Abstract

This work describes the synthesis and study of two new hybrid (organic–inorganic) three-layered systems with improved semiconductive behavior. As far as the first system is concerned, CdSe-Fc-Zn x Cd1−x Se, the inner layer is CdSe, while the outer one is Zn x Cd1−x Se, both prepared by electrodeposition. The partial substitution of Cd by Zn in the outer layer leads to an environmentally friendlier product compared with those containing exclusively Cd. The organic layer of the hybrid system is ferrocene (Fc), which is enveloped between the two inorganic layers in a sandwich-like structure. Ferrocene is deposited on CdSe layer using the spin-coating technique. It was found that the as-prepared CdSe-Fc-Zn x Cd1−x Se system has improved properties and photoconductivity compared with the Zn x Cd1−x Se monolayers. In order to further enhance the photoresponse of the system described above, a second three-layer hybrid was developed, the CdSe-Fc-Zn x Cd1−x Se/oxalate. This system was produced with the electrodeposition of the outer layer Zn x Cd1−x Se in the presence of disodium oxalate, a selected organic additive in the bath. All the products were fully characterized via XRD, SEM–EDAX, band gap, and photoelectrochemical cell (PEC) measurements, and the results confirmed the development of the new hybrid semiconductive systems. The as-described CdSe-Fc-Zn x Cd1−x Se and CdSe-Fc-Zn x Cd1−x Se/oxalate systems, compared to the pure inorganic CdSe and Zn x Cd1−x Se thin films, present remarkably improved photoresponse due to the synergetic action of their components.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Binary 12–16 compounds, such as CdSe, CdTe, and ZnSe, are well-known semiconductive materials that present particular interest and have found various applications in the fields of solar energy conversion and electronics. Possessing direct energy gaps (1.7, 1.5, and 2.7 eV, respectively), which are more efficient to the absorption of electromagnetic radiation, they are very promising materials for thin film solar cell applications, high temperature electronics and lasers, optoelectronic, luminescent and light-emitting devices, photoconductors, etc. [1,2,3]. Recently, semiconductive, substitutional ternary systems (general formula A x B1−x C), such as Zn x Cd1−x Se and Zn x Cd1−x Te, have also received much attention, because of their interesting properties of band gap and lattice constant modulation by composition that can lead to tandem-type variable band-gap solar cells, fabrication of superlattices, and various optical device applications [4].

The present study focuses on (Zn,Cd)Se solid solution aiming to exploit the advantages of both ZnSe and CdSe precursor binary compounds and partially address the issue of cadmium toxicity [5,6,7,8]. The development and use of new semiconductive materials with reduced cadmium content will pose fewer issues, other aspects being equal. The use of abundant, durable, and low cost materials, such as zinc, is a key requirement for thin film technology, alongside high efficiency and non-toxicity. Consequently, the substitution of Cd with Zn is a step towards the right direction [9].

Cadmium selenide, thoroughly investigated in previous reports [10,11,12,13], is considered as our starting material, based on strong indications supporting that Zn is inserted in a CdSe matrix. During the last decades CdSe has been applied in thin film solar cells because of its proper band-gap width (1.7 eV) and large optical absorption. Moreover, it has been found to undergo photocorrosion when it is used in photoelectrochemical cells. On the other hand, ZnSe is reported to be more stable though less photoactive due to its wide band gap (2.7 eV). Using ternary Zn x Cd1−x Se compounds with gap energies ranging from 1.7 to 2.7 eV (or lower due to non-linear band-gap width variation from x = 0 to x = 1) [14,15,16], the exploitation of a large part of the photons present in the solar spectrum can be attained. Zn x Cd1−x Se can accomplish both tasks of increased solar spectrum absorption and good stability with respect to environment [17]. Thin films of Zn x Cd1−x Se have been prepared by vacuum evaporation, molecular beam epitaxy, electron beam pumping, chemical bath deposition, and electrodeposition [18]. The latter is chosen here as a flexible, low cost, and soft growth technique.

The lattice structure of CdSe and ZnSe exists in the forms of wurtzite (hexagonal) and zinc blende (cubic), as well. The former is a meta-stable phase, constituting the almost exclusive product of an electrochemical formation process, while the latter is the thermodynamically stable structure that can be obtained by annealing the cubic phase [19]. It has been found that samples of the Zn x Cd1−x Se composition are of sphalerite structure at x > 0.7 and wurtzite structure at x < 0.6. Within the interval both phases are observed [20].

The aim of this work is the development of new three-layer hybrid (organic–inorganic) semiconductive systems with improved photoelectrochemical performances, based on low cost and commercially available organic compounds. As it is demonstrated in some of our previous studies [21, 22], hybrid semiconductive materials, developed either by the formation of a sandwich-like structure with altering inorganic–organic layers or by the application of one step electro-code position, can possess interesting new physical and/or chemical properties and functionality. Indeed, hybrid systems usually present a particular semiconductive behavior due to a synergic combination of their component properties. Moreover, the incorporation of various functional groups in the organic part of the hybrid semiconductor could permit a regulation of the final product’s properties.

In this paper a combination of previously applied techniques was employed in order to develop hybrid semiconductive systems involving two inorganic thin film layers, a CdSe (inner) layer and a Zn x Cd1−x Se (outer) layer; the latter electrodeposited in the presence or absence of oxalate additive [23] in the bath, divided by a thin organic ferrocene film in a sandwich-like structure. The CdSe-Fc-CdSe system, which has been synthesized and studied in the past, presents remarkably improved photoresponse [24].

2 Experimental

Zn x Cd1−x Se and CdSe thin films were developed potentiostatically, using a potentio-scan system (Metrohm Autolab PGSTAT302N MBA potentiostat/galvanostat) with a conventional three-electrode setup. The cathode was a rotating Ti disk electrode (mean diameter: 12 mm, cathode’s rotation rate: 500 rpm). The counter electrode was a large platinum-plated grid. The potential of the working electrode was monitored against an Hg/HgSO4-saturated sulfate reference electrode (S.S.E.).

The electrolytic bath was an aqueous solution, containing typically: 0.2 M CdSO4 (Acros Organics, ACS reagent 98.0–102.0%) and 2 mM SeO2 (Acros Organics, 98%) for CdSe plating, 0.2 M ZnSO4 (Alfa Aesar, ACS reagent 99.0–103.0%) and equal amounts of CdSO4 and SeO2 (0.10, 0.25 or 0.50 mM) for Zn x Cd1−x Se plating, respectively. Bath temperature was kept constant at 85 ± 1 °C. The concentration of the additive disodium oxalate (Alfa Aesar, 99%) was set to 2 mM. In all cases the bath pH value was adjusted to 2.2.

The organic layers were deposited dropwise, from solutions of commercially available ferrocene, Fc (Acros Organics, 98%) in toluene, onto the rotating inorganic electrode (spin-coating technique). In this way, a thin film of the organic substance was formed. The three-layered products were prepared by applying a second Zn x Cd1−x Se layer over the organic one to give a sandwich-like structure. The inner CdSe layer of all specimens was electrodeposited at the potential of −1.0 V versus S.S.E, whereas the outer one at −1.1 V versus S.S.E.

All deposits were examined by X-ray diffraction (XRD; Bruker D8 Advance with a CuKα X-ray source) and scanning electron microscopy (SEM; FΕΙ-Quanta 200) techniques. Compositional data were obtained using energy-dispersive X-ray (EDAX) analysis. The band-gap widths were valued by spectrophotometry of the reflected light (V-770 Jasco Spectrophotometer, equipped with an integrating sphere ISV-922/ISN-901i 60 mm) [25]. Photoresponse studies were performed in a photoelectrochemical cell (PEC) with a three-electrode configuration comprising platinum wire rods as counter and reference electrodes. An alkaline sulfide–polysulfide solution [S 2−; x 1 M NaOH (Lach-Ner, 99.6%), 1 M Na2S (Alfa Aesar, ≥60%), 1 M S (Fluka, ≥99.5%) solution] was used as the working redox electrolyte. The PEC measurements were conducted under a white illumination generated by a halogen lamp and focused in front of the quartz window of the cell. Illumination intensity was 1000 W m−2.

3 Results and discussion

Zn x Cd1−x Se thin films have been developed as described above. The electrodeposition process from acidic aqueous solutions underlies the general principal, outlined by Kröger [26], for the deposition of 12–16 compounds, proceeding through the following simplified reduction scheme:

The chemical similarity between CdSe and ZnSe allows the formation of ZnSe–CdSe solid solutions; however, the direct formation of the alloy is not plain, basically due to the difference in the redox potentials of Zn2+ and Cd2+ ions. That is why a large excess of Zn ions (0.2 M) must be employed. Equal concentrations of cadmium and selenium precursor compounds were used: 0.10, 0.25, and 0.50 mM, depending on sample, to differentiate Zn/Cd ratio in the final products. A deposition potential of −1.1 V versus SSE is chosen in order to avoid the formation of elemental Cd phase, often observed in more negative potentials and limit the elemental Se content of the deposits at the same time. All electrodeposited CdSe and Zn x Cd1−x Se monolayers, as well as inner CdSe thin films of the hybrid samples, are approximately 3–4 μm thick. All external Z x Cd1−x Se layers are approximately 1–2 μm thick.

A direct determination of the absorption edge and band-gap energies of these new materials was attempted, by analyzing the data provided by their diffuse reflectance spectrums. Regarding the hybrid samples, it was observed that a secondary transition occurs in lower wavelengths, in addition to the main transition attributed to the inorganic semiconductor (Fig. 1). This may indicate the development of a new semiconductive compound formed between ferrocene and the outer inorganic layer, in the three-layered samples. It can also be attributed to the introduction of crystal defects, due to the presence of oxalate additive during electrodeposition that affects the photon absorption mechanism. The occurrence and the exact spectral position of this secondary edge (approx. 2.0–2.4 eV, in all cases) seems to depend on Zn/Cd ratio of the outer layer, as well as the organic compounds that participate in the hybrid system.

Ferrocene and oxalate species directly contribute to the secondary edge observed in the hybrid samples’ reflectance spectrums, as described above. However, their presence also, indirectly, affects the main transition corresponding to the inorganic part of the systems. Zinc content seems to be reduced in three-layered samples compared to the corresponding monolayers, as confirmed from the SEM–EDAX analysis data, leading to a shift towards higher wavelengths. As already mentioned, gap width variation with composition in ternary Zn x Cd1−x Se systems is not linear, so the main transition in most cases occurs in wavelengths higher than 730 nm (1.7 eV).

The appearance of a secondary absorption edge at approximately 2.4 eV, that seems to be possible only at small x fractions, coincides with a different type of surface morphology observed by SEM (Fig. 2). These three-layered hybrid samples do not exhibit cauliflower-like surface growth, common for all the other deposits, but a grass-like one. The properties of such systems depend on the interface formed between the semiconductor and the electrolyte and this structure is possible to affect PEC performance [27,28,29,30].

SEM–EDAX investigation (Fig. 2) confirmed the presence of carbon due to ferrocene and oxalate moieties and consequently the formation of a hybrid system.

Figure 3 summarizes the XRD diagrams of the as-prepared CdSe-Fc-Zn x Cd1−x Se (abbrev. CdSe-Fc-(Cd, Zn)Se) and CdSe-Fc-Zn x Cd1−x Se/oxalate (abbrev. CdSe-Fc-(Cd, Zn)Se/oxalate) hybrid semiconductors. Diagrams corresponding to pure (Cd, Zn)Se samples prepared under the same conditions, in the absence or presence of oxalate, are also included for comparison. All deposits exhibit a cubic zinc blende structure with a predominating [111] crystalline orientation with the exception of Cd-rich CdSe-Fc-Zn x Cd1−x Se/oxalate samples where a clear CdSe hexagonal wurtzite structure coexists. Low Zn content is observed when hexagonal CdSe is formed. In consequence, it is assumed that the incorporation of zinc in a wurtzite matrix lattice is not promoted, which complies with the fact that ZnSe is mostly obtained as zinc blende. Peaks corresponding to the cubic structure that are observed in all cases have 2θ values between those corresponding to pure CdSe and ZnSe. As CdSe content increases, the above-mentioned peaks shift towards CdSe side and vice versa.

Table 1 summarizes the values of four characteristic parameters (J sc short circuit current density, V OC open circuit potential, FF fill factor, and η photo electrochemical efficiency). These parameters were calculated according to the photoconversion curves, received for all the above-mentioned semiconductive thin films, used directly as absorbed electrodes in conventional PEC.

Zinc concentration in Zn x Cd1−x Se thin films seems to play an important role for their performance in photoelectrochemical solar cells and properties. Cadmium concentration increasing, the deposits become more photoactive, presenting much larger photocurrent densities. In the outer layer of the three-layered hybrid samples with low zinc content, a pure hexagonal CdSe crystal phase, which is associated with better photoresponses, coexisting with the ZnxCd1−xSe cubic one, often appears. At the same time, the introduction of Zn in the CdSe lattice increases the energetic gap leading to higher open circuit potentials. The incorporation of Zn induces a Fermi level shift of the n-CdSe in the direction of enhancing the barrier height, while stabilizing the semiconductor surface against dissolution.

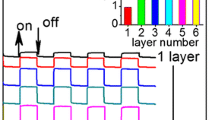

Figure 4 illustrates the respective current–potential photoresponse curves. It is observed that all photocurrents are anodic, characteristic of an n-type semiconducting behavior.

Current density versus electrochemical potential given by (Cd,Zn)Se-based semiconductive thin films prepared by electrodeposition at −1.1 V versus SSE from a bath containing 0.2 M ZnSO4 as well as 0.10 (a), 0.25 (b) or 0.50 (c) mM SeO2 and CdSO4, used directly as absorbed electrodes in a conventional PEC in the dark and under illumination of 1000 W m−2

Zn x Cd1−x Se/oxalate deposits present improved properties, such as better short circuit current and photoelectrochemical efficiency values, compared with Zn x Cd1−x Se ones, prepared in the absence of disodium oxalate in the electrolytic bath. The three-layered specimens, CdSe-Fc-Zn x Cd1−x Se and CdSe-Fc-Zn x Cd1−x Se/oxalate, also exhibit remarkably improved semiconductive behavior regarding short circuit currents and photoconversion efficiencies compared with the Zn x Cd1−x Se and Zn x Cd1−x Se/oxalate layers, respectively. This improvement is more pronounced in the case of CdSe-Fc-Zn x Cd1−x Se/oxalate products and is attributed to the synergetic action of the hexagonal structure phase of the outer inorganic film, the incorporation of the additive into the semiconductor lattice, and the formation of the new semiconductive compound CdSe-Fc-Zn x Cd1−x Se/oxalate as well.

4 Conclusions

Two new three-layered systems, the CdSe-Fc-Zn x Cd1−x Se and CdSe-Fc-Zn x Cd1−x Se/oxalate, belonging to the category of hybrid (organic–inorganic) semiconductors, were prepared. They were developed with a simple and flexible experimental procedure using low cost starting materials. The hybrid products were friendlier for humans and the environment compared with the widely used semiconductors based exclusively on Cd and presented remarkably improved photoconductivity. The Zn x Cd1−x Se layers electrodeposited using the disodium oxalate additive exhibit enhanced photoconductive character compared to the Zn x Cd1−x Se ones, prepared in its absence. The synergetic action of oxalate and ferrocene compounds leads to semiconductive materials with modified crystal structure and particularly improved photoelectrochemical efficiencies reaching up to a fivefold increase compared to pure electrodeposited CdSe thin films. It is supposed that a new chemical semiconductive compound tends to be formed between the organic and the inorganic part of the hybrid system (CdSe/Zn x Cd1−x Se and ferrocene, respectively) as indicated by SEM/EDAX and spectrophotometric data.

References

Bouroushian M, Kosanovic T, Loizos Z, Spyrellis N (2002) Electrochemical formation of zinc selenide from acidic aqueous solutions. J Solid State Electrochem 6:272–278

Kowalik R, Zabinski P, Fitzner K (2008) Electrodeposition of ZnSe. Electrochim Acta 53:6184–6190

Mitzithra C, Hamilakis S, Kollia C, Loizos Z (2012) CdSe semiconducting layers produced by pulse electrolysis. Semiconductors 46:615–618

Bouroushian M, Kosanovic T (2006) Electrochemical formation and composition analysis of Zn x Cd1−x Se solid solutions. J Solid State Electrochem 10:223–229

Fowler BA (2009) Monitoring of human populations for early markers of cadmium toxicity: a review. Toxicol Appl Pharmacol 238:294–300

Moskowitz PD, Zwelbel K, Fthenakis VM (1990) Health, safety and environmental issues relating to cadmium usage in photovoltaic energy systems. Solar Energy Research Institute. http://www.nrel.gov/docs/legosti/old/3621.pdf. Accessed 21 Nov 2016

Godt J, Scheidig F, Grosse-Seistrup C, Esche V, Brandenburg P, Reich A, Groneberg DA (2006) The toxicity of cadmium and resulting hazards for human health. J Occup Med Tox 1:22. doi:10.1186/1745-6673-1-22

Bernhoft RA (2013) Cadmium toxicity and treatment. SciWorld. doi:10.1155/2013/394652

Green MA (2006) Consolidation of thin-film photovoltaic technology: the coming decade of opportunity. Prog Photovolt 14:383–392

Loizos Z, Spyrellis N (1991) Electrochemical synthesis of semiconducting CdSe thin films. Thin Solid Films 204:139–149

Bouroushian M, Loizos Z, Spyrellis N (2000) Electrocrystallization of CdSe upon various substrates. Structural arrangement and photoelectrochemical performance. Appl Surf Sci 156:125–134

Bouroushian M, Kosanovic T, Loizos Z, Spyrellis N (2000) On a thermodynamic description of Se(IV) electroreduction and CdSe electrolytic formation on Ni, Ti and Pt cathodes in acidic aqueous solution. Electrochem Commun 2:281–285

Loizos Z, Mitsis A, Spyrellis N (1993) Cadmium chalcogenide semiconducting thin films prepared by electrodeposition from boiling aqueous electrolytes. Thin Solid Films 235:51–56

Bouroushian M, Kosanovic T, Xu HY, Papadimitriou D (2005) Structural and optical investigation of electrosynthesized Zn x Cd1−x Se thin films. J Phys D Appl Phys 38:1540–1545

Natarajan C, Nogami G, Sharonb M (1995) Electrodeposition of Zn1−x Cd x Se (x = 0–1) thin films. Thin Solid Films 261:44–51

Santhosh TCM, Bangera KV, Shivakumar GK (2017) Band gap engineering of mixed Cd(1−x)Zn (x)Se thin films. J Alloy Comp 703:40–44

Murali KR, Balasubramanian M (2010) Characteristics of pulse plated Cd x Zn1−x Se films. Curr Appl Phys 10:734–739

Chavhan SD, Mane RS, Wonjoo Lee, Senthilarasu S, Sung-Hwan Han, Lee J, Soo-Hyoung Lee (2009) Study on photoelectrochemical solar cells of nanocrystalline Cd0.7Zn0.3Se—water soluble conjugated polymer. Electrochim Acta 54:3169–3175

Bouroushian M, Loizos Z, Spyrellis N (1993) Influence of heat treatment on structure and properties of electrodeposited CdSe or Cd(Te, Se) semiconducting coatings. Thin Solid Films 229:101–106

Kulakov MP, Balyakina IV (1991) Solid state wurtzite-sphalerite transformation and phase boundaries in ZnSe–CdSe. J of Cryst Growth 113:653–658

Mitzithra C, Kaniaris V, Hamilakis S, Kordatos K, Kollia C, Loizos Z (2011) Development and study of new hybrid semi-conducting systems involving Cd chalcogenide thin films coated by a fullerene derivative. Mater Lett 65:1651–1654

Chountoulesi E, Mitzithra C, Hamilakis S, Kordatos K, Kollia C, Loizos Z (2013) One-step electro-codeposition for developing new hybrid semiconductors. Mater Lett 93:45–48

Hamilakis S, Balgis D, Milonakou-Koufoudaki K, Mitzithra C, Kollia C, Loizos Z (2015) Electrodeposition of CdSe photoabsorber thin films in the presence of selected organic additives. Mater Lett 145:11–14

Hamilakis S, Gallias N, Mitzithra C, Kordatos K, Kollia C, Loizos Z (2015) Hexagonal electrodeposited CdSe in new-multi-layer hybrid organic–inorganic semiconductive systems with remarkable high photoconductivity. Mater Lett 143:63–66

Zhu J, Liao X, Zhao X, Wang J (2001) Photochemical synthesis and characterization of CdSe nanoparticles. Mater Lett 47:339–343

Kröger FA (1978) Cathodic deposition and characterization of metallic or semiconducting binary alloys or compounds. J Electroch Soc 125(12):2028–2034

Gao P, Liu D (2015) Facile synthesis of copper oxide nanostructures and their application in non-enzymatic hydrogen peroxide sensing. Sensor Actuat B-Chem 208:346–354

Tong Z, Lv H, Zhang X, Yang H, Tian Y, Li N, Zhao J, Li Y (2015) Novel morphology changes from 3D ordered macroporous structure to V2O5 nanofiber grassland and its application in electrochromism. Sci Rep. doi:10.1038/srep16864

Hanedar Y, Demir U, Oznuluer T (2016) Electrochemical synthesis and photoelectrochemical properties of grass-like nanostructured a-Fe2O3 photoanodes for use in solar water oxidation. Superlatt Microstr 98:371–378

Gao P, Gong Y, Mellott NP, Liu D (2015) Non-enzymatic amperometric detection of hydrogen peroxide using grass-like copper oxide nanostructures calcined in nitrogen atmosphere. Electrochim Acta 173:31–39

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Milonakou-Koufoudaki, K., Lyros, T., Mitzithra, C. et al. Development, characterization, and study of new (Cd,Zn)Se-based hybrid semiconductive systems. J Appl Electrochem 47, 1023–1033 (2017). https://doi.org/10.1007/s10800-017-1097-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-017-1097-7