Abstract

The ferroelectric, dielectric and piezoelectric properties of compositions Pb1−x Ce x (Zr0.60Ti0.40)O3, (x = 0.0, 0.01, 0.02, 0.04, 0.06 and 0.08) are studied. The above compositions are prepared from their constituent oxides, calcined at 900 °C for 4 h and various phases present are characterized by X-ray diffraction (XRD) technique. The above powders are uniaxially pressed into circular compacts, sintered at 1,250 °C for 2 h, electroded, poled at 2 kV/mm D.C. voltage and their electrical properties are measured. The XRD analysis shows the presence of rhombohedral phase up to 2 mol% ceria while tetragonal phase found at higher concentrations. It is observed that the ferroelectric, dielectric and piezoelectric properties increase with the addition of ceria with a maximum at 2 mol% and then decreases. The higher piezo properties associated with low ceria concentration are attributed to rhombohedral phase.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lead zirconate titanate (PZT), Pb(Zr,Ti)O3, is a solid solution of a ferroelectric, PbTiO3 (PT) (T c = 490 °C) phase and an anti-ferroelectric, PbZrO3 (PZ) (T c = 230 °C) phase. PZTs with different Zr:Ti ratios have been considered as important materials for wide range of piezoelectric, pyroelectric and ferroelectric applications such as actuators, transducers, computer memory, pyroelectric sensors, hydrophones, electro-optical modulators etc. [1–7]. PZTs belong to the perovskite family with general formula ABO3 (A = divalent, B = tetravalent cation). While Pb2+ occupies “A” sites, Zr4+ or Ti4+ occupies “B” sites. One very significant advantage of ceramic ferroelectrics is that their properties can be modified by the addition of dopants substituting part of the host atom. Depending on the valence and ionic radius of a dopant, it can enter either in to A or B site [8]. Donor dopants are compensated by cation vacancies and acceptor dopants are compensated by oxygen vacancies. Doping in PZT is carried out in bulk ceramics to enhance their electrical properties. Several acceptor, donor and isovalent dopants such as Fe3+, Sb3+, La3+, Nd3+, Nb5+, Sr2+, Ba2+, Ca2+ etc. have been extensively studied in bulk PZTs [9–12]. It is evident that “cerium (Ce)” has almost equal probability to either replace Pb2+ at A site or Zr4+/Ti4+ ions at B sites of ABO3 perovskite lattice [13]. This is feasible because “Ce” can exist both in +3 and +4 valence states and it can replace Pb2+(1.22 Å) by Ce3+(1.15 Å) and/or Zr4+ (0.79 Å) by Ce4+ (0.96 Å) [14]. Agarwal et al. [13, 15] reported the effect of ceria on piezoelectric and mechanical properties of PZT bulk and thin film at MPB region. They observed that the maximum in strain coefficient and piezoelectric properties are found at 0.1% of ceria. This could be due to the presence of optimum concentration of the rhombohedral and tetragonal phases at that concentration of ceria. It is well established that the piezo-properties are enhanced with compositions with zirconia rich rhombohedral region (Zr:Ti > 53/47). Therefore, it is interesting to study the effect of ceria on the compositions in the rhombohedral region, which generates high electrical properties. To our knowledge, no literature is available on the effect of ceria on electrical properties of PZT compositions in the rhombohedral region.

Therefore, in the present study, we present the effect of ceria on electrical properties of PZT with a typical composition of Zr:Ti = 60:40 on piezoelectric, dielectric and ferroelectric properties.

Experimental

Analytical grade lead oxide (99.5%), zirconium dioxide (99.9%), titanium dioxide (99.9%) and cerium oxide (99.9%) powders are used as precursors. All the powders are weighed accurately with stoichiometric amount except PbO, which is taken 3% in excess to minimize its loss during calcination and sintering. Combined precursor powders thoroughly mixed to obtain an intimate mixture of the components, which are calcined at 900 °C for 4 h, granulated, compacted and sintered at 1,250 °C for 2 h in a closed lead rich atmosphere. Product phases present in the samples after calcination are identified by X-ray diffraction (XRD) technique (M/s. Phillips, Holland) using CuKα radiation (l.5418 Å). Similarly, using a Scanning Electron Microscope (SEM) (LEO 440i make), the morphological features of the sintered compacts are studied. The micrographs are taken at an operating voltage of 20–30 kV, a probe current of 100 pA using secondary electron sources. The compositions of grain boundary particles are analyzed by Energy Dispersive X-ray Spectrometer (EDS) at an accelerating voltage of 20–30 kV and a probe current of 1,000 pA. Dielectric constant and loss factor of the samples are measured at room temperature, at a frequency of 100 Hz. The sintered pellets are leveled, polished, electroded and finally poled in a D.C. field of 2 kV/mm in a silicone oil bath for about 30 min. The linear piezoelectric charge coefficient (d 33) is measured using a piezometer (Model PM-35, M/s. Take control, UK). The remnant polarization (P r), saturation polarization (P s) and coercive field (E c) of the samples are recorded from their hysteresis loops by a modified Sawyer-Tower circuit (M/s Digital systems, Model HLT-2, Mumbai).

Results and discussions

X-ray diffraction studies

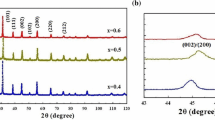

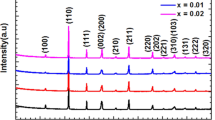

From the XRD patterns of the calcined powders (Fig. 1), a pure rhombohedral phase is observed for the undoped composition, which gradually decreases with the increase in ceria concentration. Above 2 mol%, tetragonal phase is present with its characteristics peak splitting at 2θ in the range of 43–46°. In addition, some extra peaks corresponding to pure ceria phase are found present at higher ceria concentrations. While Prado et al. [16] observed the ceria phase at 2 at.%, the same has been observed in our case above 2 mol%.

Microstructure analysis

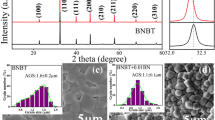

SEM micrographs of the chemically etched surfaces of the sintered ceria doped PZT samples are shown in Fig. 2a–e. At higher dopant concentration (6 and 8 mol%), very fine particles are precipitated in the grain boundary region. Energy Dispersive X-ray spectroscopy (EDS) study confirms these particles as ceria, might have precipitated at higher concentrations (Fig. 3). It is in good agreement with XRD analysis presented earlier.

Dielectric properties

The change in dielectric constant (K) and loss factor with different mol% of ceria is presented in Fig. 4. It is observed that the dielectric constant gradually increases up to 2 mol% ceria and then decreases. This could be due to the absence of long-range ferroelectric order in the material with increase in ceria concentration. Generally, the stability of a spontaneously polarized ferroelectric phase requires a permanent dipole moment as well as their coupling [17]. The increase in ceria concentration may break the transnational symmetry of the polarization, favoring the establishment of local dipoles which are weakly coupled with each other and suppress the long-range ferroelectric order inside the material resulted in decrease of dielectric constant. In other scenario, ceria is precipitated at grain boundary regions, which is already indicated in the XRD studies, also confirmed by EDS studies. Due to low relative dielectric constant of ceria (K = 11) [18], the dielectric constant value decreases. The trend is opposite for loss factor, gradually decreases up to 2 mol% and then increases. The peak dielectric constant of 2 mol% ceria doped sample is 936 and the corresponding loss factor is 0.024, both measured at 100 kHz.

Piezoelectric properties

The variation in piezoelectric constant (d 33) with different mol% of ceria is presented in the Fig. 5. The d 33 value increases up to 2 mol%, then decreases. It could be due to the structural change from rhombohedral phase to tetragonal with the increase in ceria concentration since rhombohedral phase is known to generate/produce high piezoelectric coefficient (d 33), compared to tetragonal phase. Generally, the tetragonal structure is not easily switched under the influence of an external field [19] therefore, decreases the piezo properties. The other reason could be the ineffective poling due to precipitation of ceria at grain boundary may resist the grain boundary movement. Nag and Agarwal [15] reported that the strain coefficient and piezoelectric properties are found maximum for 0.1 mol% ceria in case of PZT near MPB composition (Zr in tetragonal state). In our case, the properties are found maximum at 2 mol% for PZT composition with higher Zr content (rhombohedral state). This is because higher amount ceria could enter into solid solutions with higher amounts of zirconia present in rhombohedral rich composition.

Polarization measurement

The hysteresis loops generated by a hysteresis loop tracer for compositions with different ceria concentration are presented in Fig. 6(a–f). The variation of saturation polarization (P s), remnant polarization (P r) with different mol% of ceria is presented in Fig. 7a. Similarly, the plots of coercive field (E c) are presented in Fig. 7b. It is observed that the remnant and saturation polarization increase with ceria concentration up to 2 mol% while the corresponding E c value decreases. Beyond 2 mol%, the reverse trend is noticed. The precipitation of excess ceria is the cause of hindrance in domain wall movement leading to the decrease in polarization.

Conclusions

Ceria doped PZTs with rhombohedral rich compositions i.e. Pb1−x Ce x (Zr0.60Ti0.40)O3, 0 ≤ x ≤ 0.08, have been prepared and are characterized for ferroelectric, piezoelectric and dielectric properties. It is observed that the addition of ceria enhances the dielectric, piezoelectric and ferroelectric properties up to 2 mol% due to the presence of rhombohedral phase at lower ceria concentration. The degradation in properties for higher ceria concentrations is due to its precipitation in the grain boundaries.

References

Newnham RE, Ruschau GR (1991) J Am Ceram Soc 74:463

Haertling GH (1999) J Am Ceram Soc 82:797

Cross LE (1996) Mater Chem Phys 43:108

Setter N, Waser R (2000) Acta Mater 48:151

Wallaschek J (1995) J Intell Mat Syst Struct 6:71

Sugawara Y, Onitsuka K, Yoshikawa S, Xu Q, Newnham RE, Uchino K (1992) J Am Ceram Soc 75:996

Tressler JF, Alkoy S, Newnham RE (1998) J Electroceram 2:257

Gonnard P, Troccaz M (1978) J Solid State Chem 23:321

Weihng Q, Hoon H (2002) Mater Chem Phys 75:151

Garg A, Agrawal DC (2001) Mater Sci Eng B 86:134

Chen XM, Yang JS (1998) J Euro Ceram Soc 18:1059

Hayashi T, Inoue T, Akiyama Y (1999) J Euro Ceram Soc 19:999

Majumder SB, Agrawal DC, Mohapatra YN, Katiyar RS (2003) Mater Sci Eng B 98:25

Shannon RD (1976) Acta Crystallogr A32:751

Nag SK, Agarwal DC (1992) J Mater Sci 27:4125

Prado EC, Perez W, Kaityar RS, Garg A, Agarwal DC (1995) IEEE J 26:108

Dai X, Digiovanni A, Viehland D (1993) J Appl Phys 74:3399

Mogensen M, Sammes NM, Tompsett GA (2000) Solid State Ionics 129:63

Nasar RS, Cerqueira M, Longo E, Varela JA, Beltran A (2002) J Eur Ceram Soc 22:209

Acknowledgements

The authors are very grateful to Dr. S. Usha Devi for XRD patterns and Mr. M. A. Venkatswami for SEM. The authors also gratefully acknowledge Head, Materials Science Division and Director, NAL for the encouragements during the course of this study. One of the authors, Mr. B. Sahoo also thanks CSIR, New Delhi for the research fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sahoo, B., Panda, P.K. Ferroelectric, dielectric and piezoelectric properties of Pb1−x Ce x (Zr0.60Ti0.40)O3, 0 ≤ x ≤ 0.08. J Mater Sci 42, 9684–9688 (2007). https://doi.org/10.1007/s10853-007-1948-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-1948-4