Abstract

Carbon xerogels, synthesized through the resorcinol–formaldehyde polycondensation and subsequently dried under subcritical condition, have been studied as electrodes for supercapacitors. In particular, the influence of the catalyst concentration has been investigated by systematically changing the amount of catalyst (Na2CO3) utilized to synthesize the xerogels. To clarify the effect of such variable, both the surface properties and the electrochemical behavior of xerogel-based supercapacitors have been examined. From the xerogels characterization, it can be inferred that the amount of catalyst used has a strong influence on the properties of the material. Contrary to what happens with carbon aerogels, the best properties are obtained with the xerogels synthesized with the least amount of catalyst: in this case the highest measured specific capacitance of the supercapacitor cells, which is assembled coupling two symmetric electrodes in series, is 25 F/g, value that corresponds to a single-electrode specific capacitance of 100 F/g. The maximum energy storage capacity in an aqueous electrolyte is 3.1 Wh/kg. Using more concentrated catalyst solutions, the gel microstructure becomes finer, composed of smaller particles and pores, which in turns leads to an increase of the capillary drying stresses and to the collapse of the organic structure. Consequently, the shrinkage of the gels is high and the final carbon xerogels do not posses sufficient surface area and porosity to store a significative amount of energy.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

During the last few decades, electrochemical double-layer capacitors (EDLCs) have generated increasing interest both as complementary devices to batteries and as important competitors among the energy storage systems. Various porous carbon materials such as activated carbons, CNT, carbon aerogels, carbon fibers, and carbide-derived carbons have been studied as suitable materials for EDLC electrodes [1, 2]. In particular, carbon aerogel and xerogels are considered a promising alternative because of their good electrical conductivity, their tridimensional porous structure, and elevated specific surface areas [3–5]. Carbon aerogels, produced through a sol–gel polycondensation of resorcinol (R) and formaldehyde (F), activated by a catalyst (Na2CO3), have been widely studied, clarifying, in particular, the influence of the catalyst concentration on the materials properties [3]. Some fundamental studies about carbon xerogels have also been published elucidating the relationship between some synthesis parameters and the main physical and electrochemical features of such materials [5–8]. Lin and Ritter [9] have extensively studied, for example, the influence of variables as the dilution or the pH of the initial solution, as well as the carbonization temperature [10] on some physical and electrochemical properties of carbon xerogels. The substitution of the expensive and complex supercritical drying process (used to obtain aerogels) with an ambient drying method (used in the case of xerogels) has proved to be a cheaper and more feasible strategy to synthesize porous carbon structures. However, the presence of the capillary pressure inside the pores during the subcritical drying step, may cause changes in the microstructural properties of the xerogels and consequently might also affect the performance of such materials when utilized as electrode for supercapacitors. Accordingly, there is a need to investigate the influence of the synthesis parameters used for xerogels (as the catalyst concentration) not only on the material microstructure (specific surface area and porosity), but also on the electrochemical properties of xerogel-based EDLCs, comparing the results to what is already known about carbon aerogels. Moreover, it is crucial to evaluate the electrochemical features of the different electrodes testing the materials in a real EDLC configuration (two electrode cell) which better simulates the real operative conditions usually not reproduced working with a single-electrode set-up.

Experimental

Xerogel synthesis

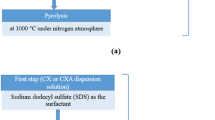

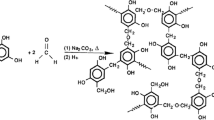

The organic xerogels were synthesized through a sol–gel method with the polycondensation of resorcinol (R) and formaldehyde (F) in an aqueous solution with Na2CO3 as the catalyst (C). The procedure followed in this study was introduced by Pekala and described in detail elsewhere [3, 8, 11, 12]. After the polymerization the wet gels were dried in subcritical conditions, namely at temperature and pressure below the thermodynamical critical point of the solvent. During the preparation of the initial solution, the R/F molar ratio and the dilution factor (D), quantified by the ratio between the moles of water and the moles of solids in the solution, were kept fixed at 1/2 and 10 respectively. The molar ratio R/C varies systematically from 50 to 1500 (the R/C used are 50, 100, 250, 500, 1000, and 1500). The different solutions were poured in cylindrical vials and sealed to avoid the evaporation of the solvent during the curing stage that was performed at 80° C for 5 days. After the curing, the specimens underwent a solvent exchange in isopropanol at 50° C (4 × 24 h). Afterwards, the samples were slowly dried in subcritical conditions (at 50° C and ambient pressure atmosphere) until all the solvent was completed removed. Finally, the dried organic gels were carbonized using a graphite furnace (Astro, Thermal Technology, USA) in inert atmosphere (Argon, flow rate of 100 ml/min). They were kept at 1000° C for 2 h with a heating rate of 10° C/min. All the samples are labeled according to the R/C ratio used to synthesize them (i.e., the label RC500 is related to the xerogel synthesized with a R/C ratio of 500). The samples densities and the shrinkage were monitored both after the drying and at the end of the carbonization. The porosity of xerogels was evaluated by N2 adsorption at 77°K (Micromeritics, Gemini Model 2010, USA): the specific surface area was determined using the BET equation with an accuracy of ± 10 m2/g while the pore size distribution (PSD) was obtained using the Barrett–Joyner–Halenda (BJH) method. The total pore volume (TPV) was calculated as: TPV = V a × D, where V a is the volume adsorbed at p/p 0 = 0.99, D is the density conversion factor (0.0015468 for nitrogen as adsorbate gas). The micropores volume was evaluated by the t-plot method applying the Harkins and Jura model for the statistical thickness. The surface morphology was analyzed using a field emission gun electron microscope (FEG-SEM, Zeiss Supra 40).

Cell construction and electrochemical characterization

After the carbonization, the carbon xerogel samples were ground to obtain the powder for the electrodes. A slurry was prepared, mixing the xerogel powder with 10 wt% of PTFE (60 wt% in water, Sigma-Aldrich) as binder and 5 wt% of graphite (1-2 micron, Sigma-Aldrich) to enhance electrical conductivity, using acetone as solvent. The slurry was casted onto a current collector (pressed graphite sheets , Toyo Tanso Co., Ltd.) and pressed to reduce the contact resistance between the powder particles, as well as the resistance between the active material and the collector. Finally, the electrodes were dried for 12 h at 100° C to completely remove the solvent. A two electrodes EDLC capacitor was built coupling two symmetric electrodes in series (each electrode has an active mass of ca. 10 mg), a paper filter as the separator membrane and a 6 M KOH aqueous solution as electrolyte. The EDLC cell, that has an active area of 1 cm2, was sealed to prevent the evaporation of the electrolyte during the tests. Constant current charge–discharge (CD), cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS) measurements were performed to analyze the electrochemical behavior of the EDLC cell. All the tests were carried out at room temperature with an Autolab potentiostat (Metrohn Autolab potentiostat 302N). The CD tests were performed at different current densities (2, 5, 10, 20 , 40, and 60 mA/cm2) and the maximum potential was fixed at 1 V. Using this technique has been possible to calculate the specific capacitance, the energy and power densities of the EDLC. The voltammetries were carried out using a two electrodes configuration (without the reference electrode), a potential window of 800 mV and different scan rates (10, 20, 50, and 100 mV/s). The EIS tests were executed with a frequency range between 100 kHz and 5 mHz with a voltage amplitude of 0 ± 10 mV. The specific capacitance of the EDLC cell (C SC) was calculated from the slope of the discharge curve in the CD test according to the following expression:

where I is the current applied to the cell, dV/dt the slope of the curve, and m is the mass of the active material of both the electrodes. The specific energy of the cell was evaluated integrating the discharge curve according to the Eq. 2 (where m is again the mass of both the electrodes). Finally, the specific power was calculated dividing the total energy stored by the net discharge time

All the electrochemical quantities presented in this study are associated to the properties of the entire EDLC cell. To compare them with what is reported in the literature about the electrochemical features of a single-electrode configuration, attention must be paid concerning both the type of set-up used (single-electrode or two electrodes cell), and how the specific results are normalized.

Results and discussion

Xerogel characterization

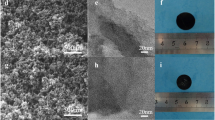

After curing, the wet organic gels have a characteristic brown–red color. The shrinkage, due to capillary tension inside the pores during the drying, decreases as the R/C ratio increases (Table 1). The density of the organic dried gels varies from 0.94 g/cm3, with low R/C ratio, to 0.28 g/cm3 when R/C is 1500. As thoroughly reported in the literature about the base-catalyzed resorcinol–formaldehyde reactions [3, 8], the sodium carbonate does not catalyze directly the addition of formaldehyde to the resorcinol molecules but it affects the pH of the solution, and consequently it indirectly promotes or hinders the formation of methylol-susbstituted resorcinols during the first step of the polymerization. This fact has also an influence on the gel structure: low R/C ratios give small polymeric particles with a fibrous structure and a high density; high R/C ratios produce a colloidal gel with coarser particles interconnected by small necks [3]. Because the internal stresses developed inside the porous network are inversely proportional to the diameter of the pores, a structure made up of small fibrous particles, as that obtained with low R/C ratios, undergoes to a higher internal tension that causes the collapse of the porous network. Consequently, a dense organic structure is obtained as clearly showed in Fig. 1a. Using lower catalyst concentrations (R/C ratio above 500), since the average diameter of the pores is wide enough to limit the intensity of the internal stress during the drying, the shrinkage is substantially reduced (Table 1) and hence the organic xerogels have the lowest densities among all the samples synthesized.

During carbonization, the samples undergo a further shrinkage (Table 1) accompanied by a weight loss due to the removal of oxygen and hydrogen atoms with a total weight loss of 51–52 % for all the xerogels. Comparable values have already been reported in literature for Na2CO3-catalyzed resorcinol–formaldehyde xerogels [13, 14]. The structure of the xerogel named RC100 collapses leading to a negligible SSA value and to a dense microstructure, revealed by the FEG-SEM image (Fig. 1a). On the contrary, Fig. 1b, c confirm that, synthesizing the organic gels with a lower amount of catalyst, it’s possible to form homogeneous porous microstructures with specific surface areas higher than 500 m2/g (Table 1).

The adsorption–desorption isotherms are provided in Fig. 2. According to IUPAC classification, the isotherms of the xerogels RC250, RC500, and RC1000 are clearly of Type IV, which is characteristic of mesoporous materials. For these curves, the hysteresis loop is visible in the mesopores filling section of the isotherms and, for the RC250 sample, it can be classified as H2, ascribed to ink-bottle-shaped pores [15]. As the amount of catalyst decreases (higher R/C ratios) the hysteresis loop shifts towards higher pressure regimes, as a result of mesopores widening and pore size broadening. This hypothesis is further supported by the BJH-derived PSD plot, reported in the inset graph of Fig. 2 and confirmed by the SEM images. The isotherm curve related to the sample obtained with the least amount of catalyst (RC1500) does not show a limiting adsorption plateau at high p/p 0 indicating the presence of a consistent fraction of macropores. Moreover, since the N2 gas reaches its saturation pressure before having completely filled the pores, the resulting total volume is, for this sample, underestimated. Apart the xerogel RC100, whose adsorbed volume is negligible, indicating the formation of a non porous material, all the xerogels exhibit also a fraction of micropores that typically is believed to appear during the carbonization step due to the shrinkage of the smallest mesopores [8].

Electrochemical characterization

Figure 3 reports an example of the CD curves performed with the EDLC assembled using the xerogel RC500 at different current densities.

The voltage curves have a typical symmetric triangular shape with a linear slope both during the charge and the discharge, proving that the electrodes have a pure capacitive behavior. The ohmic drop at the beginning of the discharge is very limited: this fact proves that the carbon xerogel has a good electric conductivity. The specific capacitances (C SC) of different xerogels, evaluated from the slope of the discharge curve, are reported in Table 2.

The values correlated to more dense xerogels, RC50 and RC100, never exceed 5 F/g even applying low current densities. Since these types of xerogels have a limited specific surface area and a dense structure, they are not able to store a significant amount of charge on their surface. The xerogels synthesized increasing the R/C ratio, having higher SSA, are able to attract a larger number of ions and consequently also their specific capacitances are higher. The highest values are obtained in the case of xerogels RC1000 (25.9 F/g) and RC1500 (25.1 F/g). Using the EDLC cell capacitance is possible to estimate the specific capacitance of the double layer of each electrode. Knowing that the cell is assembled coupling in series two electrodes having the same area and the same active mass, is possible to approximately calculate backward the single-electrode capacitance multiplying the EDLC capacitance by a factor of four. Therefore, in the case of RC1000 and RC1500 the electric double-layer capacitance of each electrode would reach about 100–104 F/g, values comparable, despite the unavoidable charge losses introduced using the two electrodes configuration, to those reported in the literature about non-activated carbon xerogels when tested in a single-electrode cell configuration [1, 10].

The ragone plot presented in Fig. 4 shows that the highest specific energies, calculated integrating over time the discharge curve, are reached using xerogel with R/C ratios of 1000 and 1500 (3.1 and 2.9 Wh/kg) whereas the use of more concentrated catalyst solution reduces both the energy stored and the correlated power of the EDLC. The specific energy stored by the device depends strongly on the maximum voltage reached by the cell. In the case of aqueous solutions, the voltage window is limited to 1 V due to the electrochemical instability of water above this value. Taken into account this variable, the energies measured with the best xerogels (RC1000 and RC1500) are comparable with other classes of carbon materials tested in similar conditions [1, 12].

The cyclic voltammetries of the xerogels with the best electrochemical properties (RC1000 in Fig. 5), exhibit a typical rectangular and symmetric shape without peaks related to redox or faradic reactions.

The constant step of the current is assured by the presence of the mesopores that enhances the diffusion of ions into the electrode. For the same reason, when the structure of the xerogel is dense and mesopores are absent, as in the case of EDLC RC100 (Fig. 5), the formation of the double layer is not immediate and the shape of the curve changes approaching the diagonal of the ideal rectangle. The capacitances evaluated with this technique confirm the values calculated with the galvanostatic measurements. The EIS results were analyzed with the complex capacitance model [16] which allows to separate the real contribution of the capacitance, from the imaginary part (Fig. 6). The plot confirms that the best capacitances are obtained with higher R/C ratios whereas, in the case of RC50 and RC100, the step of the real capacitance moving from higher to lower frequencies is negligible, as a consequence of irreversible phenomena occurring in the charge or discharge of the electrodes.

Conclusions

In this study, different carbon xerogels have been synthesized systematically studying the effect of the catalyst concentrations both on the material microstructural features (specific surface area, porosity, and pore size) and on the electrochemical properties of such xerogels when tested as active material for supercapacitors electrodes. Contrary to what reported in the literature about carbon aerogels [3], which are usually synthesized with the same recipe used in this study but dried in supercritical conditions, the use of a low resorcinol to catalyst ratio does not provide carbon xerogels with significant porosity. Indeed, the ambient drying technique used in this study causes the collapse of the porosity of xerogels having RC ratios below 250. The best properties are obtained working with high R/C ratios: using a R/C ratio of 1500 the final carbon xerogels has a density of 0.3 g/cm3 and surface area of 578 m2/g. This result can be explained knowing that decreasing the amount of catalyst used in the initial solution, leads to a microstructure composed of coarser particles, which can be subcritically dried without developing high internal stresses. Accordingly, it is possible to prevent the collapse of the structure and to synthesize highly porous xerogels. In parallel to the material characterization, the electrochemical testing of xerogel-based supercapacitors demonstrates that the best electrochemical properties are showed by xerogels with higher R/C ratios (1000 and 1500). The highest specific capacitance of the supercapacitor cell, calculated with the galvanostatic constant current analysis, reaches 25.9 F/g, whereas the maximum energy stored is 3.1 Wh/kg. In conclusion, both the characterizations presented in this study confirm that the critical catalyst concentration, which distinguishes those xerogels that provide significative porous electrodes from the xerogels with no energy storage capability, can be identified by the R/C ratio of 500.

References

Inagaki M, Konno H, Tanaike O (2010) J Power Sources 195(24):7880

Simon P, Gogotsi Y (2008) Nat Mater 7(11):845

Al-Muhtaseb SA, Ritter JA (2003) Adv Mater 15(2):101

Arbizzani C, Beninati S, Lazzari M, Soavi F, Mastragostino M (2007) J Power Sources 174(2):648

Job N, Thery A, Pirard R, Marien J, Kocon L, Rouzaud J, Beguin F, Pirard J (2005) Carbon 43(12):2481

Job N (2004) Analysis 5:619

Sharma CS, Kulkarni MM, Sharma A, Madou M (2009) Chem Eng Sci 64:1536

Elkhatat AM, Al-Muhtaseb SA (2011) Adv Mater 23:2887. doi:10.1002/adma.201100283

Lin C, Ritter JA (1997) Carbon 35(9):1271

Lin C, Ritter JA, Popov BN (1999) J Electrochem Soc 146:3639

Lee YJ, Jung JC, Park S, Seo JG, Baeck S-H, Yoon JR, Yi J, Song IK (2010) Curr Appl Phys 10(3):947

Kim SJ, Hwang SW, Hyun SH (2005) J Mater Sci 40(3):725. doi:10.1007/s10853-005-6313-x

Fairenjimenez D, Carrascomarin F, Morenocastilla C (2006) Carbon 44(11):2301

Reuß M, Ratke L (2008) J Sol–Gel Sci Technol 47(1):74

Sing KSW, Everett DH, Haul RAW, Moscou L, Pierotti RA, Raquerol J, Siemieniewska T (1985) Pure Appl Chem 57(4):603

Taberna PL, Simon P, Fauvarque JF (2003) J Electrochem Soc 150(3):A292

Acknowledgements

G.D. Soraru and P.R. Aravind acknowledge the financial contribution from Provincia Autonoma di Trento under the project NAOMI and the European Community, through a Marie Curie Initial Training Network "FUNEA" through the contract MC-ITN- 264873.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mezzavilla, S., Zanella, C., Aravind, P.R. et al. Carbon xerogels as electrodes for supercapacitors. The influence of the catalyst concentration on the microstructure and on the electrochemical properties. J Mater Sci 47, 7175–7180 (2012). https://doi.org/10.1007/s10853-012-6662-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6662-1