Abstract

We report herein the synthesis of carbogenic dots (CDs) by a one-step pyrolysis from N-acetylcysteine. The as-prepared CDs show excellent dispersibility with particle sizes in the range of 3–5 nm. Under stimulation with blue light, the CDs emit broad yellow fluorescence, which is still rarely reported by now. The optical properties were throughly investigated, and we found the CDs exhibit stable fluorescence, high quantum yield, and pH dependence. Moreover, an economical approach for constructing white light-emitting diodes (LEDs) was developed by combining the yellow-emitting CDs with blue GaN-based LED chips. The white LEDs exhibit warm white light with the color coordinates of (0.34, 0.35), very close to the coordinates of balanced white-light emission (0.33, 0.33). These results suggest that the CDs can be a promising candidate as yellow-emitting phosphor for white LEDs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Solid-state optoelectronic devices in the form of light-emitting diodes (LEDs) have been the subject of intense research for years due to their potential applications in backlighting, general illumination, and liquid–crystal displays of digital cameras, cellular phones, and notebook computers [1–11]. An efficient and commercial route for constructing white LEDs is to combine blue-LED chips with broadband yellow-emitting phosphors, such as Y3Al5O12:Ce3+ (YAG:Ce) [2], Sr3SiO5 [3, 4], Sr-α-SiAlON:Eu2+ [5], and Ba3SiO5:Eu2+ [6]. However, these phosphors were synthesized with expensive raw materials and high reaction temperature at least over 1200 °C. More recently, semiconductor quantum dots (QDs) for white LEDs have been reported, like trap-rich CdS [7], silica-coated InP/ZnS nanocrystals [8], and CdSe nanocrystals [9–11]. Nevertheless, the fabrication and isolation process of semiconductor QDs often involve the tremendous energy consumption as well as the occurrence of aggregation, photooxidation, and fluorescence diminishing of QDs, along with the intrinsic toxicity and potential environmental hazards, greatly limiting their practical applications.

Recently, carbogenic dots (also called carbon dots, CDs) have been extensively spotlighted to be a promising alternative to traditional toxic metal-based semiconductor QDs because of their excellent properties such as unique fluorescence, photostability, chemical resistance, low toxicity, and good biocompatibility [12–35]. Up to now, a variety of methods have been developed to prepare CDs, such as laser ablation of graphite [13–16], electrochemical oxidation of multiwalled carbon nanotubes or graphite [17, 18], chemical oxidation of carbohydrates or activated carbon [19, 20], separation of candle soot [21, 22], supported synthesis [23, 24], thermal oxidation of suitable precursors [25, 26] or microwave routes [27–29]. Simultaneously, great efforts have been made to exploit the potential applications of fluorescent CDs in bioimaging [30–32], biological labeling [33] and optoelectronic devices [34]. For instance, despite rare reports, CDs have been explored for the application of LEDs. A LED based on CDs’ electroluminescence was reported by Liu et al. in 2011 [35]. Our previous work has reported that CDs generated from unzipping of poly(styrene-co-glycidylmethacrylate) photonic crystals could be applied in white LEDs [36]. Much work is still needed in this fledgling area, since either most of reported synthesis methods often require elaborate equipment, multi-step procedure, expensive raw materials, complicated and time-consuming isolation or purification, or the obtained products usually exhibit dull blue fluorescence under single-wavelength ultraviolet (UV) excitation or low quantum yields.

Herein, we developed a simple route to fabricate CDs derived from N-acetylcysteine (NAC) precursor by a simple pyrolysis process (Fig. 1a). Interestingly, the obtained CDs exhibit unique yellow-emitting fluorescence with quantum yield of 13 %, overcoming the drawback of the dull blue fluorescence of traditional CDs. The PL properties and stability in different solvents and pH conditions were thoroughly investigated. Also, we applied these CDs as yellow phosphor coated on blue-LED chips to produce white LEDs. In comparison with conventional phosphor (YAG:Ce), this new generation of phosphor presents advantages: easy fabrication with lower reaction temperature, lower cost, and lower toxicity. Also, the white LEDs developed herein are more powerful and less-cost than those constructed from CDs with white emission stimulated by UV-LED chips.

Experimental

Materials

Reagent-grade NAC was purchased from Aldrich and used as-received. Reagent-grade cyclohexane, toluene, ethanol, N, N-dimethylformamide (DMF) and cyclohexanone were supplied by Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China) and used as purchased. Epoxy resin A and epoxy resin B were purchased from Shenzhen Gaohejidian Co., Ltd. (China). The commercial blue GaN-based LED chips (peak at 460 nm) were obtained from Lambert Co., Ltd. (China). High-purity water with the resistivity greater than 18 MΩ cm−1 was used in the experiments.

Preparation of CDs

NAC was chosen as the precursor. In a typical process, 0.3 g NAC was directly calcined in a tube furnace at 300 °C for 2 h under N2 flow with a heating rate of 5 °C min−1. The as-derived carbogenic solid was grinded in a mortar and dispersed in ethanol. The suspension solution of carbogenic solid was sonicated, followed by high-speed centrifugation (12000 rpm, 20 min) to remove large particles. The resultant homogeneous supernatant contained strongly fluorescent CDs, which was kept for further use. The CDs powder was prepared by volatilizing solvent in air.

Preparation of the white LEDs

The blue GaN-based LED chips with the peak wavelength centered on 460 nm were used and attached on the bottom of the LED bases. The two threads on LED were prepared to connect to the power supply. Afterward, epoxy resin A and epoxy resin B were mixed with the CDs phosphor and put in a vacuum chamber to remove the bubbles. About 30 μL of the phosphor mixture was dispensed into the conventional cup-shaped void on the LED chip and thermally cured at 120 °C for 1 h. Finally, the optical lenses were placed on the bottom of the LED chips.

Characterization

High-resolution transmission electron microscope (HRTEM) observation was performed with a JEOL JEM-2010 transmission electron microscope. X-ray diffraction (XRD) was performed on a Rigaku Corporation D/max-rC rotating anode X-ray powder diffractometer using a copper target. Fourier transform infrared (FT-IR) spectra were recorded on a Nicolet 6700 FT-IR spectrometer. Ultraviolet–visible (UV–vis) absorption spectra were taken with a Perkin-Elmer Lambda 900 UV–vis spectrometer. PL measurements were carried out on a Varian Cary Eclipse spectrophotometer. Time-correlated single-photon counting (TCSPC) data were performed on SLM 48000 spectrofluorometer using a 400 nm laser as the excitation source. The element analysis of the product was measured on an Elementar Vario EL-III (Germany). The emission spectrum of the white LED was measured by a USB4000 Miniature Fiber Optic Spectrometer of Ocean Optics. All the spectra were measured at room temperature.

Results and discussion

The schematic representation of the formation of CDs is illustrated in Fig. 1a. The calcination of NAC at 300 °C for 2 h under carrier gas of nitrogen directly obtain CDs with bright yellow fluorescence under blue light, which could be used as the yellow phosphor to apply in producing white LEDs with blue-LED chips. This one-step route avoids time-consuming multi-step procedures and complicated particles separation step, opening a simple rapid way to fabricate CDs with novel photoluminescent properties.

Figure 1b shows the HRTEM image of CDs. The as-prepared CDs have well dispersion with particle size of 3–5 nm. No crystalline lattices were observed in the HRTEM measurement. XRD pattern of the CDs displays a broad diffraction peak located at 2θ = 24° (Fig. 2b), which further confirms an amorphous nature of the CDs [37]. FT-IR spectra were acquired to determine the surface chemistry of as-prepared CDs (Fig. 2a). The spectrum of CDs shows obvious peaks around 3437 and 1634 cm−1, which can be ascribed to the stretching vibrations of O–H and C=O, respectively. In addition, the absorption peaks in the spectrum of CDs around 1285 and 1070 are referred to C–O and C–N stretching vibrations. However, the characteristic absorption peaks around 1717 and 2547 cm−1 for carboxylate group and S–H stretching vibration observed in the spectrum of NAC are disappeared in the spectrum of CDs. Although there are no data in the literature describing in detail the pyrolysis of NAC, we speculate that the carboxyl and sulfhydryl in NAC molecules had decomposed during high-temperature treatment. The elemental analysis reveals the composition of CDs as follows: C 55.7 wt%, H 4.7 wt%, N 14.6 wt%, S 7.2 wt%, O (calculated) 17.8 wt%. Compared to the parent precursor, the contents of H, S, and O are remarkably reduced during the pyrolysis process.

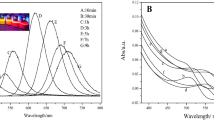

The as-prepared CDs exhibit excellent photoluminescent properties. Figure 3 depicts the UV–vis absorption and PL spectra of CDs in ethanol. An intense absorption characteristic peak at ~320 nm is observed in the UV–vis absorption spectrum. As frequently reported, the PL emission wavelength of the CDs is dependent on the excitation, with PL peaks red-shift from 480 to 600 nm by increasing excitation wavelength (λ ex) from 370 to 550 nm. Excited at 460 nm, a PL peak centering at 530 nm with maximum intensity and a full width at half maximum of about 110 nm is observed, suggesting the CDs could exhibit broad yellow fluorescence and are favorable as the yellow phosphor toward white LEDs. Quantum yield was calculated using quinine sulfate in 0.10 M H2SO4 solution as the standard [12]. The quantum yield of the as-prepared CDs was determined to be 13 % (see details in Fig. S1 and Table S1). CDs in most cases present quantum yield less than 10 %, and this value is comparable to those for desirable CDs prepared previously [17–29]. It is worth noting that NAC precursor does not exhibit any detectable fluorescence. Thus, the fluorescence in the products should be engendered from the nanoparticles, where a widely recognized explanation is the radiative recombination of excitons at the particle surfaces [13].

Another indication is the fluorescent stability of CDs. Time-resolved fluorescence was performed to access the fluorescent lifetime of CDs using TCSPC methodology, as seen in Fig. 4a. The decay lifetime of CDs was evaluated by biexponential fit process [38], using the expression (1)

where α 1, α 2 are fractional contributions of time-resolved decay lifetimes τ 1, τ 2. And, average lifetime \( \bar{\tau } \) could be concluded from the Eq. (2)

The best fit gives the decay lifetime of 4.00 ns for CDs (see Table 1), similar to those of CDs obtained by other groups [13, 14]. In addition, after being stored under ambient conditions for 6 months, the CDs showed no significant change in PL spectra (see Fig. 4b), revealing the excellent photoluminescent stability of the as-prepared CDs. The excellent PL properties in terms of brightness and stability make the as-prepared benign CDs useful in various applications.

The effect of various organic solvents on the PL spectra of CDs was investigated. Figure 5a shows the different PL intensity of CDs dispersed in cyclohexane, water, toluene, ethanol, DMF, and cyclohexanone, from which we can see that CDs exhibit excellent fluorescence in water and various organic solvents except cyclohexane (see original PL emission spectra in Fig. S2). As evidenced in the FT-IR spectra (Fig. 2a), there are abundant organic functional groups on the surfaces of CDs (–OH, C=O, C–O and C–N). These functional groups confer the CDs with excellent dispersibility in diverse solvents, which might be responsible for the strong PL intensity and is highly desirable for practical applications of CDs.

Figure 5b shows the effect of pH on PL intensity of the CDs in aqueous solution. As depicted in Fig. 5b, the PL intensity of the CDs is pH-dependent. The PL is relatively stable in the pH range of 5–9, while the PL intensity decreased significantly for either a strong acidic or a strong basic solution. Meanwhile, there is an interesting phenomenon that the PL intensity of CDs decreased linearly with the increase of the pH from 9 to 14. These pH-sensitive CDs could be exploited to monitor reactions which may cause a minor change in pH values.

Perhaps more importantly, we directly employed as-prepared solid CDs as the yellow phosphor for incorporation into solid- state lighting applications in the form of white LEDs. As we know, the development of LEDs continues to be a topic of intense interest for their great potential in lighting and display [35]. The prototype white LED was made by coating CDs encased in epoxy resin on the solid-state lighting unit comprised of a blue-LED chip with 460 nm excitation. The light-emissive property of the prototype white LED was investigated. As shown in Fig. 6a, the emission spectra of the white LED consists of two emission bands, blue emission centering at 460 nm from the LED chip and broad yellow emission from CDs. These two emission bands are combined to give a spectrum that produces white light. As seen in Fig. 6b, the device provided a bright white illumination. The prepared white LED displays the Commission Internationale d’Eclairage (CIE) chromaticity coordinates of (0.34, 0.35) (Fig. 6c), which is close to those of balanced white-light emission (0.33, 0.33), and hence it exhibits warm white light approximating natural sunlight. These results demonstrate the success in white LEDs’ fabrication based on yellow emission of CDs, which has not been reported previously. In previous report, white LEDs were constructed by white emission of CDs stimulated by UV light. The UV-LED chips have smaller power rating and more cost than blue-LED chips. Thus, the white LEDs comprised of yellow-emitting CDs and blue-LED chips are more practical than those reported previously. Meanwhile, the CDs also possess advantages of easy fabrication, lower cost, and lower toxicity over conventional YAG:Ce and semiconductor QDs.

Conclusions

We have developed a simple route to fabricate CDs derived from NAC precursor by a simple pyrolysis process. Interestingly, the obtained CDs exhibit unique yellow-emitting fluorescence, overcoming the drawback of the dull blue fluorescence of traditional CDs. The as-prepared CDs are well-dispersed in various hydrophilic and hydrophobic solvents and possess high quantum yield of 13 % without further surface treatment. Also, we applied these CDs as the yellow phosphor in combination with blue-LED chips to construct white LEDs for the first time. The environmentally friendly white LEDs exhibited warm white light with the color coordinates of (0.34, 0.35). Consequently, coupled with their low cost, low toxicity, and PL stability, the CDs as a promising alternative yellow phosphor for white LEDs may further widen the applicability of CDs.

References

Schubert EF, Kim JK (2005) Science 308(5726):1274

Pan YX, Wu MM, Su Q (2004) Mater Sci Eng, B 106(3):251

Park JK, Kim CH, Park SH, Park HD, Choi SY (2004) Appl Phys Lett 84(10):1647

Jang HS, Jeon DY (2007) Appl Phys Lett 90(4):041906

Shioi K, Hirosaki N, Xie RJ, Takeda T, Li YQ (2010) J Mater Sci 45:3198

Park JK, Lim MA, Choi KJ, Kim CH (2005) J Mater Sci 40:2069

Sapra S, Mayilo S, Klar TA, Rogach AL, Feldmann J (2007) Adv Mater 19(4):569

Ziegler J, Xu S, Kucur E, Meister F, Batentschuk M, Gindele F, Nann T (2008) Adv Mater 20(21):4068

Bowers MJ II, McBride JR, Rosenthal SJ (2005) J Am Chem Soc 127(44):15378

Lita A, Washington AL II, van de Burgt L, Strouse GF, Stiegman AE (2010) Adv Mater 22(36):3987

Jang HS, Yang H, Kim SW, Han JY, Lee SG, Jeon DY (2008) Adv Mater 20(14):2696

Xu XY, Ray R, Gu YL, Ploehn HJ, Gearheart L, Raker K, Scrivens WA (2004) J Am Chem Soc 126(40):12736

Sun YP, Zhou B, Lin Y, Wang W, Fernando KAS, Pathak P, Meziani MJ, Harruff BA, Wang X, Wang HF, Luo PJG, Yang H, Kose ME, Chen BL, Veca LM, Xie SY (2006) J Am Chem Soc 128(24):7756

Wang X, Cao L, Lu FS, Meziani MJ, Li H, Qi G, Zhou B, Harruff BA, Kermarrec F, Sun YP (2009) Chem Commun (25):3774

Li XY, Wang HQ, Shimizu Y, Pyatenko A, Kawaguchi K, Koshizaki N (2011) Chem Commun 47(3):932

Wang X, Cao L, Yang ST, Lu FS, Meziani MJ, Tian LL et al (2010) Angew Chem Int Ed 49(31):5310

Zhou JG, Booker C, Li RY, Zhou XT, Sham TK, Sun XL et al (2007) J Am Chem Soc 129(4):744

Zhao QL, Zhang ZL, Huang BH, Peng J, Zhang M, Pang DW (2008) Chem Commun (41):5116

Peng H, Travas-Sejdic J (2009) Chem Mater 21(23):5563

Qiao ZA, Wang YF, Gao Y, Li HW, Dai TY, Liu YL et al (2010) Chem Commun 46(46):8812

Liu HP, Ye T, Mao CD (2007) Angew Chem Int Ed 46(37):6473

Tian L, Ghosh D, Chen W, Pradhan S, Chang XJ, Chen SW (2009) Chem Mater 21(13):2803

Liu RL, Wu DQ, Liu SH, Koynov K, Knoll W, Li Q (2009) Angew Chem Int Ed 48(25):4598

Zong J, Zhu YH, Yang XL, Shen JH, Li CZ (2011) Chem Commun 47(2):764

Bourlinos AB, Stassinopoulos A, Anglos D, Zboril R, Karakassides M, Giannelis EP (2008) Small 4(4):455

Bourlinos AB, Stassinopoulos A, Anglos D, Zboril R, Georgakilas V, Giannelis EP (2008) Chem Mater 20(14):4539

Zhu H, Wang XL, Li YL, Wang ZJ, Yang F, Yang XR (2009) Chem Commun (34):5118

Wang QL, Zheng HZ, Long YJ, Zhang LY, Gao M, Bai WJ (2011) Carbon 49(9):3134

Wang XH, Qu KG, Xu BL, Ren JS, Qu XG (2011) J Mater Chem 21(8):2445

Cao L, Wang X, Meziani MJ, Lu FS, Wang HF, Luo PJG et al (2007) J Am Chem Soc 129(37):11318

Yang ST, Cao L, Luo PGJ, Lu FS, Wang X, Wang HF et al (2009) J Am Chem Soc 131(32):11308

Yang ST, Wang X, Wang HF, Lu FS, Luo PJG, Cao L et al (2009) J Phys Chem C 113(42):18110

Li Q, Ohulchanskyy TY, Liu RL, Koynov K, Wu DQ, Best A et al (2010) J Phys Chem C 114(28):12062

Zheng LY, Chi YW, Dong YQ, Lin JP, Wang BB (2009) J Am Chem Soc 131(13):4564

Wang F, Chen YH, Liu CY, Ma DG (2011) Chem Commun 47(12):3502

Guo X, Wang CF, Yu ZY, Chen L, Chen S (2012) Chem Commun 48(21):2692

Wang F, Kreiter M, He B, Pang SP, Liu CY (2010) Chem Commun 46(19):3309

Yang SY, Wang CF, Chen S (2011) J Am Chem Soc 133(22):8412

Acknowledgements

This study was supported by the National High Technology Research and Development Program of China (863 Program) (2012AA030313), National Natural Science Foundation of China (21076103), Natural Science Foundations for Jiangsu Higher Education Institutions of China (11KJB530004), and Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Chen, QL., Wang, CF. & Chen, S. One-step synthesis of yellow-emitting carbogenic dots toward white light-emitting diodes. J Mater Sci 48, 2352–2357 (2013). https://doi.org/10.1007/s10853-012-7016-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-7016-8