Abstract

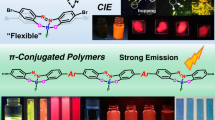

A series of nonlinear optical chromophores with the strong electron-withdrawing tricyanopyrroline (TCP) acceptor and rigid-flexible dendron was synthesized and their thermal and optical properties were investigated. Modification of the TCP chromophore with rigid-flexible dendron groups provides reduction of dipole–dipole interactions and thus great improvement of the macroscopic electro-optic (EO) response of the polymeric materials obtained by incorporating these derivatives as a guest in a high Tg amorphous polycarbonate (APC). The best result was obtained with chromophore Lj-Dr1, with three rigid-flexible dendrons, which shows the largest EO activity (39 pm V−1 at 1,310 nm). Furthermore, all chromophores in this study possess good processability and exhibit high thermal decomposition temperatures (highest T d = 300 °C).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Organic second order nonlinear optical materials have been intensively studied in the past decade. They have great potential for use in telecommunication, information processing, phased array radar, optical storage devices, THz generation, and many other applications as active materials in photonic microdevices [1–6]. The advantages of organic materials over traditional inorganic materials such as LiNaO3 are high and fast nonlinearities, ease of processing, device integration and the possibility of structural modification depending on the desired application. However, high nonlinearity is not enough to ensure wide scale commercial utilization of polymeric electro-optic devices. Other essential properties, such as good thermal, mechanical and photochemical stability, low optical loss and good processability, need to be simultaneously optimized in order for the active material tobe successfully implemented in a practical device.

A major obstacle impeding the development and employment of organic electro-optic materials is the difficulty of translating a high hyperpolarizability into a macroscopic EO coefficient. This is because, in particular at high chromophore number density, dipole–dipole interactions start to become competitive with chromophore dipole-applied poling field interactions, favoring centro-symmetric arrangements of chromophores [7, 8]. From both theoretical and experimental analyses the Dalton group has shown that the maximum achievable EO activity of a chromophore can be greatly enhanced by modification of its shape. In fact, the derivatization of chromophores with bulky substituents will make them more spherical and hence limit intermolecular electrostatic interactions [9–14]. These added side groups are only expected to contribute in minimizing the tendency of the dipoles to cluster in an anti-parallel fashion, and improving the solubility of the chromophores, positively affecting the poling efficiency and the macroscopic EO response of polymeric materials in which these chromophores are incorporated, without having any influence on the molecular hyperpolarizability.

Jen et al. [15–20] have firstly reported the strong potential of tricyanopyrroline (TCP) chromophore and their detailed microscopic analysis data. The electron-withdrawing properties of TCP unit are considerably stronger than those of tricyanofuran (TCF) and other electron acceptors. In their research, the largest molecular first hyperpolarizability was 8,700 × 10−30 esu, which was six times higher than the chromophore with TCF acceptor, but the macroscopic electro-optic coefficients couldn’t increase so obviously. To solve this problem, Min Ju Cho et al. [26] had introduced dendritic moieties to TCP acceptor, but that kind of dentritic moieties was rigid. They can’t improve the solubility of the chromophores and there was still some Л, Л stacks which embarrass the poling progress. In this contribution we modified the TCP chromophores with rigid-flexible dendron and describe how the EO response and the poling efficiency of a series of thermally stable TCP-based chromophore considerably improve by shape modification. The chromophores are incorporated as guests in a high Tg amorphous polycarbonate (APC) polymer host matrix. The chemical, thermal, linear optical and nonlinear optical characterization of these chromophores and the polymeric materials derived therefore are described.

Results and discussion

Synthesis of chromophore

The structure and synthesis of push–pull chromophore Lj-D was shown in Scheme 2. The target chromophore was synthesized by first protecting alcohol in the donor group with TBDMS and then coupling the donor with TCP acceptor to complete the active material through Knoevenagel condensation. The structure of TCP acceptor was shown in Scheme 1. The TCP acceptor was prepared according to reference [15]. The hydroxy groups of the donors must be protected by t-butyldimethylsiloxy (TBDMS) groups before the Knoevenagel condensation, if the hydroxy groups were not protected by any other groups, the donors can hardly react with the TCP acceptor. Lj-4 was synthesized from a straight forward nucleophilic substitution of compound 3 on benzyl bromide using potassium carbonate as the base. The chromophore Lj-4-OH was synthesized by acidic deprotection of Lj-4, then chromophore Lj-4-OH reacted with trimesoyl chloride and iso-octyl alcohol in acetonitrile. The reaction among trimesoyl chloride, iso-octyl alcohol and chromophore Lj-4-OH gave us a high yield of 97%, because of the stability of chromophore Lj-4-OH in acidic solution.

The structure and synthesis of push–pull chromophore Lj-Dr1 was shown in Scheme 3. The process of the synthesis of chromophore Lj-Dr1 is the same with the synthesis of chromophore Lj-D. The only two differences are that we introduced 3,5-bis(2′-ethylhexyloxy)benzyl bromide instead of benzyl bromide into the TCP-acceptor and the donor had two hydroxy groups.

The thermal stabilities of the chromophores

Thermal stability is an important requirement for the incorporation of new chromophores in poled polymer structures. The thermal stabilities of the chromophores were investigated by TGA under nitrogen, with a heating rate of 10 °C min−1. Figure 1 gives the thermogravimetric curves of the chromophore Lj-4, Lj-D and Lj-Dr1. The results show that all the chromophores are thermally stable with decomposition temperatures (T d) higher than 217 °C, and no weight loss was observed at lower temperatures. The degradation of chromophore Lj-4 started at 265 °C while of chromophore Lj-D at 217 °C. The significant difference in the temperature of degradation for these two chromophores indicates that TBDMS group is more stable than ester group. But chromophore Lj-Dr1 showed the highest decomposition temperature. This may be due to the long carbon chain in the amino of the donor, which prevent the amino from reacting with acceptor cyano groups when being heated. The thermal degradation is largely related to oxidation whereby the molecular bonds of a chromophore are attacked by oxygen molecules. The core of the chromophore which is a large conjugated group is more easily attacked by oxygen molecules. If the chromophores can have more and larger flexible structures around the core, the probability of the core be attacked will become lower and the chromophores will have better thermal stability. So chromophore Lj-Dr1 has the best thermal stability. Another phenomenon was also found in Fig. 1. The chromophore whose hydroxyl group was protected by ester group decomposed more sufficiently than protected by TBDMS. This may be also due to the stability of the TBDMS.

Linear optical properties

It has been experimentally and theoretically illustrated that a large λmax, meaning low charge transition energy, is often directly associated with an enhanced second-order NLO response [21]. And the shifts of the absorption maxima in different solvents show the effect of solvent on the energy gap between the ground state and excited state molecules [22, 23], which reflects different electronic distribution in the molecules. DeMartino et al. [24] have suggested that the high solvate chromic effects are related with a large second-order optical nonlinearity. So the UV–vis spectra of synthesized chromophores are determined in THF and DCM, with a concentration of 2.02 × 10−5 mol L−1, and the absorption maxima (λmax) are summarized in Table 1. All chromophores studied have a strong charge-transfer band (550–750 nm) in the visible region of the spectrum. In general, no significant change in the solvate chromic effects was caused by the modification, with Δλmax lying between 12 and 14 nm. This indicated that the functionalization of the chromophores didn’t have a large influence on the hyperpolarizability. The UV–vis spectra of chromophore Lj-D and Lj-D1 were also determined in acetone with different concentration (from 1.0 × 10−5 to 4.0 × 10−5 mol L−1). The absorption maxima has not changed for chromophore Lj-Dr1, as the concentration increased, but the absorption maxima of chromophore Lj-D increased to 694 from 691 nm. The shape of UV–vis spectra of chromophore Lj-D had been changed with the increasing of concentration, which was shown in Fig. 2. These phenomenons indicated that the dipole–dipole interaction of chromophore Lj-Dr1 is less than chromophore Lj-D. If there is very strong dipole–dipole interaction, this kind of molecules can be easily aggregated, and they will grow up to nanocrystal via solvent exchange method (self-assembly). We have found this phenomenon in most of the chromophores we synthesized before, but we found there was no crystallization behaviour for chromophore Lj-Dr1.

The NLO properties of the chromophores

Normally, the EO coefficients (γ33) value depends on the chromophore density in the films, so the films were prepared with the same chromophore loading density of 0.1 mmol g−1 and the poling process is completely same. The poling process was carried out for 10 min at a temperature of about 5 °C above the Tg of the polymer. The applied voltage is set at 8 kV. The sample was subsequently cooled to room temperature and then the applied voltage was withdrawn.

The γ33 value for a poled film was calculated from the equation [25]:

Where I m is the amplitude of the modulation, λ is the wavelength of the light, V m is the modulating voltage, I c is half the maximum laser intensity, n is the index of refraction, θ is the incident angle.

The film with Lj-4 showed a little phase separation after poling, but the films with chromophore Lj-Dr1 and Lj-D were in good condition, phase separation phenomenon was not found under the instrument of Surface Profiler—Alpha Step IQ. The γ33 for three kinds of films are summarized in Table 1. It is found that as the modified groups became larger, the EO coefficient increased. The EO coefficient of the film contained chromophore Lj-4 was 26 pm V−1. The best result was obtained with chromophore Lj-Dr1 which provided a more significant enhancement of the EO response reaching the maximum γ33 of 39 pm V−1. Probably, three very bulky rigid-flexible dendrons provided the site isolation needed for free chromophore reorientation under electric field poling conditions. We also got the largest γ33 of 334 pm V−1 for chromophore Lj-Dr1 with high concentrations (2.0 × 1020/g, about 35 wt%), but the signal is not very stable, it would become lower to around 40 pm V−1 for only several hours. It can be concluded that, since the hyperpolarizability is similar for all chromophores, the enhancements in γ33 for the shape modified chromophores are not due to improvements at the molecular level, but indeed to reduced electrostatic interactions between chromophores and hence to better poling efficiency. After the corona poling, the dipole moments of the chromophore moieties in the polymer were aligned, and the absorption curve decreased due to birefringence. From the absorption change, the order parameter (Φ) for polymer can be calculated according to the following equation:

where A 1 and A 0 are the absorbances of the polymer film after and before cornona poling, respectively. The Φ value of chromophore Lj-Dr1 in the poled film is 22%, but the order parameter of the films contained chromophore Lj-4 and Lj-D is about 10–15%, which was measured by UV–vis spectra of the films (Fig. 3). It also indicates that the dendritic moieties which make the chromophore molecular radius increase largely, the interaction among the dendritic chromophore molecules is less and the material is easier to be polarized. The optimized structure of Lj-Dr1 was also shown in Fig. 4; we can see that the TCP core was tightly surrounded by the three rigid-flexible dendrons. The other two chromophores were also optimized, and their dipole moments were also calculated in the optimized process, which was shown in Table 1. The change of the dipole moment was not very large after the chromophore was modified by the dendron.

Conclusions

A series of nonlinear optical chromophores was synthesized by applying a shape modification to the TCP chromophore. These changes have led to a great reduction of intermolecular interactions. Consequently, improved poling efficiencies were observed for the derivatives when incorporated in APC guest polymer. Great improvement of the EO activity was obtained for chromophore Lj-Dr1, compared with Lj-4, showing an EO coefficient of 39 pm V−1 at 1,310 nm. Moreover, all chromophores exhibit good processability and solubility.

Experimental section

All the reagents were used as received unless stated. 1H NMR spectra were determined by Varian Gemini 300 (300 MHz) NMR spectrometer (tetramethylsilane as internal reference). FT-IR spectra were recorded on BIO-RAD FTS-165 spectrometer; MS spectra were obtained on MALDI-TOF (Matrix Assisted Laser Desorption/Ionization of Flight) on BIFLEX III (Bruker Inc.) spectrometer. UV–vis spectra were performed on Hitachi U2001 photo spectrometer. TGA was determined by TA5000-2950TGA (TA co) with heating rate of 10 °C min−1 under the protection of nitrogen.

Synthesis of chromophore Lj-D

Chromophore Lj-4

To a solution of 4-[N-(2-hydroxyethyl), N-methylamino]benzaldehyde 1 (1.79 g, 10 mmol) in 20 mL anhydrous DMF, tert-butylchlorodimethylsilane (1.65 g, 11 mmol) and imidazole (0.82 g, 12 mmol) were added. After stirring at room temperature under N2 overnight, the mixture was poured into water. Following workup with diethyl ether and water, flash column chromatography was performed to afford 4-{N-[2-(tert-butyldimethylsilyloxy)ethyl, N-methyl]amino}benzaldehyde 2 (2.54 g, 8.7 mmol). Yield: 87%. The product was used in the next step directly.

To a solution of TCP acceptor (1.84 g, 10 mmol) in 2 mL of ethanol was added compound 2 (2.54 g, 8.7 mmol), and the mixture was heated at 60 °C under argon for 30 min to complete the reaction. The resulting reaction mixture was cooled, filtered, washed with cool ethanol and dried to give 2.5 g (5.5 mmol) of pure compound 3. The yield was 63%. m/z: 459(M+).

Compound 3 (0.91 g, 2 mmol) and 1 g sodium carbonate were mixed in 50 mL of Acetonitrile under argon. After heating the solution at 70 °C, benzyl bromide (0.37 g, 2.2 mmol) was added dropwise and the reaction mixture was stirred for 0.5 h. It was poured into ice water to obtain the greenish solid product. The solid was filtered and dried at 60 °C in vacuum. The resulting product was purified by silica-gel column chromatography to yield chromophore Lj-4 (1.03 g, 1.88 mmol). Yield 94%, UV–vis (CH2Cl2): λmax = 729 nm; IR (KBr, υmax/cm−1): 2926, 2856, 2220, 1727; MS (MALDI-TOF), m/z: 549(M+); 1H NMR (300 MHz, CD3COCD3), δ: 8.57(d, 1H), 7.79(d, 2H), 7.35(t, 2H), 7.28(d, 2H), 7.26(t, 1H), 7.11(d, 1H), 7.00(d, 2H), 5.34(s, 2H), 3.94(t, 2H), 3.83(t, 2H), 2.05(s, 3H), 0.83(s, 9H), 0.02(s, 6H).

Chromophore Lj-D

Chromophore Lj-4 (1.03 g, 1.88 mmol) was dissolved in 20 mL of THF. Aqueous solution of HCl (10 mL, 1 N) was added and the mixture was stirred at room temperature for 1 h. Then solvent was removed, the crude product was purified by flash chromatography over silica gel using 20% ethyl acetate in hexane as eluent to afford 0.79 g (1.82 mmol) of chromophore Lj-4-OH. The yield was 97%. MS (MALDI-TOF), m/z: 435(M+).

Trimesoyl chloride (0.53 g, 2 mmol) was added to the solution of chromophore Lj-4OH (0.79 g, 1.82 mmol) in 50 mL Acetonitrile. The mixture was stirred for 2 h under an N2 atmosphere at room temperature. Iso-octyl alcohol (0.65 g, 5 mmol) was then added to the mixture, and the solution was stirred for 2 h. Then solvent was removed, the crude product was purified by flash chromatography over silica gel using 20% ethyl acetate in hexane as eluent to afford 1.5 g (1.76 mmol) of chromophore Lj-Dr1. The yield was 97%. MS (MALDI-TOF), m/z: 851(M+); 1H NMR (300 MHz, CD3COCD3), δ: 8.79(s, 3H), 8.48(d, 1H),7.76(d, 2H), 7.74(m, 2H), 7.34(m, 3H), 7.13(d, 1H), 7.05(d, 2H), 5.35(s, 2H), 4.71(t, 2H), 4.31(d, 4H), 4.14(t, 2H), 3.31(s, 3H), 1.88(m, 2H), 1.38(m, 16H), 0.8696(t, 12H). 13C NMR (100 MHz, CD3COCD3): δ (ppm) 167.4, 165.2, 161.8, 154.1, 150.5, 145.0, 138.4, 134.6, 132.7, 125.8, 113.8, 112.5, 71.2, 68.5, 63.8, 50.1, 45.1, 40.0, 39.6, 30.3, 24.5, 14.4, 11.6.

Synthesis of dendritic chromophore Lj-Dr1

The process of the synthesis of chromophore Lj-Dr1 is the same with the synthesis of chromophore Lj-D.

Chromophore Lj-1

Yield: 73%. UV–vis (CH2Cl2): λmax = 731 nm; IR(KBr), υmax/cm−1: 2928, 2857, 2224, 1734, 1528, 1175, 1059; MS (MALDI-TOF), m/z: 951.3(M+); 1H NMR (300 MHz, CD3COCD3), δ: 8.50(d, 1H), 7.81(d, 2H), 7.12(d, 1H), 6.93(d, 2H), 6.43(s, 1H), 6.39(s, 2H), 5.30(s, 2H), 3.93(t, 4H), 3.85(t, 8H), 1.65(m, 2H), 1.37(m, 16H), 0.90(t, 12H), 0.85(s, 18H), 0.02(s, 12H).

Chromophore Lj-Dr1

Yield: 97%. MS (MALDI-TOF), m/z: 1553(M+); 1H NMR (300 MHz, CD3COCD3), δ(ppm): 0.86(t, 24H), 0.96(t, 12H), 1.31(m, 36H), 1.46(d, 12H), 2.01(m, 6H), 3.85(d, 4H), 4.22(t, 4H), 4.32(d, 8H), 4.75(t, 4H), 5.27(s, 2H), 6.42(s, 2H), 6.44(s, 1H), 7.13(d, 1H), 7.25(d, 2H), 7.78(d, 2H), 8.48(d, 1H),8.67(s, 4H), 8.71(s, 2H). 13C NMR (100 MHz, CD3COCD3): δ (ppm) 167.3, 165.2, 161.8, 156.1, 154.1, 150.5, 144.9, 138.3, 134.5, 132.4, 125.7, 113.8, 112.5, 105.8, 101.0, 71.1, 68.5, 63.8, 50.1, 45.1, 40.1, 39.7, 30.2, 24.6, 23.6, 14.4, 11.4.

IR(KBr), v/cm: 2960 (CH2, CH3), 2220 (CN), 1730 (COO), 1610 (C=C), 1460 (C–N); UV–vis (CH3COCH3): λmax = 683.5 nm.

Film preparation

For the UV–vis analysis and γ33 measurements, the films were prepared by a spin-coating method. Firstly APC was dissolved in dibromomethane, and a given amount of chromophore was then added into the solution, and filtered through a syringe filter (0.44 um) to remove the undissolved particulates. The indium–tin oxide (ITO)-coated glass was pre-cleaned using acetone, distilled water, and THF sequentially in ultra sonic bath. The obtained homogenous solution was spin coated onto the ITO-coated glass substrate at room temperature with the spinning rate of 800 rpm to give a film, which was dried in a vacuum oven at 50 °C for 12 h to remove the residual solvent.

References

Kajzar, F., Lee, K.-S., Jen, A.K.-Y.: Polymeric materials and their orientation techniques for second-order nonlinear optics. Adv. Polym. Sci 161, 1 (2003)

Shi, Y., Zhang, C., Zhang, H., Bechtel, J., Dalton, L.R., Robinson, B.H., Steier, W.H.: Low (sub-1 volt) halfwave voltage polymeric electro-optic modulators achieved. Science 288, 119 (2000)

Lee, M., Katz, H.E., Erben, C., Gill, D.M., Gopalan, P., Heber, J.D., McGee, D.J.: Broadband modulation of light by using an electro-optic polymer. Science 298, 1401–1403 (2002)

Dalton, L.R.: Nonlinear optical polymeric materials: from chromophore design to commercial applications. Adv. Polym. Sci. 158, 1–86 (2002)

Sinyukov, A.M., Leahy, M.R., Haller, L.M., Luo, J.D., Jen, A.K.Y., Dalton, L.R.: Functional organic materials: syntheses, strategies and applications. Appl. Phys. Lett. 85, 5827–5829 (2004)

Samyn, C., Verbiest, T., Persoons, A.: Second-order non-linear optical polymers. Macromol. Rapid Commun. 21, 1–15 (2000)

Wurthner, F., Yao, S., Debaerdemaeker, T., Wortmann, R.: Dimerization of merocyanine dyes: structural and energetic characterization of dipolar dye aggregates and implications for nonlinear optical materials. J. Am. Chem. Soc. 124, 9431–9447 (2002)

Wortmann, R., Rosch, U., Redi-Abshiro, M., Wurthner, F.: Large electric field effects on dipolar aggregation of merocyanine dyes. Angew. Chem. 42, 2080–2083 (2003)

Dalton, L.R., Steier, W.H., Robinson, B.H., Zhang, C., Ren, A., Garner, S., Chen, A., Londergan, T., Irwin, L., Carlson, B., Fifield, L., Phelan, G., Kincaid, C., Amend, J., Jen, A.K.Y.: From molecules to opto-chips: organic electro-optic materials. J. Mater. Chem. 9, 1905–1920 (1999)

Robinson, B.H., Dalton, L.R.: Monte Carlo statistical mechanical simulations of chromophore/polymer materials. J. Phys. Chem. A 104, 4785–4795 (2000)

Nielsen, R.D., Rommel, H.L., Robinson, B.H.: Simulation of the loading parameter and soft lithography. J. Phys. Chem. B 108, 8659–8667 (2004)

Harper, A.W., Sun, S., Dalton, L.R., Garner, S.M., Chen, A., Kalluri, S., Steier, W.H., Robinson, B.H.: Translating microscopic optical nonlinearity into macroscopic optical nonlinearity: the role of chromophore electrostatic interactions. J. Opt. Soc. Am. B 15, 329–337 (1998)

Faccini, M., Balakrishnan, M., Diemeer, M.B.J., Hu, Z., Clays, K., Asselberghs, I., Leinse, A., Driessen, A., Reinhoudt, D.N., Verboom, W.: Enhanced poling efficiency in highly thermal and photostable nonlinear optical chromophores. J. Mater. Chem. 18, 2141–2149 (2008)

Liu, J., Zhou, T., Qiu, L., Liu, X., Zhen, Z.: Synthesis and characterization of dendrimer encapsulated chromophoreby one step method for electrooptics. Optoelectron. Adv. Mater. Rapid Commun. 3, 921 (2009)

Jang, S.H., Luo, J., Tucker, N.M., Leclercq, A., Zojer, E., Haller, M.A., Kim, T.D., Kang, J.W., Firestone, K., Bale, D., Lao, D., Benedict, J.B., Cohen, D., Kaminsky, W., Kahr, B., Bredas, J.L., Reid, P., Dalton, L.R., Jen, A.K.Y.: Pyrroline chromophores for electro-optics. Chem. Mater. 18, 2982–2988 (2006)

Dalton, L.R., Jen, A.K.Y., Steier, W., Robinson, B., Jang, S.H., Clot, O., Song, H.C., Kuo, Y.H., Zhang, C., Rabiei, P., Ahn, S.W., Oh, M.C.: Organic electro-optic materials: some unique opportunities. Proc. SPIE. 5351, 1–15 (2004)

Dalton, L.R.: Organic electro-optic materials. Pure Appl. Chem. 76, 1421 (2004)

He, M., Leslie, T.M., Sinicropi, J.A.: Synthesis of chromophores with extremely high electro-optic activity. 1. Thiophene-bridge-based chromophores. Chem. Mater. 14, 4662–4668 (2002)

Hoang, M.H., Kim, M.H., Cho, M.J., Kim, K.H., Kim, K.N., Jin, J.I., Choi, D.H.: Dendronized tricyanopyrroline-based chromophores in nonlinear optical active host polymer. J. Polym. Sci. A. 46, 5064–5076 (2008)

Lee, S.K., Cho, M.J., Jin, J.I., Choi, D.H.: Stability control of the electrooptic effect with new maleimide copolymers containing photoreactive tricyanopyrrolidene-based chromophores. J. Polym. Sci. A. 45, 531–542 (2006)

Cheng, L.T., Tam, W., Stevenson, S.H., Meredith, G.R.: Experimental investigations of organic molecular nonlinear optical polarizabilities. 1. Methods and results on benzene and stilbene derivatives. J. Phys. Chem. 95, 10631 (1991)

Kim, J.J., Choi, H., Lee, J.W., Kang, M.S., Song, K., Kang, S.O., Ko, J.: A polymer gel electrolyte to achieve $6% power conversion efficiency with a novel organic dye incorporating a low-band-gap chromophore. J. Mater. Chem. 18, 5223 (2008)

Asiri, A.M., Fatani, N.A.: Novel dyes derived from hydrazones. Part 4. Synthesis and characterizations of 2-{4-[(2E)-2-(1-arylylidene)hydrazino]phenyl}ethylene-1,1,2-tricarbonitrile. Dyes Pigments 72, 217 (2007)

DeMartino, R.N., Choe, E.W., Khanarian, G., Haas, D., Leslie, T., Nelson, G.: Development of polymeric nonlinear optical materials. In: Prasad, P.N., Ulrich, D.R. (eds.) Nonlinear Optical and Electroactive Polymers, p. 169. Plenum Press, New York (1988)

Teng, C.C., Man, H.T.: Simple reflection technique for measuring the electro-optic coefficient of poled polymers. Appl. Phys. Lett. 56, 1734 (1990)

Cho, M.J., Lim, J.H., Hong, C.S., Kim, J.H., Lee, H.S., Choi, D.H.: A tricyanopyrroline-based nonlinear optical chromophore bearing a lateral moiety: a novel steric technique for enhancing the electro-optic effect. Dyes Pigments 79, 193 (2008)

Acknowledgments

We are grateful to the Chinese Academy of Science Knowledge Innovation Project Key Direction Project foundation (KJCX2.HO2) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, J., Bo, S., Liu, X. et al. Enhanced poling efficiency in rigid-flexible dendritic nonlinear optical chromophores. J Incl Phenom Macrocycl Chem 68, 253–260 (2010). https://doi.org/10.1007/s10847-010-9781-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10847-010-9781-9