Abstract

P-octyl polyethylene glycol phenyl ether (Triton X-100) and cetyltrimethylammonium bromide (CTAB) were mixed to be used as surfactant for preparing reverse microemulsion with n-hexane, n-hexanol and water. Effects of weight ratio of the two surfactants, temperature, concentrations of water and cosurfactant on the conductivity were studied. The results indicate that the conductivity of the mixed surfactants reverse microemulsion is greatly higher than that of the single surfactant system. The reverse microemulsion has been modified to be with good conductivity. The weight ratio of the two surfactants, temperature, concentrations of water and cosurfactant have obvious effects on the conductivity of the reverse microemulsion. Furthermore, the electrochemical behavior of potassium ferricyanide [K3Fe(CN)6] in the mixed surfactants reverse microemulsion was investigated by cyclic voltammetry. The result shows that the redox processes of \( {{\text{Fe}}\left( {\text{CN}} \right)_{ 6}}^{ 3- } / {{\text{Fe}}\left( {\text{CN}} \right)_{ 6}}^{ 4-} \) present good reversibility and are controlled by diffusion in the system.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Microemulsion is transparent, isotropic, thermodynamically stable dispersion of nanosized oil or water droplets which are stabilized by surfactant and cosurfactant molecules [1, 2]. It has received considerable attention since it can be widely used in oil recovery, nanoparticle synthesis, polymerization and organic catalysis [3–8]. However, due to the defect of its electrical conductivity, conventional reverse microemulsion cannot be used as electrolyte in electrochemistry research. Additive such as electrolyte or organic molecule can improve the conductivity while decreasing the stability and water solubilization of microemulsion greatly [9–11]. Therefore, electrochemistry investigation based on the conductive behavior of microemulsion can extend its application field. The previous research in our lab has proven that the higher H+ concentration in the water phase can increase the stability and conductivity of reverse microemulsion. And this kind of microemulsion has been used in the electrodeposition of Au and Ni nanoparticles [12–14].

Generally, microemulsion consists of oil, water, cosurfactant and one kind of surfactant. The anionic surfactant, cationic surfactant, non-ionic surfactant or amphoteric surfactant is chosen singly in preparation of microemulsion based on their characteristics. Sometimes two different surfactants can be mixed as surfactant in a certain microemulsion. The surfactant mixtures are commonly used in many practical applications in order to form mixed micelle aggregates which have shown remarkable differences from those individual components [15]. Some investigations on the conducting property of mixed reverse micelles discussed about the interaction between different kinds of surfactant [16–21]. However, there is still further work can be done to improve the conductivity of microemulsion in the case of applying surfactant mixture. In this paper, we investigated the effect of the mixed surfactants containing CTAB and Triton X-100 on the conductivity of reverse microemulsion for the first time. And the electrochemical behavior of K3Fe(CN)6 in this system was also studied.

2 Materials and methods

2.1 Materials

Triton X-100, CTAB, n-hexanol, n-hexane and potassium ferricyanide were used. Triton X-100 was chemical grade and all the other reagents were analytical grade, which were obtained from Chemistry Reagent Co. of National Medicine Group. Double distilled water was used during all the experiments.

2.2 Methods

For sample preparation, reverse microemulsion was prepared in a 100 mL one-neck flask. The oil phase was mixed together with surfactants and cosurfactant, followed by adding water to obtain the desired microemulsion. In the research of different influencing factors, the components of reverse microemulsion are summarized in Table 1.

The high speed centrifuge (H-1650, Xiangyi Centrifuge Company, China) was employed to characterize microemulsion by setting the mixture in the centrifuge with a speed of 10,000 r min−1 for 10 min. Electrical conductivity measurements were carried out by using a conductivity meter (SDD-11A, Shanghai Rex Instrument Factory, China) at 25 °C except the temperature experiment. The cyclic voltammetry (CV) studies were performed using a CHI model 660C electrochemical workstation (Shanghai Chenhua Instrument Factory, China). The working electrode was a glassy carbon electrode with a surface area S = 0.07 cm2. The platinum wire and saturated calomel electrode (SCE) were used as the counter electrode and reference electrode, respectively.

3 Results and discussion

3.1 Influence of surfactants weight ratio on the conductivity of mixed surfactants reverse microemulsion

Generally, reverse microemulsion containing a single surfactant cannot be used in electrochemistry research directly due to its limitation in conductivity. For instance, the CTAB reverse microemulsion and the Triton X-100 microemulsion have a conductivity of only 30.9 and 16 μS cm−1, respectively, in our research (entries 2 and 3, Table 1). As to the conducting mechanism of reverse microemulsion, there are many kinds of viewpoint. In non-ionic surfactant reverse microemulsion, dispersed droplets are charged during the momentary collision processes and the conductivity is generally considered to be the result of the motion of charged droplets in the electrical field. On the other hand, in ionic surfactant reverse microemulsion such as CTAB system, Lang et al. attributed the conductivity to the motion of the counterions through the transient water channels formed in reverse microemulsion [22]. Based on these mechanisms, we can explain the low conductivity of reverse microemulsion using a single surfactant. Non-ionic surfactant Triton X-100 exists as molecule in the system and the charges of dispersed droplets are difficult to transmit in the continuous phase. While in the CTAB system, ionic surfactant molecule dissociates to counterion and cation. The surfactant group can combine with water or oil molecule tightly and form a compact interfacial film. Therefore, the counterions are difficult to cross the interfacial film during the thermal motion process.

The influence of mixed surfactants weight ratio on the conductivity is presented in Fig. 1 (entry 1, Table 1). Initially, the conductivity of reverse microemulsion increased linearly with increasing the weight ratio of Triton X-100 to CTAB. Then the conductivity increased slowly and stabilized at 1400 μS cm−1 finally, which was 1–2 order of magnitude higher than that of the single surfactant reverse microemulsion. Therefore, the synergistic effect of the two surfactants is obvious.

In the mixed surfactants reverse microemulsion, the interfacial film is composed of surfactant molecules, counterions adsorbed by the hydrophilic part, H2O molecules combined with the EO chain, oil molecules adsorbed by the hydrophobic part and cosurfactant molecules. The characteristics of the two kinds of surfactant might give the mixed interfacial film a special structure. The Triton X-100 molecules are electropositive due to the combination between their EO chain and H2O. Similarly, the CTAB molecules decompose to halide counterions and cations at the same time. When the two surfactants were mixed in the interfacial film, the electrostatic repulsion decreased the compactness of the interfacial film and the transmission of charge became easier. Moreover, because the monomer mole fractions of the two surfactants in mixed film and micelles are different from those in the bulk phase, the composition of the interfacial film is special as well. And the special composition is beneficial to improve the flexibility of the surfactant film which is an important factor in the formation of reverse microemulsion [23]. All these factors above made the conductivity of the reverse microemulsion increase obviously while the whole system still kept stable. When mTriton X-100:mCTAB > 3, the conductivity of reverse microemulsion did not change with further increase of Triton X-100. The reason may be that the structure of interfacial film does not change further with the saturated Triton X-100 molecules. From the aforesaid results, it can be concluded that the interaction between the two surfactants can increase the conductivity of reverse microemulsion to an ideal level which is desired in the direct application of electrochemistry.

3.2 Influence of cosurfactant concentration on the conductivity of mixed surfactants reverse microemulsion

Cosurfactant has some roles which are well documented: (i) prevent formation of rigid structures such as gels, liquid crystals, precipitates, etc.; (ii) lower the viscosity of the system; (iii) reduce the interfacial tension; (iv) increase the fluidity of the interface and thereby increasing the entropy of the system; (v) increase the mobility of the hydrocarbon tail and allow greater penetration of oil into this region; and (vi) influence the solubility properties of the aqueous and oleic phases due to its partitioning between the phases [24]. Due to the effects mentioned above, cosurfactant must have influence on the conductivity of the mixed surfactants reverse microemulsion.

Figure 2 shows the relationship between cosurfactant volume and the conductivity of reverse microemulsion (entry 4, Table 1). The increase of cosurfactant volume resulted in an obvious decrease in the conductivity of reverse microemulsion.

In the reverse microemulsion using CTAB and Triton X-100 as surfactants, the cosurfactant n-hexanol is beneficial to the formation of interfacial film. However, the hydroxyl group of n-hexanol can form hydrogen bond with EO chain and weaken the hydrophilicity of Triton X-100 molecule. The intensity and compactness of interfacial film increase with the further addition of n-hexanol. Simultaneously, the concentration of dissociative n-hexanol molecule increases and the aggregates of n-hexanol molecules form easily on the interfacial film, which hinder the transmission of charges. Therefore, the conductivity of mixed surfactants reverse microemulsion decreases obviously with the increase of n-hexanol volume.

3.3 Influence of H2O concentration on the conductivity of mixed surfactants reverse microemulsion

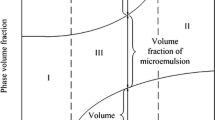

The effect of the volume ratio of water to oil on the conductivity of reverse microemulsion is shown in Fig. 3 (entry 5, Table 1). Initially, the conductivity increases linearly with the addition of water and stabilized till the water to oil ratio climbed up to 0.3. Finally it decreased quickly with the further increase of water because the whole system turned to be translucent liquid crystal state with high viscosity.

Initially, the amount of dispersed droplet increases with the addition of water while its diameter increased slightly. The increase of collision probability enhances the conductivity of reverse microemulsion. With the further addition of water, the density of surfactant molecules in the interfacial film decreases due to the expansion of dispersed droplets, and the hydration of Triton X-100 is enhanced. The aforesaid two influences make the interfacial film more unconsolidated which is beneficial to the increase of conductivity. Finally, when the system presents liquid crystal phase with the further increase of water, the conductivity reaches to a minimum value because of the anisotropy of liquid crystal phase.

3.4 Influence of the temperature on the conductivity of mixed surfactants reverse microemulsion

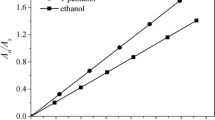

The influence of the temperature was investigated in the system containing all the components (entry 6, Table 1). Figure 4 shows that the conductivity of reverse microemulsion increases linearly in the whole range of temperature selected in the experiment.

This result is caused by the reasons described below. First, with the increase of temperature, the viscosity of the whole system reduces while the thermal motion strengthens simultaneously. Furthermore, the intensity of hydrogen bond between H2O and EO chain is weakened and the surface activity of non-ionic surfactant decreases with the rise of temperature. Therefore, the compactness of interfacial film is destroyed. All these will result in the increase of conductivity.

3.5 The electrochemical behavior of K3Fe(CN)6 in the mixed surfactants reverse microemulsion

According to our research aforesaid, the reverse microemulsion containing two kinds of surfactant with a certain weight ratio has good conductivity. Accordingly, it can be used as electrolyte in electrochemical study. K3Fe(CN)6 was selected as electrochemical probe and its electrochemical behavior in the reverse microemulsion was studied here. Figure 5 shows the cyclic voltammograms of K3Fe(CN)6 in the mixed surfactants reverse microemulsion under different scan rates. The results indicated that the redox peak potentials of \( {{\text{Fe}}\left( {\text{CN}} \right)_{ 6}}^{ 3- } / {{\text{Fe}}\left( {\text{CN}} \right)_{ 6}}^{ 4-} \) were almost constant with the change of scan rate, and the redox potentials gaps under the four different scan rates were about 70 mV. Furthermore, the ratios of redox peak currents of \( {{\text{Fe}}\left( {\text{CN}} \right)_{ 6}}^{ 3- } / {{\text{Fe}}\left( {\text{CN}} \right)_{ 6}}^{ 4- } \, \) at all scan rates were close to 1. Figure 6 shows the relationship between IpO (oxidation peak current) and v1/2. It can be observed that the IpO increased linearly with the square root of scan rate. These conclusions indicate that the electrochemical reaction of K3Fe(CN)6 is a reversible electrochemical reaction and is controlled by diffusion in the reverse microemulsion. Therefore, the mixed surfactants reverse microemulsion that we studied has ideal electrochemical properties and can be used in the research of some special electrochemical reaction processes.

4 Conclusions

The reverse microemulsion with good conductivity is obtained by using Triton X-100 and CTAB as mixed surfactants. The difference between the properties of the two kinds of surfactant makes the interfacial film have special structure and composition. In the mixed surfactants reverse microemulsion, the increases of water concentration and temperature can enhance the conductivity of the system while the addition of cosurfactant n-hexanol will decrease the conductivity obviously. Moreover, this system can be applied directly in electrochemistry. The CV results show that the electrochemical reaction of K3Fe(CN)6 in the reverse microemulsion is controlled by diffusion and presents good reversibility.

References

Jada A, Lang J, Zana R (1989) J Phys Chem 93:10

Giustini M, Palazzo G, Colafemmina G et al (1996) J Phys Chem 100:3190

Han Y, Jiang J, Lee SS et al (2008) Langmuir 24:5842

Wang Y, Shi YC, Xu XK et al (2009) Colloids Surf A 345:71

Li L, Yan GP, Wu JY et al (2008) J Colloid Interface Sci 326:72

Reddy KR, Sin BC, Yoo CH et al (2009) J Colloid Interface Sci 340:160

Milano-Brusco JS, Schwarze M, Djennad M et al (2008) Ind Eng Chem Res 47:7586

Nardello-Rataj V, Caron L, Borde C et al (2008) J Am Chem Soc 130:14914

Ray S, Paul S, Moulik SP (1996) J Colloid Interface Sci 183:6

Zhang XG, Dong JF, Zhang GY et al (2005) J Colloid Interface Sci 285:336

Garcıá-Rıó L, Hervés P, Leis JR et al (1997) Langmuir 13:6083

Zhou HH, Peng CY, Jiao SQ et al (2006) Electrochem Commun 8:1142

Zeng W, Zhou HH, Ying XF et al (2007) Acta Phys Chim Sin 23:769

Peng CY, Zhou HH, Zeng W et al (2006) Acta Phys Chim Sin 22:409

Tejas J, Jitendra M, Pratap B (2005) Colloids Surf A 260:209

Liu DJ, Ma JM, Cheng HM et al (1999) Colloids Surf A 148:291

Bumajdad A, Eastoe J (2004) J Colloid Interface Sci 274:268

Liu DJ, Ma JM, Cheng HM et al (1998) Colloids Surf A 143:59

Fanun M (2008) J Mol Liq 142:103

Liu DJ, Ma JM, Cheng HM et al (1998) Colloids Surf A 139:21

Liu DJ, Ma JM, Cheng HM et al (1998) Colloids Surf A 135:157

Lang J, Mascolo G, Zana R et al (1990) J Phys Chem 94:3069

Lamaallam S, Bataller H, Dicharry C et al (2005) Colloids Surf A 270–271:44

Mitra RK, Paul BK (2005) J Colloid Interface Sci 283:565

Acknowledgments

This work was supported by National Natural Science Foundation of China (No. 20673036, J0830415) and Hunan Provincial Natural Science Foundation of China (09JJ3025).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, J., Zhou, H., Zhang, G. et al. Investigation on conductivity of mixed surfactants reverse microemulsion. J Appl Electrochem 40, 2033–2037 (2010). https://doi.org/10.1007/s10800-010-0184-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-010-0184-9