Abstract

In this study, we investigated the relaxation properties of wet wood based on spectra isolated from the whole wood relaxation spectrum, calculated using Alfrey’s approximation at temperatures ranging from 25 to 85 °C. Three relaxation processes were identified, I, II, and III, in the order of low to high temperature, and these were attributed to local molecular motions of hemicellulose, lignin, and cellulose, respectively. Processes I and II (but not III) depended on temperature and the apparent activation energy, which was calculated from the temperature dependence of their relaxation time and was approximately 85 kJ/mol (20 kcal/mol) for both processes. The peak positions and intensity of the isolated relaxation spectra indicated that the molecular motion of the relaxation processes in the temperature range studied represent not whole molecular motion, but rather local molecular motion of the hemicellulose and lignin matrix. This study also demonstrated that the isolation procedure using a Gaussian function can be used to analyze the relaxation process of wood.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The aim of this article is to analyze relaxation properties of wood on the basis of the new method that spectra of wood components are isolated from the whole relaxation spectrum of wood at each temperature. The method has never been tried for wood and woody materials to our knowledge.

Many reports have examined the relaxation properties of wood, as described in Yamada et al.’s [25] review of previous measurement conditions and analytical methods, as well as both static and dynamic methods. However, it has been difficult to discuss relaxation spectrum for wood, because the relaxation spectrum is not obtained over a wide time range due to the uncertainty regarding the validity of the time–temperature superposition principle (TTSP) for the whole wood. Several studies have suggested that this principle does not hold perfectly, regardless of wet or dry wood [9, 10, 15, 22, 24, 26]. On the other hand, the principle has been reported to hold for water-saturated milled wood lignin [11], for wood and isolated wood components with various moisture contents [11] and for in situ lignin under wet conditions [20]. Kelley et al. [14] also reported a similar result. Additionally, Bond et al. [3] reported that the TTSP was valid under limited conditions or wood species.

The TTSP is the principle of equivalence of time and temperature effects. On the basis of the principle, data obtained at each temperature over time or frequency scale are shifted into superposition along logarithmic scale time or frequency axis. The amount of shift \( \log a_{T} \) is referred to “shift factor.” The TTSP requires that all relaxation mechanisms depend equally on temperature. Thus, it does not apply multi-phase materials such as hybrid materials, crystalline polymers and so on, because in general each phase for them has different temperature dependence.

Fesco and Tschoegl [7] clarified analytically that the shift factor depends on the temperature and frequency for the application of the TTSP to a multi-component system. This implies that the TTSP does not hold in a multi-component system, especially one consisting of different temperature/frequency-dependent components. Considering the results of past reports, the cellulose in wood, especially crystalline cellulose, may negate the principle. Furthermore, for wood, the validity of the principle cannot be verified solely by a smooth master curve. Since the relaxation curves for wood are generally flat under various conditions, so that they can be apparently superposed in many cases if shifted along a logarithmic time axis. As well known, wood is a multi-component system, consisting of cellulose, hemicellulose, and lignin, which differ from one another in chemical structure and physical properties. Thus, an amorphous matrix with hemicellulose and lignin should differ from crystalline cellulose in terms of relaxation behavior and its temperature dependence.

Therefore, we examine the new method that spectra of wood components are isolated from the whole relaxation spectrum of wood at each temperature and then their temperature dependence is examined. This method can be applied regardless of validity of the TTSP and allow us to describe the molecular dynamics of wood components in detail according to the temperature dependence of the relaxation-time dispersion and the intensity, i.e., the shape change and shift along the time axis of a relaxation spectrum obtained at a certain temperature.

Experimental

Sample and measurement

Yezo spruce (Picea jezoensis Carr.) with dimensions of 90 (R) × 1.5 (L) × 8 (T) mm was prepared as a sample, where L, R, and T represent measurements in longitudinal, radial, and tangential directions, respectively. The specimens were kept at room temperature overnight after being injected with distilled water under vacuum.

Stress-relaxation measurement

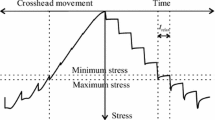

For stress-relaxation measurements at various temperatures, wet samples were subjected to a three-point bending test with a center-concentrated load in a water bath with a heater. Load signal under constant deformation was detected by load cell at a constant logarithmic time interval ∆ln[t/s] = 0.1, except immediately after the start of measurement, when the interval was approximately ∆ln[t/s] >0.1 due to the ability to receive the signal. The detected signal was converted from analog to digital using an A/D converter and then treated with a home-made program on a microcomputer.

The span was 70 mm. The load was applied to a radial–tangential face of a sample which was less than 30% of the proportional limit load under the wet condition (i.e., 1.0–2.0 mm deflection, depending on the measurement temperature). Measurements were carried out in a water bath at a fixed temperature from 25 to 85 °C for approximately 17 h. Two or three samples were measured under the same condition to confirm reproducibility; however, no statistical analyses were performed. The relaxation modulus in the bending mode was calculated by

where P(t) represents the detected load as a time function, l is the span, and a, b, and d are the width, thickness, and deflection of a sample, respectively.

The relaxation spectrum H(lnτ) was calculated from the relaxation modulus as a time function using Alfrey’s approximation equation [1], given as

which can be obtained from the following relaxation modulus based on linear viscoelastic theory:

by approximating the exponential function \( \exp [ - t/\tau ] \) to the step function, where \( E(\infty ) \) represents the equilibrium relaxation modulus, and t and τ are measurement time and relaxation time, respectively.

Isolation of relaxation spectrum

Spectra of wood components were isolated from the whole relaxation spectrum of wood at each temperature using the PeakFit (SeaSolve Software, Inc.) software for peak isolation. The software has three methods for peak isolation: a residuals method, a second derivative method, and a de-convolution method. We used the residuals method after preliminary trials, because the others detected many virtual hidden peaks due to the lack of smooth curves of experimental data. Considering previous reports about the relaxation behavior of wood, we assumed that the target component curves were Gaussian and consisted of two or three components. Both the whole and isolated curves were obtained by the first trial run after inputting the number of peaks. The curve obtained on the display screen was roughly fitted to an experimental curve by manually changing the width and height of the component Gaussian curves. Then, the parameters of the component curves were computed to have the least difference in area between the empirical and simulated curves. The best fit results were obtained under the two-component condition for all relaxation curves.

Results and discussion

Relaxation curves and spectra

Figure 1 illustrates typical relaxation curves at various temperatures in our experiment. These curves are similar to the findings reported previously for other wood species, as reviewed by Yamada et al. [25]. The relaxation curves shifted to lower values along the relaxation modulus axis with increasing temperature; the curves show a rapid decrease below 50 °C and are relatively flat above 60 °C. Additionally, the rapid-decrease region appears to shift to a shorter time along the time axis. These shape changes have been pointed out previously and interpreted as a transition in wood components. However, they have not been shown to represent a single-relaxation process isolated from those of all wood components.

As noted above, the validity of the TTSP is uncertain for wood, although Yamada [26] found that the relaxation spectrum obtained from a master curve showed a single broad dispersion assuming the principle. The principle did not hold over the entire time region, but it held partially, especially over a shorter time range, when the data obtained over time intervals of about 10 Napierian-logarithmic decades at different temperatures were shifted into superposition along the Napierian-logarithmic time axis. Similarly, several studies have reported that the principle was valid in shorter time regions [9, 10, 22, 24]. This suggests that the principle holds for a matrix with hemicellulose and lignin wood components as has been found in a number of studies [11, 12, 14, 20].

Considering the above, the relaxation spectra obtained at various temperatures in the current study were calculated using Alfrey’s approximation and examined without applying the TTSP (Fig. 2). Asymmetric spectra with clear peaks were obtained in the range of 25–85 °C. The peak position of the spectrum shifted to a shorter time along the time axis with an increase in temperature (Fig. 2b), whereas the intensity increased gradually up to 50 °C and then rapidly decreased above 55 °C (Fig. 2a). The shape of the spectra changed with temperature. As is well known, the spectrum of dried wood showed little change in shape (i.e., no large peak), unlike wet wood, because dried wood is rigid due to creation of hydrogen bonds in wood substances.

Isolating relaxation spectra of wood as a multi-component system

We found in the above discussion that the relaxation process of a system such as wood, which consists of multiple components with a partial crystalline region, is complex and has no set shape for each part of the relaxation spectrum. The temperature dependence of wood sample cannot necessarily be confirmed, because each wood component has different temperature dependence. Thus, it is necessary to isolate the behavior of each component to allow for a detailed understanding.

Considering wood to be a material consisting of substances and voids, the modulus of wood is represented by

where E and E s represent the moduli of the whole wood and the substance, respectively, θ is the volume fraction of cell wall substance and is equal to the ratio of the whole wood density, ρ, to the density of substance, ρS (i.e., θ = ρ/ρS), and m is the parameter related to the porous structure of wood and has values of ab. 1.0, 1.1, and 1.5 for loads along the longitudinal, radial, and tangential axes, respectively [18]. Equation 4 shows good agreement with experimental results [18].

Wood cells consist of multiple components, namely cellulose, hemicelluloses, and lignin, and thus, the modulus of a wood substance should also be represented by their moduli. Layers in wood cell wall are parallel to load direction under loading in tension and bending for radial span so that both S1 and S2 layers mainly support an applied load where wood components are parallel to load direction [23]. Thus, assuming that the volume fraction has no time dependence, E S(t) in our experiment is approximately represented by

where θi(i = C, H, and L) is volume fraction of wood components, C, H, and L represent cellulose, hemicellulose, and lignin, respectively, and θ C + θ H + θ L = 1.

From Eqs. 4 and 5, the relaxation spectrum using Alfrey’s approximation is

Here, by setting \( \theta^{m} \cdot \theta_{\text{i}} = \Upphi_{\text{i}} \) (i = C, H, L) and considering \( H(\ln \tau ) = \left. {dE(t)/d\ln t} \right|_{t = \tau } \)

Accordingly, the relaxation spectrum of the whole wood is represented by the sum of the spectra with the contribution weight of all wood components.

Equation (7) suggests that the TTSP does not hold for the whole modulus of wood when the moduli of wood components differ in their temperature dependence. Because Eq. (7) implies that temperature dependence is apparent for the whole wood relaxation spectrum when the relaxation spectra of wood components differ in temperature dependence. Thus, the molecular dynamics of wood components cannot be discussed based on the temperature dependence of the whole wood spectrum. An isolated spectrum allows us to discuss the molecular dynamics of wood components. The above discussion has already been described in detail by Nakano [17].

On the basis of the above discussion, we tried to isolate the each relaxation spectrum from the spectrum of the whole wood calculated from the measurements, assuming that the spectrum of the whole wood consists of Gaussian spectra of each relaxation process. Because spectrum of the whole wood shows an asymmetric broad shape with a single peak in the measurement time region as shown in Fig. 2.

Temperature dependence of isolated spectra

The selection of a peak-fit function is important for spectrum isolation. Here, a Gaussian function was selected for the isolation, assuming that the target component curves were Gaussian curves. According to the central-limit theorem, a Gaussian function can be expected for each process, when relaxation dynamics is described by the convolution of the independent single-relaxation mode. Thus, we considered that a Gaussian function would be approximately valid for each relaxation process of wood components, although it might not precisely hold because of complex interactions among wood components. The relaxation curve obtained at each temperature was isolated, with the best isolation being considered to have the least difference between the empirical and simulation data.

Figure 3 illustrates typical results at 25 and 70 °C, where each relaxation spectrum consists of two relaxation processes, L and H, in order of increasing temperature. The peak intensity H p(ln[τ]), the peak position ln[τp], and the standard deviation SD were determined for spectra obtained from the relaxation spectrum at each temperature. An isolated spectrum does not necessarily correspond to the same relaxation process at different temperatures and will change with increasing temperature. For example, the relaxation process of spectrum H at 25 °C corresponds to spectrum L at 70 °C. The assignment can be confirmed based on the temperature dependence of ln[τp], as shown in Fig. 4.

Figure 4 presents the relationship between temperature, T, and peak position, ln[τp], for the confirmed stress-relaxation spectra consisting of two relaxation processes. Symbols circle and square in Fig. 4 denote lower and higher peaks of two spectra isolated from the spectrum at each temperature, respectively. In Fig. 4, plots of higher peaks at each temperature below 55 °C and lower peaks at each temperature above 55 °C are on the same straight line, expressed by the symbol II, whereas plots of lower peaks below 55 °C and higher peaks above 55 °C are on the straight lines expressed by I and III. We concluded from the results in Fig. 4 that there are three relaxation processes: process I with lower peaks below 55 °C, process II with higher peaks below 55 °C and lower peaks above 55 °C, and process III with higher peaks above 55 °C. Processes I and II showed linearity with a high correlation (Fig. 4). That is, two relaxation processes have a temperature dependence with a high correlation, at least in the temperature range tested. Process III is probably related to restricted molecular motion, such as that in crystalline cellulose chains or nearby cellulose chains. However, process III cannot be precisely confirmed because it appeared just at the tail of the spectrum.

The apparent activation energy was calculated for processes I and II from ln[τp] versus 1/T, as shown in Fig. 5. The relationships for both processes showed a high correlation. The apparent activation energy was nearly equal for both processes, with values of 84.6 kJ/mol for process I and 86.3 kJ/mol for process II. Generally, the degree of apparent activation energy corresponds to the local molecular motion of polymers.

The apparent activation energy calculated from the temperature dependence of the shift factor without the peak isolation treatment has been reported previously by assuming the TTSP. The temperature dependence of the shift factor corresponds to that of ln[τp] in this study. Urakami and Nakato [24] reported 142.3 kJ/mol below 60 °C and 27.9 kcal/mol above 50 °C for moist hinoki wood. Hushitani [10] also measured stress relaxation in moist hinoki and reported a range of 146.5–372.6 kJ/mol, with the value thought to decrease by delignification or acetylation. Sawabe [22] reported a value of 92.1 kJ/mol by creep measurement of dried hinoki. Bond et al. [3] calculated 33.1–125.6 kJ/mol in tension and 41.4–175.8 kJ/mol in compression for various species with various moisture contents. These estimates of apparent activation energy are generally less than 209.3 kJ/mol, but with some scattering that is probably due to the arbitrary setting of the shift factor. Nakano and Nakamura [15] and Nakano [16] noted that the apparent activation energy of esterified wood was too low when obtained based on the temperature dependence of the shift factor. They explained that the overall relaxation process consists of multiple relaxation processes, and the temperature dependence of the shift factor would relate to those multiple relaxation processes.

Not only ln[τp], but also H(lnτ)p changed with temperature. Figure 6 shows the temperature dependence of H(lnτ)p. Process II had a peak near 60 °C, whereas processes I and III had no peak. According to Dunell and Tobolsky’s [6] equation, \( E^{\prime \prime } \propto - dE(t)/d\ln t \), the data in Fig. 6 correspond to the temperature dispersion of the dynamic loss, \( E^{\prime \prime } (T) \). Thus, the peaks \( E^{\prime \prime } (T) \) of the processes would be near 60 °C for process I, below 20 °C for process II, and above 85 °C for process III, if it exists. Figure 7 depicts the temperature dependence of the SDs of the isolated relaxation processes. The SD of process I tended to decrease with temperature, whereas those of processes II and III increased with temperature. This result indicates that the relaxation-time distribution of process I narrows due to increased mobility of molecular motion with increased temperature and that the distributions for processes II and III broaden due to the creation of molecular motion with longer relaxation times.

The temperature dependence of ln[τp], H p(lnτ) and SD indicates that the whole relaxation process consists of three relaxation processes in the experimental temperature range and that process II makes the largest contribution. Additionally, the processes below 20 °C and above 85 °C shown in Fig. 2 suggest the existence of the other process.

The glass transition temperature, T g, of wood components, which indicates the molecular motion of a polymer, has also been examined by many researchers. Goring [8], in a study using a thermo-mechanical apparatus, reported that the T g values of cellulose, hemicellulose, and lignin were in the ranges 222–250, 54–142, and 77–128 °C, respectively. Salmén and Back [19] examined the effects of water on the T g of cellulose on the basis of Kaelbe’s equation [13]. They also reported that the T g of hemicellulose decreased to below room temperature with water adsorption, whereas that of lignin was not influenced by water adsorption and remained constant at 115 °C [2]. Causins [4, 5] and Irvine [11, 12] found that the T g values of hemicellulose and lignin depended on the water content, and that T g of milled wood lignin was 45°C and higher than that of moist hemicellulose. Salmen [20] found the major transition between 20 and 140 °C related to the glass transition of the in situ lignin. Kelley et al. [14] reported T g values for lignin and hemicellulose of 60 and −10 °C, respectively, by measurement of wood with 30% moisture content using DSC and a viscoelastic apparatus.

These reports suggest that T g values of hemicellulose, lignin, and cellulose are below room temperature, 60 °C, and above 100 °C under wet conditions, respectively. Thus, processes I, II, and III in this study appear to be due to the molecular motions of hemicellulose, lignin, and cellulose, respectively.

As mentioned above, the apparatus activation energy in processes I and II was about 85 kJ/mol. This value was obtained from the isolated spectrum, meaning that it was obtained from components apart from the rigid microfibrils, at least. Considering that the activation energy of main chains is generally more than 400 kJ/mol, the molecular motion corresponding to our values should not be assigned to the molecular motion of main chains. Rather, these values may be more appropriately assigned to local molecular motion; that is, to the local mode in which their molecular motion is restricted by the other components due to interactions among the components. This suggests, as pointed out by Salmén and Olsson [21], that under moist conditions, wood components without cellulose exist in a matrix with strong interaction between components that causes only local mode relaxation.

Conclusions

Spectra isolated from the whole wood spectrum have been discussed to examine relaxation behavior based on the relaxation spectrum of moist wood. The asymmetric shape of the relaxation spectrum of moist wood and its temperature dependence indicate the involvement of multiple relaxation processes. Spectra isolated from the whole spectrum were attributed to the molecular motions of hemicellulose, lignin, and cellulose, referred to as processes I, II, and III, respectively. The apparatus activation energy, calculated from the temperature dependence of spectral peaks of processes I and II (but not process III), was about 85 kJ/mol (20 kcal/mol). Thus, processes I and II appear to relate to the local mode relaxation process. This shows that wood components without cellulose under moist conditions exist in a matrix under conditions of strong interactions between components that causes only local mode relaxation. The above discussion also demonstrates the effectiveness of the isolation procedure using a Gaussian function for the analysis of wood relaxation processes.

References

Alfrey T, Doty P (1945) J Appl Phys 16:700

Back EL, Salmén NL (1982) Tappi 65:107

Bond BH, Loferski J, Tissaoui I, Holzer S (1997) For Prod J 47:97

Cousins WJ (1976) Wood Sci Technol 210:9

Cousins WJ (1978) Wood Sci Technol 12(161–167):320

Dunell BA, Tobolsky AV (1949) J Chem Phys 17:1001

Fesko DG, Tschoegl NW (1971) J Polym Sci Part C 35:51

Goring DAI (1963) Pulp Paper Mag Can 64(12):T517

Hirai N, Maekawa T, Nishimura Y, Yamano S (1981) Mokuzai Gakkaishi (in Japanese) 27:703

Husitani M (1968) Effect of delignifiing treatment on static viscoelasticity of wood II. Mokuzai Gakkaishi (in Japanese) 14:18

Irvine GM (1980) The glass transitions of lignin and its relevance to thermomechanical pulping, CSIRO division of chemical technology research review, p. 33

Irvine GM (1984) Tappi 67(5):118

Kaelbe K (1971) Physical chemistry of adhesion. Wiley-Interscience, New York

Kelley SS, Rials TG, Glasser WG (1987) J Mater Sci 22:617. doi:10.1007/BF01160778

Nakano T, Nakamura H (1986) Mokuzai Gakkaishi (in Japanese), 32: 176

Nakano T (1994) Holzforschung 48:318

Nakano T (1995) Holz als Roh-und Werkstoff 53:39

Ohgama T, Yamada M (1971) Zairyoh (J Soc Mater Sci Jpn) 20:1194

Salmén NL, Back EL (1977) Tappi 60:137

Salmén NL (1984) J Mater Sci 19:3090. doi:10.1007/BF01026988

Salmén NL, Olsson A-M (1998) J Pulp Paper Sci 24:99

Sawabe O (1974) Mokuzai Gakkaishi 20:517

Tang RC, Hsu NN (1973) Wood Fiber Sci 5:139

Urakami H, Nakato K (1966) Mokuzai Gakkaishi 12:118

Yamada T, Sumiya K, Norimoto M, Morooka T, Yano H (1985) Wood Res Rev 20: 129

Yamada T (1962) Zairyo (J Soc Mater Sci Jpn) 11:50

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kurenuma, Y., Nakano, T. Analysis of stress relaxation on the basis of isolated relaxation spectrum for wet wood. J Mater Sci 47, 4673–4679 (2012). https://doi.org/10.1007/s10853-012-6335-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6335-0