Abstract

The behavior of cuprous species at electrodes polarized in hydrochloric acid solutions has been investigated in order to obtain the fundamental knowledge of electrodeposition of copper from chloride media. The rest potentials of the cuprous/copper couple in hydrochloric acid solutions were determined by the activity of the Cu+ aquo cuprous ions. It was found that the rest potential could be controlled by the concentration of chloride ions according to their correlation with the aquo species. Dissolution of metallic copper primarily yielded Cu(I) species in hydrochloric acid solutions, in contrast to the Cu(II) species in sulfuric acid solutions. However, cuprous chloride precipitation may also appear in 1–2 mol dm−3 hydrochloric acid solutions and even cuprous oxide may be formed at the surface of the copper electrode at higher HCl concentrations. The experimental results suggested the possibility to produce a relatively dense and smooth deposited surface, while reducing the power consumption of copper electrowinning.

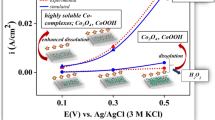

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Copper is an outstandingly important base metal, widely used as conductive material. Extracting it from ores, either by pyro- or hydrometallurgical routes is becoming increasingly difficult because of the deterioration of ore quality, environmental concerns, political instability, transportation costs, etc. However, a concept of urban mining—as an alternative source of valuable materials—has been proposed by Nanjo [1] and it has received genuine attention. It also implies the need of developing novel extracting methods, corresponding to the various compositions of the waste materials.

The extracting route applying halide media may be advantageous. The properties of halides (e.g. vapor pressures, solubilities, etc.) are quite specific. Utilizing these characteristics, various attempts have been tested and reported. Among them, separation of copper and other valuable metals from printed circuit boards by chlorination or bromination followed by distillation has been investigated [2, 3]. The final step, however, should always be the recovery of the metal from the separated halides. Extraction by electrolysis can be a direct solution. It has been applied to the recycling of pure tin by the electrorefining of soldering waste materials in chloride media [4]. The major concern was related to the cathodic deposition with an acceptable surface morphology and current efficiency.

The authors have been investigating the purification processes of base metals by anion-exchange separation in chloride media [5,6,7,8,9]. This approach has resulted in ultra-high purity copper extracted from the purified chloride solution by evaporation to dryness followed by hydrogen reduction implying the potential of contamination but no refining effect. Higher purity is expected to be attainable when it is substituted by electrowinning, which may have further refining effect and helps avoiding any contamination.

Electrodeposition from the Cu(II) species in CuCl2–HCl solutions is difficult. Intermittent stirring of the electrolyte may facilitate the production of dense cathodes, but smooth surface was hardly obtained, while the current efficiency was usually found very low [10, 11]. Pure cupric chloride solutions may not be practically applied as electrolytes because of the serious corrosion of the copper cathode. The corroding effect is provoked by the attack of cupric species on the metallic copper, caused by the com-proportionation reaction [12]:

where Kcomp. is the average equilibrium constant of the com-proportionation reaction in the hydrochloric acid solutions applied. Conversely, electrodeposition from the Cu(I) species can successfully result in the production of metallic copper at the cathode [13,14,15], but they did not use hydrochloric acid solutions. The process implies a further technical advantage of lower electric power consumption resulting from the single charge on the cuprous species to be neutralized at the cathode. This may also be considered as a contribution to a sustainable society.

However, electro crystallization from aqueous chloride solutions may often result in roughly dendritic or powdery deposits [10, 11, 16]. Jin et al. obtained denser surface from cupric chloride aqueous electrolyte by controlling mass transport of cupric species and Cu2O was included in the deposit [11]. Park et al. investigated dendritic Cu deposits using chloride and sulfate aqueous electrolyte and it was found that a density of Cu dendrite from chloride aqueous electrolyte was the lowest [16]. Therefore, some investigations have been devoted also to the electrodeposition of cuprous species from alkaline halides or ammoniacal alkaline electrolytes [13,14,15], reporting denser, but also dendritic deposits too. Relatively smooth cathode surface has been obtained from ammoniacal electrolytes, and Oishi et al. have found that gelatin can be useful for reducing the surface roughness [15], however the application of any additives should be avoided if super pure copper is aimed to be deposited.

Due to the efficiency considerations, electrodeposition from cuprous species is preferable, and the presence of cupric species should be avoided in order to prevent com-proportionation reaction in chloride solutions. Therefore, it is desired that cuprous species be anodically dissolved from copper electrode. A mechanism of anodic dissolution of copper in chloride aqueous media was proposed [17,18,19,20,21,22,23,24,25], which however contains some ambiguity.

The purpose of this work is to clarify the polarization behavior of copper in chloride aqueous electrolytes involving the electrolytic deposition of cuprous species and the anodic dissolution of copper, in order to justify the concept of an efficient electrolysis process in cuprous chloride media. Therefore, a detailed potentiodynamic investigation was carried out to expand the knowledge of electrolysis of copper in hydrochloric acid solutions. As a result, a model of anodic dissolution of copper in hydrochloric acid solution is proposed, in addition to the interpretation of the cathodic deposition from the complexing chloride electrolyte.

2 Experimental procedure

In order to interpret the characteristic phenomena of the copper electrode in cuprous chloride electrolyte solutions, potentiodynamic examination of the polarization behavior is the fundamentally required technique. The measured potentials can be related to the activities of the electro active ions also influenced by the stabilities of the various chloro complex species. The correlation of the computed and the measured values may reveal the nature of this particular system.

2.1 Electrolytic cell

Due to the simultaneous redox and chloro complex formation and decomposition equilibria in the Cu–HCl–H2O system, coupled by the possibility of chloride precipitation [10], stabilizing the examined conditions at the electrode required a special technical setup. The schematic diagram of the equipment is shown in Fig. 1. The cell of 350 cm3 volume on the left was connected to a reducing reactor of 1 dm3 on the right, both made of Pyrex™ glass and equipped with water jackets. The temperature during polarization was regulated at 20 °C by thermostated water circulation. Saturated calomel electrode (S.C.E.) was used as the reference. The other two electrodes in the standard setup were made of high purity copper (∼ 99.999%). The working electrode was embedded in resin, allowing an active surface area of 1 cm2. Mechanical polishing was applied up to #1500 emery paper prior to installation. The distance between the working and counter electrodes was set at 5 cm. The reference electrode was connected to a Luggin-Haber capillary [26] with the tip positioned close to the central surface of the working electrode. These electrodes were connected to a potentiostat of the HAL-3001 and HB-305 models made by HOKUTO DENKO CORPORATION. As a special feature of the equipment, the electrolyte was circulated by a peristaltic pump from the reducing reactor to the cell and the Luggin-Haber capillary. The electrolyte was agitated by a magnetic stirrer with a 30 mm long football shaped stirring bar.

2.2 Preparation of electrolyte

Three types of electrolytes were investigated in this series of experiments: cuprous or cupric species in hydrochloric acid solutions and cupric species in sulfuric acid solution. Solubility of cuprous species in hydrochloric acid solutions [27] is poor relative to cupric species in either hydrochloric [28] or sulfuric acid solutions [29]. Figure 2 shows the relevant solubilities in both acid media. The concentrations of cuprous species in the electrolytes were set within their solubilities at the lowest examined hydrochloric acid concentration. Hence, the compositions of electrolytes were determined as shown in Table 1 and enabled by the sufficient solubilities as shown in Fig. 2. The electrolysis of cupric species in hydrochloric and sulfuric acid solutions were performed with the same copper and acid concentrations for comparison.

For preparing the electrolyte, special grade CuCl2·2H2O and CuSO4·5H2O (Wako Pure Chemical Industries, Ltd.) were dissolved, in appropriate concentrations of hydrochloric and sulfuric acid solutions, respectively. Also, special grade hydrochloric and sulfuric acid solutions were used, diluted with deionized water whose resistivity was more than 18.2 MΩ cm.

Cupric species were reduced to the cuprous state using high purity copper wire chips as reagent in the reducing reactor on the right in Fig. 1, following the com-proportionation reaction represented by Eq. (1). As cuprous species are easily oxidized by oxygen from the atmosphere [5], special care was taken to maintain reduced conditions. Inert gas, N2, purging eliminated atmospheric air from both of the electrolysis cell and the reducing reactor. Completion of reduction can be observed, as cuprous chloro complexes are colorless, thus the solution must be transparent. Then cuprous species were transferred to the electrolysis cell on the left. The electrolyte was circulated during electrolysis to keep concentrations constant.

The concentrations of copper were analyzed by titration with ethylene-diamine-tetraacetic acid (EDTA) using murexide as the indicator after neutralization with sodium hydroxide using methyl orange as an indicator, respectively [30]. The following pretreatment was necessary for the analysis of cuprous concentration. One cm3 of 30 mass% hydrogen peroxide was added to the cuprous solution samples for oxidation, followed by heating to dryness with a Bunsen burner, and finally dissolution in pure water.

Polarization was carried out from the rest potential in both cathodic and anodic directions, and the scanning speed was set at 0.001 V s−1. All data were recorded digitally, using LOGGER 220 made by Graphtec Corporation. The surface of working electrode was wiped after each run, also polishing was done if it appeared necessary.

3 Results and discussion

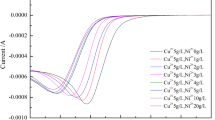

The potentiodynamic experiments were repeated at least three times with each setting of the parameters shown in Table 1, and the parallel results were averaged. Preliminary tests have shown that the electrolyte could be considered homogeneous if a stirring speed over 400 r.p.m. was applied. The first several points of the anodic and cathodic polarization curves were extrapolated and the least squares method was applied in determining the rest potential. The polarization curves of cuprous species in hydrochloric acid solutions are shown in Fig. 3, whereas those of cupric species in hydrochloric and sulfuric acid solutions are compared in Fig. 4. The recorded potentials, η, are expressed directly relative to S.C.E., but they are also displayed relative to the standard hydrogen electrode (S.H.E.) by applying a 0.248 V shift at 20 °C [31]. Figure 3a also includes an embedded box, showing two of the anodic polarization curves in a separate diagram of logarithmic scale for the overpotentials. Arrows in Figs. 3 and 4 indicate the measured rest potentials, E, which correspond to the theoretical equilibrium electrode potentials. The first aspect of examining the polarization curves should be the interpretation of the rest potentials.

Polarization curves of 5 g dm−3 Cu(I) in 1, 2, and 4 mol dm−3 HCl solutions and of 5 g dm−3 Cu(I) in 2 and 4 mol dm−3 HCl solutions (a) and of 5, 10, 20, and 40 g dm−3 Cu(I) in 4 mol dm−3 HCl solutions (b) at 20 °C at 400 r.p.m. Arrows indicate the rest potentials, Eexp.. Scanning speed was set at 0.001 V s−1

3.1 The effect of the electrolyte conditions on the rest potential

The rest potentials, as shown in Figs. 3 and 4, were found to vary from 0.002 to 0.264 V vs. S.H.E. The major steps of the electrode processes are described by the following electrode reactions [12],

and their equilibrium electrode potentials, corresponding to the “rest potentials”, E, are defined as follows:

where a is the activity of a subscripted electro active species, T is the absolute temperature, R is the molar gas constant and the F is the Faraday constant. As expressed by Eqs. (2)–(5), the electro active species are simple ions free of any coordinated ligands. In sulfuric acid solutions, any theoretically possible complex of cupric species virtually dissociate [32], and the concentration of the simple aquo cupric species can be considered as equal to the concentration of the total dissolved copper. On the other hand, in hydrochloric acid solutions, cuprous and cupric chloro complex ions are formed in a series defined by the stepwise equilibria. These complex species—of various resultant electric charge—have to decompose before taking part in the charge transfer step at the cathode. Decomposition is though enhanced by the final step of the electrode process, implying the charge transfer and the consumption of the electroactive ions. In turn, however, it influences the sequential equilibria of complex species:

supplying finally the electroactive ions, where ν is the valency of the copper ion and x is the coordination number of the chloro complex species. At the anode, on the other hand, the steps of chloro complexation can happen after the simple ion is initially generated. As a result of the complex formation, the concentration of the electroactive aquo species must be effectively lower than that of the total dissolved copper concentration. Therefore, the distributions of the complex species in both the cuprous and cupric chloride solutions can be important for discussing electrode potentials.

Based on the total amount of the metal dissolved in the hydrochloric acid solutions, concentrations of the various species—including the simple aquo and the series of chloro complex ions—in the available oxidation states could be determined from the basic collection of the relevant stability constants and the redox-potentials [12], as earlier published by Kékesi et al. [6] for copper and cobalt. In a further approach, the cumulative formation constants of cuprous complexes were determined in LiCl aqueous solutions [33] and those of cupric chloro complexes in HCl aqueous solutions [34]. The conformity of these results is based on the application of the modified Debye-Hückel model [35, 36] for calculating the activity coefficients by both investigations [33, 34], just as the method in this work. The details of the assessment have been described in previous papers [34, 37, 38]. and the relevant results referring to cuprous and cupric species of 5 g dm−3 total concentration in HCl solutions are shown in Fig. 5.

A specific inconvenience of electrodeposition from cuprous chloride solution is the low solubility of CuCl at low HCl concentrations. However, increasing the acid concentration may result in excessive H2 evolution at the cathode. Therefore, the HCl concentration should be optimized for any technical implementation. Based on equilibrium redox potentials and complex ion stability data, Kékesi and Isshiki [10] have determined the limiting conditions expressed by the free chloride ion concentration and the redox potential where CuCl precipitation may arise. In Fig. 5, the grayed area indicates a range in which CuCl precipitates because of its solubility referred to Fig. 2. The rest potentials were calculated by Eqs. (4) and (5) using activities of the simple cuprous and cupric aquo species determined according to Fig. 5. In the case of sulfuric acid solutions, the total dissolved copper concentration corresponds to the activities of the cupric species.

The equilibrium electrode potentials, Ecalc., calculated from the derived concentrations of the electro active ions for the experimental conditions resulting the experimentally measured rest potentials, Eexp., are compared in Fig. 6. The observed ∼ 0.024 V standard deviation of the measured and the calculated values is indicated by the grayed area including the theoretical line of equivalence.

Most of the points—marked by filled symbols—of the calculated and measured rest potentials tend to fall on the ideal line. Only the rest potentials obtained in the electrolyte consisting of cupric species in hydrochloric acid solutions were far from the expected line. This is because some cuprous species were inadvertently produced according to the reaction expressed by Eq. (1) as soon as the working electrode was immersed in the cupric electrolyte containing hydrochloric acid. In this case, the equilibrium redox potentials calculated assuming the following electrode reaction and an activity ratio of the cuprous to cupric species of 10 near the electrode fell within the variance to the expected line [12].

On the other hand, the calculated and the measured rest potentials of cupric species in sulfuric acid solutions were in agreement within the limit of the standard deviation because of the virtual lack of cuprous species in sulfuric acid solutions. Thus, it is demonstrated that the rest potential of the Cu(I)/Cu couple can also be controlled by the concentration of chloride ions. Conversely, the observed rest potentials have confirmed the available stability constants of the chloro complex species, as well as the method of expressing the electrode potentials in a complexing media. Due to the different distributions among the various chloro complex species, the concentrations of the electro active ions are different for any metal and oxidation state. Thus, the rest potentials of elements in hydrochloric and sulfuric acid solutions are different. It also implies that different refining efficiencies can be expected.

3.2 Anodic polarization behavior

The polarization curves in the anodic direction exhibited changing characteristics. As shown in Figs. 3 and 4, the current densities started to increase rapidly and after reaching a peak, there was a remarkable decline, indicating a passivating effect. At higher potentials it is followed by another increasing section with a final saturation. A tendency in the polarization curves in the chloride aqueous electrolytes similar to the present work was observed by Lee and Nobe [22, 39] and Braun et al [21]. The embedded section in Fig. 3 a shows Tafel plots divided into three distinct regions following the manner suggested by Lee and Nobe [22], namely, Apparent Tafel region, Peak region, and Plateau region. Dashed lines in Tafel plots are the extensions of the linear sections in the Apparent Tafel regions.

The polarization curve obtained with the electrolyte containing 5 g dm−3 Cu(I)–4 mol dm−3 HCl has a definite shoulder in the Apparent Tafel region, although it is generally considered to be linear. In addition, the shoulder was also observed in the polarization curve of the 10 g dm−3 Cu(I)–4 mol dm−3 HCl electrolyte, but not at higher Cu(I) concentrations. Such a shoulder has not been reported yet.

The noticed shoulder indicates that the anodic dissolution was promoted. Higher coordination of cuprous chloro complexes are formed at higher molarities of HCl, as shown in Fig. 5, and the solubility of CuCl also increases, as demonstrated in Fig. 2. Furthermore, the activity of Cl− increases exponentially as the molarity of HCl increases [38, 40]. Therefore, the formation of chloro complexes is promoted by higher HCl molarity which in turn promotes the anodic dissolution. The shoulder was not observed in the electrolytes containing 20 and 40 g dm−3 Cu(I) because of the relatively less available free chloride ions and the suppression of the dissolution due to the solubility.

The surface of the working electrode became reddish brown after the current started to decline in the 4 mol dm−3 HCl electrolyte as shown in Fig. 7a. Contrastingly, some white material was observed on the surface of the anodically polarized working electrode in the electrolyte of 1 and 2 mol dm−3 HCl as shown in Fig. 7b. In order to better understand the transformations and reactions taking place during the anodic polarization of the copper electrode in the examined Cu(I)Cl–HCl electrolytes, it is worth determining also the materials balance. The amount of the anodically dissolved copper until the current declines is shown in Fig. 8, and it was estimated by integrating the recorded current with respect to the elapsed time and assuming the dissolved copper species to be cuprous in hydrochloric acid solutions and cupric in sulfuric acid solutions, respectively. The tendencies of the amounts of dissolved copper in hydrochloric acid solutions were in agreement with the solubility of CuCl as shown in Fig. 2. The same tendency was observed in sulfuric acid solutions, although the dissolution produced cupric species there. It can be deduced that the anodic dissolution of copper may get interfered by the solubility of CuCl and CuSO4 in hydrochloric and sulfuric acid solutions, respectively.

The white material having been observed was supposed to be CuCl(s) film in literature [20, 24, 39]. The current density declined in the Peak region because CuCl(s) is not conductive. The film is, however, porous [18, 24, 39], therefore the current was not blocked. Cooper suggested the reddish brown material was Cu2O and a possible formation reaction was also proposed by Eq. (8) [17]. However, a direct evidence of Cu2O has not been acquired and its formation is still a possible assumption. Others suggested further oxidation of cuprous species to the cupric state. However, according to the current work, this may be doubted because no sign of blue or green color of cupric species was observed during anodic polarization, neither when the reddish brown material dissolved into the electrolyte. Knowing what substance is formed on the electrode under certain conditions may help understand the overall electrode reaction. The appearance of the precipitate showing the unique color of Cu2O by in situ observation can be considered deserves further attention. It may justify the following chemical reaction:

This reaction may be induced by the anodic polarization if OH− ions are attracted to the immediate vicinity of the electrode surface by the electrostatic force and the primary product of oxidation is the simple Cu+ ion. Comparison of the rest potentials obtained by calculation and experiment shown in Fig. 6 suggests that the species contributing to the anodic reaction is the simple cuprous ion free of ligands.

Based on the indirect proof offered by the observation of the two distinctly different precipitates, an anodic dissolution model is proposed as shown in Fig. 9. In this model, the reddish brown material is assumed to be Cu2O. It may arise in the following mechanism: region (I) represents the anodic oxidation of metallic copper to simple cuprous species on the electrode described by the reverse reaction of Eq. (2), region (II) involves the formation of various chloro complexes represented by Eq. (6), followed by dissolution, while region (III) is made up of the diffusion of the species to the bulk solution. Additionally, in range (IIIa) a precipitation of CuCl(s) can occur due to the limited solubility in the low (≤ 2 mol dm−3, as found here) HCl electrolytes, which range can (IIIb) involve the possible formation of a Cu2O film at higher (≥ 4 mol dm−3, as observed here) HCl range.

On the other hand, earlier literature of this subject [17,18,19,20,21,22,23,24,25, 41] has suggested the following scheme for the anodic oxidation in this system:

where the subscript “ads” indicates the species adsorbed on the electrode. It has been also claimed [17,18,19,20,21,22,23,24, 41] that the anodic oxidation represented by Eq. (9) was controlled by the diffusion of Cl− ion from the bulk solution to the surface of the anode. It is, however, hardly acceptable because Cl− can even be concentrated near the anode by electrostatic attraction. Furthermore, if the electrode reaction was Eq. (9), dissolution would occur via CuClads., and only CuCl(s) precipitate should be observed. However, either CuCl(s) or Cu2O(s) films were formed as shown in Fig. 7, supposedly precipitated in a secondary step. As a consequence, simple cuprous species free from Cl− ligands could be formed primarily. This is followed in the normal anodic reaction by the formation of dissolved complexes according to the distribution shown in Fig. 5a. Whether the formation of either CuCl(s) or Cu2O(s) occurs depends on the HCl molarity in electrolyte. While the precipitation of CuCl is understandable at low concentrations of free HCl, the appearance of a Cu2O precipitate at higher HCl concentrations may be caused by an indirect effect. If the primary formation of a CuCl precipitate can be assumed generally, higher HCl concentration helps its solubility, thus allowing the access of the OH− ions—also attracted to the anode surface at high overpotentials—to more Cu+ ions.

3.3 Cathodic polarization behavior

Extremely different deposit morphologies obtained by cathodic polarization at the working electrode surfaces in different electrolytes are shown in Fig. 10. As shown in Fig. 10 a, powdery deposits began to grow at more negative overpotentials than − 0.060 V in every cathodic polarization experiment. As powdery deposition occurred, the current densities had a tendency to become noisy.

Deposition was hindered at the center because of the tip of the Luggin-Haber capillary. As shown in Fig. 10b, a densely deposited base layer was revealed after wiping off the powdery deposit with a thin piece of paper cloth. It is obvious that the underlying layer represented the morphology in the earlier stages of the process at lower overpotentials. Thus, it is possible to obtain a smooth electrodeposited surface at the appropriate range of overpotentials.

Average cathodic current densities obtained with different compositions of the CuCl–HCl electrolytes at the preferred overpotential of − 0.100 ± 0.005 V are listed in Table 2. These conditions—except for the last line listed—were found to be suitable to produce practically dense deposits. Strict control of the cathodic overpotential may therefore allow obtaining smooth copper deposit surfaces from cuprous chloride aqueous solutions. In this way, the morphology of the deposit and the polarization characteristics of the cathode can be made similar to those obtained with sulfuric acid solutions—examined for comparison—where powdery deposits were generally not observed.

3.4 Cell voltage and energy requirements

Some of the characteristic polarization curves are shown as Tafel plots in Fig. 11 for comparison. It is clearly seen that electrolytes consisting of cuprous species in hydrochloric acid solutions yielded higher currents than those consisting of cupric species in sulfuric acid solutions.

The cathodic current densities in the electrolytes consisting of cuprous species in hydrochloric acid solutions reached the limiting values at the over potential of about − 0.050 V, while those from electrolytes consisting of cupric species in sulfuric acid solutions were still gradually increasing and reached their limiting values at overpotentials of about − 0.160 V to − 0.180 V, out of the plotted range. The limiting current densities at equal concentrations of the electroactive ions were, however, almost equivalent in hydrochloric and sulfuric acid solutions. Hence, the limiting current density is assumed to be determined by diffusion of copper species between the diffusion layer and the bulk solution, but it is independent of the number of electrons involved in the electrode reaction.

Further, not just the overpotentials to generate the same current density can be lower, but also the conductivity of the chloride electrolyte is higher, thus the cell voltage can be reduced. This is an additional technical advantage beside the virtually half of the specific charge involved in the electrode process of the univalent cuprous species. Consequently, significantly less electric energy may be required to obtain the same mass of copper from the cuprous chloride solution than from the cupric sulfate, provided the current efficiency is not significantly lower and the cathodic deposit is of acceptable structure. This can be ensured by proper control of the electrolyte composition and the overpotentials, as suggested above. Therefore, application of cuprous–hydrochloric acid solutions can be considered prospective for developing the electrolytic copper technology.

It has to be noted that similar phenomena have been reported in the case of electrorefining tin in hydrochloric acid solutions [42]. The preference of stannous species over stannic ones in hydrochloric acid solutions was a clue for establishing stable conditions and high current efficiencies for cathodic tin deposition, although the difficulty of loose dendritic deposit structures could be practically handled only by mechanical interventions.

4 Summary

The electrolytic behavior of cuprous species at the electrodes polarized in hydrochloric acid solutions was investigated and compared to those of cupric species in hydrochloric and in sulfuric acid solutions. The rest potentials in hydrochloric acid solutions were more negative than those in sulfuric acid solutions, and the difference was about 0.150 V. This is interpreted as the activities of the simple aquo species directly involved in the electrode reactions are strongly decreased by the formation of chloro complexes. The interpretation is based on the computed concentrations and activities of the various species of dissolved copper. It was deduced that the rest potential could be controlled by the chlorine concentration.

The copper anode is dissolved in hydrochloric acid solutions as cuprous species, while cupric species are negligible. Precipitated cuprous chloride was formed on the electrode at lower than 2 mol dm−3 HCl concentrations in the electrolyte and so was cuprous oxide at higher than 4 mol dm−3 HCl. This phenomenon can be interpreted basically in terms of the primary formation of CuCl and its solubility depending on HCl concentration. However, the appearance of the precipitate showing the characteristic color of Cu2O could be used as a further indicator to other auxiliary processes. These findings could lead to the formulation of an assumed mechanism of the anodic dissolution of copper in CuCl–HCl electrolytes.

In the cathodic deposition of cuprous species from hydrochloric acid solutions, relatively dense and smooth structure was obtained if the overpotential was kept above − 0.100 V. Due to the lower specific charge required to neutralize cuprous ions, the lower overpotentials for the same current densities and the higher conductivity of chloride solutions, electrowinning and electrorefining of copper in CuCl–HCl media must be more economical than in CuSO4–H2SO4 solutions. The conclusions drawn from the results of the potentiodynamic studies and from the simulation of the chloro complex formation/decomposition equilibria can be justified by actual electrolysis tests of longer duration. If the conditions can be controlled within the optimum range, relatively dense deposits of copper should be produced with high energy efficiency. The fundamental characteristics of the examined system may apply to similar cases of extracting other transition metals from chloride media. Electrolysis from hydrochloric acid solutions is expected to play an important role especially in the extraction of high purity metals from such solutions which may be even preliminarily purified by anion-exchange separations.

References

Nanjo M (1988) Urban mine, new resources for the year 2000 and beyond. Bull Res Inst Miner Dress Metall 43:239–251

Hosoi A, Hiruta K, Takasaki Y, Shibayama A (2012) Metal recovery from printed circuit board waste by chlorination-volatilization and the volatilization behavior of metals. J Jpn I Met 76:155–163. https://doi.org/10.2320/jinstmet.76.155

Oleszek S, Grabda M, Shibata E, Nakamura T (2013) Distribution of copper, silver and gold during thermal treatment with brominated flame retardants. Waste Manage 33:1835–1842. https://doi.org/10.1016/j.wasman.2013.05.009

Kékesi T (2013) Electrorefining in aqueous chloride media for recovering tin from waste materials. Acta Metall Slovaca 19:196–205. https://doi.org/10.12776/ams.v19i3.161

Kékesi T, Isshiki M (1997) Ultra high purification of copper chloride solutions by anion exchange. Hydrometallurgy 45:345–361. https://doi.org/10.1016/s0304-386x(96)00091-6

Kékesi T, Uchikoshi M, Mimura K, Isshiki M (2001) Anion-exchange separation in hydrochloric acid solutions for the ultrahigh purification of cobalt. Metall Mater Trans B 32B:573–582. https://doi.org/10.1007/s11663-001-0113-8

Kékesi T, Mimura K, Isshiki M (2002) Ultra-high purification of iron by anion exchange in hydrochloric acid solutions. Hydrometallurgy 63:1–13. https://doi.org/10.1016/s0304-386x(01)00208-0

Uchikoshi M, Shibuya H, Imaizumi J, Kékesi T, Mimura K, Isshiki M (2010) Preparation of high-purity cobalt by anion-exchange separation and plasma arc melting. Metall Mater Trans B 41B:448–455. https://doi.org/10.1007/s11663-009-9331-2

Isshiki M, Mimura K, Uchikoshi M (2011) Preparation of high purity metals for advanced devices. Thin Solid Films 519:8451–8455. https://doi.org/10.1016/j.tsf.2011.05.038

Kekesi T, Isshiki M (1997) Electrodeposition of copper from pure cupric chloride hydrochloric acid solutions. J Appl Electrochem 27:982–990. https://doi.org/10.1023/a:1018418105908

Jin W, Su J, Zheng S, Lei H (2017) Controlled electrodeposition of uniform copper powder from hydrochloric acid solutions. J Electrochem Soc 164:D723–D728. https://doi.org/10.1149/2.1491712jes

Sillén LG, Martell AE (eds) (1964) Stability constants of metal-ion complexes. Chemical Society, London

Koyama K, Tanaka M, Miyasaka Y, Lee J (2006) Electrolytic copper deposition from ammoniacal alkaline solution containing Cu(I). Mater Trans 47:2076–2080. https://doi.org/10.2320/matertrans.47.2076

Murase K, Tamagawa K, Mizota N, Motoba K, Abe Y, Awakura Y (2005) Electrodeposition behavior of dendritic copper from aqueous copper(I) chloride solution containing condensed sodium halides. Shigen to Sozai 121:103–110. https://doi.org/10.2473/shigentosozai.121.103

Oishi T, Yaguchi M, Koyama K, Tanaka M, Lee J (2013) Effect of additives on monovalent copper electrodeposition in ammoniacal alkaline solutions. Hydrometallurgy 133:58–63. https://doi.org/10.1016/j.hydromet.2012.11.015

Park DJ, Park CM, Kang NH, Lee KH (2016) Effect of electrolyte type on shape and surface area characteristics of dendritic Cu powder. J Korean Inst Surf Eng 49:416–422. https://doi.org/10.5695/jkise.2016.49.5.416

Cooper RS (1956) Anodic transients of copper in hydrochloric acid. J Electrochem Soc 103:307–315. https://doi.org/10.1149/1.2430319

Cooper RS, Bartlett JH (1958) Convection and film instability copper anodes in hydrochloric acid. J Electrochem Soc 105:109–116. https://doi.org/10.1149/1.2428773

Hurlen T, Nilsson E, Nilsson R, Olsen G, Pedersen C, Toft J (1961) Electrochemical behavior of copper in acid chloride solution. Acta Chem Scand 15:1231–1238. https://doi.org/10.3891/acta.chem.scand.15-1231

Bonfiglio CH, Albaya HC, Cobo OA (1973) The kinetics of the anodic dissolution of copper in acid chloride solutions. Corros Sci 13:717–724. https://doi.org/10.1016/s0010-938x(73)80010-1

Turner M, Brook P (1973) The anodic behaviour of copper in static and flowing hydrochloric acid solutions. Corros Sci 13:973–983. https://doi.org/10.1016/s0010-938x(73)80080-0

Braun M, Nobe K (1979) Electrodissolution kinetics of copper in acidic chloride solutions. J Electrochem Soc 126:1666–1671. https://doi.org/10.1149/1.2128773

Lee HP, Nobe K (1986) Kinetics and mechanisms of Cu electrodissolution in chloride media. J Electrochem Society 133:2035–2043. https://doi.org/10.1149/1.2108335

Crundwell FK (1992) The anodic dissolution of copper in hydrochloric acid solutions. Electrochimi Acta 37:2707–2714. https://doi.org/10.1016/0013-4686(92)85197-s

Ding L, Song Z, Wu P, Cheng J, Chen C, Niu Y, Li B (2019) Electrochemical oscillations during copper electrodissolution in hydrochloric acid solution. Int J Electrochem Sci 14:585–597. https://doi.org/10.20964/2019.01.63

Barnartt S (1961) Magnitude of IR-drop corrections in electrode polarization measurements made with a luggin-haber capillary. J Electrochem Soc 108:102–104. https://doi.org/10.1149/1.2427994

Fritz JJ (1982) Solubility of cuprous chloride in various soluble aqueous chlorides. J Chem Eng Data 27:188–193. https://doi.org/10.1021/je00028a027

Foote HW (1923) Equilibrium in the systems, nickel chloride, cobalt chloride, cupric chloride-Hydrochloric acid-water. J Am Chem Soc 45:663–667. https://doi.org/10.1021/ja01656a014

Juan DD, Messenguer VF, Lozano LJ (1999) Una contribución al estudio de la solubilidad del CuSO4∙5H2O en medio acuoso. Rev Metal 35:47–52. https://doi.org/10.3989/revmetalm.1999.v35.i1.605

Ueno K (1972) Chelate titration. Nan-e dou, Tokyo

Sawyer DT, Sobkowiak A, Roberts JL (1995) Electrochemistry for chemists. Wiley-Interscience, New York

Filipponi A, D'Angelo P, Pavel NV, Cicco AD (1994) Triplet correlations in the hydration shell of aquaions. Chem Phys Lett 225:150–155. https://doi.org/10.1016/0009-2614(94)00622-9

Liu W, Brugger J, McPhail DC, Spiccia L (2002) A spectrophotometric study of aqueous copper(I)-chloride complexes in LiCl solutions between 100 °C and 250 °C. Geochim Cosmochim Acta 66:3615–3633. https://doi.org/10.1016/s0016-7037(02)00942-0

Uchikoshi M, Shinoda K (2019) Determination of structures of cupric-chloro complexes in hydrochloric acid solutions by UV-Vis and X-ray absorption spectroscopy. Struct Chem 30:61–74. https://doi.org/10.1007/s11224-018-1164-7

Helgeson HC, Kirkham DH (1974) Theoretical prediction of the thermodynamic behavior of aqueous electrolytes at high pressures and temperatures; I, Summary of the thermodynamic/electrostatic properties of the solvent. Am J Sci 274:1089–1198. https://doi.org/10.2475/ajs.274.10.1089

Helgeson HC, Kirkham DH (1974) Theoretical prediction of the thermodynamic behavior of aqueous electrolytes at high pressures and temperatures; II, Debye-Hückel parameters for activity coefficients and relative partial molal properties. Am J Sci 274:1199–1261. https://doi.org/10.2475/ajs.274.10.1199

Uchikoshi M (2018) Determination of the distribution of cobalt-chloro complexes in hydrochloric acid solutions at 298 K. J Solution Chem 47:2021–2038. https://doi.org/10.1007/s10953-018-0831-z

Uchikoshi M (2019) Determination of the distribution of ferric chloro complexes in hydrochloric acid solutions at 298 K. B Chem Soc Jpn 92:1928–1934. https://doi.org/10.1246/bcsj.20190195

Lee HP, Nobe K, Pearlstein AJ (1985) Film formation and current oscillations in the electrodissolution of Cu in acidic chloride media. J Electrochem Soc 132:1031–1037. https://doi.org/10.1149/1.2114010

Partanen JI, Juusola PM, Vahteristo KP, Mendonca AJG (2007) Re-evaluation of the activity coefficients of aqueous hydrochloric acid solutions up to a molality of 16.0 mol kg−1 using the hückel and pitzer equations at temperatures from 0 to 50 °C. J Solution Chem 36:39–59. https://doi.org/10.1007/s10953-006-9099-9

Pearlstein AJ, Lee HP, Nobe K (1985) Film formation and current oscillations in the electrodissolution of copper in acidic chloride media. J Electrochem Soc 132:2159–2165. https://doi.org/10.1149/1.2114309

Kulcsar T, Toth G, Kékesi T (2016) Complex evaluation and development of electrolytic tin refining in acidic chloride media for processing tin-based scrap from lead-free soldering. Miner Proc Extr Met 125:228–237. https://doi.org/10.1080/03719553.2016.1206693

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Uchikoshi, M., Kékesi, T. The behavior of cuprous species at electrodes polarized in hydrochloric acid solutions. J Appl Electrochem 50, 597–608 (2020). https://doi.org/10.1007/s10800-020-01420-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-020-01420-5