Abstract

To develop a montelukast sodium-loaded clear oral solution with enhanced stability that was bioequivalent to commercial granules in rats for the treatment of asthma, various montelukast sodium-loaded solutions were prepared with various amounts of solubilizers and stabilizer, and their solubility and stability were investigated. Furthermore, the dissolution and pharmacokinetic studies were carried out in rats with the optimised formulation and the commercial montelukast sodium-loaded granules. Among the solubilizers tested in this study, hydroxypropyl-β-cyclodextrin (HP-β-CD) was selected because it greatly improved the drug solubility and stability. Furthermore, EDTA sodium was used as a stabilizer because it gave excellent stability. In particular, the montelukast-loaded oral solution, an aqueous clear solution containing montelukast sodium, HP-β-CD, methylparaben sodium, propylparaben sodium and EDTA sodium at w/v percentages of 1.04/156/1.8/0.2/1, gave similar dissolution to the commercial granules in 0.5 % (w/v) sodium lauryl sulphate in water, FDA-regulated dissolution medium. This oral solution gave similar plasma concentrations and pharmacokinetic parameters to the commercial granules, suggesting that it was bioequivalent to the commercial granules in rats. Moreover, it was physically and chemically stable at 25 °C/60 % RH and 40 °C/75 % RH for at least 12 months. Thus, this oral solution is strongly recommended as an alternative to the oral montelukast-loaded product for the treatment of asthma.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Asthma is an inflammatory airway obstructive disease with symptoms of dyspnea and severe cough caused by swelling of the bronchial mucosa due to bronchial inflammation, and bronchial obstruction due to bronchial muscle spasm [1–3]. Asthma is a problematic disease that is prevalent worldwide, and about 200 million asthma patients are estimated to be present. Half of childhood asthma cases persist until adulthood and continue as adult asthma [4]. Therapeutic agents of asthma are mainly divided into disease-controlling agents and symptom-alleviating agents [5, 6]. The disease-controlling agents are used for controlling symptoms of asthma mainly by anti-inflammatory effects. The symptom-alleviating agents are medications to alleviate symptoms in a short time-period by rapidly dilating the airway, which are used when necessary [7].

Montelukast, [1-[[[(1R)-1-[3-[(E)-2-(7-chloroquinolin-2-yl)ethenyl]phenyl]-3-[2-(1-hydroxy-1-methylethyl) phenyl]propyl]sulphanyl]methyl]cyclopropyl]acetate (Fig. 1), is an oral selective leukotriene receptor antagonist that specifically inhibits cysteine leukotriene [8]. This drug is well tolerated in the treatment of chronic asthma and the relief symptoms of seasonal allergies in children and adults [3, 5]. However, this drug has low aqueous solubility of 0.2 μg/ml [9] and high membrane permeability with a log P of 8.98, indicating that it is a class II molecule as per the Biopharmaceutics drug Classification System (BCS) [10, 11]. Moreover, it is a light-sensitive compound, which must be protected from light [12, 13]. Recently, a commercial product (Singulair®; Astellas Pharm. Co., Surrey, UK) that contains montelukast sodium equivalent doses of 10, 4–5 and 4 mg montelukast based on tablets, chewable tablets and granules, respectively, for once-daily oral administration was made available on the market [14–17]. However, this drug is sensitive to light, humidity and heat, leading to a degraded product, montelukast sulphoxide (Fig. 1) [18, 19]. It was reported that, on exposure of Singulair® chewable tablet to light or 0.1 M HCl solution for 6 h, the contents of montelukast sulphoxide in this commercial product increased to 2.4 % [12, 20]. Thus, it is not easy to maintain the stability of montelukast containing products over time. In particular, the commercial montelukast sodium-loaded granule is usually taken by children aged 6 months to 2 years. However, this fine granule form has a disadvantage in that it should be taken directly or mixed in soft foods followed by immediate administration within 5 min due to fast degradation of montelukast [5, 17]. Therefore, in this study, a montelukast sodium-loaded clear oral solution with enhanced stability has been developed as an alternative to commercial granules (Singulair®; Sharp & Dohme Co.) for the treatment of asthma.

Materials and methods

Materials

Montelukast sodium was obtained from Hanmi Fine Chemical Co. (Siheung, South Korea). Hydroxypropyl-β-cyclodextrin (HP-β-CD) was purchased from Ashland Co. (Schaffhausen, Switzerland). Soluplus® (polyvinylcaprolactam-vinyl acetate-ethylene glycol graft copolymer), Kolliphor® (RH40 polyoxyhydrogenated castor oil) and polyvinylpyrrolidone (PVP, Kollidon® K-30) were purchased from BASF Co. (Ludwigshafen, Germany). Ethylenediaminetetraacetic acid sodium (EDTA sodium), methylparaben sodium and propylparaben sodium were supplied by Hanmi Pharm. Co. (Seoul, South Korea). The montelukast sodium-loaded commercial granules (Singulair®) were purchased from Merck Sharp & Dohme Co. (Whitehouse station, NJ, USA). All other chemicals were of reagent grade and were used without further purification.

Animals

Sprague–Dawley male rats, weighing 250–280 g, were obtained from Orient Bio (Seongnam, South Korea). They were fasted for 15 h before the experiments but allowed free access to water at 20–24 °C and 55 ± 10 % RH. The procedures for the animal studies were implemented consistent with the NIH Policy and Animal Welfare Act under the approval by the Institutional Animal Care and Use Committee (IACUC) at the Hanmi Research Centre.

Preparation of montelukast sodium-loaded oral solutions

Various amounts of solubilizers, preservatives and EDTA sodium were completely dissolved in 100 ml distilled water. Soluplus, Kolliphor, PVP and HP-β-CD were used as solubilizers. Methylparaben sodium and propylparaben sodium were used as preservatives. Then, montelukast sodium was added into these solutions and stirred for 1 h, leading to the montelukast sodium-loaded oral solutions. The drug solubility and stability tests were carried out with these solutions as mentioned below.

Drug solubility

For determining the drug solubility in the montelukast sodium-loaded oral solutions, these solutions were filtered through a Whatman nylon filter (0.45 µm) and diluted with the mobile phase [21, 22]. The concentrations of drug in these diluted solutions were determined using an HPLC system (Hitachi L-2000 series; Hitachi, Tokyo, Japan) consisting of an octylsilane analytical column (Inertsil® C8, 4.6 mm × 15 cm, 5 µm). As a mobile phase, a mixture of phosphate buffer (pH 6.6) and acetonitrile (40:60, v/v) was used with the following conditions: injection volume of 10 µl, flow rate of 1.0 ml/min and UV detection at 225 nm [23].

Stability of drug in the montelukast sodium-loaded oral solutions

To check the stability of the drug in the montelukast sodium-loaded oral solutions, these solutions were kept under the controlled condition of 40 °C and 75 % RH for 2 months [24, 25]. At 0, 1 and 2 months, their appearance and precipitation were visually observed. Furthermore, the content of degraded product of montelukast, montelukast sulphoxide, was assayed as follows. The samples were filtered through a Whatman nylon filter (0.45 µm) and diluted with the mobile phase. The concentration of degraded product in these diluted solutions was assessed with an HPLC system (Hitachi L-2000 series; Hitachi, Tokyo, Japan) consisting of a phenyl analytical column (Zobax® SB-Phenyl, 4.6 mm × 25 cm, 5 µm). The eluent A (distilled water containing 0.1 % trifluoroacetic acid) and eluent B (acetonitrile containing 0.1 % trifluoroacetic acid) was used as the mobile phase. The wavelength for UV detection was 238 nm, the injection volume was 40 µL and the flow rate was 1.5 ml/min [19].

Dissolution

The dissolution tests were carried out with montelukast sodium-loaded commercial granules (Singulair®) and oral solution (equal to 10 mg drug) in the dissolution apparatus (PTWS 1210, Pharma Test; Hainburg, Germany) at 37 ± 0.5 °C using the paddle method [22, 25]. As the dissolution media, 900 ml of distilled water, pH 1.2, pH 4.0, pH 6.8 and 0.5 % (w/v) sodium lauryl sulphate in water were used. The paddle speed was adjusted to 50 rpm. Each sample (1 ml) was collected at predetermined time intervals, filtered through a Whatman nylon filter (0.45 µm) and assayed for the content of montelukast using the HPLC method as mentioned above.

Pharmacokinetics

Oral administration and blood collecting

Ten Sprague–Dawley male rats were divided into two groups. A rat anaesthetised in an ether-saturated chamber was tied to a surgical board in the supine position with threads. A polyethylene tube was passed into the right femoral artery of the rat. The montelukast sodium-loaded commercial granule (Singulair®) and oral solution at the montelukast base dose of 2 mg/kg was orally administered. After administration, 0.2 ml of blood was withdrawn from the cannulated right femoral artery of the rat at the predetermined timepoints [37, 39, 40]. The blood sample was centrifuged at 14,000×g at 4 °C for 3 min using a 5415C centrifuge (Eppendorf, Hauppauge, NY, USA) and plasma was separated from the blood. The collected plasma was stored at −80 °C before subsequent analysis.

Sample preparation and drug assay

Plasma samples (50 µl) were vortex-mixed with 20 μl of internal standard (montelukast d6, 1 μg/ml in acetonitrile) (Fig. 1) and 200 μl of acetonitrile for 5 min. After centrifugation at 12,000×g for 3 min, the supernatants were evaporated under a nitrogen stream at 40 °C. The residue was reconstituted with 300 μl of 50 % acetonitrile, which was then vortexed for 4 min and centrifuged at 12,000×g for 3 min. Each supernatant (10 μl) was injected into the ultra-performance liquid chromatography tandem mass spectrometry (UPLC-MS/MS) system for assaying the concentration of montelukast in rat [11]. The separation was performed on a C18 column (Acquity UPLC HSS T3, 100 × 2.1 mm, 1.7 μm; Waters Co., Milford, MA, USA) at a flow rate of 0.4 m//min. Acetonitrile/distilled water (8:2, v/v) with 0.1 % formic acid was used as the mobile phase. Moreover, a XEVO TQD triple quadrupole mass spectrometer (Waters Co.; Milford, MA, USA) equipped with an electrospray ionization (ESI) interface was used for mass spectrometric detection. The ESI–MS data were acquired in the positive mode and the conditions of MS analysis were as follows: drying gas, argon; flow rate, 50 l/h; capillary voltage, 4.0 kV; cone voltage, 35 V; source temperature, 150 °C; desolvation temperature, 400 °C; collision energy, 25 V. The drug and the internal standard gave mainly protonated molecules at m/z 586 and 592, respectively. Furthermore, the product ions were scanned in Q3 after collision with argon in Q2 at m/z 422 and 427, respectively. Quantification was performed by multiple reaction monitoring (MRM) of the protonated precursor ions and the related product ions, using the ratio of the area under the peak for each solution and a weighting factor of 1/χ2. The analytical data were processed with Analyst software (MassLynx, version 4.0). The calibration curve was constructed over a range of 0.1–500 (R2 = 0.9976) and with a lower limit of quantification (LLOQ) of 0.1 ng/ml for montelukast. For the validation, inter- and intra-day differences were conducted and the differences were found to be within an acceptable range.

Pharmacokinetic data analysis and statistical analysis

From the area under the drug concentration time-curve (AUC), the maximum plasma concentration of the drug (Cmax) and the time taken to reach the maximum plasma concentration (Tmax) were calculated using non-compartmental analysis (WinNonlin; professional edition, version 2.1; Pharsight Co., Mountain View, CA, USA). Levels of statistical significance (p < 0.05) were assessed using the Student’s t test between the two means for unpaired data. All data are expressed as the mean ± standard deviation (SD)

Stability of montelukast sodium-loaded oral solution

The montelukast sodium-loaded oral solution was kept at 25 °C/60 % RH for 12 months and at 40 °C/75 % RH for 6 months [24, 25]. At predetermined intervals, any physical change in appearance was examined by precipitation, and the content of montelukast sodium and montelukast sulphoxide in the oral solution was analysed by HPLC as described above.

Results and discussion

To assess the effect of solubilizer on the drug solubility and stability in the montelukast sodium-loaded oral solutions, the stabilizers (15.6 mg/ml) and montelukast sodium (3.12 mg/ml) were entirely dissolved in the distilled water, and their solubility and stability tests were performed (Fig. 2). The solubility and stability of montelukast sodium in the oral solution were two important factors. Soluplus [26, 27], Kolliphor [28], PVP [29, 30] and HP-β-CD [31, 32] were used as solubilizers in this study, and have been extensively used in pharmaceutical oral products. Montelukast sodium had an aqueous solubility of about 2 mg/ml, indicating that it was slightly soluble in water [9, 10]. Soluplus and Kolliphor significantly increased the drug solubility by 1.5-fold. In addition, PVP and HP-β-CD slightly increased the drug solubility compared to montelukast sodium alone, but the solubility was not significantly different (Fig. 2a).

Effect of solubilizer on the solubility (a) and stability (b) of the drug in montelukast sodium-loaded solutions. Each stabilizer (15.6 mg/ml) was added to the montelukast sodium-loaded oral solutions at a five-fold concentration compared to the drug (3.12 mg/ml). The drug stability in the montelukast-loaded oral solution was determined by the concentration of montelukast sulphoxide. *Precipitation. # P < 0.05 when compared with drug. Each value represents the mean ± SD (n = 3)

The stability of montelukast sodium in the distilled water was determined at 40 °C and 75 % RH over 2 months, and was evaluated using its appearance/precipitation and the contents of montelukast sulphoxide, the decomposed product of montelukast (Fig. 2b). When exposed to light, humidity and heat, montelukast sodium precipitated and degraded to produce montelukast sulphoxide [13, 18, 19]. It was reported that the commercial montelukast sodium-loaded products with less than 1 % montelukast sulphoxide were useful as a practical pharmaceutical product, even though it was degraded [14, 19, 33]. Thus, in this study, the threshold for the degraded product was chosen to be 1 %. As shown in Fig. 2b, the montelukast sodium-loaded solution without stabilizer had about 1.5 % montelukast sulphoxide at 1 month, and showed the precipitation phenomenon at 2 months, suggesting that this solution was very unstable. The solution prepared with Soluplus gave more than 1 % montelukast sulphoxide, even if it did not induce the precipitation phenomenon. Thus, Soluplus increased the drug solubility, but hardly improved the drug stability in the montelukast sodium-loaded solution. Moreover, Kolliphor and PVP resulted in more than 1 % degraded product at 1 month and the precipitation phenomenon at 2 months, indicating that these solubilizers could not enhance the drug stability. On the other hand, HP-β-CD resulted in less than 1 % degraded product and no precipitation over 2 months. Therefore, HP-β-CD was selected as the solubilizer for development of montelukast sodium-loaded oral solution because it greatly improved both the drug solubility and the stability. HP-β-CD has been widely used to improve the solubility and stability of poorly water-soluble [34, 35]. Furthermore, HP-β-CD gave very low toxicity when administered via the oral and parenteral route even at high doses in rat [31, 32].

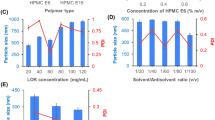

To investigate the effect of HP-β-CD amounts on the drug solubility and stability in the montelukast sodium-loaded oral solutions, various amounts of HP-β-CD were added to the distilled water, and their solubility and stability tests were performed (Fig. 3). As the HP-β-CD/drug ratio was increased to ten-fold, the solubility of the drug greatly increased. However, from 10- to 50-fold, there were no significant changes in drug solubility (Fig. 3a). Furthermore, all the montelukast sodium-loaded solution prepared with HP-β-CD resulted in less than 1 % degraded product and no precipitation for 2 months (Fig. 3b). Higher concentrations of HP-β-CD resulted in lower concentrations of montelukast sulphoxide.

Effect of HP-β-CD amounts on the solubility (a) and stability (b) of the drug in montelukast sodium-loaded solutions. The montelukast sodium-loaded solutions was composed of various ratios of drug and HP-β-CD. *Precipitation. The drug stability in the montelukast-loaded oral solution was determined by the concentration of montelukast sulphoxide. Each value represents the mean ± SD (n = 3)

Montelukast sodium-loaded commercial granules are orally administered with one packet of granules equal to 4 mg montelukast base [14, 15, 17]. Therefore, in the development of the montelukast sodium-loaded oral solution, one dose of this solution was 4 ml, and the concentration of the drug was 1.04 mg/ml of montelukast sodium, i.e. equal to 1 mg/ml of montelukast base. In addition, in the conventional oral preparation, preservatives must be added in order to prevent microbial growth [36]. Similarly, methylparaben sodium and propylparaben sodium were added as the preservatives in the montelukast sodium-loaded solution. However, these preservatives have a negative effect on the stability of the drug in the montelukast sodium-loaded oral solutions, because they form an inclusion complex with HP-β-CD and competed with the drug [37]. Thus, another stabilizer, EDTA sodium, was added to these solutions to improve stability of the drug [38, 39]. To investigate the effect of EDTA sodium on the stability of the drug in the montelukast sodium-loaded oral solutions, various amounts of EDTA sodium (0.1–1 mg/ml) were added to the montelukast sodium-loaded solutions containing montelukast sodium, HP-β-CD, methylparaben sodium and propylparaben sodium at the w/v percentages of 1.04/156/1.8/0.2 (Table 1, I–VI). All these montelukast sodium-loaded oral solutions containing EDTA sodium gave a clear appearance with less than 1 % degraded product (Fig. 4a). As the concentration of EDTA sodium increased, the amounts of montelukast sulphoxide decreased. Our results suggest that EDTA sodium improved the stability of the drug, and thus, the amount of EDTA sodium in the montelukast sodium-loaded oral solutions was fixed at 1 mg/ml.

To determine the effects of HP-β-CD, various amounts of HP-β-CD (10.4–156 mg/ml) were added to the montelukast sodium-loaded solutions containing montelukast sodium, methylparaben sodium, propylparaben sodium and EDTA sodium at the w/v percentages of 1.04/1.8/0.2/1 (Table 1, IV–VIII). All these montelukast sodium-loaded oral solutions containing HP-β-CD gave a clear appearance with less than 1 % degraded product. As the concentration of HP-β-CD increased, the amount of montelukast sulphoxide decreased (Fig. 4b). Our results suggest that, like EDTA sodium, HP-β-CD improved the stability of drug. Thus, the amount of HP-β-CD in the montelukast sodium-loaded oral solutions was fixed at 156 mg/ml.

From these findings, the following optimal formulation of the montelukast-loaded oral solution for composition (Table 1, IV) was selected for further study: aqueous solution containing montelukast sodium, HP-β-CD, methylparaben sodium, propylparaben sodium and EDTA sodium at the w/v percentages of 1.04/156/1.8/0.2/1.

The dissolution profiles of the montelukast sodium-loaded oral solution and commercial granules in 0.5 % (w/v) sodium lauryl sulphate in water are given in Fig. 5. In FDA regulation on montelukast sodium-loaded commercial oral products, 0.5 % (w/v) sodium lauryl sulphate in water must be used as a dissolution medium [9, 40]. The drug from the oral solution and commercial granules was rapidly dissolved in this medium at the initial times. Moreover, the oral solution gave a similar dissolution rate to the commercial granules. The dissolution profiles of the oral solution and the commercial granules were compared using the following equation of difference factor (f1) and similarity factor (f2); f1 = [∑(Gt − Ot)/∑(Gt + Ot)/2] × 100 and f2 = 50 × log{[1 + 1/n∑(Gt − Ot)2]−0.5 × 100}, where n is the number of timepoints, and Ot and Gt are the dissolved rates at the time (t) for the oral solution and the commercial granules, respectively [21, 24]. In these equations, 0 < f1 < 15 and 50 < f2 < 100 are a similar correlation between the dissolution patterns of the two products. The difference factor (f1) and the similarity factor value (f2) between them were 0.90 and 93.23, respectively. Thus, in this FDA-regulated dissolution medium, the oral solution gave dissolution that was equivalent to the commercial granules, predicting that the former will be bioequivalent to the latter.

Dissolution profiles of drug from the montelukast-loaded oral solution and commercial granules in distilled water (a), pH 1.2 (b), pH 4.0 (c), pH 6.8 (d) and in 0.5 % (w/v) sodium lauryl sulphate in water (e). All dissolution rates in the montelukast-loaded oral solution at each time were not significantly different from those in the commercial granules (P > 0.05). Each value represents the mean ± SD (n = 6)

Figure 6 illustrates the change in mean plasma concentration of montelukast after oral administration of the oral solution and commercial granules at a dose of 2 mg/kg montelukast base in rats. The montelukast-loaded oral solution was an aqueous solution containing montelukast sodium, HP-β-CD, methylparaben sodium, propylparaben sodium and EDTA sodium at the w/v percentages of 1.04/156/1.8/0.2/1. The total plasma concentrations of drug in the oral solution were not significantly different from those in the commercial granules in rats. All the pharmacokinetic parameters, such as AUC, Cmax, Tmax, Kel and t1/2 values, of the oral solution did not significantly differ from those of the commercial granules (Table 2). Thus, the oral solution was bioequivalent to the commercial granule in rats [22, 24, 25].

Plasma concentration versus time profiles of drugs after oral administration of montelukast-loaded oral solution and commercial granules to rats. All plasma concentrations in the montelukast-loaded oral solution at each time were not significantly different from those in the commercial granules (P > 0.05). The montelukast-loaded oral solution was an aqueous solution containing montelukast sodium, HP-β-CD, methylparaben sodium, propylparaben sodium and EDTA sodium at the w/v percentages of 1.04/156/1.8/0.2/1. Each value represents the mean ± SD (n = 5)

The stability of the montelukast sodium-loaded oral solution was evaluated by the physical appearance (precipitation) and the contents of montelukast sodium and montelukast sulphoxide in the oral solution over 12 months at two different accelerated conditions (Table 3) [24, 25]. There were no noticeable precipitations in the oral solution during the period. At 25 °C/60 % RH and 40 °C/75 % RH, this oral solution had more than 99 % of drug contents and less than 1 % of degraded product contents. Our results suggested that this montelukast sodium-loaded oral solution was physically and chemically stable for at least 12 months.

Conclusion

Taken together, it is concluded that this montelukast-loaded oral solution was bioequivalent to the commercial granules in rats and was stable for at least 12 months. Thus, this oral solution would be strongly recommended as an alternative to oral montelukast-loaded product.

References

Bennett, G., Craig, T.: Hereditary angioedema with a focus on the child. Allergy Asthma Proc. 36(1), 70–73 (2015)

Chong, J.K., Chauhan, B.F.: Addition of antileukotriene agents to inhaled corticosteroids in children with persistent asthma. Paediatr. Child Health 19(9), 473–474 (2014)

Gibson, P.G., Simpson, J.L., Ryan, N.M., Vertigan, A.E.: Mechanisms of cough. Curr. Opin. Allergy Clin. Immunol. 14(1), 55–61 (2014)

Strauch, E., Moske, O., Thoma, S., Storm Van’s Gravesande, K., Ihorst, G., Brandis, M., Kuehr, J.: A randomized controlled trial on the effect of montelukast on sputum eosinophil cationic protein in children with corticosteroid-dependent asthma. Pediatr. Res. 54(2), 198–203 (2003)

Aagaard, L., Hansen, E.H.: Adverse drug reactions associated with asthma medications in children: systematic review of clinical trials. Int. J. Clin. Pharm. 36(2), 243–252 (2014)

Paul, S.P., Bhatt, J.M.: Preschool wheeze is not asthma: a clinical dilemma. Indian J. Pediatr. 81(11), 1193–1195 (2014)

Patil-Gadhe, A., Pokharkar, V.: Montelukast-loaded nanostructured lipid carriers: part I oral bioavailability improvement. Eur. J. Pharm. Biopharm. 88(1), 160–168 (2014)

Okamoto, Y., Yokota, M., Kawazoe, S., Kubota, H., Nagaoka, H., Arakida, Y., Takeuchi, M.: A novel dual antagonist of thromboxane A2 and leukotriene D4 receptors: synthesis and structure-activity relationships of chloroquinolylvinyl derivatives. Chem. Pharm. Bull. 54(5), 603–610 (2006)

Okumu, A., DiMaso, M., Löbenberg, R.: Dynamic dissolution testing to establish in vitro/in vivo correlations for montelukast sodium, a poorly soluble drug. Pharm. Res. 25(12), 2778–2785 (2008)

Mahajan, H.S., Gundare, S.A.: Preparation, characterization and pulmonary pharmacokinetics of xyloglucan microspheres as dry powder inhalation. Carbohydr. Polym. 102, 529–536 (2014)

Muppavarapu, R., Guttikar, S., Rajappan, M., Kamarajan, K., Mullangi, R.: Sensitive LC-MS/MS-ESI method for simultaneous determination of montelukast and fexofenadine in human plasma: application to a bioequivalence study. Biomed. Chromatogr. 28(8), 1048–1056 (2014)

Al Omari, M.M., Zoubi, R.M., Hasan, E.I., Khader, T.Z., Badwan, A.A.: Effect of light and heat on the stability of montelukast in solution and in its solid state. J. Pharm. Biomed. Anal. 45(3), 465–471 (2007)

Rana, N.S., Rajesh, K.S., Patel, N.N., Patel, P.R., Limbachiya, U., Pasha, T.Y.: Development and validation of RP-HPLC method for the simultaneous estimation of montelukast sodium and ebastine in tablet dosage form. Indian J. Pharm. Sci. 75(5), 599–602 (2013)

Amirav, I., Luder, A.S., Kruger, N., Borovitch, Y., Babai, I., Miron, D., Zuker, M., Tal, G., Mandelberg, A.: A double-blind, placebo-controlled, randomized trial of montelukast for acute bronchiolitis. Pediatrics 122(6), e1249–e1255 (2008)

Medina, A.P., Olaya, F.J., Navas, M.P., Tilano, A.M., Muñoz, E.: Bioequivalence study of montelukast 5 mg chewable tablets. Biomedica 32(3), 399–407 (2012)

Stelmach, I., Jerzynska, J., Kuna, P.: A randomized, double-blind trial of the effect of glucocorticoid, antileukotriene and beta-agonist treatment on IL-10 serum levels in children with asthma. Clin. Exp. Allergy 32(2), 264–269 (2002)

Wang, K., Birring, S.S., Taylor, K., Fry, N.K., Hay, A.D., Moore, M., Jin, J., Perera, R., Farmer, A., Little, P., Harrison, T.G., Mant, D., Harnden, A.: Montelukast for postinfectious cough in adults: a double-blind randomised placebo-controlled trial. Lancet Respir. Med. 2(1), 35–43 (2014)

Ahmed, T.A., Ibrahim, H.M., Samy, A.M., Kaseem, A., Nutan, M.T., Hussain, M.D.: Biodegradable injectable in situ implants and microparticles for sustained release of montelukast: in vitro release, pharmacokinetics, and stability. AAPS PharmSciTech. 15(3), 772–780 (2014)

Balani, S.K., Xu, X., Pratha, V., Koss, M.A., Amin, R.D., Dufresne, C., Miller, R.R., Arison, B.H., Doss, G.A., Chiba, M., Freeman, A., Holland, S.D., Schwartz, J.I., Lasseter, K.C., Gertz, B.J., Isenberg, J.I., Rogers, J.D., Lin, J.H., Baillie, T.A.: Metabolic profiles of montelukast sodium (Singulair), a potent cysteinyl leukotriene1 receptor antagonist, in human plasma and bile. Drug Metab. Dispos. 25(11), 1282–1287 (1997)

Fey, C., Thyroff-Friesinger, U., Jones, S.: Bioequivalence of two formulations of montelukast sodium 4 mg oral granules in healthy adults. Clin. Transl. Allergy 4, 29 (2014)

Lim, H.T., Balakrishnan, P., Oh, D.H., Joe, K.H., Kim, Y.R., Hwang, D.H., Lee, Y.B., Yong, C.S., Choi, H.G.: Development of novel sibutramine base-loaded solid dispersion with gelatin and HPMC: physicochemical characterization and pharmacokinetics in beagle dogs. Int. J. Pharm. 397, 225–230 (2010)

Kim, Y.I., Kim, K.S., Suh, K.H., Shanmugam, S., Woo, J.S., Yong, C.S., Choi, H.G.: New clopidogrel napadisilate salt and its solid dispersion with improved stability and bioequivalence to the commercial clopidogrel bisulphate salt in beagle dogs. Int. J. Pharm. 415, 129–139 (2011)

Kassem, M.G., Ezzeldin, E., Korashy, H.M., Mostafa, G.A.: High-performance liquid chromatographic method for the determination of dasatinib in rabbit plasma using fluorescence detection and its application to a pharmacokinetic study. J. Chromatogr. B Analyt. Technol. Biomed. Life Sci. 939, 73–79 (2013)

Cho, K.H., Choi, Y.K., Kang, J.H., Choi, H.G., Yong, C.S., Park, Y.J.: Development of a novel combination tablet containing trimebutine maleate and mosapride citrate for the treatment of functional dyspepsia. Int. J. Pharm. 400, 145–152 (2010)

Cho, K.H., Choi, H.G.: Development of novel bepotastine salicylate salt bioequivalent to the commercial bepotastine besilate in beagle dogs. Drug Dev. Ind. Pharm. 39(6), 901–908 (2013)

Hughey, J.R., Keen, J.M., Miller, D.A., Kolter, K., Langley, N., McGinity, J.W.: The use of inorganic salts to improve the dissolution characteristics of tablets containing Soluplus®-based solid dispersions. Eur. J. Pharm. Sci. 48, 758–766 (2013)

Zhang, Y., Liu, Y., Luo, Y., Yao, Q., Zhong, Y., Tian, B., Tang, X.: Extruded soluplus/SIM as an oral delivery system: characterization, interactions, in vitro and in vivo evaluations. Drug Deliv. 30, 1–10 (2014)

Ramadhani, N., Shabir, M., McConville, C.: Preparation and characterisation of Kolliphor (®) P 188 and P 237 solid dispersion oral tablets containing the poorly water soluble drug disulfiram. Int. J. Pharm. 475, 514–522 (2014)

Sarode, A.L., Malekar, S.A., Cote, C., Worthen, D.R.: Hydroxypropyl cellulose stabilizes amorphous solid dispersions of the poorly water soluble drug felodipine. Carbohydr. Polym. 112, 512–519 (2014)

Tackenberg, M.W., Geisthövel, C., Marmann, A., Schuchmann, H.P., Kleinebudde, P., Thommes, M.: Mechanistic study of carvacrol processing and stabilization as glassy solid solution and microcapsule. Int. J. Pharm. 478(2), 597–605 (2014)

Ansari, M.T., Iqbal, I., Sunderland, V.B.: Dihydroartemisinin-cyclodextrin complexation: solubility and stability. Arch. Pharm. Res. 32(1), 155–165 (2009)

Orlu-Gul, M., Fisco, G., Parmar, D., Gill, H., Tuleu, C.: A new reconstitutable oral paediatric hydrocortisone solution containing hydroxypropyl-β-cyclodextrin. Drug Dev. Ind. Pharm. 39(7), 1028–1036 (2013)

Neves, J.S., Radke, A.L., Weller, P.F.: Cysteinyl leukotrienes acting via granule membrane-expressed receptors elicit secretion from within cell-free human eosinophil granules. J. Allergy Clin. Immunol. 125(2), 477–482 (2010)

Alvarez, C., Calero, J., Menéndez, J.C., Torrado, S., Torrado, J.J.: Effects of hydroxypropyl-beta-cyclodextrin on the chemical stability and the aqueous solubility of thalidomide enantiomers. Pharmazie 63(7), 511–513 (2008)

Battu, S.K., Repka, M.A., Maddineni, S., Chittiboyina, A.G., Avery, M.A., Majumdar, S.: Physicochemical characterization of berberine chloride: a perspective in the development of a solution dosage form for oral delivery. AAPS PharmSciTech. 11(3), 1466–1475 (2010)

Silva, G.H., Bottoli, C.B., Groppo, F.C., Volpato, M.C., Ranali, J., Ramacciato, J.C., Motta, R.H.: Methylparaben concentration in commercial Brazilian local anesthetics solutions. J. Appl. Oral Sci. 20(4), 444–448 (2012)

Turakka, L., Ojanen, T., Henell, U., Karjalainen, A.: Parabens as antimicrobial preservatives in creams. Pharmazie 43(10), 701–703 (1988)

Damian, F., Fabian, J., Friend, D.R., Kiser, P.F.: Approaches to improve the stability of the antiviral agent UC781 in aqueous solutions. Int. J. Pharm. 396, 1–10 (2010)

Keowmaneechai, E., McClements, D.J.: Influence of EDTA and citrate on physicochemical properties of whey protein-stabilized oil-in-water emulsions containing CaCl2. J. Agric. Food Chem. 50, 7145–7153 (2002)

Zaid, A.N., Natour, S., Qaddomi, A., Abu Ghoush, A.: Formulation and in vitro and in vivo evaluation of film-coated montelukast sodium tablets using Opadry® yellow 20A82938 on an industrial scale. Drug Des. Devel. Ther. 7, 83–91 (2013)

Acknowledgments

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MEST) (No. NRF-2012R1A2A2A01045658).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Young Hun Kim and Dong Wuk Kim have contributed equally to this work.

Rights and permissions

About this article

Cite this article

Kim, Y.H., Kim, D.W., Kwon, M.S. et al. Novel montelukast sodium-loaded clear oral solution prepared with hydroxypropyl-β-cyclodextrin as a solubilizer and stabilizer: enhanced stability and bioequivalence to commercial granules in rats. J Incl Phenom Macrocycl Chem 82, 479–487 (2015). https://doi.org/10.1007/s10847-015-0519-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10847-015-0519-6