Abstract

Mechanical and thermal properties of poly(arylene disulfide) synthesized by ring-opening reaction of cyclic(aromatic disulfide) oligomer were reported. These oligomers were prepared from 4,4′-oxybis(benzenethiol). Three-point bending tests were performed to measure the flexural properties of the poly(arylene disulfide). DSC and TGA techniques were used to characterize the thermal properties of these polymers. Ring-opening reactions were carried out by hot-press under atmosphere and nitrogen atmosphere, respectively. Oxidation reaction of these polymers was detected from Raman spectra under atmosphere. The glass transition temperature increased but 10% weight loss temperature decreased with increasing ring-opening temperature. The flexural strength decreased with increasing the temperature of ring-opening polymerization under both atmosphere and nitrogen atmosphere. The polydisulfides could be used as high temperature and thermally curing insulating materials to substitute epoxy resins.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

For past decade, macrocyclic oligomers received considerable attention as precursors of high performance thermoplastics [1–10] since the pioneering work of Brunelle et al. on macrocyclic carbonates [11–13]. The macrocyclic oligomers offered an extremely low melt viscosity, and can be polymerized by ring-opening reaction without liberation of any byproduct. Especially for aromatic cyclicdisulfide oligomers, they can undergo free radical ring-opening reaction upon heating without any catalyst. Their corresponding polymers had high resistance to environmental degradation, low water-vapor transmission, excellent resistance to organic solvents, acids and bases, and good adhesion to metal, glass and concrete. Due to the importance both in industry and academia, there were many papers devoted to this class of macrocyclics recently [14–19].

It has been well documented that the disulfide bond broken to form radicals at elevated temperature [20]. This property has been utilized to initiate ring-opening polymerization of cyclic oligomers containing thio-ether linkages [21, 22] and cyclic(aromatic disulfide) oligomer derived from 4,4′-isopropylidene bis thiophenol [23].

We have previously prepared a series of homo- and co-(aromatic disulfide) oligomers [19]. In the course of the study of these macrocyclics, we found that homo-cyclic(aromatic disulfide) oligomers derived from 4,4′-oxybis(benzene dithiol) had low melt flowing temperature and can undergo ring-opening reaction upon heating under mild condition without any catalyst. The cheap material and easy processability endow them potentially applications in industry. In this respect, we study the mechanical and thermal properties of the corresponding polymers derived from these macrocyclics. In this paper, we report herein the mechanical and thermal properties of these poly(arylene disulfide)s synthesized by ring-opening polymerization of aromatic cyclicdisulfide oligomers.

Experimental

Materials

Cyclic 1 was prepared from 4,4′-oxybis(benzenethiol) with oxygen using a copper-amine catalyst as reported previously [18], which is depicted in Eq. 2. The synthesis of cyclic oligomer is complicated by the formation of linear oligomers and high-molecular-weight polymers via competing polycondensation reaction. Selective formation of cyclic oligomers can be achieved using dilute condition (for example, 1 g reagent in 100 mL solvent), which favors the cyclization and suppresses linear polycondensation. In our work, a pseudo-high dilution principle was used to achieve high yield of cyclic oligomers instead of using a large amount of solvent. A pseudo-high dilution condition can be created by slow addition of the reactants into the reaction vessel. The reactants were added to the reaction mixture through a dropping funnel over a 4h period. The final concentration of the reactants in the mixture was 0.05 M. No–SH group (δ = 3–4 ppm) was observed in 1H NMR spectra of the resulted macrocyclics, indicating the completion of oxidation without the formation of linear oligomers. GPC analysis of cyclic 1 showed that the product has a number average molecular weight Mn of 704 Da, which is very close to the formula weight of trimmer (∼696). This also showed that there was no high-molecular-weight polymer produced.

Samples preparation

General procedure for ring-opening polymerization

The dried cyclic 1 was press-molded into small discs at 140 °C under a pressure of 20 MPa. Some discs were heated to designed temperature to perform ring-opening polymerization in air, and other discs were introduced into autoclave to carry out ring-opening polymerization with the protection of nitrogen flow. The preparation description of these samples was shown in Eq. 1.

Instrumentation

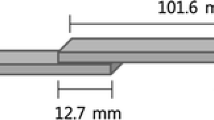

Flexural tests were carried out using a Sansi testing machine (CMT4104, P.R. China). Three point bending tests were performed to measure the flexural properties (DIN 178) at room temperature. The support span was 25 mm, and the cross-head speed was fixed to 1mm/min. Differential scanning calorimetry (DSC) scans were obtained using a NETZSCH DSC 204 instrument at a heating rate of 20 °C/min in N2 (20 mL/min) atmosphere. Thermogravimetric analysis (TG), and differential thermal analysis (DTA) were performed on a Perkin-Elmer TG/DTA 6300 instrument at a heating rate of 20 °C/min in N2 (300 mL/min) atmosphere. Structural characterization was investigated by using ultraviolet spectroscope RENISHAW. The wavelength produced by semiconductor laser was 785 nm, and the receiver was charge coupling detector (CCD) system.

Results and discussion

Mechanical properties of poly(arylene disulfide)

Generally, catalytic oxidation cyclization of aromatic dithiols has been demonstrated using various oxidants such as dimethyl sulfoxide (DMSO) [24], iodine [25]. Hay reported that dithiol compounds could be oxidized to form polydisulfides with oxygen using copper-amine catalysts [26]. A series of homo- and cocyclic (aromatic disulfide) oligomers were also synthesized under high dilution conditions using this method [14–19]. Similarly, cyclic 1 was synthesized as depicted in Eq. 2. Cuprous chloride and N,N,N,N -tetramethylethylene-diamine (TMEDA) were used as copper salt and amine ligand, respectively.

The ring-opening polymerization (ROP) of cyclic 1 was carried out under both air and N2 atmosphere as depicted in Eq. 1. The specimens subjected to mechanical measurements were prepared directly from the resulting polymers. In order to increase the accuracy, five specimens were tested to determine the flexural properties. The average values were calculated and reported with the derivations marked as shown as error bars. Figure 1 illustrates the flexural modulus and flexural strength for the specimens obtained at different ROP temperatures. It can be seen that the flexural modulus increased from 1327 MPa to 1395 MPa with increasing ROP temperature from 200 °C to 220 °C, and then decreased dramatically with further increasing ROP temperature. Moreover, the flexural strength decreased from 57.3 MPa to 41.2 MPa with increasing ROP temperature. Presumably, this is mainly due to the thermal decomposition of disulfide bonds in the polymer chain at higher temperature because disulfide polymers exhibit poorer thermal stability when compared with monosulfide polymer [23]. The decomposition temperature of disulfide polymer is generally 150 °C lower than that of monosulfide polymer.

Figure 2 shows the variation of flexural modulus and flexural strength with ROP time in air. Both flexural modulus and flexural strength had peak values at 60 min and 30min, respectively. Same changing tendency was observed for both properties. The deteriorated properties before the peak value were thought to result from the unreacted macrocyclics within resulting polymers. We have demonstrated that the contents of these unreacted small molecules were <4 wt% [16]. The deteriorated properties after the peak value were believed to result from the thermal decomposition of disulfide bonds due to the long time process.

Compared with polymers synthesized in air, the flexural modulus of polymers obtained in N2 had no fluctuating as shown in Fig. 3. The flexural strength of polymers obtained both in air and N2 decreased with increasing ROP temperature as shown in Fig. 4.

Structure investigation

It has been found that the color of resulting polymers became dark after ROP in air. In previous work [27], we reported that crosslinking reaction took place during the ROP. In order to further explore the possible reaction mechanism, Raman spectrum was used to investigate the structure of resulting polymers. Figure 5 shows the Raman absorption spectra of polymers and corresponding cyclics. By assignment, we found that 1199 cm−1 peak attributed to –SO2-S- groups or other intermediates became strong with increasing ROP temperature. In has been well documented that organic disulfide can be readily oxidized to produce thiosulfinates, thiosulfonates, sulfonic acids and a variety of other products. Thiosulfonate are the major product [28, 29]. This indicated that disulfide bonds could be oxidized during ROP at elevated temperature, especially in air. The intensity of the peak at 1199 cm−1 was evaluated by comparing the integrated areas of this peak to that of the largest peak. The integration was conducted with GRAMS-32 Special Notebase software equipped with ultraviolet spectroscope instrument, and the results are listed in Table 1. It can be seen from this table that the intensity ratio of this peak increased with increasing the ROP temperature.

Thermal properties of poly(arylene disulfide)

The thermal properties of resulted polymers were measured by using DSC and TGA at a heating rate of 20 °C min−1 under N2 atmosphere as shown in Figs. 6 and 7. It can be seen that the maximum weight loss temperatures for the polymers b, d and f decreased with increasing ROP temperature as shown in Fig. 6. Similarly, the maximum weight loss temperatures for the polymers i, j, and k decreased in the same manner.

Thermal properties of synthesized polymers are listed in Table 2. It can be seen that the 10% weight loss temperature of these polymers increased from 416.6 °C to 420.6 °C, and decreased to 393.1 °C with increasing ROP temperature from 200 °C to 250 °C in air. For the polymers obtained via ROP in N2, the 10% weight loss temperature decreased from 420.5 °C to 414.9 °C, and leveled off with further increasing ROP temperature. This demonstrated that the polymers derived from ROP in air exhibited poorer thermal stability than those obtained in N2. The poorer thermal stability was presumably due to the presence of small molecule such as unreacted cyclic oligomers. These unreacted small molecules were believed to result from the difficult movement or transition of macrocyclic or linear oligomers during the free radical ROP in viscous melt.

From the same table, it can also be seen that the glass transition temperature (Tg) increased with increasing temperature in both air and N2. Moreover, the polymers obtained in air had higher Tg than those obtained in N2. This behavior was owing to the formation of thiosulfonate or other products produced during the ROP in air.

Conclusions

The mechanical and thermal properties of poly(arylene disulfide) derived from macrocyclic(4,4′-oxybis(benzene)disulfide) by ring-opening polymerization (ROP) were studied. Both higher ROP temperature and longer ROP duration can lead to the decrease in flexural modulus. The flexural strength of the polymers obtained via ROP in both air and N2 decreased with increasing ROP temperature. Disulfide groups were oxidized into thiosulfonate or other products at elevated temperature in the presence of oxygen. The produced rigid thiosulfonate in turn led to the increase of glass transition temperature as evidenced by DSC measurement. The polymers obtained via ROP in air exhibited poorer thermal stability than those obtained in N2.

References

Guggenheim TL, lMcCormick SJ, Kelly JJ, Brunelle DJ, Colley AM, Boden EP, Shannon TG (1989) Polym Prepr (Am Chem Soc, Div Polym Chem) 30(2):579

Hubbard P, Brittain WJ, Simonsick WJ Jr, Ross CW III (1996) Macromolecules 29:8304

Ganguly S, Gibson HW (1993) Macromolecules 26:2408

Mullins MJ, Woo EP, Murray DJ, Bishop MT (1993) Chemtech (August) 25

Xie DH, Gibson HW (1994) Polym Prepr (Am Chem Soc, Div Polym Chem) 35(1):401

CoIquhoun HM, Dudman CC, Thomas M, O′Mahoney CA, Williams DJ (1990) J Chem Soc Chem Commun 336

Chan KP, Wang YF, Hay AS (1995) Macromolecules 28:653

Jonas A, Legras R (1993) Macromolecules 26:2674

Chen MF, Gibson HW (1996) Macromolecules 29:5502

Kim YH, Calabrese J, McEwen CJ (1996) Am Chem Soc 118:1545

Brunelle DJ, Bodeen EP, Shannon TG (1990) J Am Chem Soc 112:2399

Brunelle DJ, Shannon TG (1991) Macromolecules 24:3035

Evans TL, Brunelle DJ, Salem AJ, Stewart KR. (1991) Polym Prepr (Am Chem Soc, Div Polym Chem) 32(2):176

Ding Y, Hay AS (1996) Macromolecules 29:6386

Ding Y, Hay AS (1996) Macromolecules 29:3090

Meng YZ, Hay AS (1999) J Appl Polym Sci 74:3069

Ding Y, Hay AS (1997) Polymer 38(9):2239

Meng YZ, Tjong SC, Hay AS (2001) Polymer 42:5215

Chen K, Du XS, Meng YZ, Tjong SC, Hay AS (2003) Polym Adv,Technol 14:114

Chandrasiri JA, Wilkie CA (1994) Polym Degrad Stabil 46:275

Wang ZY, Hay AS (1991) Macromolecules 24:333

Wang YF, Chan KP, Hay AS (1995) Macromolecules 28:6371

Ding Y, Hay AS (1997) polymer 38:2239

Tanikaga R, Tanaka K, Kaji A (1978) J Chem Soc Chem Commun 865

Bottino F, Foti S, Pappalardo S, Bresciani-Pahor N (1979) Tetrahedron Lett 13:1171

Hay AS (1966) US patent 3, 294, 760

Chen K, Liang ZA, Meng YZ, Hay AS (2004) Polymer 45:1787

Fang XQ, Bandarage UK, Wang TS, Schroeder JD, Garvey DS (2001) J Org Chem 66:4019

Benassi R, Fiandri LG, Taddei F (1997) J Org Chem 62:8018

Acknowledgements

The authors would like to thank the China High-Tech Development 863 Program (Grant No: 2003AA302410), the Natural Science Foundation of China (Grant No. 50203016), Guangdong Province Sci & Tech Bureau (Key Strategic Project Grant No. 2003C105004, A1100402), and Guangzhou Sci & Tech Bureau (2005U13D2031) for financial support of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, L.N., Xiao, M., Shu, D. et al. Mechanical and thermal properties of poly(arylene disulfide) derived from cyclic(4,4′-oxybis(benzene)disulfide) via ring-opening polymerization. J Mater Sci 42, 1156–1161 (2007). https://doi.org/10.1007/s10853-006-1433-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-1433-5