Poly(lactic acid) (PLA), a biodegradable polymer which can be produced from annually renewable resources (i.e., corn starch or sugarcanes), has gained recently a growing attention [1–5]. Because of its relatively low cost, processibility as well as biocompatibility, PLA is an interesting candidate for producing food packaging materials, an area in which, today, mainly polyolefins are used [6–9]. However, a large amount of crystallinity in PLA results in it having not only a high modulus and strength, but also a brittle nature and a lack in toughness [10]. There is no tolerance for the PLA film tearing or cracking when it is subjected to forces.

A large number of substances, such as κ-carrageenan, poly (ε-caprolactone), cellulose, and limonene, have been blended with PLA in order to improve its flexibility, toughness, and barrier properties of films [5, 11–13]. Poly(trimethylene carbonate) (PTMC) is a biodegradable amorphous polymer with a low glass transition temperature (T g) between −14 and −25 °C. PTMC was a more ductile polymer than PLA. In our previous study, we have tried to prepare PLA/PTMC blends with various blend ratios (PLA/PTMC = 90/10, 80/20, 70/30, 60/40, and 50/50 (w/w)). PLA/PTMC (70/30) blend film, which appeared to be softer and more elastic than those with different blend ratios, was selected to use in this study [14, 15].

Foodborne pathogens have become an increasingly relevant health and safety concern in the food industry [16]. It drives us to find better ways to extend the shelf-life of foods. As a new kind of food packaging, active packaging offers a means to potentially increase the shelf life of perishable foods or to maintain food quality [17]. In order to inhibit the growth of undesirable microorganisms on foods, antimicrobial substances can be incorporated in films and released to the surface of food [18–20].

Natural compounds can potentially serve as effective alternatives to conventional antimicrobial agents. Cinnamon is traditionally harvested in Asian countries. Cinnamaldehyde (3-phenyl-2-propenal) is the main component in essential oils from some cinnamon species with a wide-spectrum antimicrobial activity, extended to food spoilage, or pathogenic microorganisms [21–23]. Recently, films containing cinnamaldehyde have been prepared by a wide variety of raw materials, such as cellulose, chitosan, pectin, and starch [21, 24–26]. However, to the best of our knowledge, there are still no reports on the use of PLA-based materials as carriers of cinnamaldehyde for the development of antimicrobial packaging films.

In this study, cinnamaldehyde was directly added to the polymer matrix prior to processing. The effect of cinnamaldehyde addition on the properties of PLA/PTMC packaging films was relatively unknown. The objective of the present study was to investigate the effects of the direct incorporation of cinnamaldehyde (0, 3, 6, 9, and 12 wt%) on the physical, mechanical, and antimicrobial properties of PLA/PTMC films. A structure–property relationship for PLA/PTMC/cinnamaldehyde composite films was also studied.

Materials and methods

Materials

Poly(lactic acid) (PLA, M w = 280 kDa, M w/M n = 1.98) was purchased from Natureworks LLC (Nebraska, USA). Poly(trimethylene carbonate) (PTMC, M w = 120 kDa, M w/M n = 1.71) was prepared in the laboratory of Engineering research center of biopolymer functional materials of Yunnan, Yunnan University of Nationalities, Yunnan, China. Cinnamaldehyde (3-phenyl-2-propenal, purity ≥ 98 %) was purchased from Sigma (St. Louis, MO, USA) and used as received without further purification.

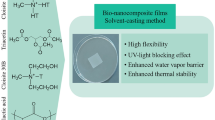

Film preparation

PLA/PTMC/cinnamaldehyde composite films were prepared by a solvent casting method. Briefly, 2 g PLA/PTMC (70/30) was dissolved in 50 mL chloroform. 0, 3, 6, 9, and 12 wt% cinnamaldehyde was added to PLA/PTMC chloroform solution by vigorous mixing. After processed, the solutions were cast and dried to form films. All of the films were dried in vacuum and cut into 10 cm × 2.54 cm. Cinnamaldehyde was incorporated into PLA/PTMC as 0, 3, 6, 9, and 12 wt% loading named as PLA/PTMC, PLA/PTMC/C3, PLA/PTMC/C6, PLA/PTMC/C9, and PLA/PTMC/C12.

Scanning electron microscopy (SEM)

The surface morphology of the various composite films was examined using scanning electron microscopy (SEM) technique. The surfaces of samples were sputter-coated with a thin conductive gold layer in 20 nm thick. The SEM experiment was operated by a Hitachi S-4800 (Japan) machine, equipped with a secondary electron detector under an accelerating voltage of 10 kV.

Mechanical properties test

Mechanical properties [tensile strength (TS), elongation at break (E), and tensile modulus] of the various composite films were evaluated by tensile test using a Universal tensile machine (CMT 4104, MTS Systems Co., Ltd, China). The tensile test was carried out at a crosshead speed of 50 mm/min with initial grip length of 50 mm at room temperature. At least five specimens were tested for each sample. Average values of TS, E, and tensile modulus were then calculated and reported.

Thermal properties

Differential scanning calorimetry (DSC) experiments were carried out in a TA Instruments (DSC-200PC, Netzsch, Germany). The sample weight was approximately 10 mg. Nitrogen was used as the purging gas, and an empty aluminum pan was used as the reference. Samples were heated from 20 to 200 °C at a heating rate of 10 °C/min, held at 200 °C for 5 min to eliminate the previous thermal history, then cooled, and finally heated to the maximum temperature at a heating rate of 10 °C/min. Peak temperatures and peak areas were determined using the instrument software.

Thermogravimetric analysis (TGA) was carried out with a TA Instruments (DSC-200PC, Netzsch, Germany). Approximately, 10 mg of specimens was sealed in an aluminum pan and heated from 20 to 600 °C in a nitrogen atmosphere at a heating rate of 10 °C/min.

Water vapor permeability (WVP)

The standard method E96 (ASTM 1995) was used to determine water vapor permeability of film samples with a 50 % relative humidity (RH) gradient at 25 °C [11]. The covered acrylic cups were placed in a temperature and RH controlled chamber with the same conditions required for film equilibration. The weight loss of the cup was considered equal with the transferred water through the film and adsorbed by the desiccant. Changes in the weight of the cup were recorded and plotted as a function of time for 12 h [27]. The WVP of each sample was calculated by the following equation [28].

where WVTR is the water vapor transmission rate (g/m2 s) through the film, L is the film thickness (m), and ΔP is the water vapor pressure differential across the film (Pa).

Optical properties

Film color properties were evaluated by measuring L* (lightness), a* (redness), and b* (yellowness) using a colorimeter (Minolta Chroma Meter CR-300; Minolta Camera Co., Ltd., Osaka, Japan). Total color difference (ΔE) induced by cinnamaldehyde incorporation was calculated by Eq. (2):

Opacity of the composite films was determined using a UV–Vis spectrophotometer (T90, Beijing Purkinje general instrument Co., Ltd, Beijing, China). A rectangular piece of film was cut and directly placed in the spectrophotometer test cell with air as a reference. The opacity was calculated by measuring the percent transmittance of light at a wavelength of 600 nm [29].

Antimicrobial activity

The liquid culture test was used to determine the ability of cinnamaldehyde (both incorporated and in the free form) in inhibiting the growth of two food pathogenic bacteria, including Escherichia coli and Staphylococcus aureus. All bacterial strains were obtained from Laboratory of Microbiology, Faculty of Life Science and Technology, Kunming University of Science and Technology, Yunnan, China. The bacteria were activated by vaccination to MHB. The antimicrobial test was determined by method of Liu et al. with some modification [30]. Bacteria constant temperature cultivation condition was 37 °C and 18–24 h. A glass test tube containing testing specimens (0.18–0.20 g for each) was filled with 10 mL of broth. The medium was inoculated with 0.1 mL of an overnight culture of bacteria. The bacterial cultures were adjusted to a cell concentration of 105 CFU/ml. The test tubes were transferred to a shaker at room temperature and shaken at 200 rpm. After 0, 2, 16, and 24 h of the experiment, aliquots containing 1 mL of incubated sample were serially diluted with sterile phosphate buffer (pH 7.4) and then pour plated onto culture medium. All plates were incubated at 37 °C for 24 h and the colony-forming units (CFU) were counted.

Statistical analysis

ANOVA test was employed to evaluate significant differences between the values obtained in PLA/PTMC with cinnamaldehyde component. A p value of < 0.05 was considered significant.

Results and discussion

SEM analysis

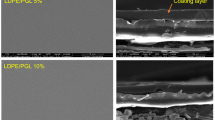

The SEM images obtained for PLA/PTMC/cinnamaldehyde composite films are shown in Fig. 1a–e. The surface of PLA/PTMC film was homogenous (Fig. 1a). When cinnamaldehyde was incorporated into the PLA/PTMC blends, the surface became rougher with certain porosity. This might be due to the presence of a certain amount of cinnamaldehyde in the materials surface and partially evaporation from the polymer matrix during processing. The increase in the extent of porosity also contributed to descent in the barrier properties of food packaging material. The pores in PLA/PTMC/C12 film (Fig. 1e) were much more than those in other materials, thus the WVP value of PLA/PTMC/C12 film was the highest among all the films.

Mechanical properties

Adequate mechanical properties are very important for polymeric films designed for food packaging application. This indicates ability of films to maintain integrity under stress during the processing, handling, and storage of the packaged materials [31]. Tensile tests were performed in order to study the effect of cinnamaldehyde amount on polymer mechanical properties, by the evaluation of different parameters, such as TS, E, and tensile modulus (Table 1). The addition of cinnamaldehyde to PLA/PTMC resulted in a significant (p < 0.05) decrease in TS and tensile modulus. This behavior had been reported for PLA-based films with limonene [13].

It could be seen that elongation at break of PLA/PTMC/cinnamaldehyde composite films was improved by 12.6, 42.2, and 22.2 % upon incorporation of 6, 9, and 12 wt% of cinnamaldehyde content, respectively. Similar results were reported by Erdohan et al. studying olive leaf extract addition influence on mechanical properties of PLA films [32]. The increase in E might be because the plasticizing effect caused by the addition of cinnamaldehyde to the polymer matrix resulting in the increase in ductile properties, which would also result in changes in the X c of materials. With the addition of 9 % cinnamaldehyde, PLA/PTMC/cinnamaldehyde composite film had the highest value of elongation at break (192.80 %), the lowest value of TS (12.57 MPa), and the lowest value of tensile modulus (771.01 MPa). The plasticizing effect of cinnamaldehyde was well evident. This was due to the phase slipping induced by the low molecular weight additive incorporated into the polymeric matrix [23]. The results also showed that the appropriate amount of cinnamaldehyde in the composites led to obvious improvements in the mechanical properties of the composites, but additional increases in the amount of cinnamaldehyde did not improve the mechanical properties any more.

DSC

Thermal properties of films were studied by DSC analysis where four parameters were determined: glass transition temperature (T g), peak crystallization temperature (T c), melting temperature (T m), and melting enthalpy (ΔH m). The DSC scan curves of PLA/PTMC/cinnamaldehyde composites in heating process are shown in Fig. 2. The results of thermal characteristics are summarized in Table 2. Previous studies indicated that T g of PTMC was −24 °C [15]. However, pure PLA exhibited a glass transition around 57 °C. The difference in the T g between PTMC and PLA was 70 °C. For PLA/PTMC blends, both T gs was between the T gs of the two component polymers. As the amount of cinnamaldehyde increased, the T g value of PLA decreased from 56.7 to 43.8 °C. This indicated that PLA/PTMC/cinnamaldehyde composites were partially miscible to some extent. This also confirmed that cinnamaldehyde exerted a plasticizer effect. The appearance of a second melting peak of PLA at lower temperature in the composites (Fig. 2) was in accordance with the results reported in the literature for PTMC as plasticizer of PLA [15].

As it could be seen, peak crystallization temperature did not show significant differences for the composite films and melting temperature slightly decreased with the increase of cinnamaldehyde amount. However, it should be noted that the melting enthalpy of PLA/PTMC was higher than those incorporated with cinnamaldehyde. This observation could indicate a higher crystallinity of PLA/PTMC without cinnamaldehyde. The percentage of crystallinity (X c) for each material was calculated according to the following equation:

where ΔH m (J/g) is the melting enthalpy of sample, W is the PLA weight fraction in the sample, and ΔH°m is the melting enthalpy of 100 % crystalline PLA (93.7 J/g) [12].

The value of X c was also shown in Table 2. X c of PLA/PTMC was 46.8 % and apparently higher than that of PLA/PTMC/cinnamaldehyde composites. So, it could be concluded that the crystallinity of the composites decreased with the addition of cinnamaldehyde. The plasticization effect of cinnamaldehyde was also observed by mechanical tests, as discussed in mechanical properties section. This decrease in X c might be because the interactions between the polymer matrix and additive molecules in the polymer macromolecular network.

TGA

Thermal degradation of PLA/PTMC/cinnamaldehyde composites was shown in Fig. 3. A slight decrease in weight for PLA/PTMC/C6, PLA/PTMC/C9, and PLA/PTMC/C12 below 180 °C was evident which was due to the evaporation of cinnamaldehyde incorporated in the composites. As could be seen from Fig. 3, the PLA/PTMC/cinnamaldehyde composites showed a slightly lower T onset value when compared to the PLA/PTMC blends (293.4 °C). However, TGA thermograms indicated that all materials were substantially thermally stable in the region below 180 °C. The processing temperature of the solvent casting method did not affect the thermal degradation profile of all materials [33]. Furthermore, when the PLA-based materials are applied in fruits and vegetables packaging, they are usually stored at room temperature or below. This also did not affect the thermal stability of PLA/PTMC/cinnamaldehyde composites.

Barrier properties

WVP is one of most important properties in food packaging because of the noticeable role of water in deteriorative reactions and microbial growth [8]. The effect of cinnamaldehyde amount on WVP of PLA/PTMC blends was shown in Fig. 4. Incorporation of cinnamaldehyde into PLA/PTMC blends increased the WVP from 2.21 × 10−14 kg m/m2 s Pa (PLA/PTMC) to 3.37 × 10−14 kg m/m2 s Pa (PLA/PTMC/C12) (p < 0.05). The results were in accordance with the decrease in T g values. Arrieta et al. also reported that the incorporation of limonene as plasticizer led to a decrease in barrier properties [13]. The decrease in barrier properties for the active films might be because the modification of the polymer matrix structure in the presence of the additives, consequently reducing the resistance of films to oxygen or water vapor diffusion through them [34, 35]. This could also be verified by SEM images (Fig. 1a–e) that many voids existed in PLA/PTMC/cinnamaldehyde composite films and permitted more water vapor transfer.

The WVP of PLA/PTMC/cinnamaldehyde composite films was 2.08 × 10−14, 2.73 × 10−14, 3.01 × 10−14, and 3.37 × 10−14 kg m/m2 s Pa upon incorporation of 3, 6, 9, and 12 wt% of cinnamaldehyde content, respectively. The WVP of commercial low density polyethylene films with the same thickness as PLA/PTMC/cinnamaldehyde composite films was 2.85 × 10−14 kg m/m2 s Pa. As previous reported, a slight decrease in RH within the packaging due to the high water vapor permeability of film would be beneficial for postharvest vegetable and fruit quality [36]. No condensation was observed when using materials with higher water vapor permeability. This would help to reduce microbial growth and maintain an acceptable color of postharvest mushrooms [37]. So, the active PLA/PTMC/cinnamaldehyde composite films showed adequate barrier properties and could be acceptable for food packaging application.

Optical properties

The color and opacity of PLA/PTMC/cinnamaldehyde composite films was shown in Table 3. There was no significant (p > 0.05) difference in L* (lightness) among all the samples. a* (redness) value significantly (p < 0.05) decreased and b* (yellowness) value significantly (p < 0.05) increased as the cinnamaldehyde content increased. The transparency of the PLA/PTMC/cinnamaldehyde composite films decreased significantly (p < 0.05) compared to the PLA/PTMC film. This might be attributed to cinnamaldehyde having a clear yellowish color. The decrease in film transparency as a consequence of the addition of natural antimicrobials or antioxidants had also been reported with PLA-base films [38]. The visual appearance of PLA/PTMC and PLA/PTMC/cinnamaldehyde composite films was shown in Fig. 5. Statistically significant differences were found between samples with cinnamaldehyde, but the differences were not perceptible to the human eyes (Fig. 5). This result suggested high transparency for PLA/PTMC/cinnamaldehyde composite films and the possibility to see through the film is one of the most important requirements for consumers [39].

Antimicrobial activity of PLA/PTMC/cinnamaldehyde composite films

There have been many studies on antimicrobial activity of active films incorporated with cinnamon oil or cinnamaldehyde [23, 40]. Nostro et al. tested the antimicrobial activity of cinnamaldehyde polyethylene-co-vinylacetate films against E. coli, L. monocytogenes, and S. aureus. They revealed that microbial growth rate of E. coli was decreased when cinnamaldehyde content increased [23]. Zodrow et al. reported that poly(lactic-co-glycolic acid) film with 0.1 % cinnamaldehyde lessened biofilm growth by S. aureus [40]. As mentioned above, cinnamaldehyde is known for its antimicrobial activity against several bacteria and fungi. E. coli and S. aureus were selected in this study and they represented typical spoilage organism groups commonly occurring in various kinds of food products.

Film samples were tested for antimicrobial activity by the agar diffusion method or the liquid culture test. There was no agreement upon standard methods to determine the effectiveness of active antimicrobial films [32]. The liquid culture test was used in this study.

Figure 6 showed the results of the antimicrobial tests performed against E. coli and S. aureus. As could be seen from Fig. 6, PLA/PTMC itself was not harmful to E. coli and S. aureus. PLA/PTMC blend film did not show any antimicrobial activity. Films containing 9 or 12 wt% cinnamaldehyde were significant (p < 0.05) effective against E. coli and S. aureus at 16 and 24 h, when compared with other samples. After 16 h of incubation, PLA/PTMC/C9 had already reduced E. coli from 5.0 to 3.0 logs and S. aureus from 5.0 to 3.8 logs. In this study, films containing 9 wt% cinnamaldehyde or higher showed a good antimicrobial activity against E. coli and S. aureus. This might be because that the gradual release of the molecules over time allowed their continuous availability and partitioning to the cell membranes [23]. The pores in composite films also facilitated the release of cinnamaldehyde to the surface of films. As a matter of fact, the efficacy of antimicrobial films activated with cinnamaldehyde should be further tested by food storage application.

Conclusions

The effect of cinnamaldehyde on the structure/properties relationships was analyzed. This study showed that the incorporation of cinnamaldehyde could improve TS and elongation at break of composite films and cinnamaldehyde exerted a plasticizer effect. WVP and optical properties of films were slightly lowered by the addition of cinnamaldehyde. DSC spectra revealed that the crystallinity of the composites decreased with the addition of cinnamaldehyde. In this study, films containing 9 wt% cinnamaldehyde or higher showed a good antimicrobial activity against E. coli and S. aureus. The best compromise between mechanical, barrier, thermal, and antimicrobial properties was achieved by the addition of 9 wt% cinnamaldehyde into PLA/PTMC blends. Further research is needed to evaluate the diffusion and release kinetics for the active agent release from the polymer matrix, to ensure their ability to be used in food packaging applications.

References

Courgneau C, Domenek S, Guinault A, Avérous L, Ducruet V (2011) Analysis of the structure–properties relationships of different multiphase systems based on plasticized poly (lactic acid). J Polym Environ 19:362–371

Persico P, Ambrogi V, Carfagna C, Cerruti P, Ferrocino I, Mauriello G (2009) Nanocomposite polymer films containing carvacrol for antimicrobial active packaging. Polym Eng Sci 49:1447–1455

Intawiwat N, Myhre E, Øysæd H, Jamtvedt SH, Pettersen MK (2012) Packaging materials with tailor made light transmission properties for food protection. Polym Eng Sci 52:2015–2024

Ambrosio-Martín J, Fabra MJ, Lopez-Rubio A, Lagaron JM (2014) An effect of lactic acid oligomers on the barrier properties of polylactide. J Mater Sci 49(8):2975–2986. doi:10.1007/s10853-013-7929-x

Hossain KMZ, Ahmed I, Parsons AJ, Scotchford CA, Walker GS, Thielemans W, Rudd CD (2012) Physico-chemical and mechanical properties of nanocomposites prepared using cellulose nanowhiskers and poly (lactic acid). J Mater Sci 47(6):2675–2686. doi:10.1007/s10853-011-6093-4

Ljungberg N, Wesslén B (2003) Tributyl citrate oligomers as plasticizers for poly (lactic acid): thermo-mechanical film properties and aging. Polymer 44:7679–7688

Burgos N, Martino VP, Jiménez A (2013) Characterization and ageing study of poly (lactic acid) films plasticized with oligomeric lactic acid. Polym Degrad Stab 98:651–658

Jamshidian M, Arab Tehrany E, Cleymand F, Leconte S, Falher T, Desobry S (2012) Effects of synthetic phenolic antioxidants on physical, structural, mechanical and barrier properties of poly lactic acid film. Carbohydr Polym 87:1763–1773

Marras SI, Zuburtikudis I, Panayiotou C (2010) Solution casting versus melt compounding: effect of fabrication route on the structure and thermal behavior of poly (l-lactic acid) clay nanocomposites. J Mater Sci 45(23):6474–6480. doi:10.1007/s10853-010-4735-6

Ljungberg N, Wesslén B (2005) Preparation and properties of plasticized poly (lactic acid) films. Biomacromolecules 6:1789–1796

Rhim JW (2013) Effect of PLA lamination on performance characteristics of agar/κ-carrageenan/clay bio-nanocomposite film. Food Res Int 51:714–722

Jain S, Reddy MM, Mohanty AK, Misra M, Ghosh AK (2010) A new biodegradable flexible composite sheet from poly (lactic acid)/poly (ε-caprolactone) blends and micro-talc. Macromol Mater Eng 295:750–762

Arrieta MP, López J, Ferrándiz S, Peltzer MA (2013) Characterization of PLA-limonene blends for food packaging applications. Polym Test 32:760–768

Qin Y, Yuan M, Li L, Guo S, Yuan M, Li W, Xue J (2006) Use of polylactic acid/polytrimethylene carbonate blends membrane to prevent postoperative adhesions. J Biomed Mater Res B 79:312–319

Qin Y, Yang J, Yuan M, Xue J, Chao J, Wu Y, Yuan M (2014) Mechanical, barrier, and thermal properties of poly(lactic acid)/poly(trimethylene carbonate)/talc composite films. J Appl Polym Sci 131:40016.1–40016.7

Hill LE, Taylor TM, Gomes C (2013) Antimicrobial efficacy of poly (dl-lactide-co-glycolide) (PLGA) nanoparticles with entrapped cinnamon bark extract against Listeria monocytogenes and Salmonella typhimurium. J Food Sci 78:626–632

Hosseini MH, Razavi SH, Mousavi MA (2009) Antimicrobial, physical and mechanical properties of chitosan-based films incorporated with thyme, clove and cinnamon essential oils. J Food Process Preserv 33:727–743

Balaguer MP, Lopez-Carballo G, Catala R, Gavara R, Hernandez-Munoz P (2013) Antifungal properties of gliadin films incorporating cinnamaldehyde and application in active food packaging of bread and cheese spread foodstuffs. Int J Food Microbiol 166:369–377

Chinma CE, Ariahu CC, Alakali JS (2013) Effect of temperature and relative humidity on the water vapour permeability and mechanical properties of cassava starch and soy protein concentrate based edible films. J Food Sci Technol. doi:10.1007/s13197-013-1227-0

Raouche S, Mauricio-Iglesias M, Peyron S, Guillard V, Gontard N (2011) Combined effect of high pressure treatment and anti-microbial bio-sourced materials on microorganisms’ growth in model food during storage. Innov Food Sci Emerg Technol 12:426–434

Sanla-Ead N, Jangchud A, Chonhenchob V, Suppakul P (2012) Antimicrobial activity of cinnamaldehyde and eugenol and their activity after incorporation into cellulose-based packaging Films. Packag Technol Sci 25:7–17

Ye H, Shen S, Xu J, Lin S, Yuan Y, Jones GS (2013) Synergistic interactions of cinnamaldehyde in combination with carvacrol against food-borne bacteria. Food Control 34:619–623

Nostro A, Scaffaro R, D’Arrigo M, Botta L, Filocamo A, Marino A, Bisignano G (2012) Study on carvacrol and cinnamaldehyde polymeric films: mechanical properties, release kinetics and antibacterial and antibiofilm activities. Appl Microbiol Biotechnol 96:1029–1038

Ouattara B, Simard RE, Piette G, Bégin A, Holley RA (2000) Inhibition of surface spoilage bacteria in processed meats by application of antimicrobial films prepared with chitosan. Int J Food Microbiol 62:139–148

Ravishankar S, Jaroni D, Zhu L, Olsen C, McHugh T, Friedman M (2012) Inactivation of Listeria monocytogenes on ham and bologna using pectin-based apple, carrot, and hibiscus edible films containing carvacrol and cinnamaldehyde. J Food Sci 77:M377–M382

Kechichian V, Ditchfield C, Veiga-Santos P, Tadini CC (2010) Natural antimicrobial ingredients incorporated in biodegradable films based on cassava starch. LWT-Food Sci Technol 43:1088–1094

Vásconez MB, Flores SK, Campos CA, Alvarado J, Gerschenson LN (2009) Antimicrobial activity and physical properties of chitosan–tapioca starch based edible films and coatings. Food Res Int 42:762–769

Martins JT, Cerqueira MA, Vicente AA (2012) Influence of α-tocopherol on physicochemical properties of chitosan-based films. Food Hydrocoll 27:220–227

Siripatrawan U, Harte BR (2010) Physical properties and antioxidant activity of an active film from chitosan incorporated with green tea extract. Food Hydrocoll 24:770–775

Liu L, Jin TZ, Coffin DR, Hicks KB (2009) Preparation of antimicrobial membranes: coextrusion of poly (lactic acid) and Nisaplin in the presence of Plasticizers. J Agric Food Chem 57:8392–8398

Rhim JW, Mohanty AK, Singh SP, Ng PK (2006) Effect of the processing methods on the performance of polylactide films: thermocompression versus solvent casting. J Appl Polym Sci 101:3736–3742

Erdohan ZÖ, Çam B, Turhan KN (2013) Characterization of antimicrobial polylactic acid based films. J Food Eng 119:308–315

Fortunati E, Armentano I, Zhou Q, Iannoni A, Saino E, Visai L, Berglund LA, Kenny JM (2012) Multifunctional bionanocomposite films of poly(lactic acid), cellulose nanocrystals and silver nanoparticles. Carbohydr Polym 87:1596–1605

Ramos M, Jiménez A, Peltzer M, Garrigós MC (2012) Characterization and antimicrobial activity studies of polypropylene films with carvacrol and thymol for active packaging. J Food Eng 109:513–519

Sothornvit R, Krochta JM (2000) Oxygen permeability and mechanical properties of films from hydrolyzed whey protein. J Agric Food Chem 48:3913–3916

Guillaume C, Schwab I, Gastaldi E, Gontard N (2010) Biobased packaging for improving preservation of fresh common mushrooms (Agaricus bisporus L.). Innov Food Sci Emerg Technol 11(4):690–696

Roy S, Anantheswaran RC, Beelman RB (1996) Modified atmosphere and modified humidity packaging of fresh mushrooms. J Food Sci 61:391–397

Hwang SW, Shim JK, Selke SE, Soto-Valdez H, Matuana L, Rubino M, Auras R (2012) Poly (l-lactic acid) with added α-tocopherol and resveratrol: optical, physical, thermal and mechanical properties. Polym Int 61:418–425

Introzzi L, Fuentes-Alventosa JM, Cozzolino CA, Trabattoni S, Tavazzi S, Bianchi CL, Farris S (2012) “Wetting enhancer” pullulan coating for antifog packaging applications. ACS Appl Mater Interfaces 4:3692–3700

Zodrow KR, Schiffman JD, Elimelech M (2012) Biodegradable polymer (PLGA) coatings featuring cinnamaldehyde and carvacrol mitigate biofilm formation. Langmuir 28:13993–13999

Acknowledgements

This work was supported by the National Natural Science Foundation of China (31160198) and (31360417).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qin, Y., Yang, J. & Xue, J. Characterization of antimicrobial poly(lactic acid)/poly(trimethylene carbonate) films with cinnamaldehyde. J Mater Sci 50, 1150–1158 (2015). https://doi.org/10.1007/s10853-014-8671-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8671-8