Abstract

This work studies the electrical and optical properties of the conducting polymer composite films of polypyrrole–chitosan (PPy–CHI). The surface plasmon resonance (SPR) technique was used to study the optical properties of PPy and PPy–CHI composite films. Then, the values of the real and imaginary parts of the refractive indexes of PPy and PPy–CHI films were obtained by nonlinear least square fitting using Fresnel equations for a three-layer system of SPR system. The electrical conductivity measurements showed that the conductivity of the electrochemical prepared films improved in the presence of CHI and can be controlled by varying the CHI amount in the composite. The thermal diffusivity of the PPy–CHI composite films was measured by open photoacoustic spectroscopy and it has been shown that the thermal diffusivity is related to the electron migration in the conjugation chain length. The increase in electromagnetic interference shielding effectiveness (EMI SE) with the increase in electrical conductivity of the films is mostly from shielding by reflection rather than absorption.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, conducting polymers have attracted much attention to chemists and physicists due to their applications in many fields. Among these conducting polymers, polypyrrole (PPy) has been one of the most studied polymers in the conducting polymer subject, because of its physical and electrical properties [1]. Chitosan is a biodegradable, nontoxic, and low-cost biopolymer which in this study has been used as an insulating polymer to improve mechanical properties of PPy. The amount of chitosan was varied to determine the maximum conductivity achievable in the composite film.

Several techniques have been used for in situ investigation of optical and electrical properties of PPy conducting films, for example, Raman and optical absorption spectroscopy [2], electrochemical quartz crystal microbalance (EQCM) [3], Fourier transform infrared spectroscopy (FTIR) [4], photoacoustic effect [5], electromagnetic interference shielding effectiveness (EMI SE) [6, 7], and more recently, surface plasmon resonance (SPR) [8–10]. Since there is no study on the electrical and optical properties of PPy–CHI composite film, the present work focused on the effects of chitosan content on the electrical conductivity, photoacoustic effect, EMI SE, and dielectric constant of the resulting films.

Thermal diffusivity as a physical quantity represents an intrinsic property for each material and indicates how fast heat propagates through a sample [5]. In this study the open photoacoustic cell (OPC) technique was used for thermal diffusivity measurements. In this method as a nondestructive technique a chopped light impinges on a solid in an enclosed cell and the process of light-into-heat conversion occurs. The signal produced in the sample depends on the amount of heat generated by this process and its diffusion through the sample. The heat transfer is obtained by measuring the thermal diffusivity α, a quantity defined by Eq. 1:

where k, ρ, and c are the thermal conductivity, density, and specific heat at constant pressure, respectively.

Another physical property that has been studied in this research is EMI SE which is the process of limiting the flow of electromagnetic fields between two locations, by separating them with a barrier made of conducting materials. Transmission of electromagnetic waves may cause electromagnetic interference (EMI), as well as can be harmful to the human body. The total EMI shielding effectiveness (EMI SE) of a material is the sum of shielding effectiveness (SE) resulting from the three shielding mechanisms: reflection on the surface of a material, absorption by the material, or multiple internal reflection inside the material and the rest of the wave is transmitted [6, 7]. The requirements for reflection and absorption of the radiation by the shield are the existence of mobile charge carriers (electrons or holes) and electric and/or magnetic dipoles, respectively which interact with the electromagnetic fields in the radiation [11].

SPR is an optical phenomenon related to charge density oscillation at the interface between two materials that their signs of dielectric constant are opposite [12, 13]. The basic of SPR is the propagation of surface plasmon wave (SPW) along the interface of metal and dielectric which behaves like quasii-free electron plasma. The wave number of light should be matched with the wave number of surface plasmon given as:

where np, θ are refractive index of the prism and angle of resonance, while ɛm and ɛd are the dielectric constants of metal and last medium, respectively [14].

Experimental section

Materials

Pyrrole (Py) monomer was provided by Acros. Chitosan (CHI) obtained from a local company with 88% degree of deacetylation and p-toluene sulfonate (P-TS) was supplied by Fluka. All of the electropolymerization of pyrrole were done in a typical three-electrode electrochemical cell arrangement. A saturated calomel electrode, SCE, a carbon rod and an indium–tin oxide (ITO) glass, were used as reference, counter, and working electrodes, respectively.

Electrochemical deposition

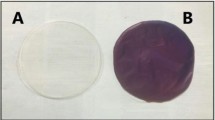

Various amounts of chitosan powder (w gram) were dissolved in 1% acetic acid solution (v). The mixtures were left at the laboratory over night and then stirred continuously with a magnetic stirrer for several minutes at room temperature until the chitosan powder was completely dissolved in the weak acid solution and various concentrations (w/v) of chitosan acetate were formed. Electrochemical deposition of PPy–CHI was performed using a potentiostat (Model: PS 605, USA). The anodic potential of the working electrode was measured as +1.2 V against a saturated calomel electrode (SCE). All the polymers were potentiostatically prepared in solution containing 0.3 M Pyrrole (pre-distilled), 0.1 M P-TS dopant, and various concentrations of CHI in acetic acid at room temperature. For the comparison purposes, a PPy film without chitosan was prepared. The average thickness of the composite films was in the region of 3.3 × 10−5–6.2 × 10−5 μm.

Polymer characterization

Characterization methods included conductivity measurement, thermal diffusivity, electromagnetic shielding effect, and SPR measurements were performed to elucidate the relation between the synthetic procedures and composite properties. The electrical dc conductivity of the films was measured at room temperature using the standard four probe technique.

The thermal diffusivity of the PPy–CHI films was measured by open photoacoustic spectroscopy. In this experiment the signal generated in the sample was detected and amplified by low-noise preamplifier (Stanford Research Systems, SR 540) which will be processed by lock-in amplifier (Stanford Research Systems, SR 530). The photoacoustic signal as a function of modulated frequencies measured in frequency range of 5–100 Hz. The thermal diffusivity of the samples was obtained by fitting the experimental data to the signal equation.

The EMI SE of the PPy–CHI and PPy films were measured using Agilent technologies N5230A network analyzer (Hewlett Packard), in the frequency range of 8–12 GHz. The samples of PPy–CHI composite films were sandwiched by clamping them between two waveguide-to-coaxial transducers (WR 90) and the SOL (Short-Open-Load) was used for calibration. EMI SE value expressed in dB was calculated from the ratio of the incident to transmitted power of the electromagnetic wave as following Eq. 3:

where P1 (E1) and P2 (E2) are the incident power (incident electric field) and the transmitted power (transmitted electric field), respectively. The reflectance (Re) and transmittance (Tr) of the composite were measured and the absorbance (Ab) calculated using the following Eq. 4

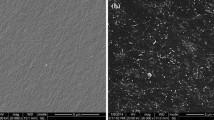

For SPR experiment, a thin layer of gold (43 nm) deposited onto a glass microscope slide and electrochemical deposition of PPy–CHI and PPy films were performed potentiostatically imposing a constant potential of 0.8 V (versus SCE) for 75 s. In order to form a thin film on the gold with a homogeneous surface, electrodeposition should be done at low potential in short time.

The sample of PPy–CHI was prepared in a solution containing 0.02 M Pyrrole, 0.01 M P-TS, and 0.07% (w/v) chitosan in acetic acid. The PPy film was prepared using the same composition of pyrrole and P-TS without chitosan. The thin slides were attached to the prism with high index glass (ZF52, n = 1.85) by using matching index gel (n = 1.44 TOURLAB company).

SPR characterization of the thin films was performed by using a set-up assembled according to the Kretschmann’s prism configuration (Fig. 1). The He–Ne laser (with wavelength of 632.8 nm) was used as light source and silicon detector (Newport, 818-SL) and Lock-In-Amplifier were used for detection the light. The sensitivity of amplifier was 20 mV and the chopper frequency was 125 Hz. The values were calculated by comparing the experimental SPR data to the theoretical values provided by the Fresnel theory applied to the SPR optical configuration used for our study. The values of the real and imaginary parts of the refractive indexes of PPy and PPy–CHI films were obtained by nonlinear least square fitting using Fresnel equations to the three-layer of SPR system.

Results and discussion

Electrical conductivity of the composite films

Each composition of PPy–CHI composite film was prepared 5 times (five films) and for each film, the electrical conductivity was measured by taking the average value of several reading at various points of the film. Subsequently, average value of conductivity was taken from five films. Figure 2 displays the dependence of the dc conductivity and thermal diffusivity on the CHI concentration in the composite film. The conductivity increased from 39.3 to 69.1 S cm−1, with the increase in CHI concentrations from 0.3% to 0.7% (w/v), respectively. Since the electrical conductivity is a function of the conjugation length of the polymer [15], the presence of CHI helps to increase the conjugation chain length. With further increase in CHI concentration from 0.7% (w/v) to 1.1% (w/v), the conductivity showed a decreasing trend. This is due to the fact that in high concentration of CHI, the solution becomes more viscous causing the slow rate of oxidation; hence the amount of the electrodeposited film is much lower.

Thermal diffusivity

Thermal diffusivity of the PPy–CHI composite films increased from 4.29 × 10−8 m2 s−1 to 4.17 × 10−7 m2 s−1 as the concentration of chitosan increased from 0.3% to 0.7% (w/v) and then showed a decreasing trend with further increase in chitosan concentration to 1.1%. Figure 2 shows that there is a good correlation between thermal diffusivity and electrical conductivity of the composite films. Tian and Zerbi [16] have shown that conductivity related to the conjugation chain length of the polymer, where with the increase in conjugation chain length of polymer, the free movement of charge carriers and hence the electrical conductivity increases. These results indicate that the thermal diffusivity of the PPy–CHI composite films related to the electron migration in the conjugation chain length [17].

Electromagnetic interference shielding effectiveness

The results of transmission, reflection, absorption, SE, and total attenuation of the PPy–CHI composite films and PPy film over the frequency range of 8–12 GHz have been shown in the Table 1. It shows that the total attenuation increased with the increase in conductivity. Most of the composite films had more than 98% shielding of the electromagnetic energy. Figure 3 shows that the EMI SE of PPy–CHI composite film is around 33.9 dB while an average SE of around 19.8 dB has been offered by the PPy film without CHI. Thus, it shows that when PPy is incorporated with CHI forming PPy-CHI composite film, is capable of the offering higher EMI SE.

From the Table 1 it can be seen that EMI SE gradually increased from 21.2 to 33.9 dB with the increase in the conductivity and then decreased to 18.3 dB which is due to the decrease in conductivity. The increase in EMI SE with the increase in electrical conductivity is from shielding by reflection rather than absorption. In other words, SE by reflection increased with the increase in conductivity, while the SE by absorption decreased. This is due to the fact that the sample with high conductivity has more mobile charge carriers that can interact with the electromagnetic fields in the radiation, hence shielding by reflection increases. The decrease of Ab must be due to shallower skin depth of the composite film with higher electrical conductivity. The relationship between EMI SE and electrical conductivity of the PPy–CHI composites is in good agreement with the results obtained by others [6, 18].

Surface plasmon resonance

SPR technique is usually applied for attaining information about the optical properties of the last dielectric medium. In this work, the first layer (Au) and last medium (Air) are explicit, hence the optical properties of the second layer (electrodeposited film) can be obtained. Figure 4 shows the SPR reflectivity curves for the glass/Au/Air, (Au), and glass/Au/PPy/Air, (Au–PPy), systems. Both of them showed a minimum in the reflectivity corresponding to the SPR effect. The resonance of the Au–PPy thin film occurred at larger angles compared to the Au, which can be ascribed to a change in the actual refractive index of the gold layer when the PPy film is deposited on it. The resonance angle (θspr) and optical constant of the PPy film were 45.30 + 0.01° and 1.6355 + 0.15i, respectively.

Figure 5 shows SPR reflectivity curves for Au, Au–PPy, and Au–PPy–CHI films. The resonance angle (θspr) and optical constant of the PPy–CHI film were 42.88 ± 0.01° and 1.6025 + 0.172i, respectively. The dip width of the curves for PPy–CHI and PPy films is larger than gold/air which is proportional to the attenuation of the surface plasmon. The thickness of the thin films was calculated using Fresnel equation and the thicknesses of 33 and 38 nm were obtained for the PPy–CHI and PPy thin films, respectively. In the presence of chitosan solution becomes viscose, the rate of oxidation and polymerization is slower and the amount of deposited polymer is much lower which leads to lower thickness.

Conclusions

This study shows that the incorporation of chitosan in the PPy structure helps to increase the electrical conductivity and thermal diffusivity of PPy–CHI composite film. The thermal diffusivity of the composite films increased with the increase in conductivity. It has been shown that there is a good correlation between thermal diffusivity, EMI SE, and conductivity of PPy–CHI conducting polymer composite film. The refractive indexes of the samples were successfully measured by SPR technique. Since the SPR angle shifted clearly to the right and produced a sharp peak of resonance angle, this technique is capable for using in sensitive optical sensors. It seems that the EMI shielding effectiveness of 33.9 dB for the PPy–CHI composite films is very attractive in any electromagnetic interference (EMI) shielding applications where a minimum shielding effectiveness of 30 dB is required.

References

Migahed MD, Fahmy T, Ishra M, Barakat A (2004) Polym Test 23:361

Furukawa Y, Tazawa S, Fujii Y, Harada I (1988) Synth Met 24:329

Zhao C, Jiang Z (2004) Appl Surf Sci 229:372

Mahmud HNME, Kassim AB, Zainal Z, Mat Yunus WM (2005) J Appl Polym Sci 100(5):4107

Costa ACR, Siqueira AF (1996) J Appl Phys 80:5579

Kim MS, Kim HK, Byun SW, Jeong SH, Hong YK, Joo JS, Song KT, Kim JK, Lee CJ, Lee JY (2002) Synth Met 126:233

Kim HK, Kim MS, Chun SY, Park YH, Jeon BS, Lee JY (2003) Mol Cryst Liq Cryst 405:161

Yu JCC, Lai EPC, Sadeghi S (2004) Sens Actuators, B 101:236

Baba A, Lubben J, Tamada K, Knoll W (2003) Langmuir 19:9058

Damos FS, Luz RCS, Kubota LT (2006) Electrochim Acta 51:1304

Chung DDL (2001) Carbon 39:279

Peyghambarian N, Koch SW, Mysyrowicz A (1993) Introduction to semiconductor optics. Prentice Hall, Englewood Cliffs, New Jersey

Homola J, Yee SS, Gauglitz G (1999) Sens Actuators, B 54:3

Holmola J (2006) Surface plasmon resonance based sensors. Springer, New York

Mohammad F (1998) J Phys D Appl Phys 31:951

Tian B, Zerbi G (1990) J Chem Phys 92:3892

Naoto T, Satosh I, Tsuyoshi K (1994) J Polym Sci 32:1899

Chandrasekhar P, Naishadham K (1999) Synth Met 105:115

Acknowledgements

The authors would like to thank the Department of Chemistry and University Putra Malaysia for their financial support. We also thank Dr. Zulkifly Abbas and Mr Hassan Soleimani for their assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abdi, M.M., Kassim, A., Mahmud, H.N.M.E. et al. Physical, optical, and electrical properties of a new conducting polymer. J Mater Sci 44, 3682–3686 (2009). https://doi.org/10.1007/s10853-009-3491-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3491-y