Abstract

The aims of this study were to characterise the composition of five seaweed species (Ascophyllum nodosum, Fucus serratus, Fucus vesiculosus, Laminaria hyperborea and Sargassum muticum), their extracts and commercial formulations, using thermogravimetry (TGA), energy dispersive X-ray microanalysis (EDX), Fourier-transform infrared spectroscopy (FTIR) and pyrolysis gas chromatography/mass spectrometry (Py-GC/MS). Analyses of the samples by TGA and EDX provided information on the proportions of algal cell wall, inorganic fractions and minerals. The main carbohydrate constituents of the five species and extracts were identified by their pyrolysis products, e.g. 1-(2-furanyl) ethanone, 5-methyl-2-furcarboxaldehyde, 2-hydroxy-3-methyl-2-cyclopenten-1-one, diannhydromannitol, 1,6-anhydromannopyranose and 1,6-anhydromannofuranose, using Py-GC/MS. The differences in relative intensities of the infrared bands of the five species were enhanced, especially after acid extraction compared with alkaline or neutral treatments, resulting in improved understanding of the compositional changes. In addition four commercial formulations and two acidic extracts of A. nodosum were evaluated for composition using the techniques. The dry matter, pH, electrical conductivity, ash, carbon and nitrogen content of the six preparations showed significant differences in composition. Variations in fatty acid, alginic acid, mannitol, laminarin and fucoidan content of the six formulations were reported. The results have shown that TGA, EDX, Py-GC/MS and FTIR are complementary techniques for rapid evaluation of seaweed materials and products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the 1950s, the seaweed industry developed rapidly, as the agricultural sector needed low cost fertilizers to expand food production in Europe and North America. Milton (1952) was the first to develop a patent based on the production of a liquid product from seaweed. The extracts can be directly applied as soluble seaweed constituents, to plant shoots and on the soil to provide nutrients for enhancing productivity of crops. Currently seaweed extracts are used extensively in agriculture, as plant growth supplements and some examples of commercially available products from many countries are: Actiwave® (Italy), Algifol (Germany), Ferriton (Ireland) and AlgaGreen (Ireland). The ability of these formulations to alleviate abiotic and biotic stresses of crop plants and turf grasses have been widely reported (Christobel 2008; Rathore et al. 2009; Rayorath et al. 2008; Spinelli et al. 2010). Preliminary experiments reported by Spinelli et al. (2010) have shown that the product can enhance biomass and root growth of many crop plants and it can be used as an iron chelate for organic strawberry production. Similar products, such as Ferriton (BioAtlantis, Ireland) obtained by formulating A. nodosum extract with chelated iron have been used, where iron deficiencies are evident in sports turf and amenity sectors. However, the biostimulatory potential of the products has not been fully exploited due to a lack of understanding of the mechanisms underlying the mode of action, for example: modulation of phytohormones, increased photosynthetic efficiency and carbon assimilation, delayed senescence and up-regulation of disease resistant genes (Khan et al. 2009). They emphasized the possibility of examining the effect of active fractions on the whole genome/transcriptome of target plants to improve understanding of the mechanisms of stress alleviation.

The organic components in brown seaweed species are characterised by carbohydrate, protein and glycolipid contents and composition changes according to species, seasons and habitats. The major bioactive polysaccharides are alginic acid, laminarin and fucoidan (Rathore et al. 2009; Rayorath et al. 2008; Rioux et al. 2007). Alginic acid is the linear co-polymer of ß-d-mannuronic (M) acid and α-l-guluronic (G) acid (1→4) linked residues, arranged either in heteropolymeric (MG) and/or homopolymeric (M or G) blocks (Leal et al. 2008; Mackie 1971). Laminarin is composed of (1,3)-ß-d-glucan (Zvyagintseva et al. 1999) with ß (1,6) branching (Nelson and Lewis 1974) and can vary according to macro-algae species especially in the reducing group (mannitol [M] and glucose [G] residues). Laminarin is the principal low molecular weight (5,000 Da) polysaccharide and is composed of ß-glucans (Rioux et al. 2007). The fucoidan of Fucus vesiculosus has been reported as consisting of l-fucopyranose units with alternating (1→3) and (1→4) glycosidic linkages (Bilan et al. 2004). The structure of fucoidans is heterogeneous and highly branched (Pereira et al. 2009; Zvyagintseva et al. 1999).

Fourier-transform infrared spectroscopy (FTIR) is a rapid and environment friendly technique, capable of identifying functional groups of pure compounds and macromolecules of phycocolloids (Matsuhiro 1996; Pereira et al. 2009). The thermal characteristics of major carbohydrate fractions (alginic acid, mannitol, laminarin and fucoidan) of seaweeds were investigated using pyrolysis gas chromatography (Py-GC/MS) and thermogravimetry (TGA; Anastasakis et al. 2011; Ross et al. 2009). The authors showed that the compounds produce characteristic fingerprints, such as furfural for alginic acid; 5-methyl 2-furancarboxaldehyde and 2-methoxy-5-methyl thiophene for fucoidan; 1-(2-furanyl) ethanone and dianhydromannitol for mannitol and 1,2-cyclopentanedione, 2-hydroxy-3-methyl-2-cyclopenten-1-one and citric acid for laminarin. Mineral content of samples can be estimated by energy dispersive X-ray microanalysis (EDX; Sharma et al. 2011).

The aims of this study were to analyse the composition of five seaweed species, their extracts and commercial biostimulant formulations using TGA, EDX, FTIR and Py-GC/MS with the objective of developing complementary rapid techniques for characterisation of the materials.

Materials and methods

Seaweed, extract and commercial samples

Ascophyllum nodosum, Laminaria hyperborea, Sargassum muticum, Fucus vesiculosus and F. serratus were harvested from the coastal area of Strangford Lough, Northern Ireland during February and June 2009 (Sharma et al. 2011). The acidic (acetic acid, 1 M), alkaline (KOH, 2 N) and neutral extraction protocols were previously described by Sharma et al. (2011) and lyophilised samples from the February sample set were used for analyses (Fig. 1). Samples of the five seaweed species, extracts and commercial samples were evaluated to provide a comparative data set. Four commercial formulations (A, B, C and D) were evaluated (Table 1). The commercial products were selected because of differences in the extraction protocols employed by the manufacturers but trade names were not disclosed to maintain confidentiality. An acidic extract of A. nodosum from the June sample set was homogenised at 41,415 g for 5 min to reduce particle size and two acidic formulations (E and F) were prepared with different dry matter (DM) contents. The different methods used to analyse the samples are listed in Table 2. The commercial standards of carbohydrates: alginic acid from brown seaweeds (A-7003), laminarin from L. digitata (L-9634), mannitol (M-4125) and fucoidan from F. vesiculosus (F-5631) were obtained from Sigma-Aldrich (UK).

Summary of the extraction steps of the five seaweed species (Sharma et al. 2011)

Compositional, TGA and EDX analyses

The protocols used for sampling, freeze drying and milling of the biostimulant samples were previously reported as were the methods for determining DM, nitrogen, carbon and ash contents of the samples (Sharma et al. 2011). The test products were diluted (1 g/50 mL water) prior to pH and electrical conductivity measurements and replicated three times. Freeze-dried samples were analysed using a Mettler Toledo (TGA/DSC1) thermogravimetric analyser. A typical sample mass of 3.1 mg was heated from 30°C to 780°C at a heating rate of 20°C min−1 in a flow rate of 50 mL min−1of nitrogen (Sharma et al. 2011). The test materials were also evaluated semi-quantitatively using energy dispersive X-ray microanalysis (Inca Energy, Oxford Instruments, UK) to determine elemental composition. Internal standards were used for the analysis of the samples using the same microscope and EDX parameters for each spectrum (Sharma et al. 2011).

Py-GC/MS

Py-GC/MS was carried out using a CDS 5200 series pyrolyser in the trap mode linked to an Agilent Technologies 5975 GC/MS system. Samples (1 mg) were pyrolysed at 500°C at a ramp rate of 20°C ms−1 for 20 s. The trap was desorbed at 280°C for 2 min to the GC/MS with a split ratio of 75:1. The pyrolysis products were separated on an Agilent Technologies HP5-MS (30 m × 0.25 mm × 0.25 μm) capillary column. The column was initially held at 40°C for 2 min and then ramped at 5°C min−1 to 300°C with a constant flow rate of 0.9 mL min−1. The MS was operated in the full scan mode scanning the mass range 30–700 amu.

Infrared spectroscopy

The spectra of air-dried ground seaweed samples, freeze-dried extracts, biostimulant formulations and polysaccharide standards were obtained using a Spectrum One FTIR spectrometer (Perkin Elmer Inc., USA) equipped with an attenuated total reflectance sampling device containing a diamond/ZnSe crystal. Spectra were scanned at room temperature over the wave number range 4000–650 cm−1, with a scan speed of 0.20 cm s−1 and 60 accumulations at a resolution of 4 cm−1. Triplicate scans of each sample after repacking were used to obtain an average spectrum and the background spectrum was scanned under the same instrumental conditions. The spectra were acquired using Spectrum software version 5.01, base line corrected but not smoothed and normalised with zero point at the peak ca 900 cm−1. Replicate scans of each sample were evaluated for variation between the scans by exporting a continuous absorbance data set with the aid of principal component analysis (Unscrambler 9.6, Camo Software, AS, Norway).

Statistical analysis

The compositional differences between the six formulations were evaluated using ANOVA and presented as the least significant difference (LSD) at 5% level.

Results

Composition of biostimulant formulations

The compositional differences between the six formulations are presented in Table 3. The DM contents (%) ranged between 3.7 (F) to 43.9 (C) and differences between the means were significant (P < 0.001). The variations in pH, EC and ash content of the samples were significantly (P < 0.01 to P < 0.001) different and ranged between 4.3–8.9, 0.5–6.3 mS cm−1 and 8.2–31.0% respectively (Table 3). Sample C was associated with the highest DM, pH, EC and ash content compared with the other samples. Carbon and nitrogen contents of A and D were the highest and lowest respectively and differences were significant (P < 0.001; Table 3). The concentration of Na, Mg, S, Cl, Ca, Cu and I were significantly (P < 0.01 to <0.001) highest in D compared with the other five formulations. Potassium concentrations were significantly (P < 0.001) higher in C compared with the others (Table 4).

TGA analyses of the biostimulant formulations

Thermogravimetry provided a rapid method for differentiating between the formulations with major differences in weight loss (WL) profiles and rate of weight loss in the different temperature bands. The thermograms of products are presented in Fig. 2 showing differences in the decomposition bands (WL1 30–190°C; WL2 190–450°C, WL3 450–660°C and WL4 660–800°C, Table 5). Mean WL in the WL1 ranged between 6.8% and 10.6%. The peak temperatures (PT) in this range were significantly higher (P < 0.001) for B and C compared to the rest (Table 5). In the 190–450°C, WL2 values ranged between 13.8% and 53.5% and product B showed significantly (P < 0.001) higher weight loss compared to the others. The PT2 was significantly (P < 0.001) lower (247°C) for B compared to others, indicating a higher alginic acid and fucoidan content (Fig. 2a, b, c) as these two carbohydrates decompose at a lower temperature compared to mannitol and laminarin (Sharma et al. 2011). In the 450–660°C band, WL3 values of the samples varied between 7.3% and 15.0% with products B and C showing significantly (P < 0.001) higher WL than the others (Table 5). Mean WL4 in the 660–800°C band ranged from 4.9% to 11.1% and products C and D displayed significantly (P < 0.001) the highest WL compared with the other samples indicating pyrolysis of residual carbon bound to the inorganic fraction (Table 5, Fig. 2). Products B and C contained the lowest and highest residues (Table 5) respectively, showing the impact of highly alkaline (pH > 12) extraction on increased K content of C compared to the milder (pH ∼ 9) hydrolysis step employed for B with lower cationic content (Tables 3 and 4).

Py-GC/MS

Recent studies (Anastasakis et al. 2011; Ross et al. 2009) have demonstrated that the pyrolysis of the four main carbohydrates in brown algae, alginic acid, fucoidan, laminarin and mannitol, produce characteristic pyrolysis products. These authors considered furfural as a marker for alginic acid; 5-methyl-2-furcarboxaldehyde and 2-methoxy-5-methyl thiophene for fucoidan; 1-(2-furanyl) ethanone and diannhydromannitol for mannitol and 2-hydroxy-3-methyl-2-cyclopenten-1-one for laminarin. Helleur (1987) identified 1-6-anhydromannopyranose and 1,6-anhydromannofuranose as pyrolysis products of mannitol.

Samples of fucoidan, alginic acid, mannitol and laminarin were subjected to Py-GC/MS to establish the retention times and mass spectra of the pyrolysis products. Identification was established by comparison with the mass spectral library (NIST) and identifications by the aforementioned studies (Table 6). It was not possible to identify 2-methoxy-5-methyl thiophene as a pyrolysis product of fucoidan although an unidentified compound of the same molecular weight (128 amu) at a retention time of 12.34 min was unique to fucoidan. Additionally, a second unidentified compound of the same molecular weight (128 amu, retention time 13.68 min) was detected in laminarin which could be used to indicate its presence. Anastasakis et al. (2011) found that alginic acid, fucoidan, mannitol and laminarin produced furfural in the ratio 100:59:4:22 when each substance was pyrolysed at 500°C. Additionally, Waymack et al. (2004) detected furfural production from the pyrolysis of sodium polygalacturonate was ∼1% that of polygalacturonic acid itself. Therefore, the use of furfural as a marker for alginic acid was not considered for seaweed extracts or bioformulations as ratio of these carbohydrates in extracts may vary considerably compared to seaweed and the use of acids and alkalis will impact upon its pyrolytic release. The marker compounds for the main carbohydrates used in this study are presented in Table 6.

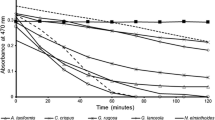

Seaweed species

The characteristic pyrolysis products of fucoidan, mannitol, laminarin and alginic acid (furfural 6.25 min) were present in all five of the brown seaweeds under investigation. However the relative abundances of the pyrolysis products were different for each species indicating compositional differences (Fig. 3) consistent with thermogravimetric data published earlier (Sharma et al. 2011). In particular S. muticum contained only trace levels of mannitol which may therefore originate from the end chains of laminarin rather than free mannitol and L. hyperborea produced less abundant peaks than the other seaweeds due to the high ash content of this sample (Sharma et al. 2011). Additionally, peaks in all species at retention times 31.01, 35.02 and 38.29 min were identified as fatty acids arising from the lipid fraction. The different ratio of the peak areas at these retention times, for each seaweed species suggest differences in the fatty acid profiles between species.

Evaluation of seaweed species showing differences in composition, pyrolysis product numbers identified in Table 6

Lyophilised acidic extracts of all seaweed species from February, showed stimulation of rooting and increased dry matter content of Mung bean plants (Sharma et al. 2011) and were therefore analysed by Py-GC/MS along with the neutral and alkaline extracts from F. serratus. The presence of 1,6-anhydromannopyranose and 1,6-anhydromannofuranose which produce broad peaks between the retention times 25–35 min along with 1-(2-furanyl) ethanone and diannhydromannitol indicated that mannitol was a major component of all lyophilised extracts. The pyrogram from the lyophilised acidic extract from F. serratus is compared to the seaweed it was extracted from in Fig. 4. Although the pyrolysis products of mannitol, fucoidan and laminarin could be detected in F. serratus in the acid extract those from fucoidan were present at much lower levels. However, when treated with either acid or alkali, the ratios of the marker peaks for both fucoidan and laminarin changed significantly compared to the parent seaweed suggesting that the extraction of these carbohydrates or the pyrolysis process itself had been modified by the treatment. Additionally, the polysaccharides themselves may have been chemically modified with a reduced degree of polymerisation. It was therefore not possible to unambiguously confirm the presence of fucoidan and laminarin in the acidic or alkaline sample or indeed the extracts of any of the acidified samples from other species by Py-GC/MS alone.

Comparison of Py-GC/MS profiles of F. serratus and its lyophilised acid extract, product numbers identified in Table 6

Biostimulant formulations

For product D, the pyrolysis products clearly indicated the presence of mannitol, fucoidan and laminarin (Fig. 5). The more intense peaks for the fucoidan markers (2 and 4) compared to the other formulations is consistent with the higher sulphur content of this sample (Table 4). The marker compounds for mannitol, fucoidan and laminarin were also present in product A, although peaks were less abundant than that of D. However, the most abundant peak present in this pyrogram corresponded to 2-phenoxyethanol (Fig. 5). Product B contained the markers for laminarin with diannhydromannitol and 1-(2-furanyl) ethanone also present. As these latter compounds were much less abundant than for product A or D, it is likely that it arises from mannitol in the end chains of laminarin rather than free mannitol. The presence of fucoidan in B could not be confirmed as only one of the marker peaks (5-methyl-2-furancarboxaldehyde) could be detected. This conclusion was supported by the weak band (S═O) at 1244 cm−1 in B (Fig. 11). While 1-(2-furanyl) ethanone, was detected in product C, only traces of diannhydromannitol, 1,6-anhydromannopyranose and 1,6-anhydromannofuranose were found. Therefore, mannitol is unlikely to be a major carbohydrate in sample C (Fig. 5). Only one of the marker peaks for laminarin and none of the expected pyrolysis products of fucoidan were present so this sample had a very different composition to the other commercial samples as a result of its high pH and 120°C extraction. Samples E and F contained the marker compounds identifying mannitol as a major component. Fucoidan and laminarin were easily identified in E, in contrast to the acid extracts from February, but in much lower amounts in F. The differences observed between formulations E and F may explain the higher rate of weight loss ∼250°C in the former sample when analysed by TGA (Fig. 2c).

Comparison of Py-GC/MS profiles of products (A, B, C, D, E and F) showing differences in composition, pyrolysis product numbers identified in Table 6

FTIR

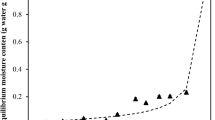

FTIR bands were observed in the 4000–2000 cm−1 region at 3250–3300 cm−1 assigned to OH stretching vibrations and a weak signal at 2,925 cm−1 due to C–H stretching vibrations (data not shown). The medium to strong infrared bands at 1200–970 cm−1 were due to C–C and C–O stretching vibrations in the pyranose ring and to C-O-C stretching of the glycosidic bonds (Chandía and Matsuhiro 2008; Chopin and Whelan 1993; Gómez-Ordóñez and Rupérez 2011; Kačuráková and Wilson 2001). The FTIR spectra of reference alginic acid, mannitol, laminarin and fucoidan samples were compared with the spectra of native seaweed samples and the formulations. Emphasis was given to the 1800–650 cm−1 region, which presents several vibrational modes, sensitive to the type of polysaccharides and glycosidic linkages in seaweeds. The sample spectra exhibited changes in the intensity and the shape of absorption bands after extractions in alkaline, neutral and acidic pH (Figs. 6, 7, 8, 9 and 10, Table 7).

PCA of FTIR spectra (4000–650 cm−1) of the seaweed samples {AN—A. nodosum; FS—F. serratus, FV—F. vesiculosus, LH- L. hyperborea and SM—S. muticum}, extracts {AN-Feb-Acid; or AN-June-Acid [acidic extract]; AN-Feb-N [neutral extract]; AN-Feb-A [alkaline extract]} and reference samples {alginic acid, fucoidan, mannitol and laminarin}

Seaweed species and extracts

The absorption bands of A. nodosum (Fig. 7a) showed well-defined signals after extractions, especially with the acidic protocol, at 1726, 1625, 1575, 1475, 1412, 1336, 1263, 1116, 1077, 1050, 1020, 953, 929, 885 and 732 cm−1, displaying composite characteristics of laminarin, alginic acid and fucoidan (Table 7, band 1–7; Figs. 6–7a). An overlay of F. serratus spectra are shown in Fig. 7b, indicating changes in the absorption bands of acidic extracts at 1561, 1413, 1372, 1316, 1262, 1196, 1076, 1076, 1049, 1022, 952, 927, 884, 783 and 723 cm−1. For example the acidic extract of F. serratus (Fig. 7b) demonstrated distinct spectral bands for mannitol (Fig. 7b) in agreement with Py-GC/MS. In contrast, alkaline and neutral extracts of F. vesiculosus showed similar spectral bands at 1607/1576, 1405/1407, 1253, 1160, 1073/1076, 1022/1023, 932/930, 886/890 and 826 cm−1 showing composite characteristics of alginic acid, laminarin and fucoidan (Fig. 8a). In the case of L. hyperborea major absorption bands were at 1643, 1538, 1411, 1234, 1077, 1028, 797 and 695 cm−1 (Fig. 8b) and the spectral intensity of the extracts improved significantly compared to the spectra of the unextracted biomass. The absorption peak at 1643 cm−1 shifted to 1615, 1626 and 1568 cm−1 in the alkaline, neutral and acidic extracts respectively and also showed intense peaks linked to mannitol (Fig. 8b). The low- intensity spectral bands of S. muticum showed increased intensity after extractions at 1560, 1410, 1079, 1028, 885 and 825 cm−1. The alkaline and neutral extracts exhibited a composite characteristic similar to laminarin and alginic acid (Fig. 9). The raw spectra (4000–650 cm−1) of the reference standards, seaweed samples and their extracts were evaluated by principal component analyses and a majority of the extracted samples from the five species were positioned in the two lower quadrants along with laminarin and also showing a high degree of similarity between laminarin and L. hyperborea extracts (Fig. 10). The unextracted control samples were positioned in the upper quadrants and this observation agreed with the greater relative absorbance of the extracts compared to the unextracted samples.

Biostimulant formulations

FTIR spectra of the 1800–650 cm−1 region of samples A–F are presented in Fig. 11. The absorption bands of product A showed defined signals at 1746, 1604, 1415, 1244, 1033, 1000, 894, 823 and 755 cm−1 displaying composite characteristics of laminarin, alginates and fucoidan. The spectral bands of products A, D, E and F had similar characteristics (e.g. the band at 1604–1610, carboxylate anion; Fig. 11). When considered with the assignments made by Py-GC/MS all four reference compounds are present. The relative position of the carbonyl group (Mathlouthi and Koenig 1987) in alginates shifted to 1600–1610 cm−1 and similar shifts were observed for all test products, except C which showed additional signals at 1665 and 1564 cm−1 linked to alginates and CN stretching, respectively. FTIR spectra of sample D showed spectral signals at 1608, 1416, 1229, 1030 and 819 cm−1 linked to polysaccharides, such as alginic acid, fucoidan and laminarin (Fig. 11) supporting the identification of these compounds by Py-GC/MS. However, sharper spectral intensities of B, indicated better depolymerisation especially in the laminarin fraction (Fig. 11). The spectral features of B at 1590, 1399, 1337, 1116, 1039, 987, 926, 856 and 832 cm−1 were well defined and different from others probably due to the mild alkaline and >40°C process step employed to depolymerise the polysaccharides. The process step was likely to be followed by an acid treatment protocol to enhance breakdown of the organic fractions (lower pH and ash content of sample B; Fig. 11, Tables 3 and 7).

Discussion

Previous reports on composition of biostimulant products were limited to pH, DM and mineral content (Rathore et al. 2009; Rayorath et al. 2008; Temple and Bomke 1989). Elemental analysis of the six samples (A–F) revealed high alkali and alkaline earth metal content (e.g. Ca, K and Na) confirming previous reports (Ross et al. 2008; Ruperez 2000). The differences in the composition of carbon, nitrogen and inorganic fractions were likely to be linked to variations in raw material composition, e.g. time of harvest used and the processing conditions employed for various end-use sectors (e.g. agriculture, horticulture, viticulture and amenity/turf grass). Although products B and C were based on an alkaline extraction process, our results indicated that an acid treatment was employed for product B (e.g. low pH, low ash and high WL2). In contrast, product C exhibited increased char formation due to high K concentration (Roman and Winter 2004). The concentrations of minerals and carbon content in A, E and F were similar due to comparable extraction protocols.

TGA

Anastasakis et al. (2011) reported that laminarin (342°C) decomposed at a similar peak temperature to mannitol (336°C) but recent results (Sharma et al. 2011) indicated differences between laminarin (310°C and 485°C, indicating two thermal steps) and mannitol (325°C). Fucoidan showed decomposition peaks at 223, 420 and 500°C (Sharma et al. 2011) rather than two thermal steps at 200 and 700°C (Anastasakis et al. 2011). The variations in the decomposition temperatures of the major fractions and thermal profile could be due to differences in the composition of reference samples and instrument parameters, heating rate used 25°C min−1 (Anastasakis et al. 2011) and 20°C min−1 (Sharma et al. 2011). Major differences in the test samples (A–F) could be due to the presence of sodium and potassium alginates (Anastasakis et al. 2011; Ross et al. 2009). The acidic or near neutral extracted products A, E and F yielded higher WL values in the 190–450°C band, which can be attributed to the decomposition of the organic component compared to C, in which a stable carbon-cation complex was formed, confirming the influence of alkaline extraction protocol on the rate of decomposition. The thermal profile of product C showed decomposition peaks over all four temperature bands at 140°C, 270°C, 455°C and 738°C linked to the pyrolysis of alginic acid and fucoidan in WL2, followed by the decomposition of char and carbon/inorganic component in WL3 and WL4 respectively (Sharma et al. 2011). The associated minor peak at 150°C for B, C, E and F was due to the release of acetic acid (Sharma et al. 2011). Product D exhibited sharp decomposition at 275°C followed by a secondary peak at 769°C and this latter peak indicated decomposition of carbon bound in the mineral fraction (Anastasakis et al. 2011). Product A exhibited a shoulder at 230°C followed by a major PT at 247°C, caused by the pyrolysis of alginic acid and fucoidan. The following shoulder at 330°C was due to the pyrolysis of mannitol and laminarin (Sharma et al. 2011). The major difference between the profiles of E and F was in the 190–450°C temperature band with a shoulder at 250°C for E, followed by a sharp peak at 298°C. This shoulder was absent in F and the rate of weight loss at 298°C was greater due to a higher mannitol content (Figs. 2 and 11). This conclusion is supported by the intense infrared and Py-GC/MS peaks linked to mannitol content and lower amounts of laminarin and fucoidan markers (Figs. 5, 6 and 11). The weight loss profiles of B, D, E and F showed similar decomposition steps but differed in the peak temperatures at 247°C, 275°C, 292°C and 299°C, respectively due to differences in alginic acid content.

PY-GC/MS

Characteristic pyrolysis products from fucoidan, alginic acid, mannitol and laminarin have been used to identify their selective removal from brown seaweed (Ross et al. 2009). Although some of the products are common to more than one of these saccharides, their relative intensities differ markedly permitting the presence or absence of a particular carbohydrate to be inferred. Compositional differences in the five species of seaweed under investigation in this study were observed by the variation in the relative amounts and ratio of these marker compounds and also in the fatty acid profile. However, for the acidic extracts and biostimulant formulations while compositional differences between samples were easily observable, unambiguous identification of individual carbohydrates was more difficult as the relative amounts of alginic acid, fucoidan, laminarin and mannitol may be very different to that of the parent seaweed. The amount of furfural production from pyrolysis of uronic acids is largely dependent upon whether the carboxylate functional group is present in the free acid or salt form. This can result in a difference of two orders of magnitude in its abundance (Waymack et al. 2004). Ross et al. (2009) detected furfural from the pyrolysis of calcium and sodium alginates although the different cationic species modified the distribution and intensity of the pyrolysis products with furfural not the dominant product for sodium alginate (Ross et al. 2011). Therefore, care must be taken when interpreting the presence or absence of furfural as a marker for alginic acid particularly when samples may have been subjected to acid/alkali treatments.

FTIR

The medium to strong bands in the range of 1800–650 cm−1 could be used to highlight structural variations in the five species, extracts and commercial formulations studied (Figs. 6, 7, 8, 9, 10 and 11). The major spectral segments of the samples, including alginic acid, fucoidan, laminarin and mannitol are listed in Table 7 to allow comparison of the differences as a result of extraction and to aid evaluation of unknown samples.

The relative position of the bands linked to the carbonyl group in alginates can be present as free carboxylic acid (C═O, 1726 cm−1) group in alginic acid and as carboxylate anion (COO¯, 1600–1610 cm−1) form (Table 7; Chandía et al. 2001; Mathlouthi and Koenig 1987; Kačuráková and Wilson 2001). The ratios of d-mannuronic acid (M, 808/796 cm−1) and l-guluronic acid (G, 1075/1025 cm−1) in alginic acids can vary widely according to the species of seaweeds, such as A. nodosum, F. serratus and F. vesiculosus compared with L. hyperborea and S. muticum (Coimbra et al. 1998; Mackie 1971; Sakugawa et al. 2004). In the reference alginic acid sample, the absorbance bands representing the carbonyl group were 1726 and 1405 cm−1 (Barker et al. 1954; Figueira et al. 1996) compared to weak bands (1634–1650 and 1405–1420 cm−1) for alginates in F. vesiculosus, L. hyperborea and S. muticum. The differences in absorbance between reference compound and cell wall material may be due to higher symmetry in the native matrix which occurred due to the crosslinking of the carboxyl groups by cations (Ca, Mg, K; Figueira et al. 1996). In addition, absorption peaks at 1035, 1072, 1108, 1154 and 1203 cm−1 for laminarin suggested a mixture of predominantly 1,3-ß with a small proportion of 1,6-ß linked structure (Nelson and Lewis 1974; Silverstein et al. 1991). The absorption band at 1210–1240 cm−1 can be attributed to asymmetrical stretching of S═O bonds in fucoidan (Barker et al. 1954; Patankar et al. 1993). This segment was observed in a majority of the seaweed species and biostimulant products tested except product B where it could not be identified by Py-GC/MS (Figs. 7, 8, 9 and 11; Table 7). An additional sulphate band at 820–850 cm−1 was reported to be linked at a C-4 axial position on fucose (Patankar et al. 1993). A shoulder was observed at 790–800 cm−1 [suggesting sulphate groups (C–S–O) at C-2 or C-3]. The band at 690–700 cm−1 can be attributed to the asymmetric and symmetric O═S═O deformation of sulphates (Barker et al. 1954; Figueira et al. 1996; Patankar et al. 1993).

There are numerous commercial biostimulants available worldwide and the majority of extracts are made from brown algae using a range of extraction protocols (Christobel 2008; Rathore et al. 2009; Rayorath et al. 2008; Spinelli et al. 2010). The six formulations prepared using different extraction processes showed variations in composition, e.g. high and low mannitol content, which would impact on bioactivity. The cations and anions in the products may need to be balanced in order to maintain stability of the active biomolecules (Milton 1952; Temple and Bomke 1989). The commercial manufacturers have adopted a raw material preparation step to remove epiphytes and residual salt, followed by mechanical reduction of particle size, using a cutter or high pressure plant cell burst technology at ambient conditions (Temple and Bomke 1989). The product yield from the low temperature environment friendly process step is likely to be high as all materials can be blended mechanically. In addition, the end products can be modified with bioactive mineral compounds, plant/microbial extracts, growth hormones and amino acids to enhance bioactivity and reduce use of fungicides and pesticides, e.g. Actiwave® and Ferriton (Rathore et al. 2009; Spinelli et al. 2010).

Plant oligosaccharides, consisting of a mixture of 4–8 DP (degree of polymerization) oligomers, have shown regulatory functions in cell growth, morphogenesis and defence reactions and these effects have been demonstrated with a range of xyloglucan fragments (Dumville and Fry 2000). The commercial products need to be evaluated regularly for particle size distribution and DP of oligomers for reducing production cost, leading to an efficient use of valuable raw materials and improving productivity with decreasing environmental impact of the process steps. The transportation and storage of products should also be evaluated to identify interaction of volume, temperature, shelf life and its impact on product quality.

Conclusion

The biostimulant manufacturers require rapid quality assurance (QA) protocols for evaluating raw materials and processed products. This study has shown that TGA, EDX, Py-GC/MS and FTIR are complementary techniques and sensitive to changes in composition for rapid evaluation of seaweed materials and commercial products. For example: TGA and EDX can provide information on the proportions of algal cell wall and inorganic fractions. FTIR can provide information on the extraction protocol (e.g. acidic or alkaline). The identity of major carbohydrate fractions can be confirmed by Py-GC/MS and FTIR. Both methods are promising techniques to identify key components in unknown samples. In addition, the sample preparation methods used in this study required no chemical extraction and the four techniques could carry out qualitative and semi quantitative evaluation of unknown samples. The reduction in environmental impact of using the techniques as QA tools is obvious compared to complex wet chemical protocols and this aspect should be considered as part of an overall impact assessment of biostimulant production.

References

Anastasakis K, Ross AB, Jones JM (2011) Pyrolysis behaviour of main carbohydrates of brown macro-algae. Fuel 90:598–607

Barker SA, Bourne EJ, Stacey M, Whiffen DH (1954) Infrared spectra of carbohydrates Part 1. Some derivative of D-glucopyranose. J Chem Soc 171–176

Bilan M, Grachev AA, Ustuzhanina NE, Shashkov AS, Nifantiev NE, Usov AI (2004) A highly regular fraction of a fucoidan from the brown seaweed Fucus distichus L. Carbohyd Res 339:511–517

Chandía NP, Matsuhiro B (2008) Characterization of a fucoidan from Lessonia vadosa (Phaeophyta) and its anticoagulant and elicitor properties. Int J Biol Macromol 42:235–240

Chandía B, Matsuhiro E, Mejías E, Moenne A (2001) Alginic acids in Lessonia vadosa: characterisation by formic acid hydrolysis and FTIR. Carbohyd Poly 46:81–87

Chopin T, Whelan E (1993) A new rapid method for carrageenan identification by FTIR diffuse reflectance spectroscopy directly on dried, ground algal material. Carbohyd Res 246:51–59

Christobel GJ (2008) Effect of seaweed (Sargassum weightii L.) on the germination and growth of green gram (Phaseolus aureus, L.). J Basic Appl Biol 2:105–108

Coimbra MA, Barros A, Barros M, Rutledge DN, Delgadillo I (1998) Multivariate analysis of uronic acid and neutral sugars in whole pectic samples by FT-IR spectroscopy. Carbohyd Polym 37:241–248

Dumville JC, Fry SC (2000) Urionic acid-containing oligosaccharins: their biosynthesis, degradation and signalling roles in non-diseased plant tissue. Plant Physiol Biochem 38:125–140

Figueira MM, Volesky B, Mathieu HJ (1996) Instrumental analysis study of iron species biosportion by Sargassum biomass. Environ Sci Technol 30:277–282

Gómez-Ordóñez E, Rupérez P (2011) FTIR-ATR spectroscopy as a tool for polysaccharide identification in edible brown and red seaweeds. Food Hydrocolloids 25:1514–1520

Helleur RJ (1987) Characterization of the saccharide composition of heteropolysaccharides by pyrolysis-capillary gas chromatography-mass spectrometry. J Anal Appl Pyrolysis 11:297–311

Kačuráková M, Wilson RH (2001) Developments in mid-infrared FT-IR spectroscopy of selected carbohydrates. Carbohyd Polym 44:291–303

Khan W, Rayirath UP, Subramanian S, Jithesh MN, Rayorath P, Hodges DM, Critchley AT, Craigie JS, Norrie J (2009) Seaweed extracts as biostimulants of plant growth and development. J Plant Growth Regul 28:386–399

Leal D, Matsuhiro B, Rossi M (2008) FT-IR spectra of alginic acid block fractions in three species of brown seaweeds. Carbohyd Res 343:308–316

Mackie W (1971) Semi-quantitative estimation of the composition of alginates by infra-red spectroscopy. Carbohyd Res 20:244–248

Mathlouthi M, Koenig JL (1987) Vibrational spectra of carbohydrates. Adv Carbohyd Chem Biochem 44:82–89

Matsuhiro B (1996) Vibrational spectroscopy of seaweed galactans. Hydrobiologia 326(327):481–489

Milton RF (1952) Improvements in or relating to horticultural and agricultural fertilizers. British Patent 664989

Nelson TE, Lewis BA (1974) Separation and characterization of soluble and insoluble components of insoluble laminarin. Carbohyd Res 33:63–74

Patankar S, Oehniger S, Barnett T (1993) A revised structure of for fucoidan may explain some its biological activities. J Biol Chem 268:21770–21776

Pereira L, Amado AM, Critchley AT, van de Velde F, Ribeiro-Claro PJA (2009) Identification of selected seaweed polysaccharides (phycocolloids) by vibrational spectroscopy (FTIR-ATR and FT-Raman). Food Hydrocolloids 23:1903–1909

Rathore SS, Chaudhary DR, Boricha GN, Ghosh A, Bhatt BP, Zodape ST, Patolia JS (2009) Effect of seaweed extract on the growth, yield and nutrient uptake of soybean (Glycine max) under rainfed conditions. S Afr J Bot 75:351–355

Rayorath P, Khan W, Palanisamy R, MacKinnon SL, Stefanova R, Hankins SD, Critchley AT, Prithiviraj B (2008) Extracts of the brown seaweed Ascophyllum nodosum induce gibberellic acid (GA3)-independent amylase activity in barley. J Plant Growth Regul 27:370–379

Rioux L-E, Turgeon SL, Beaulieu M (2007) Characterization of polysaccharides extracted from brown seaweeds. Carbohyd Polym 69:530–537

Roman M, Winter WT (2004) Effect of sulphate groups from sulphuric acid hydrolysis on the thermal degradation behaviour of bacterial cellulose. Biomacromolecules 5:1671–1677

Ross AB, Jones MJ, Kubacki ML, Bridgeman T (2008) Classification of macroalgae as fuel and its thermochemical behaviour. Bioresource Technol 99:6494–6504

Ross AB, Anastasakis K, Kubacki M, Jones JM (2009) Investigation of the pyrolysis behaviour of brown algae before and after pre-treatment using PY-GC/MS and TGA. J Anal Appl Pyrol 85:3–10

Ross AB, Hall C, Anastasakis K, Westwood A, Jones JM, Crewe RJ (2011) Influence of cation on the pyrolysis and oxidation of alginates. J Anal Appl Pyrol 91:344–351

Ruperez P (2000) Mineral content of edible marine seaweeds. Food Chem 79:23–26

Sakugawa K, Ikeda A, Takemura A, Ono H (2004) Simplified method for estimation of composition of alginates by FTIR. J Appl Polym Sc 93:1372–1377

Sharma HSS, Lyons G, McRoberts C, McCall D, Carmichael E, Andrews F, Swan R, McCormack R, Mellon R (2011) Biostimulant activity of brown seaweed species from Strangford Lough: Compositional analyses of polysaccharides and bioassay of extracts using Mung bean (Vigno mungo L.) and Pak Choi (Brassica rapa chinensis L.). J Appl Phycol. doi:10.1007/s10811-011-9737-5

Silverstein RM, Clayton BG, Morrill TC (1991) Spectrometric identification of organic compounds. Wiley, New York

Spinelli F, Fiori G, Noferini M, Sprocatti M, Costa G (2010) A novel type of seaweed extract as a natural alternative to the use of iron chelates in strawberry production. Sci Hortic 125:263–269

Synytsya A, Kim W, Kim S, Pohl R (2010) Structure and antitumour activity of fucoidan isolated from sporophyll of Korean brown seaweed Undaria pinnatifida. Carbohyd Polym 81:41–48

Temple WD, Bomke AA (1989) Effects of kelp (Macrocystis integrifolia and Ecklonia maxima) foliar applications on bean crop growth. Plant Soil 117:85–92

Waymack BE, Belote JL, Baliga VL, Hajaligol MR (2004) Effects of metal salts on char oxidation in pectins/uronic acids and other acid derivative carbohydrates. Fuel 83:1505–1518

Zvyagintseva TN, Shevchenko NM, Popivnich IB, IsakovVV SAS, Sundukova EV, Elyakova LA (1999) A new procedure for the separation of water-soluble polysaccharides from brown seaweeds. Carbohyd Res 322:32–39

Acknowledgements

We wish to acknowledge the Department of Agriculture and Rural Development for Northern Ireland for providing facilities. We wish to thank Cookham Spectrsocopy (UK), Bioatlantis (Ireland), Neomed Pharma (Germany) and OGT (Ireland). The authors have declared no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shekhar, S.H.S., Lyons, G., McRoberts, C. et al. Brown seaweed species from Strangford Lough: compositional analyses of seaweed species and biostimulant formulations by rapid instrumental methods. J Appl Phycol 24, 1141–1157 (2012). https://doi.org/10.1007/s10811-011-9744-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-011-9744-6