Abstract

This paper was aimed to modify gold electrode surface with a BODIPY derivative and to examine its electrochemical behavior on the modified surface. Firstly, a BODIPY derivative including azido terminal was synthesized and characterized with several techniques such as NMR, FT-IR, element analysis and melting point. For the electrochemical studies, a triple electrode system was applied, with Gold electrode, Ag/AgCl (in aqueous medium) or Ag/Ag+ (in non-aqueous medium) and a Pt wire. The modified surface has been characterized using different electrochemical techniques. Then, the morphologies of the bare and modified electrode surfaces were evaluated with Scanning Electron Microscopy and Atomic Force Microscope. The metal adsorption property of the modified surface was investigated by using a copper solution.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Numerous BODIPY syntheses have been published over the years of the first BODIPY complex of Dipyrromethenes, reported by Treibs and Kreuzer in 1968. BODIPY dyes have many excellent optical properties such as great absorption coefficients, excellent chemical and photochemical stability, great fluorescence quantum yields, long excited-state lifetimes as well as high solubility in organic solvents [1, 2].

Because of their wonderful properties, BODIPY dyes are used in medical expertise such as bio labeling, bioimaging, PDT, photodynamic therapy of cancer, etc. and different application areas such as solar energy conversion, chemical sensing, optoelectronic devices, laser dyes [3,4,5,6,7,8,9,10,11]. BODIPY dyes are unique materials with electrochemical properties comparable to those of aromatic hydrocarbons. Electrochemical studies to understand the redox properties of these complexes are beneficial [12, 13]. Most of the BODIPY research that has been done is on their properties, and there is less work on their electrochemical properties [14, 15]. But recently, electro-polymerization of BODIPY dyes containing electroactive groups has been investigated to produce low band gap polymers, electrochromic materials [16,17,18,19]. It has been observed that BODIPY dyes show good redox properties and exhibit both reduction and oxidation waves due to the addition or removal of electrons from the π-system [20, 21].

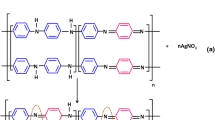

In this study, the electrochemical behavior of 8-{4-(azidomethyl)phenyl}-4,4-difluoro-1,3,5,7-tetramethyl-4-bora-3a,4a-diaza-s-indacene (BODIPY-I) (Fig. 1), which is a derivative of BODIPY synthesized for the first time by Kursunlu and his research group [22,23,24,25,26,27,28] was investigated by spectroscopic and electrochemical techniques on the gold electrode surface. Metal adsorbing property of the prepared BODIPY-I /Au surface in Cu2+ solution was investigated.

2 Experimental

2.1 Materials

Acetic acid (100%) and potassium chloride (99.0%) were purchased from Riedel-de Haen. Acetonitrile (CH3CN, ACN, 99.9%) was purchased from J.T.Baker. Copper (II) chloride (98.0%), boric acid (99.8%), o-phosphoric acid (85.0%), sodium hydroxide (97.0%), hydrochloric acid (37%) and sulfuric acid (95.0%) were purchased from Merck. Potassium ferricyanide (98.0%) and Potassium ferrocyanide (98.0%) were purchased from Alfa Aesar. Ruthenium hexamine (III) chloride (98.0%), sodium acetate trihydrate (99.0%) and tetrabutylammonium tetrafluoroborate (TBATFB, 99.0%) were purchased from Sigma-Aldrich. BODIPY-I was prepared a known synthesis procedure.

2.2 Instruments

While Gamry Reference 600 and Series G 750 potentiostate/galvanostat/ZRA instruments were used for electrochemical studies, applications of electrochemical impedance spectroscopy (EIS) technique were made with EIS 300. Gamry Framework, Echem Analyst, PHE 200, PV 220 and EIS 300 software in the computer system connected to the main unit were used to automatically perform the applied voltametric techniques and EIS technique and to evaluate the data obtained from these computer-controlled electrochemical measurement systems. A three-electrode Bioanalytical system (BAS) C3 cell system was used for electrochemical studies in which working, reference and counter electrodes were used together.

BAS Model MF-2013 gold (Au) electrode was used as working electrode. The reference electrode was used as: (i) a Ag/AgCl in saturated KCl (Ag/AgCl/(sat.KCl)), which was used in aqueous media; or (ii) a Ag/Ag+ (in 10 mM AgNO3), which was used in non-aqueous media [to prepare a Ag/Ag+ reference electrode, 10 mM AgNO3 was dissolved in acetonitrile (CH3CN) with 100mM tetrabutylammoniumtetrafluoroborate (TBATFB)]. Pt wire was used as counter electrode.

2.3 Preparation and modification of gold electrode

The slightest contamination on the electrode surface can cause adverse effects such as the decrease in the peak current in voltammograms and negative or positive shifts in the peak potential. Before starting the electrochemical experiments, the surfaces of the working electrodes to be used in the experiment must be clean. The purpose of electrode surface cleaning processes can be explained as the removal of substances adsorbed to the surface that interferes with electron transfer [29]. For this purpose, the gold (Au) electrode was first electrochemically cleaned in 0.1 M H2SO4 solution for 10 cycles in the potential range of − 0.2/+ 1.8 V. Then, suspended alumina powder was placed on the velvet surface, and this electrode was cleaned with alumina powder in circular movements in equal numbers. After cleaning with alumina, the electrode surface was washed with pure water to remove any alumina dust that might remain on the surface. Then, the electrode was sonicated in pure water and acetonitrile for three minutes each.

The gold electrode surface was modified by the drop dry method [21, 30]. 20 µL of BODIPY-I solution (1.0 × 10− 3 M) prepared in ACN medium containing 0.1 M tetrabutylammonium tetrafluoroborate as the supporting electrolyte was dropped to the cleaned gold (Au) electrode surface, and then the electrode surface was waited to dry at room temperature. The surface prepared after this step was defined as BODIPY-I/Au electrode.

3 Results and discussions

3.1 Characterization of the modified electrode

Since the BODIPY dye includes a near planar π-system and the two pyrrole rings being held co-planar by the tetrahedral geometry of the boron atom, there is scope for adsorption onto the electrode through π–π stacking similarly to what has been defined before with phthalocyanines [31, 32]. The modified electrodes were prepared and characterized several times.

3.2 Electrochemical characterization of bare Au and BODIPY-I/Au surfaces by cyclic voltammetry

The electron transfer behavior of the bare and modified BODIPY-I/Au electrode was examined using the cyclic voltammetry (CV) technique in 1mM Fe(CN)63− solution prepared in Britton–Robinson (BR) buffer solution (pH 2.0) (Fig. 2). The varying peak potentials are the result of different surfaces of the electrodes showing the different ability to electron transfer [33].

Bare electrode surface allowed electron transfer for Fe(CN)63−, while modified electrode surface coated with BODIPY-I did not allow electron transfer for Fe(CN)63−. Thus, it was determined as a result of the surface modification that a different surface was obtained from the bare electrode surface. It shows that the electrode surface is modified with BODIPY-I material since the currents and potentials of the Fe(CN)63− peaks cannot be determined on the electrode surface. We can say that the azide unit in the BODIPY-I compound binds to the gold electrode surface, thus the compound is modified to the surface. However, this does not mean that the desired analytes cannot be determined [21, 34].

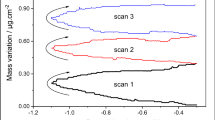

A scan rate study was performed to examine the reversibility or irreversibility of the reaction on the electrode surface modified with BODIPY-I and to determine whether the redox process of BODIPY-I material on the gold electrode surface is diffusion-controlled or adsorption-controlled. For this purpose, cyclic voltammograms were taken at different scan rates in 1.0 × 10− 3 M BODIPY-I solution (Fig. 3A).

The slope value of logV − logIp graphs gives information about whether the redox processes are diffusion or adsorption controlled. In diffusion-controlled processes, 0.5 as the slope value is the theoretical value [35,36,37] (Fig. 3B). In Fig. 3B, it is observed that the reaction occurring on the surface is not diffusion-controlled because of the slope is not close to 0.5.

3.3 Characterization of bare Au and BODIPY-I/Au surfaces by EIS

Bare Au and BODIPY-I/Au electrode surfaces were spectroscopically characterized by the EIS technique and the results were compared (Fig. 4).

When the data obtained as a result of the characterization with the EIS technique were evaluated, it was observed that the modified electrode surface showed more resistance to electron transfer in the Fe(CN)63−/Fe(CN)64− a solution containing the redox couple relative to the bare electrode surface. It shows that the BODIPY-I compound formed a film on the electrode surface and it was concluded that these data can be supported by the results obtained using the cyclic voltammetry technique.

3.4 The morphology of bare Au and BODIPY-I/Au surfaces by scanning electron microscope (SEM)

The Scanning Electron Microscopy technique was used to take surface images of the electrode surfaces, to have information about the surface morphology of the electrodes and to observe the physical changes on the electrode surfaces (Fig. 5) [38].

The morphology of the BODIPY-I coated Au surface was characterized by SEM (ZEISS EVO LS 10). When the SEM images are examined, it is clearly seen that the empty gold surface (Fig. 5a) has a flat and smooth structure before the coating and that there are deposits of BODIPY-I on the gold surface after the coating (Fig. 5b). The BODIPY-I film layer formed on the surface after coating had been created pores on the surface. This increased the microscopic area of the electrode and facilitated the interlayer diffusion of analyte species [39].

As can be seen from the figures above, when the SEM image of the surface of the modified electrode was compared with the image of the bare electrode, it was seen that the surface images are different. These surface images prove that the electrodes have been modified with BODIPY-I.

3.5 Topography of bare Au and BODIPY-I/Au surfaces by atomic force microscopy (AFM)

The topography of the electrode surface modified with BODIPY-I was also investigated by AFM studies. The presence of BODIPY-I substance on the electrode surface was demonstrated from AFM images (Fig. 6).

The significant increase in the roughness of the gold surface after coating indicated that BODIPY-I molecules were bound. The average roughness values (root mean square, rms) were 3.81 nm for the bare gold surface (Fig. 6a) and increased to 28.40 nm after coating (Fig. 6b). The higher sensitivities in electrochemical measurements can be expected using this modified electrode [40].

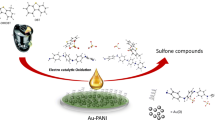

3.6 Metal application

To find the application areas of the prepared BODIPY-I/Au electrode surface and to examine the metal retention of the BODIPY-I material modified to the surface, BODIPY-I/Au electrode was immersed in CuCl2 solution (acetate buffer pH 5.0) and kept for different times (1; 2; 4; 12 h). It was reduced using the cyclic voltammetry technique (− 0.9/+ 0.9 V), then the copper retained on the surfaces was stripped by applying the differential pulse voltammetry technique (− 0.3/+ 0.3 V). Then, the metal retention of the prepared electrodes was examined. It was determined as a result of the analysis that the copper was retained on the electrode surface. The variation with time of the bonding capacity of copper on the electrode surfaces was investigated from the peak current heights of the differential pulse voltammograms shown in Fig. 7A.

To understand whether copper or whether functional groups in the BODIPY-I compound of material were stripped from the surface, BODIPY-I/Au electrode surface was kept in pH 5.0 buffer solution for the same periods. The same procedures were applied to these electrodes with the techniques of cyclic voltammetry and differential pulse voltammetry, respectively. The resulting voltammograms were recorded (Fig. 7B). The obtained peak current heights were compared with the peak current heights obtained by copper stripping (Table 1).

The results obtained from the BODIPY-I/Au electrode surface kept in Cu2+ and acetate buffer (pH 5.0) solutions are shown in Table 1.

According to the results obtained; It has been determined that the BODIPY-I/Au electrode surface is an active electrode in terms of metal retention. According to the test results in the copper solution medium, the gold electrode surface kept the copper for up to 4 h, after the 4th hour, no more copper could hold on the surface and the copper got off by oneself from the surface.

4 Conclusions

Due to the small number of electrochemical studies with BODIPY compound in the literature, the redox study of a BODIPY dyestuff was investigated in this study. The newly synthesized BODIPY-I compound was modified to the Au electrode surface by the drop-dry method. Our goal of surface modification with BODIPY-I dyestuff was successful. Successful results were obtained by examining the redox properties of BODIPY-I with electrochemical methods. In order to use the gold electrode as an electrochemical sensor, the change in the quality and conductivity of the electrode surface was investigated. The prepared electrode surface was successfully characterized and its usability in the field of metal applications was determined by voltametric methods. It is thought that this new electrode can be used successfully in studies to be carried out on the accumulation and removal of heavy metal copper.

Data availability

Not applicable.

References

Treibs A, Kreuzer FH (1968) Liebigs Ann Chem 718:208–223

Loudet A, Burgess K (2007) Chem Rev 107:4891–4932

Bonardi L, Kanaan H, Camerel F, Jolinat P, Retailleau P, Ziessel R (2008) Adv Funct Mater 18:401–413

Erten-Ela S, Yilmaz MD, Icli B, Dede Y, Icli S, Akkaya EU (2008) Org Lett 10:3299–3302

Lim SH, Thivierge C, Nowak-Sliwinska P, Han J, Van Den Bergh H, Wagnieres G, Burgess K, Lee HB (2010) J Med Chem 53:2865–2874

Kim TI, Park J, Kim Y (2011) Chem Eur J 17:11978–11982

Zhang D, Martín V, García-Moreno I, Costela A, Pérez-Ojeda ME, Xiao Y (2011) Phys Chem Chem Phys 13:13026–13033

Ni Y, Wu J (2014) Org Biomol Chem 12:3774–3791

Kue CS, Ng SY, Voon SH, Kamkaew A, Chung LY, Kiew LV, Lee HB (2018) Photochem Photobiol Sci 17:1691–1708

Zhang T, Ma C, Sun T, Xie Z (2019) Coord Chem Rev 390:76–85

Cetindere S (2020) Am J Biomed Sci Res 7:93–95

Lai RY, Bard AJ (2003) J Phys Chem B 107:5036–5042

Bura T, Ziessel R (2010) Tetrahedron Lett 51:2875–2879

Niu S, Ulrich G, Retailleau P, Ziessel R (2011) Tetrahedron Lett 52:4848–4853

Lakshmi V, Lee W-Z, Ravikanth M (2014) Dalton Trans 43:16006–16014

Forgie JC, Skabara PJ, Stibor I, Vilela F, Vobecka Z (2009) Chem Mater 21:1784–1786

Nöll G, Daub Jr, Lutz M, Rurack K (2011) J Org Chem 76:4859–4873

Algi F, Cihaner A (2012) Polymer 53:3469–3475

Biyiklioglu Z, Keleş T (2017) Inorg Chim Acta 466:130–138

Nepomnyashchii AB, Bard AJ (2012) Acc Chem Res 45:1844–1853

Ndebele N, Mack J, Nyokong T (2019) Electroanalysis 31:137–145

Bastug E, Kursunlu AN, Guler E (2020) J Lumin 225:117343

Kursunlu AN, Oguz M, Yilmaz M (2018) IEEE Sens J 19:2009–2015

Kursunlu A.N., Güler E, J. Mol. Struct, 2017, vol. 1134, 345–349.

Kursunlu AN (2014) RSC Adv 4(88):47690–47696

Kursunlu AN, Koc ZE, Obalı AY, Güler E (2014) J. Luminescence 149:215–220

Kursunlu AN (2015) Tetrahedron Lett 56(14):1873–1877

Kursunlu AN, Ozmen M, Güler E (2019) J Fluorescence. 29:1321–1329

Bilici E (2012) MS Thesis, Konya, Turkey: Selçuk University, Ins. Sci.

Peeters K, De Wael K, Vincze L, Adriaens A (2005) Anal Chem 77:5512–5519

Centane S, Achadu OJ, Nyokong T (2017) Electroanalysis 29:2470–2482

Nyoni S, Mugadza T, Nyokong T (2014) Electrochim Acta 128:32–40

Elgrishi NM, Rountree KJ, McCarthy BD, Rountree ES, Eisenhart TT, Dempsey JL (2018) J Chem Educ 95:197–206

Mpeta LS, Fomo G, Nyokong T (2018) J Coord Chem 70:1623–1638

He D, Zhang P, Li S, Luo H (2018) J Electroanal Chem 823:678–687

Tabanlıgil Calam T (2019) GU J Sci Part C 7:985–998

Öztekin Y, Yazıcıgil Z, Univ S (2008) J Sci Faculty 2:1–8

Del Rosso M, Brodie CH, Ramalingam S, Cabral DM, Pensini E, Singh A, Collier CM (2019) Sci Rep 9:1–8

Şenocak A, Köksoy B, Akyüz D, Koca A, Klyamer D, Basova T, Demirbaş E, Durmuş M (2019) Biosens Bioelectron 128:144–150

Uzun D, Arslan H, Gündüzalp AB, Hasdemir E (2014) Surf Coat Technol 239:108–115

Funding

This work was financially supported by Selçuk University/Scientific Research Projects Coordination Unit (Project No. 20201012).

Author information

Authors and Affiliations

Contributions

TG carried out the electrochemical applications. ZY carried out the some measurements. ANK synthesized compounds. EG wrote the main manuscript text.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gover, T., Yazicigil, Z., Kursunlu, A.N. et al. A new gold electrode modified with azido-terminal BODIPY derivative: synthesis, characterization and electrochemical property. J Appl Electrochem 54, 361–367 (2024). https://doi.org/10.1007/s10800-023-01963-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-023-01963-3