Abstract

Perovskite-type Ba(Sn1−x Ta x )O3 (0.01 ≤ x ≤ 0.06) ceramics with high relative densities (92.7–94.4 %) were fabricated using the hot isostatic pressing (HIP) method at 1273 K and 196 MPa for 4 h in an atmosphere of argon gas. The lattice parameter decreased slightly with increasing x. From the XPS measurement, the Ta5+ ion was stable in Ba(Sn1−x Ta x )O3 ceramics and the broad peak of the Ta4f level was the overlap between the Ta5+4f5/2 and Ta5+4f7/2 levels. Ba(Sn1−x Ta x )O3 ceramics were n-type semiconductors, and their electrical resistivities increased with increasing x. The increase in the electrical resistivity was explained by impurity scattering due to the presence of the Ta ions. The absolute value of the Seebeck coefficient (S) increased with increasing temperature and x. The power factor (S 2 σ), which was calculated from electrical conductivity (σ) and the Seebeck coefficient, was ca. 1.0 × 10−5 W m−1 K−2 at x = 0.01.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

BaSnO3 has a cubic perovskite-type structure with a = 4.116 Å and behaves as an n-type semiconductor with a band gap of 3.4 eV [1, 2]. The Seebeck coefficient (S) of BaSnO3 was reported to be ca. −300 μV/K at 900 K [3]. Upadhyay et al. measured the electrical conductivity (σ) of BaSnO3 from 310 to 520 K at 0, 1, 10, and 100 kHz [4]. The dc electrical resistivity (ρ dc) is 1.6 × 109 Ω cm or more below 350 K and decreases linearly with the rise of temperature. Since the sample was prepared at very high temperature, a slight amount of oxygen was lost from the sample. Since the released electrons were caught by the Sn4+ ion to generate the Sn2+ ion, electrical conduction was explained by the hopping of charge carriers between the Sn4+ and Sn2+ ions. According to Trari et al. [5] (Ba1−x La x )SnO3 (0 ≤ x ≤ 0.02), which was synthesized using a solid-state reaction, is metallic at least for x ≥ 0.0025. Its electrical resistivity is independent of temperature and varies strongly with increasing x. The absolute value of the Seebeck coefficient increases with the rise of temperature and exhibits a large value (ca. −120 μV/K for x = 0.001) at 300 K.

Yasukawa et al. synthesized Ba(Sn1−x Co x )O3 using a solid-state reaction and measured both electrical conductivity and the Seebeck coefficient [6]. The samples have a relative density of ca. 95 % and are p-type semiconductors. Electrical conductivity is 10−1–102 Ω−1 m−1 in the measured temperature range and increases with increasing x. They proposed that p-type conduction occurs by the hopping of holes between the localized states of the Co ions. The Seebeck coefficient increases with the rise of temperature and exhibits a large value (ca. 80 μV/K) at 770 K. The power factor (S 2 σ) is frequently used to evaluate the performance of thermoelectric materials. The sample (x = 0.15) has a high power factor (ca. 2.7 × 10−7 W m−1 K−2) at 1073 K.

According to Singh et al. [7], the electrical resistivities of the Ba(Sn1−x Nb x )O3 ceramics that were sintered at high temperatures decreases with increasing x, has a minimum value at x = 0.01, and then increases with increasing x. The decrease in the electrical resistivity in the range of 0.001 ≤ x ≤ 0.01 was explained by the electrons released from both the Nb ion and an oxygen vacancy. On the other hand, the increase in the electrical resistivity in the range of 0.01 ≤ x ≤ 0.10 was explained by impurity scattering due to the presence of the Nb5+ ions. To improve the power factor of BaSnO3, electrical conductivity must be increased. In the present study, Ba(Sn1−x Ta x )O3 ceramics with high relative densities were fabricated using the hot isostatic pressing (HIP) method. Electrical conductivity and the Seebeck coefficient were measured to investigate the potential of these oxides as thermoelectric materials.

Experimental

The Ba(Sn1−x Ta x )O3 samples were prepared by a solid-state reaction. High-purity powders of Ba(NO3)2 (Rare Metallic, Japan, 99.99 %), SnO2 (Kojundo Chemical Laboratory, Japan, 99.99 %), and Ta2O5 (Rare Metallic, 99.99 %) were weighed in the desired proportions and milled for 1 h in an agate mortar. The mixed powder was calcined at 813 K for 1 h in flowing argon and subsequently was calcined at 853 K for 6 h in flowing argon. The calcined powder was uniaxially pressed into a pellet at 49 MPa. The green compact, which was pressed at 245 MPa using the cold isostatic pressing (CIP) method after being wrapped in platinum, was covered with a boron nitride (BN) powder and was sealed in a Pyrex glass tube under vacuum. Densification was achieved using the hot isostatic pressing (HIP) method for 4 h at 1273 K in an atmosphere of argon gas, and the maximum pressure was 196 MPa [8].

The crystal phases of the sintered samples were examined by powder X-ray diffraction (XRD, RAD-2200, Rigaku, Japan) using monochromatic CuKα radiation (Kα1 = 1.5405 Å). The lattice parameter was determined from high-angle reflections with Si as a standard. The bulk density was measured using the Archimedes method. Scanning electron microscopy (SEM, Model JSM-7001FD, JEOL, Japan) was used for microstructural observation. The atomic percentages of Ba, Sn, and Ta were determined using energy-dispersive X-ray spectroscopy (EDS, Model JED-2300, JEOL). The binding energy of the Ta 4f level was measured using X-ray photoelectron spectroscopy (XPS, Model AXIS-165, Kratos, UK) with monochromatic MgKα radiation (1253.6 eV) at room temperature. The binding energy was calibrated against the C1 s level from residual hydrocarbon molecules. Electrical conductivity and the Seebeck coefficient were measured using the electrical conductivity & Seebeck coefficient measurement system (RZ2001i, Ozawa, Japan).

Results and discussion

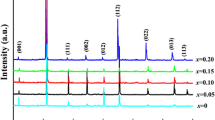

According to Upadhyay et al. [9], the relative density of BaSnO3 that was sintered at 1525 K in air was ca. 80 %. In the present study, therefore, the HIP method was used to obtain Ba(Sn1−x Ta x )O3 ceramics with high relative densities. Figure 1 shows the XRD patterns of both a mixture (x = 0.06) of the starting materials and the Ba(Sn0.94Ta0.06)O3 (x = 0.06) ceramic fabricated using the HIP method. After HIP processing, all diffraction peaks of the XRD pattern were completely indexed as the perovskite-type structure in the range of 0.01 ≤ x ≤ 0.06 [1]. The lattice parameter decreased slightly from 4.1204 Å (x = 0.01) to 4.1186 Å (x = 0.06), as shown in Table 1. The relative densities of Ba(Sn1−x Ta x )O3 ceramics were high (92.7–94.4 %) regardless of x, as shown in Table 1. SEM images of the fracture surface are shown in Fig. 2. The average particle size decreased slightly from ca. 2 µm (x = 0.01) to ca. 1.5 µm (x = 0.06). The atomic percentage of Ta determined from the EDS measurement increased linearly with increasing x, as shown in Table 1. The results of the XRD and EDS measurements indicated that the Sn ions had been replaced by the Ta ions in Ba(Sn1−x Ta x )O3 ceramics.

The measured Ta4f XPS spectra of the Ba(Sn1−x Ta x )O3 ceramics are shown in Fig. 3. The peak of the Ta4f level was broad and unsymmetrical. Hashimoto et al. used an anodic oxidized Ta2O5 thin film on a tantalum plate for the XPS measurement [10]. The binding energies of the Ta5+, Ta4+, Ta3+, and Ta0 levels were 27.5–29.2, 28.6–25.6, 24.0–26.0 and 22.4–24.0 eV, respectively. Yan et al. measured the XPS spectra of LiTaO3 wafers and reported that the binding energies of the Ta4f level were ca. 28.4 (Ta5+) and ca. 27.1 eV (Ta4+) [11]. In the present Ba(Sn1−x Ta x )O3 ceramics, since the binding energy of the Ta4f level was 29.3–29.7 eV, it is thought that the Ta5+ ion was stable in Ba(Sn1−x Ta x )O3 ceramics and that the broad peak was the overlap between the Ta5+4f5/2 and Ta5+4f7/2 levels [11]. According to Shannon [12], the ionic radii of the Sn4+ ion and the Ta5+ ion with a coordination of 6 are 0.69 Å and 0.64 Å, respectively. Therefore, the slight decrease in the lattice parameter as shown in Table 1 was explained by the difference in the ionic radii between the Sn4+ and Ta5+ ions.

The electrical resistivities (ρ) of the Ba(Sn1−x Ta x )O3 ceramics decreased slightly with the rise of temperature (T), and the log ρ–1000/T curve deviated from a straight line at high temperature, as shown in Fig. 4. Omeiri et al. reported that the electrical resistivity of BaSnO3 was very high and was assumed to be more than 108 Ω cm [13]. However, the electrical resistivities of the present Ba(Sn1−x Ta x )O3 ceramics were extremely low at x = 0.01 and increased with increasing x in the range of 0.01 ≤ x ≤ 0.06. Since the variation in the relative densities of Ba(Sn1−x Ta x )O3 ceramics was 2 % or less, it is thought that relative density hardly affected the electrical resistivity. According to Singh et al. [7], the electrical resistivity of Ba(Sn1−x Nb x )O3 decreased with increasing x in the range of 0.001 ≤ x ≤ 0.01 and then increased with increasing x in the range of 0.01 ≤ x ≤ 0.10. The decrease in the electrical resistivity up to x = 0.01 was explained by an increase in the number of electrons released from both the Nb ion on the Sn lattice site and an oxygen vacancy. On the other hand, the increase in the electrical resistivity for x > 0.01 was explained by an increase in impurity scattering due to the presence of Nb5+ ions. In the present Ba(Sn1−x Ta x )O3 ceramics, XPS and EDS measurements indicated that the valence of the Ta ion was 5+ and that the atomic percentage of Ta increased with increasing x. Therefore, it is thought that the electrical resistivities of the Ba(Sn1−x Ta x )O3 ceramics increased as a result of impurity scattering due to the presence of Ta5+ ions in the same manner as Ba(Sn1−x Nb x )O3 [7].

Singh et al. reported that the released electrons in Ba(Sn1−x Nb x )O3 were captured by the Nb5+ ions or the Sn4+ ions, and that the Nb4+ ions or the Sn3+ ions were generated [7]. Accordingly, electrical conduction occurred by the hopping of electrons between the Nb5+ and Nb4+ ions or between the Sn4+ and Sn3+ ions. Electrical conductivity (σ) for hopping in a small polaron model is given by.

where A is a constant, E h is the activation energy for hopping, and k B is the Boltzmann constant [14]. Since the log σT–1000/T curves of the Ba(Sn1−x Ta x )O3 ceramics were linear in the measured temperature range as shown in Fig. 5, it is thought that Ba(Sn1−x Ta x )O3 ceramics exhibited electrical conductivity for hopping in the small polaron model. We could not obtain data on electrical resistivity or the Seebeck coefficient above 463 K because the ceramics (x = 0.01) broke during the measurement. According to Taguchi [15], the electrical resistivity of K2NiF4-type Ca2(Mn1−x Nb x )O4 decreased extremely in the range of 0 ≤ x ≤ 0.05 because electron transfer on the Mn3+–O–Mn4+ path became active as the Mn3+ ion increased. In the range of 0.05 ≤ x ≤ 0.15, however, the decrease in electrical resistivity was very slight because the Nb5+ ion, which had no 4d electron, prevented electron transfer on the Mn3+–O–Mn4+ path. In the present Ba(Sn1−x Ta x )O3 ceramics, it is predicted that the Ta5+ ion, which had no 5d electron, prevented electron transfer on the Sn–O–Sn path. The activation energy for hopping (E h) increased slightly from 0.02 (x = 0.01) to 0.05 eV (x = 0.06), as shown in Table 1. This result indicates that impurity scattering due to the presence of the Ta ions was more dominant than conduction via hopping in the Ba(Sn1−x Ta x )O3 ceramics.

The temperature dependence of the Seebeck coefficient (S) of the Ba(Sn1−x Ta x )O3 ceramics is shown in Fig. 6. Since the Seebeck coefficient was negative, Ba(Sn1−x Ta x )O3 ceramics were n-type semiconductors and the carrier was an electron. The absolute value of the Seebeck coefficient increased with increasing temperature and x. The temperature dependence of the power factor (S 2 σ) of the Ba(Sn1−x Ta x )O3 ceramics is shown in Fig. 7. The power factor increased with the rise in temperature and decreased with increasing x despite the slight increase in the absolute value of the Seebeck coefficient. The Ba(Sn0.99Ta0.01)O3 ceramics had electrical conductivity with 35–42 Ω−1 cm−1 and the absolute value of the Seebeck coefficient was 43–53 μV/K. Therefore, the Ba(Sn0.99Ta0.01)O3 ceramics had a maximum power factor (ca. 1.0 × 10−5 W m−1 K−2) at 463 K. Yasukawa et al. reported the thermal properties of the Ba(Sn1−x Co x )O3 ceramics prepared at 1673 K in air using a solid-state reaction [6]. Electrical conductivity and the Seebeck coefficient at 470 K were 0.016–0.06 Ω−1 cm−1 and 30–45 μV/K, respectively. Although there was almost no difference in the absolute value of the Seebeck coefficient between the Ba(Sn1−x Co x )O3 ceramics and the Ba(Sn1−x Ta x )O3 ceramics, the Ba(Sn1−x Co x )O3 ceramics had lower electrical conductivity by two to three orders of magnitude compared with the Ba(Sn1−x Ta x )O3 ceramics. Therefore, the power factor of the Ba(Sn0.85Co0.15)O3 ceramics was very low (ca. 6.0 × 10−9 W m−1 K−2 at 470 K). The (Ba0.95La0.05)SnO3 ceramics were synthesized using a polymerized complex method [16]. Electrical conductivity was 0.2–0.4 Ω−1 cm−1 at 400–700 K. The absolute value of the Seebeck coefficient was 40–60 μV/K at 400–700 K; this was almost equal to that of the Ba(Sn1−x Ta x )O3 ceramics. The power factor was ca. 1.0 × 10−7 W m−1 K−2 at 400–700 K. Subsequently, Yasukawa et al. fabricated (Ba1–x La x )SnO3 ceramics with relative densities of 93–97 % using the subsequent spark plasma sintering (SPS) technique [3]. The absolute value of the Seebeck coefficient and electrical conductivity at 400–700 K were 40–65 μV/K and 400–500 Ω−1 cm−1, respectively. Although there was no difference in the Seebeck coefficients between the (Ba1−x La x )SnO3 ceramics fabricated using the polymerized complex method and those fabricated using the SPS method, the latter had greater electrical conductivity. As a result, the power factor of the (Ba0.99La0.01)SnO3 ceramics using the SPS method was high (ca. 2.8 × 10−4 W m−1 K−2) at 1073 K. These results indicate that the improvement of the electrical conductivity of the BaSnO3 ceramics is very important to obtain a high power factor.

Conclusions

The perovskite-type Ba(Sn1−x Ta x )O3 ceramics were fabricated in the range of 0.01 ≤ x ≤ 0.06 using the HIP method at 1273 K and 196 MPa for 4 h in an atmosphere of argon gas. The relative densities were 92.7–95.1 % regardless of x. The lattice parameter decreased slightly from 4.1204 Å (x = 0.01) to 4.1186 Å (x = 0.06), and the atomic percentage of Ta increased linearly with increasing x. The electrical resistivity increased with increasing x, indicating that impurity scattering due to the presence of Ta5+ ions was more dominant than conduction via hopping between the Ta5+ and Ta4+ ions or between the Sn4+ and Sn3+ ions. Ba(Sn1−x Ta x )O3 ceramics were n-type semiconductors, and the absolute value of the Seebeck coefficient increased with increasing temperature and x. The power factor was high (ca. 1.0 × 10−5 W m−1 K−2) at x = 0.1 because the decrease in σ exceeded the slight increase in S 2.

References

Maekawa T, Kurosaki K, Yamanaka S (2006) Thermal and mechanical properties of polycrystalline BaSnO3. J Alloys Compd 416:214–217

Smith MG, Goodenough JB, Manthiram A, Taylor RD, Penf W, Kimball W (1992) Tin and antimony valence state in BaSn0.86Sb0.15O3 − δ. J Solid State Chem 98:181–186

Yasukawa M, Kono T, Ueda K, Yanagi H, Hosono H (2010) High-temperature thermoelectric properties of La-doped BaSnO3 ceramics. Mater Sci Eng B 173:29–32

Upadhyay S, Dahu AK, Kumar D, Parkash O (1998) Probing electrical conduction behavior of BaSnO3. J Appl Phys 84:828–832

Trari M, Doumerc JP, Dordor P, Pouchard M, Behr G, Krabbes G (1994) Preparation and characterization of lanthanum doped BaSnO3. J Phys Chem Solids 55:1239–1243

Yasukawa M, Hamada Y, Kono T, Ueda K, Yanagi H, Kim SW, Hosono H (2011) Thermoelectric properties of p-type BaSnO3 ceramics doped with cobalt. J Jpn Soc Powder Powder Metall 58:149–154

Singh P, Parkash O, Kumar D (2005) Electrical conduction behavior of perovskite oxide system BaSn1−x Nb x O3. Solid State Ion 176:2167–2170

Hirota K, Takano Y, Yoshinaka M, Yamaguchi O (2001) Hot isostatic pressing of chromium nitrides (Cr2N and CrN) prepared by self-propagating high-temperature synthesis. J Am Ceram Soc 84:2120–2122

Upadhyay S, Parkash O, Kumar D (1997) Preparation and characterization of barium stannate BaSnO3. J Mater Sci Lett 16:1330–1332

Hashimoto S, Tanaka C, Murata A, Sakurada T (2006) Formulation for XPS spectral change of oxides by Ar ion bombardment: application of the formulation to Ta2O5 system. J Surf Anal 13:14–16

Yan T, Zheng F, Yu Y, Qin S, Liu H, Wang J, Yu D (2011) Formation mechanism of black LiTaO3 single crystals through chemical reduction. J Appl Cryst 44:158–162

Shannon RD (1976) Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Cryst A 32:751–767

Omeiri S, Hadjarab B, Bouguelia A, Trari M (2010) Electrical, optical and photoelectrochemical properties of BaSnO3−δ. J Alloys Compd 505:592–597

Böttger H, Bryksin VV (1976) Hopping conductivity in ordered and disordered solids. Phys Status Solidi (b) 78:9–56

Taguchi H (2001) Electrical property of K2NiF4-type Ca2(Mn1–x Nb x )O4. Mater Res Bull 36:1361–1367

Yasukawa M, Ikeuchi K, Kono T, Yanagi H, Hosono H (2007) Preparation of semiconductive La-doped BaSnO3 by a polymerized complex method and the thermoelectrical properties. J Jpn Soc Powder Powder Metall 54:639–644

Acknowledgements

This work was financially supported by “Advanced Study for Integrated Particle Science and Technology”, Strategic Development of Research Infrastructure for Private Universities, the Ministry of Education, Culture, Sports, Science and Technology (MEXT), Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Takada, M., Taguchi, H., Kato, M. et al. Fabrication of perovskite-type Ba(Sn1−x Ta x )O3 ceramics and their power factors. J Mater Sci 50, 476–481 (2015). https://doi.org/10.1007/s10853-014-8607-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8607-3