Abstract

Globo A is a neutral Globo-series glycosphingolipid (GSL) that shows natural properties of a cytotoxicity receptor NKp44 binding ligand. The highly complex heptasaccharide glycan structure of Globo A combined with its biological profile provides a unique target for the development of a synthetic method to facilitate its bioactivity studies. Here, a concise chemoenzymatic route to the synthesis of Globo A and its α1,3-galactose-linked congener Globo B is reported. The key to success was the use of a synthetic azido β-Globo H sphingosine (Globo H-βSph) as an acceptor substrate and two glycosyl transferases, an α1,3-N-acetylgalactosaminyltransferase from Helicobacter mustelae (BgtA) and a human blood group B α1,3-galactosyltransferase (h1,3GTB), for stereoselective construction of the terminal α1,3-GalNAc and α1,3-Gal linkages, respectively. The azido-Sph lipid sidechain is further elaborated by reduction and a chemoselective N-acylation to complete the total synthesis of the neutral Globo-series GSLs. In addition, the synthesis of Forssman and para-Forssman antigens were prepared. The strategy may be suitable for accessing other complex GSLs and related lipid-modified GSL derivatives.

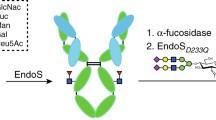

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Glycans, which are often expressed as glycosphingolipids (GSLs) or glycoproteins, play important roles in many biological and pathological processes, such as cell–cell adhesion, microbial pathogenic infection, and immune regulation [1, 2]. GSLs are amphipathic biomolecules possessing a diverse family of hydrophilic glycan structures covalently attached to the C1-hydroxyl group of a hydrophobic ceramide (Cer) component. Typically, they are ubiquitously anchored to the outer leaflet of the eukaryotic cell plasma membranes and cluster into lipid rafts [3]. GSLs can be broadly categorized into three subgroups based on the common neutral core glycans: ganglio-, (neo) lacto-, and Globo-series [4]. They are characterized to function as blood-group antigens, cell-type-specific antigens, tumor-associated antigens, stage-specific embryonic antigens (SSEAs), receptors for microbial pathogens and protein toxins, and modulators of cell signal transduction, inflammation, and apoptosis [5, 6].

The endogenous function of the Globo-series glycan family remains largely unknown. However, high-level expression of certain GSLs is associated with many types of cancer growth and progression; therefore, GSLs are useful as lineage-specific cancer biomarkers [7]. For example, Globo-pentaosyl Cer (Galβ1-3GalNAcβ1-3Galα1-4Galβ1-4Glcβ1β-Cer, Gb5-Cer, or SSEA-3) and α2,3-sialyl Gb5-Cer (SSEA-4) are expressed on many types of stem cells and considered as cell-surface markers for human embryonic stem cells (hESCs) [8]. Furthermore, α1,2-fucosyl Gb5-Cer (or Globo H Cer) is the most prevalent cancer-associated GSL, being aberrantly expressed in many epithelial-cell cancers such as endometrial, colon, ovarian, prostate, and breast cancers [9]. The emerging biological activities of these GSLs have sparked considerable interest in their preparation using chemical or chemoenzymatic methods [10], which has led to the development of GSL-targeting anticancer immunotherapeutics [11, 12].

Two notable heptasaccharide members of the Globo-series GSL family are Globo A (1) and Globo B (2) (Fig. 1). These glycans share the common neutral precursor Globo H but vary in their terminal monosaccharide: α1,3-linked 2-N-acetylgalactosamine (GalNAc) for Globo A (1) [13] and α1,3-linked galactose (Gal) for Globo B (2) [14]. Globo A is abundantly found in large quantities in the kidney, but it is also present in trace amounts in red blood cells [15]. Its expression in undifferentiated NTERA-2 cell lines was often used for human embryonal carcinoma (EC) cell characterization [16]. The differentiated cells rapidly decrease biosynthesis of Globo-series GSLs Globo A and Globo H and increase expression of lacto- and ganglio-series GSLs. Globo A specific bacterial adhesins also appeared to have been found to be blood group A antigens for attachment to uroepithelial cells [17]. Recently, this glycolipid was shown to bind with recombinant NKp44, a member of the natural cytotoxicity receptors (NCRs) but have no binding interaction between NCRs and its α1,3-Gal linked congener Globo B [14]. Globo A terminates with an α1,3-GalNAc linkage, similar to the glycan structure of the nblood group A antigen (GalNAcα1,3(Fucα1,2)Galβ-), but its relevance in the regulation of natural killer cell function is yet to be determined. This suggestive but limited evidence concerning the possible biological functions of these glycolipid glycans in addition to glycolipids prompted us to investigate in greater detail the synthesis of neutral GSLs Globo A and Globo B and their glycan derivatives (Fig. 1).

Herein, we describe the implementation of a chemoenzymatic modular assembly strategy that concisely deploys a synthetic azido β-Globo H sphingosine (Globo H-βSph) acceptor building block and α-1,3-GalNAc/Gal glycosyltransferases (GTs) for the rapid generation of Globo A (1) and Globo B (2) GSLs, as shown in Fig. 1. In addition, the method yields Globo A and Globo B glycans both presenting a readily functionalizable aglycone group. The azido-Sph glycans (3 and 5) can be used for late-stage lipid remodeling, whereas the attached short-chain azidohexyl at the reducing end may enable the glycan derivatives (4 and 6) for easy attachment to glass surfaces for microarray immobilization, both of which are crucial for structure–function relationship analysis. A similar synthetic concept was also applied to the synthesis of Forssman and para-Forssman antigens.

Results and discussion

Retrosynthetic analysis

Our group recently reported a divergent synthesis of various immunosuppressive Globo H Cers utilizing azide-containing β-Globo H Sph 7 as a starting material (Fig. 2) [18]. Globo H-βSph 7 is of particular interest to us because of its ready accessibility from β-lactosyl Sph acceptor by enzymatic glycan extension and its highly modifiable partial Cer structure, which allows for rapid elaboration by chemoselective N-acylation for lipid diversification. Most importantly, it obviates the need for multiple GT-catalyzed stepwise glycosylations to elongate glycan headgroups and build the Globo-series glycan framework. This presents a unique opportunity for divergence in the synthesis of Globo A and its α1,3-Gal-linked congener, Globo B. In our strategy (Fig. 2), fatty acid was incorporated into azido glycans Globo A-βSph (3) and Globo B-βSph (5), respectively, in a late-stage chemoselective N-acetylation to complete the total synthesis. Globosides 3 and 5 would in turn emerge from an enzymatic α1,3-glycosylation of the Globo H-βSph acceptor 7. Similar enzymatic glycosylation on Globo H-βO(CH2)6N3 8 would provide Globo A and Globo B glycans, 4 and 6, respectively.

Synthesis of Globo A and Globo B glycans

The combination of sugar nucleotides and promiscuity of GTs substantially minimizes the need for manual manipulations and purification steps involved in enzymatic oligosaccharide synthesis [19, 20]. A bacterial homolog GT for the human blood group A antigen synthesis, BgtA, expressed in E. coli cell cultures, has been reported [21]. It was shown to transfer GalNAc from UDP-GalNAc onto the C-3 position of Gal in Fucα(1–2)Gal structures. To avoid undesired intermediate purification, we first carried out acceptor specificity of α1,3-GalNAc GT (BgtA) using a one-pot multienzyme (OPME) system for GalNAc activation and transfer (Scheme 1). Synthetic Gb5 and Globo H derivatives containing azidohexyl aglycone or a hydrophobic Sph at the reducing end were investigated as potential acceptors. The results revealed that BgtA only recognized Globo H glycans as the acceptor and UDP-GalNAc as the donor (Table 1).

As shown in Scheme 1, Globo H-βO(CH2)6N3 (8) was quantitatively transformed into Globo A-βO(CH2)6N3 heptasaccharide 4. In this OPME system [18, 22], free monosaccharide donor substrate GalNAc (1.2 equiv) was first activated to form GalNAc-1-phosphate (GalNAc-1-P) by a Bifidobacterium longum N-acetylhexosamine 1-kinase (NahK) [23] in HEPES buffer in the presence of adenosine 5′-triphosphate (ATP, 1.2 equiv) and MgCl2 (20 mM). A recombinant human UDP-GalNAc pyrophosphorylase (AGX1) [24] converted GalNAc-1-P to UDP-GalNAc in the presence of uridine 5′-triphosphate (UTP, 1.2 equiv). The UDP-GalNAc generated in situ was then utilized as a donor and transferred onto the 3-O-position of the terminal Gal of 8 by a Helicobacter mustelae BgtA in HEPES buffer (100 mM, pH 7.8). Importantly, Globo H-βSph 7 was also found to be a suitable acceptor for BgtA; we introduced GalNAc residue to 7 in a similar one-pot three-enzyme procedure, which provided Globo A-βSph 3 at 80% yield for a preparative-scale synthetic reaction at 37 °C for 12 h. However, no activity was observed for non-fucosylated azidohexyl Gb5-βO(CH2)6N3 [22] (Table 1), consistent with a strict specificity of BgtA toward terminal Fucα1,2Gal sequences [21]. In addition, BgtA did not recognize donor UDP-Gal, as expected, excluding the role of the 2-hydroxyl group in substrate binding (Table 1).

To find a suitable α1,3-galactosyltransferase (α1,3-GalT), we used human blood group B galactosyltransferase (h1,3GTB) and bovine α1,3-GalT (Bvα1,3GalT) for their ability to catalyze the formation of α1,3-Gal linkage using UDP-Gal (Scheme 1 and Table 2). h1,3GTB is a retaining α1,3-GalT for in vivo biosynthesis of blood group B antigen (Galα1,3(Fucα1,2)Galβ1-) from H antigen [25]. However, its substrate specificity toward Globo H acceptor is still unknown [26, 27]. Because of its low overexpression in the E. coli host, we used purified UDP-Gal as the donor. Screening of h1,3GTB acceptor specificity showed that h1,3GTB can only tolerate Globo H glycans 7 and 8 with good conversion based on TLC analysis. The h1,3GTB-catalyzed α1,3-galactosylation was completed in 48 h at 37 °C in Tris–HCl buffer (100 mM, pH 7.2) for acceptor 8, while 51 h was required by the Sph acceptor 7 for completion of the reaction to produce Globo B glycans 5 (70%) and 6 (quant.), respectively. Notably, h1,3GTB neither transferred Gal to a non-fucosylated Gb5-βO(CH2)6N3 acceptor nor recognized UDP-GalNAc as the donor. By contrast, despite its preference toward lactose (Lac) and LacNAc-based acceptors, Bvα1,3GalT [28] could not galactosylate Globo H acceptor (8), but it was hardly reactive toward Gb5-βO(CH2)6N3 (approximately 20% based on the disappearance of acceptor on TLC) using UDP-Gal as the donor.

Synthesis of Globo A and Globo B GSLs

With Globo A-βSph 3 and Globo B-βSph 5 in hand, we turned our attention to the synthesis of GSLs Globo A and Globo B. As shown in Scheme 2, Globosides (3 and 5) were subjected to chemical N-acylation under previously described conditions to install the second lipid chain of the Cer [18]. In brief, azide reduction of glycan 3 was followed by a reaction with activated palmitoyl chloride to straightforwardly produce Globo A (1). The final glycolipid was purified first on a flash silica-gel column followed by size-exclusion chromatography (Toyopearl HW-40F) with MeOH as eluent and lyophilization to afford GSL 1 in 70% overall yield (two steps). The use of Globo B-βSph 5 with a similar reduction and palmitoylation protocol generated Globo B (2) in 66% yield (two steps). The homogeneity of the synthetic GSLs 1 and 2 was definitively confirmed by NMR and HRMS analyses.

Synthesis of Forssman and para-Forssman antigens

Forssman and para-Forssman antigens are two other members of the Globo-series GSLs, both of which have in common a core Gb4-Cer (GalNAcβ1-3Galα1-4Galβ1-4Glcβ1β-Cer). They are commonly isolated from sheep and human erythrocyte membranes, respectively [29, 30]. While altered expression levels of both α1,3GalNAc-linked Gb4 or Forssman (GalNAcα1,3GalNAcβ1-3Galα1-4Galβ1-4Glcβ1β-) and β1,3GalNAc-linked Gb4 or anti-Forssman glycolipid antigens have been observed in gastric or gastrointestinal cancer progression [31, 32], the former has also been reported to bind to SLL-2 lectin from Simularia lochmodes [33]. Chemical and chemoenzymatic methods have been developed for synthesizing these glycolipid antigens [33,34,35,36,37]. The enzymatic synthesis of para-Forssman antigen was studied by Li recently [38], using UDP-GalN as a donor and Campylobacter jejuni β1,3GalT (CgtB) [39] as the catalyst. In our study, we first investigated 10, 13, and 14 (Scheme 3) as the acceptor and UDP-GalNAc or UDP-GalN as the donor by using LgtD as the catalyst. The results showed that LgtD could not catalyze all reactions tested. Fortunately, employing Gb4 tetrasaccharide 10 [22] as an acceptor substrate in the CgtB-catalyzed glycosylation with UDP-GalN, but with modification of the selective N-acetylation condition (Ac2O, aqueous NaHCO3, rt, 5 min), para-Forssman antigen 12 was obtained in 24% yield (for two steps). It should be noted that Gb4NTFA 13 was also accepted by CgtB. However, the TFA was hydrolyzed during the reaction.

The aforementioned study (Table 2) indicated that Bvα1,3GalT could transfer Gal onto the Gal acceptor, although the conversion yield was not high. Moreover, we previously demonstrated that GalN could be the Gal mimic to serve as an acceptor for transferase-catalyzed reactions [40]. In an attempt to synthesize Forssman antigen pentasaccharide (16) straightforwardly, we envisioned that Gb4NH2 (14, Scheme 3) might serve as a viable acceptor for Bvα1,3GalT. Therefore, we turned our attention to preparing amino-Gb4 derivative 14. In addition, in our previous study [40], we found that the TFA group could serve as a good surrogate of the Ac group in enzymatic reactions. Thus, we prepared UDP-GalTFA using the previously developed sugar nucleotide regeneration system (SNRS) [41], and enzymatically assembled GalTFA on Gb3 (9) to afford intermediate 13. The reaction pH was then adjusted to 11 to remove TFA and give amino-Gb4 14 in 95% yield (for two steps). The Gb4 tetrasaccharide acceptor 14 was enzymatically glycosylated by Bvα1,3GalT using UDP-GalN as the donor. Analysis of the reaction mixture showed a newly formed spot on TLC. The resulting pentasaccharide intermediate (15), without further characterization, was selectively N-acetylated on the free amine group on two GalN residues using the aforementioned modified condition and provided the desired Forssman antigen 16 in 29% yield (for two steps).

Conclusion

This report outlines a straightforward chemoenzymatic method for the synthesis of Globo-series neutral GSLs Globo A and Globo B. The azido group on the Globo A-βSph 3 and Globo B-βSph 5 can then be reduced and selectively acylated by chemical means for lipid diversification and can serve as suitable substrates for the incorporation of designed molecular labels. In addition, oligosaccharide moiety of the Forssman and para-Forssman antigens were also prepared by using UDP-GalN as the donor. The strategy should be applicable for synthesizing non-natural glycolipids, which might have potentially useful applications for structure–activity relationship studies of these GSLs.

Materials and methods

General methods

All solvents were dried and distilled by standard techniques. N,N-Dimethylformamide (DMF) was vacuum-distilled over sodium hydride. Pyridine was distilled over sodium hydride. Tetrahydrofuran (THF) was distilled from sodium under nitrogen (N2). Dichloromethane (DCM), toluene, and acetonitrile (ACN) were distilled from calcium hydride under N2. The chemicals for the synthesis were all obtained from Acros, Merck, Fluka, or Sigma-Aldrich and used without further purification unless otherwise noted. All reactions were carried out in oven-dried glassware (104 °C) and performed under anhydrous conditions with N2 unless indicated otherwise. The reactions were monitored by analytical thin-layer chromatography (TLC) on Merck silica gel 60 F254 plates (0.25 mm). Detection was accomplished by examination under UV light (254 nm) and by staining with p-anisaldehyde, ninhydrin, cerium molybdate, or potassium permanganate staining solution. Silica gel column chromatography was performed using a forced flow of the indicated solvent on silica gel 60 (Merck). Size exclusion column chromatography was performed by gravity on polymethacrylic polymer beads (Toyopearl HW-40F or HW-40S) with MeOH or deionized H2O and polyacrylamide gel (Bio-Gel P-2) with deionized H2O. Matrixes of bacterial cultural media were purchased from BD Bioscience. The concentration of proteins was determined with Bradford protein assays purchased from Bio-Rad using bovine serum albumin as the standard. IMPACT™ system (Intein Mediated Purification with Affinity Chitinbinding Tag) was purchased from New England Biolabs. His-tag purification resin was purchased from Roche. HiTrap IMAC FF column (5 mL) was purchased from GE Healthcare Life Sciences. C18 reversephase silica column (Sep-Pak Vac C18 cartridge 20 cc/5 g 55–105 µm, Waters) was used to perform reverse-phase column chromatography with methanol and deionized H2O. 1H and 13C NMR spectra were recorded by Bruker AV-400, Varian MR-500 or Bruker AV-850. Chemical shifts are expressed in ppm using residual CDCl3 (7.24 ppm), CD3OD (3.31 ppm), or D2O (4.79 ppm at 298 K) as internal standard in 1H-NMR spectra. 13C NMR spectra were recorded in either CDCl3, CD3OD or D2O at a 126 or 214 MHz, using the central resonances of CDCl3 (77.0 ppm) and CD3OD (49.0 ppm) as the internal references. Multiplicities are reported by using the following abbreviations: s = singlet, d = doublet, t = triplet, q = quartet, m = multiplet, br = broad; J = coupling constant values are expressed in Hertz. Mass spectra were obtained in ESI mode.

General procedure of overexpression and purification of target enzymes

Bacterial strains, plasmids, and materials

Chemical competent E. coli BL21(DE3) were purchased from Yeastern Biotechnology (Taipei, Taiwan). Ni2+–NTA resin (nickel– nitrilotriacetic acid–agarose) was purchased from Roche. Phosphoenolpyruvic acid kinase (PK) from Rabbit muscle was purchased from Calzyme (San Luis Obispo, CA).

Cloning and overexpression of enzymes

MtGalK [42], NahK [43], AtUSP [44], AGX-1 [45], LgtD [46], BgtA [21], CgtB [47], h13GTB [25] and BvαGalT [28] were cloned and overexpressed as previously reported procedures.

General procedure of enzyme overexpression

Positive plasmid was selected and subsequently transformed into E. coli BL21 (DE3), Arctic Express (DE3), or BL21 GOLD (DE3), and cultured in 5 mL Luria–Bertani (LB)-rich medium containing antibiotics with rapid shaking (200 rpm) for overnight at 37 °C. Then, the cell culture was transferred into 500 mL LB rich medium or Terrific broth with appropriate concentration of antibiotics and incubated with shaking at 200 rpm at 37 °C. When the OD600 nm of the cell culture reached 0.5–0.8, IPTG was added to induce the overexpression of recombinant enzyme. The cell culture medium was incubated with shaking at 200 rpm (Firstek S300R) for 20 h at 16 °C. Cells were harvested by centrifugation at 5000 rpm for 8 min at 4 °C. The harvested cells were washed with 0.9% NaCl aqueous solution followed by centrifugation at 5000 rpm for 15 min at 4 °C.

Synthetic procedures and characterization of compounds

Compound 1

To a solution of compound 3 (6.0 mg, 0.0039 mmol) in a co-solvent of pyridine (360 µL) and H2O (360 µL) was added Et3N (48 µL) and 1,3-propanedithiol (45.6 µL). The reaction mixture was stirred at 50 °C for 1 h. After completion of reaction as indicated by TLC (n-PrOH/H2O/AcOH = 10:2:1 (v/v/v), Rf = 0.09), the reaction mixture was concentrated in vacuo. The resulting residue was purified by a C18 reverse-phase silica column (Sep-Pak Vac C18 cartridge 5 g, 55–105 µm, Waters) using a solution followed by stepwise elution of 0–100% MeOH in H2O as eluent (increase 10% MeOH per step, 20 mL eluent for each step) to give crude. The above crude was dissolved in a solution containing saturated NaHCO3 (aq.) (900 µL), THF (450 µL), and H2O (2.7 mL). The reaction mixture was cooled with ice bath and then a solution of C15H31COCl (0.0257 mmol) in THF (450 µL) was added at 0 °C. The reaction mixture was warmed to rt and stirred for 30 min. After completion of reaction as indicated by TLC (n-PrOH/H2O/AcOH = 10:2:1 (v/v/v), Rf = 0.26), the reaction mixture was concentrated and purified by silica gel chromatography (EtOAc/MeOH = 5/1 → EtOAc/MeOH/H2O = 6/2/1) and size exclusion column chromatography performed on polymethancrylic polymer beads (Toyopearl HW-40F) with MeOH to afford compound 1 (4.8 mg, 70% for two steps). 1H NMR (500 MHz, CD3OD): δ 5.68 (dt, J = 15.1, 7.5 Hz, 1H), 5.44 (dd, J = 15.1, 7.9 Hz, 1H), 5.25 (d, J = 3.8 Hz, 1H), 5.15 (d, J = 3.4 Hz, 1H), 4.94 (d, J = 3.7 Hz, 1H), 4.58 (d, J = 7.3 Hz, 1H), 4.52 (d, J = 8.6 Hz, 1H), 4.41 (t, J = 3.5 Hz, 1H), 4.32 (t, J = 8.3 Hz, 1H), 4.28 (d, J = 3.7, 1H), 4.23–3.65 (m, 32H), 3.61–3.35 (m, 10H), 3.28 (m, 1H, overlapped with residual CD3OD), 2.16 (dt, J = 7.5 Hz, 2H), 2.02 (s, 3H), 2.00 (s, 3H), 1.59 (br, 2H), 1.33–1.27 (m, 48H), 1.24 (d, J = 6.6 Hz, 3H), 0.89 (t, J = 7.0 Hz, 6H); 13C NMR (126 MHz, CD3OD): δ 176.0, 174.6, 174.4, 135.1, 130.6, 105.5 (2C), 104.4, 104.2, 102.8, 100.2, 93.4, 81.2, 80.5, 80.0, 79.4, 77.7, 76.5, 76.4 (2C), 76.2, 74.9, 74.7, 73.8, 73.5, 73.0, 72.7, 72.6, 72.4, 71.6, 71.5, 71.4, 71.34, 71.28, 71.2, 70.6, 70.0 (2C), 69.7, 68.7, 67.9, 64.7, 63.5, 62.6 (2C), 61.8, 61.6, 54.7, 53.0, 51.3, 40.3, 38.0, 37.4, 34.8, 33.5, 33.1, 31.8, 31.7, 30.8 (2C), 30.7 (2C), 30.5, 30.1, 28.1, 27.3, 27.2, 26.0, 25.9, 25.1, 24.9, 24.8, 24.0, 23.7, 23.6, 22.7, 20.7, 16.6, 14.5, 11.4; HRMS (ESI) m/z calcd for C80H143N3NaO37 [M + Na]+: 1760.9298, found 1760.9303.

Compound 2

The procedure for the synthesis of compound 2 is similar as described in the synthesis compound 1 using compound 5 (2.0 mg, 0.00135 mmol). The resulting residue was purified by silica gel chromatography (EtOAc/MeOH = 5/1 → EtOAc/MeOH/H2O = 6/2/1) and C18 reverse-phase silica column (Sep-Pak Vac C18 cartridge 5 g, 55–105 µm, Waters) using a solution followed by stepwise elution of 0–100% MeOH in H2O as eluent (increase 10% MeOH per step, 20 mL eluent for each step) to afford compound 2 (1.5 mg, 66% for two steps). 1H NMR (850 MHz, CD3OD): δ 5.68 (dt, J = 15.2, 6.7 Hz, 1H), 5.44 (dd, J = 15.2, 7.7 Hz, 1H), 5.25 (d, J = 4.1 Hz, 1H), 5.13 (d, J = 3.9 Hz, 1H), 4.94 (d, J = 4.0 Hz, 1H), 4.58 (d, J = 7.6 Hz, 1H), 4.52 (d, J = 8.4 Hz, 1H), 4.41–4.39 (m, 1H), 4.32 (dt, J = 6.6, 6.6 Hz, 1H), 4.29 (d, J = 7.8 Hz, 1H), 4.21 (t, J = 5.9 Hz, 1H), 4.17 (dd, J = 10.0, 4.5 Hz, 1H), 4.15 (dd, J = 6.5, 5.1 Hz, 1H), 4.13 (d, J = 2.3 Hz, 1H), 4.10 (t, J = 3.1 Hz, 2H), 4.06 (t, J = 8.1 Hz, 1H), 4.02 (dd, J = 10.7, 8.6 Hz, 1H), 4.00–3.97 (m, 3H), 3.93–3.87 (m, 5H), 3.84 (dd, J = 10.1, 4.5 Hz, 2H), 3.82 (d, J = 6.0 Hz, 2H), 3.80 (dd, J = 9.1, 3.1 Hz, 2H), 3.78–3.70 (m, 8H), 3.68 (td, J = 12.0, 4.5 Hz, 3H), 3.60–3.52 (m, 7H), 3.51 (dd, J = 6.8, 5.5 Hz, 1H), 3.40 (dt, J = 9.3, 3.3 Hz, 1H), 3.30–3.28 (m, 1H), 2.16 (t, J = 7.6 Hz, 2H), 2.01 (s, 3H), 1.59–1.56 (m, 2H), 1.32–1.26 (m, 48H), 1.23 (d, J = 6.5 Hz, 3H), 0.89 (t, J = 7.2 Hz, 6H); 13C NMR (214 MHz, CD3OD): δ 175.8, 174.3, 135.1, 131.0, 105.3, 105.2, 104.2, 103.9, 102.7, 100.0, 96.0, 81.1, 80.4, 80.2, 79.6, 79.2, 76.2, 76.1, 76.0, 75.9, 74.6, 74.5, 73.7, 73.2, 72.9, 72.8, 72.5, 72.3, 71.4, 71.10, 71.05, 70.3, 69.8, 69.7 (2C), 69.6, 69.3, 67.6, 65.5, 63.2, 62.6, 62.5, 62.4, 61.6, 61.4, 54.4, 52.8, 49.5, 37.3, 33.3, 32.9, 30.7, 30.65 (13C), 30.61, 30.60, 30.57, 30.53, 30.46, 30.31, 30.29, 30.2, 27.0, 23.6, 23.4, 16.5, 14.4; HRMS (ESI-TOF): m/z of C78H139N2O37 [M]−: calcd. 1695.9057, found 1695.9057.

Compound 3

The procedure for the synthesis of compound 3 is similar as described in the synthesis compound 4 using compound 7 (6.5 mg, 5 μmol, 15 mM). The resulting residue was purified by a C18 reverse-phase silica column (Sep-Pak Vac C18 cartridge 5 g, 55–105 µm, Waters) using a solution followed by stepwise elution of 0–90% MeOH in H2O as eluent (increase 10% MeOH per step, 20 mL eluent for each step). Fractions containing compound 3 were collected while solvents were removed by high-vacuum evaporator. The product was further purified by silica gel chromatography using EtOAc, MeOH and H2O (4/2/1 v/v/v) to give compound 3 in 80% yield (6.0 mg). Rf = 0.55 (n-PrOH/H2O/AcOH = 6:2:1 (v/v/v)).; 1H NMR (400 MHz, CD3OD): δ 5.76 (dt, J = 15.3, 6.9 Hz, 1H), 5.50 (ddt, J = 15.3, 7.5, 1.2 Hz, 1H), 5.25 (d, J = 4.1 Hz, 1H), 5.15 (d, J = 3.8 Hz, 1H), 4.94 (d, J = 3.9 Hz, 1H), 4.58 (d, J = 7.5 Hz, 1H), 4.51 (d, J = 8.3 Hz, 1H), 4.41 (t, J = 3.8 Hz, 1H), 4.35–4.28 (m, 3H), 4.21 (t, J = 6.3 Hz, 1H), 4.19–4.09 (m, 5H), 4.02 (dd, J = 10.8, 8.3 Hz, 1H), 3.99–3.95 (m, 2H), 3.92 (dd, J = 6.2, 3.9 Hz, 1H), 3.90–3.50 (m, 29H), 3.47 (dd, J = 6.9, 5.5 Hz, 1H), 3.40 (dt, J = 9.4, 3.3 Hz, 1H), 3.30–3.29 (m, 1H), 2.06 (dt, J = 6.8, 6.8 Hz, 2H), 2.02 (s, 3H), 2.00 (s, 3H), 1.41–1.36 (m, 2H), 1.33–1.27 (m, 20H), 1.24 (d, J = 6.5 Hz, 3H), 0.88 (t, J = 6.9 Hz, 3H); 13C NMR (126 MHz, CD3OD): δ 174.4, 174.3, 135.8, 129.3, 105.18, 105.16, 104.0, 103.9, 102.6, 99.9, 93.2, 80.9, 80.3, 80.1, 79.1, 77.4, 76.2, 76.1, 76.0 (2C), 74.5, 74.4, 73.6, 73.3, 73.2, 72.4, 72.3, 71.4, 70.34, 70.29, 70.0, 69.8, 69.7, 69.6, 69.3, 67.7, 66.9, 64.5, 63.2, 62.5, 62.4, 62.3, 61.7, 61.4, 52.73, 52.72, 51.09, 51.08, 33.2, 32.9, 30.58 (2C), 30.56, 30.55, 30.5, 30.4, 30.3, 30.1, 30.0, 23.5, 23.4, 22.7, 16.5, 14.4; HRMS (ESI-TOF): m/z of C64H111N5O36Na [M + Na]+: calcd. 1548.6906, found 1548.6893.

Compound 4

The reaction was carried out by a sequential one-pot system. To a HEPES buffer (100 mM, pH 9.0, 0.8 mL) containing GalNAc (1.5 mg, 7 μmol, 6.7 mM), ATP-2Na (4.2 mg, 8 μmol, 7.7 mM), and MgCl2 (20 mM) was adjusted its pH to 8.0. Then, NahK (0.15 mg/mL) was added to the above solution, and dd water was added up to 1 mL of total volume. The resulting mixture was incubated at 37 °C with agitation at 200 rpm for 2 h and the formation of GalNAc-1-P was monitored by thin-layer chromatography (TLC) analysis (n-PrOH/ H2O/ AcOH = 6:2:1 (v/v/v), Rf = 0.35). The formation of GalNAc-1-P was monitored from TLC. After the conversion of galactose is approximately more than 50%, HEPES buffer (100 mM, pH 9.0) 0.3 mL containing UTP-2Na (4.1 mg, 8 μmol, 5.1 mM) and MgCl2 (20 mM) was added. The pH value of the solution was adjusted to pH 7.8. Then, AGX-1 (0.1 mg/mL) and IP (0.15 mg/mL) was added to the above solution, and dd water was added up to 1.5 mL of total volume. The solution was incubated at 37 °C for 4 h with agitation at 200 rpm and the formation of UDP-Gal was monitored by TLC (n-PrOH/ H2O/ AcOH = 6:2:1 (v/v/v), Rf = 0.15). After the conversion of GalNAc-1-P to UDP-GalNAc reached approximately 50%, HEPES buffer (100 mM, pH 9.0) 0.2 mL containing compound 8 (5.6 mg, 5 μmol, final concentration 2.5 mM) and MgCl2 (20 mM) was added to the reaction mixture. The pH of solution was adjusted to 7.8. BgtA (0.4 mg/mL) was added to the above solution, and dd water was added up to 2 mL of total volume. The reaction mixture was incubated with agitation at 200 rpm at 37 °C. The progress of the reaction was monitored by TLC. More enzymes were added if necessary. When TLC analysis indicated the completion of the reaction after 15 h, the resultant was quenched by addition of the same reaction volume of EtOH. The reaction solution was centrifuged (10,000 × g, 10 min) to remove enzymes and insoluble precipitates. The supernatant was collected, concentrated and filtration (0.45 μM PVDF filter; Millipore). The resulting residue was purified by a C18 reverse-phase silica column (Sep-Pak Vac C18 cartridge 5 g, 55–105 µm, Waters) using a solution followed by stepwise elution of 0–30% MeOH in H2O as eluent (increase 10% MeOH per step, 20 mL eluent for each step). Fractions containing compound 4 were collected while solvents were removed by high-vacuum evaporator. The product was further purified by size-exclusion chromatography (Bio Gel P-2 gel packed in column, 1.5 cm × 50 cm, Bio-Rad) with dd H2O as eluent and then lyophilized to give compound 4 in quantitative yield (7.0 mg). Rf = 0.42 (n-PrOH/H2O/AcOH = 6:2:1 (v/v/v)).; 1H NMR (500 MHz, D2O): δ 5.26 (d, J = 4.0 Hz, 1H), 5.16 (d, J = 3.6 Hz, 1H), 4.88 (d, J = 3.8 Hz, 1H), 4.65 (d, J = 7.7 Hz, 1H), 4.52 (d, J = 7.4 Hz, 1H), 4.50 (d, J = 7.8 Hz, 1H), 4.47 (d, J = 8.0 Hz, 1H), 4.38 (d, J = 6.4 Hz, 1H), 4.30–4.27 (m, 2H), 4.23–4.21 (m, 3H), 4.12 (br, 1H), 4.02 (d, J = 3.0 Hz, 1H), 3.99–3.54 (m, 34H, including 1 OH), 3.33–3.27 (m, 3H), 2.03 (s, 6H), 1.63–1.59 (m, 4H), 1.40–1.37 (m, 4H), 1.21 (d, J = 6.5 Hz, 3H); 13C NMR (126 MHz, D2O): δ 175.7, 175.5, 105.1, 104.3, 103.1, 103.0, 101.5, 99.8, 92.2, 79.8, 79.3, 78.2, 77.9, 76.5, 76.4, 75.84, 75.79, 75.6 (2C), 74.0, 73.9, 73.1, 72.8, 72.0, 71.9, 71.5, 71.1, 70.9, 70.2, 69.54, 69.52, 98.8, 68.71, 68.66, 67.9, 64.0, 62.4, 62.03, 61.96, 61.35, 61.32, 61.1 52.5, 52.1, 50.6, 29.6, 28.9, 26.7, 25.6, 23.3, 22.9, 16.3; HRMS (ESI-TOF): m/z of C52H89N5O35Na [M + Na]+: calcd. 1366.5236, found 1366.5235.

Compound 5

The procedure for the synthesis of compound 5 is similar as described in the synthesis compound 6 using compound 7 (5.1 mg, 10 mM). The resulting residue was purified by a C18 reverse-phase silica column (Sep-Pak Vac C18 cartridge 5 g, 55–105 µm, Waters) using a solution followed by stepwise elution of 0–90% MeOH in H2O as eluent (increase 10% MeOH per step, 20 mL eluent for each step). Fractions containing compound 5 were collected while solvents were removed by high-vacuum evaporator and then lyophilized to give compound 5 in 70% yield (4.0 mg). Rf = 0.42 (n-PrOH/H2O/AcOH = 10:2:1 (v/v/v)); 1H NMR (500 MHz, CD3OD): δ 5.76 (dt, J = 15.3, 6.9 Hz, 1H), 5.50 (dd, J = 15.3, 7.5 Hz, 1H), 5.25 (d, J = 4.0 Hz, 1H), 5.14 (d, J = 3.7 Hz, 1H), 4.94 (d, J = 3.8 Hz, 1H), 4.58 (d, J = 7.5 Hz, 1H), 4.51 (d, J = 8.3 Hz, 1H), 4.41 (t, J = 3.7 Hz, 1H), 4.33–4.30 (m, 2H), 4.21 (t, J = 6.1 Hz, 1H), 4.17–4.13 (m, 3H), 4.11 (t, J = 3.5 Hz, 2H), 4.02 (dd, J = 10.6, 8.1 Hz, 1H), 4.00–3.97 (m, 2H), 3.92–3.85 (m, 6H), 3.84–3.62 (m, 19H), 3.60–3.50 (m, 7H), 3.40 (dt, J = 9.6, 3.1 Hz, 1H), 3.29–3.28 (m, 1H), 2.06 (dt, J = 7.0, 7.0 Hz, 2H), 2.01 (s, 3H), 1.41–1.37 (m, 2H), 1.33–1.27 (m, 20H), 1.22 (d, J = 6.5 Hz, 3H), 0.88 (t, J = 6.9 Hz, 3H); 13C NMR (126 MHz, CD3OD): δ 174.4, 135.8, 129.3, 105.21, 105.18, 104.0, 103.9, 102.6, 99.9, 95.9, 80.9, 80.4, 80.1, 79.5, 79.1, 76.2, 76.11, 76.09, 75.8, 74.5, 74.4, 73.7, 73.3, 73.2, 72.8, 72.4, 72.3, 71.3, 71.1, 71.0, 70.3, 70.0, 69.73, 69.68, 69.6, 69.3, 67.6, 66.9, 65.4, 64.2, 63.2, 62.5, 62.42, 62.36, 61.7, 61.4, 52.8, 33.3, 32.9, 30.60, 30.59, 30.57, 30.56, 30.54, 30.4, 30.3, 30.1, 30.0, 23.6, 23.4, 16.5, 14.4; HRMS (ESI-TOF): m/z of C62H108N4O36Na [M + Na]+: calcd. 1507.6641, found 1507.6624.

Compound 6

The reaction was carried out by directly using purified UDP-Gal. The pH of a buffer solution (100 mM Tris–HCl, pH 9.0, 0.17 mL) containing UDP-Gal (20 mM), compound 8 (2.0 mg, 10 mM), 40 mM of MgCl2, and 40 mM of MnCl2 was adjusted to 7.2. Then, 0.17 mL of concentrated h1,3GTB and 0.1 mg/mL of BSA, were added to the above solution. The resulting mixture was incubated at 37 °C with agitation at 200 rpm. More enzymes were added if necessary. When TLC analysis indicated the completion of the reaction after 48 h, the resultant was quenched by addition of the same reaction volume of EtOH. The reaction solution was centrifuged (10,000 × g, 10 min) to remove enzymes and insoluble precipitates. The supernatant was collected and concentrated. The resulting residue was purified by a C18 reverse-phase silica column (Sep-Pak Vac C18 cartridge 5 g, 55–105 µm, Waters) using a solution followed by stepwise elution of 0–30% MeOH in H2O as eluent (increase 10% MeOH per step, 20 mL eluent for each step). Fractions containing compound 6 were collected while solvents were removed by high-vacuum evaporator. The product was further purified by size-exclusion chromatography (Bio Gel P-2 gel packed in column, 1.5 cm × 50 cm, Bio-Rad) with dd H2O as eluent and then lyophilized to give compound 6 in quantitative yield (3.9 mg). Rf = 0.3 (n-PrOH/H2O/AcOH = 6: 2: 1 (v/v/v)); 1H NMR (850 MHz, D2O): δ 5.27 (d, J = 4.2 Hz, 1H), 5.25 (d, J = 3.8 Hz, 1H), 4.91 (d, J = 4.0 Hz, 1H), 4.70 (d, J = 7.6 Hz, 1H), 4.56 (d, J = 7.9 Hz, 1H), 4.53 (d, J = 7.8 Hz, 1H), 4.50 (d, J = 8.0 Hz, 1H), 4.41 (t, J = 6.7 Hz, 1H), 4.32–4.29 (m, 2H), 4.28 (t, J = 6.4 Hz, 1H), 4.26 (d, J = 2.8 Hz, 1H), 4.15 (d, J = 2.4 Hz, 1H), 4.05 (d, J = 3.1 Hz, 1H), 4.01–3.91 (m, 10H), 3.90–3.75 (m, 13H), 3.73–3.63 (m, 8H), 3.61–3.59 (m, 1H), 3.60 (dd, J = 10.0, 7.7 Hz, 1H), 3.58 (dd, J = 10.3, 3.2 Hz, 1H), 3.34 (t, J = 6.9 Hz, 2H), 3.32 (t, J = 8.6 Hz, 1H), 2.06 (s, 3H), 1.67–1.62 (m, 4H), 1.43–1.41 (m, 4H), 1.23 (d, J = 6.6 Hz, 3H); 13C NMR (214 MHz, D2O): δ 175.3, 105.1, 104.3, 103.1, 102.9, 101.4, 99.9, 93.9, 79.8, 79.3, 78.1, 77.9, 77.0, 76.4, 75.8, 75.6, 75.54, 75.51, 73.92, 73.90, 73.1, 72.8, 72.0, 71.8, 71.5, 71.1, 70.9, 70.4, 70.25, 70.17, 69.5, 69.1, 68.8, 68.6, 67.9, 64.4, 62.3, 62.0, 61.9, 61.33, 61.30, 61.0, 52.4, 52.1, 29.5, 28.8, 26.6, 25.6, 23.3, 16.2; HRMS (ESI-TOF): m/z of C50H85N4O35 [M]−: calcd. 1301.4994, found 1301.5007.

Compound 12

The reaction was carried out by directly using purified UDP-GalNH2. The pH of a buffer solution (100 mM Tris–HCl, pH 9.0, 4.1 mL) containing UDP-GalNH2 (20 mM), compound 10 (34.2 mg, 10 mM) (Li et al. 2019) and 20 mM of MgCl2 was adjusted to 8.0. Then, CgtB (0.3 mg/mL), were added to the above solution. The resulting mixture was incubated at 37 °C with agitation at 200 rpm. More enzymes were added if necessary. When TLC analysis indicated there was not additional product formed after 44 h, the reaction mixture was quenched by addition of the same reaction volume of EtOH. The reaction solution was centrifuged (10,000 × g, 10 min) to remove enzymes and insoluble precipitates. The supernatant was collected and concentrated. The resulting residue was purified by a C18 reverse-phase silica column (Sep-Pak Vac C18 cartridge 5 g, 55–105 µm, Waters) using a solution followed by stepwise elution of 0–40% MeOH in H2O as eluent (increase 10% MeOH per step, 20 mL eluent for each step). Fractions containing compound 11 were collected while solvents were removed by high-vacuum evaporator and then lyophilized to give crude compound 11. Rf = 0.34 (n-PrOH/H2O/AcOH = 6:2:1 (v/v/v)). The above crude compound 11 was dissolved in H2O (1 mL) and then acetic anhydride (39 μL, 0.41 mmol) and NaHCO3 (34.5 mg, 0.41 mmol) was added to the reaction. The reaction mixture was stirred at rt for 5 min. The solution was concentrated under reduced pressure and the resulting crude was purified by a C18 reverse-phase silica column (Sep-Pak Vac C18 cartridge 5 g, 55–105 µm, Waters) using a solution followed by stepwise elution of 0–40% MeOH in H2O as eluent (increase 10% MeOH per step, 20 mL eluent for each step). The resulting residue was further purified by size-exclusion column using 0.1% AcOH in H2O as eluent (HW-40S gel packed in a column 2.5 × 50 cm). Fractions containing compound 12 were collected, concentrated, and lyophilized to give crude compound 12 (10.0 mg, 24% over two steps). Rf = 0.16 (EtOAc/MeOH/H2O/AcOH = 4:2:1:0.5 (v/v/v/v)); 1H NMR (500 MHz, D2O): δ 4.87 (d, J = 3.4 Hz, 1H), 4.59 (d, J = 8.4 Hz, 1H), 4.48 (d, J = 8.2 Hz, 2H), 4.45 (d, J = 8.0 Hz, 1H), 4.35 (t, J = 6.2 Hz, 1H), 4.21 (br, 1H), 4.14 (br, 1H), 4.00–3.89 (m, 6H), 3.87–3.65 (m, 17H), 3.61 (t, J = 8.5 Hz, 3H), 3.55 (dd, J = 9.9, 7.8 Hz, 2H), 3.30 (t, J = 6.8 Hz, 2H), 3.26 (dd, J = 8.7, 7.5 Hz, 1H), 2.01 (s, 3H), 1.99 (s, 3H), 1.60 (quintet, J = 6.4 Hz, 4H), 1.38–1.36 (m, 4H); 13C NMR (214 MHz, D2O): δ 175.6, 175.3, 104.3, 104.2, 103.9, 103.0, 101.4, 79.8, 79.75, 79.69, 78.2, 76.4, 75.9, 75.8, 75.5, 75.4, 73.9, 73.1, 71.9, 71.5, 71.4, 71.2, 69.9, 69.0, 68.8, 68.6, 62.0, 61.9, 61.3, 61.2, 61.0, 53.5, 52.3, 52.1, 29.5, 28.8, 26.6, 25.6, 23.3, 23.2; HRMS (ESI-TOF): m/z of C40H68N5O26 [M]−: calcd. 1034.4153, found 1034.4167.

Compound 14

The reaction was carried out in a sugar nucleotide regeneration system. To a HEPES buffer (100 mM, pH 9.0, 3.0 mL) containing compound 9 (20 mg, 30 μmol, 10 mM), GalNTFA (12.3 mg, 45 μmol, 15 mM), ATP-2Na (0.3 mg, 0.6 μmol, 0.2 mM), UTP-2Na (1.0 mg, 1.8 μmol, 0.6 mM), PEP (24.5 mg, 120 μmol, 40 mM) and MgCl2 (20 mM) was adjusted its pH to 7.2. Then, NahK (0.1 mg/mL), AGX-1 (0.1 mg/mL), LgtD (0.2 mg/mL), PK (40 U) and IP (0.1 mg/mL) were added to the above solution. The resulting mixture was incubated at 30 °C with agitation at 200 rpm for 23 h. The formation of compound 13 was monitored by TLC analysis (n-PrOH/H2O/AcOH = 6:2:1 (v/v/v), Rf = 0.49). After completion of the reaction, the pH value of the solution was adjusted to pH 11. The reaction mixture was incubated with agitation at 200 rpm at 37 °C. The progress of the reaction was monitored by TLC. When TLC analysis indicated the completion of the reaction after 1 h, the resultant was quenched by addition of the same reaction volume of EtOH. The reaction solution was centrifuged (10,000 × g, 10 min) to remove enzymes and insoluble precipitates. The supernatant was collected and concentrated. The resulting residue was purified by a C18 reverse-phase silica column (Sep-Pak Vac C18 cartridge 5 g, 55–105 µm, Waters) using a solution followed by stepwise elution of 0–40% MeOH in H2O as eluent (increase 10% MeOH per step, 20 mL eluent for each step). Fractions containing compound 14 were collected while solvents were removed by high-vacuum evaporator. The product was further purified by size-exclusion chromatography (Bio Gel P-2 gel packed in column, 1.5 cm × 50 cm, Bio-Rad) with dd H2O as eluent and then lyophilized to give compound 14 in 95% yield (22.6 mg). Rf = 0.13 (n-PrOH/H2O/AcOH = 6: 2: 1 (v/v/v)); 1H NMR (850 MHz, D2O): δ 4.98 (d, J = 3.7 Hz, 1H), 4.82 (d, J = 8.5 Hz, 1H), 4.52 (d, J = 7.8 Hz, 1H), 4.48 (d, J = 8.0 Hz, 1H), 4.40 (t, J = 6.3 Hz, 1H), 4.30 (d, J = 2.6 Hz, 1H), 4.09 (dd, J = 10.5, 2.8 Hz, 1H), 4.06 (d, J = 2.6 Hz, 1H), 4.03 (dd, J = 10.5, 3.8 Hz, 1H), 3.99 (d, J = 11.7 Hz, 1H), 3.94 (d, J = 7.1 H, 1H), 3.92 (dd, J = 11.9, 7.4 Hz, 2H), 3.86–3.73 (m, 8H), 3.71–3.68 (m, 3H), 3.65 (dd, J = 9.2, 8.7 Hz, 1H), 3.63 (t, J = 9.0 Hz, 1H), 3.59 (t, J = 9.0 Hz, 1H), 3.59–3.58 (m, 1H), 3.33 (t, J = 6.9 Hz, 2H), 3.30 (t, J = 8.3 Hz, 1H), 3.19 (t, J = 8.5 Hz, 1H), 1.65–1.61 (m, 4H), 1.41–1.40 (m, 4H); 13C NMR (214 MHz, D2O): δ 104.2, 103.0, 102.9, 101.1, 79.7, 79.4, 78.2, 76.32, 76.30, 75.8, 75.4, 73.9, 73.0, 71.8, 71.5, 71.3, 71.1, 69.8, 68.60, 68.56, 61.8, 61.3(2C), 61.0, 54.5, 52.1, 29.5, 28.8, 26.6, 25.5; HRMS (ESI-TOF): m/z of C30H53N4O20 [M]−: calcd. 789.3253, found 789.3247.

Compound 16

The reaction was carried out by directly using purified UDP-GalNH2. The pH of a buffer solution (100 mM Tris–HCl, pH 9.0, 2.8 mL) containing UDP-GalNH2 (20 mM), compound 14 (34.2 mg, 10 mM) and 20 mM of MgCl2 was adjusted to 7.9. Then, BvαGalT (0.3 mg/mL), were added to the above solution. The resulting mixture was incubated at 37 °C with agitation at 200 rpm. More enzymes were added if necessary. When TLC analysis indicated there was not additional product formed after 92 h, the resultant was quenched by addition of the same reaction volume of EtOH. The reaction solution was centrifuged (10,000 × g, 10 min) to remove enzymes and insoluble precipitates. The supernatant was collected and concentrated. The resulting residue was purified by a C18 reverse-phase silica column (Sep-Pak Vac C18 cartridge 5 g, 55–105 µm, Waters) using a solution followed by stepwise elution of 0–30% MeOH in H2O as eluent (increase 10% MeOH per step, 20 mL eluent for each step). Fractions containing compound 15 were collected while solvents were removed by high-vacuum evaporator. The resulting residue was further purified by size-exclusion column using 0.1% AcOH in H2O as eluent (HW-40S gel packed in a column 2.5 × 50 cm). Fractions containing compound 15 were collected, concentrated, and lyophilized to give crude compound 15. Rf = 0.30 (n-PrOH/H2O/AcOH = 6:2:1 (v/v/v)). The above crude compound 15 was dissolved in H2O (1 mL) and then acetic anhydride (27 μL, 0.29 mmol) and NaHCO3 (24.0 mg, 0.29 mmol) was added to the reaction. The reaction mixture was stirred at rt for 5 min. The solution was concentrated under reduced pressure and the resulting crude was purified by a C18 reverse-phase silica column (Sep-Pak Vac C18 cartridge 5 g, 55–105 µm, Waters) using a solution followed by stepwise elution of 0–43% MeOH in H2O as eluent (increase 10% MeOH per step, 20 mL eluent for each step). Fractions containing compound 16 were collected while solvents were removed by high-vacuum evaporator and then lyophilized to give compound 16 (8.7 mg, 29% over two steps). Rf = 0.35 (EtOAc/MeOH/H2O/AcOH = 5:2:1:0.5 (v/v/v/v)); 1H NMR (500 MHz, D2O): δ 5.04 (d, J = 3.3 Hz, 1H), 4.89 (d, J = 3.7 Hz, 1H), 4.68 (d, J = 8.5 Hz, 1H), 4.49 (d, J = 7.8 Hz, 1H), 4.45 (d, J = 8.0 Hz, 1H), 4.36 (t, J = 6.1 Hz, 1H), 4.24 (br, 1H), 4.19 (dd, J = 11.1, 3.6 Hz, 1H), 4.07 (d, J = 12.5 Hz, 2H), 4.01 (br d, J = 1.9 Hz, 1H), 3.96 (d, J = 12.5 Hz, 3H), 3.92–3.65 (m, 17H), 3.61 (t, J = 8.9 Hz, 3H), 3.56 (dd, J = 10.0, 7.9 Hz, 2H), 3.30 (t, J = 6.9 Hz, 2H), 3.26 (dd, J = 8.9, 8.2 Hz, 1H), 2.03 (s, 3H), 2.01 (s, 3H), 1.60 (quintet, J = 6.0 Hz, 4H), 1.39–1.36 (m, 4H); 13C NMR (214 MHz, D2O): δ 175.9, 175.6, 104.2, 103.7, 103.0, 101.4, 94.5, 79.8, 79.7, 78.2, 76.4, 75.8, 75.7, 75.6, 75.5, 73.9, 73.1, 72.3, 71.9, 71.5, 71.3, 69.9, 69.3, 68.6, 68.5, 64.6, 62.0, 61.8, 61.35, 61.29, 61.0, 52.1, 51.9, 50.4, 29.5, 28.8, 26.6, 25.6, 23.2, 22.9; HRMS (ESI-TOF): m/z of C40H68N5O26 [M]−: calcd. 1034.4153, found 1034.4149.

Data availability

The data that support the findings presented in the current report are included in this article and the supplementary material.

References

Schjoldager, K.T., Narimatsu, Y., Joshi, H.J., Clausen, H.: Global view of human protein glycosylation pathways and functions. Nat. Rev. Mol. Cell Biol. 21, 729–749 (2020)

Reily, C., Steawrt, T.J., Renfrow, M.B., Novak, J.: Glycosylation in health and disease. Nat. Rev. Nephrol. 15, 346–366 (2019)

Hakomori, S.: Structure and function of glycosphingolipids and sphingolipids: recollections and future trends. Biochem. Biophys. Acta. 1780, 325–346 (2008)

Schnaar, R.L., Sandhoff, R., Tiemeyer, M., Kinoshita, T.: Glycosphingolipids, in Essentials of Glycobiology, 4th ed. ; Varki, A., Cummings, R.D., Esko, J.D., Stanley, P., Hart, G.W., Aebi, M., Mohen, D., Kinoshita, T., Packer, N.H., Prestegard, J.H., Schnaar, R.L., Seeberger, P.H. Eds.; Cold Spring Harbor Laboratory Press: Cold Spring Harbor, NY (2022)

Wennekes, T., van den Berg, R.J.B.H.N., Boot, R.G., van der Marel, G.A., Overkleeft, H.S., Aerts, J.M.F.G.: Glycosphingolipids-nature, function, and pharmacological modulation. Angew. Chem. Int. Ed. 48: 8848−8869 (2009)

Hannun, Y.A., Obeid, L.M.: Sphingolipids and their metabolism in physiology and disease. Nat. Rev. Mol. Cell Biol. 19, 175–191 (2018)

Zhuo, D., Li, X., Guan, F.: Biological roles of aberrantly expressed glycosphingolipids and related enzymes in human cancer development and progression. Front. Physiol. 9, 466 (2018)

Kannagi, R., Cohran, N.A., Ishigami, F., Hakomori, S., Andrews, P.W., Knowles, B.B., Solter, D.: Stage-specific embryonic antigens (SSEA-3 and -4) are epitopes of a unique Globo-series ganglioside isolated from human teratocarcinoma cells. EMBO J. 2, 2355–2361 (1983)

Bremer, E.G., Levery, S.B., Sonnino, S., Ghidoni, R., Canevari, S., Kannagi, R., Hakomori, S.: Characterization of a glycosphingolipid antigen defined by the monoclonal antibody MBr 1 expressed in normal and neoplastic epithelial cells of human mammary gland. J. Biol. Chem. 259, 14773–14777 (1984)

Hunter, C.D., Guo, T., Daskhan, G., Richards, M.R., Cairo, C.W.: Synthetic strategies for modified glycosphingolipids and their design as probes. Chem. Rev. 118, 8188–8241 (2018)

Danishefsky, S.J., Shue, Y.K., Chang, M.N., Wong, C.H.: Development of Globo-H cancer vaccine. Acc. Chem. Res. 45, 643–652 (2015)

Wei, M.M., Wang, Y.S., Ye, X.S.: Carbohydrate-based vaccines for oncotherapy. Med. Res. Rev. 38, 1003–1026 (2018)

Clausen, H., Watanabe, K., Kannagi, R., Levery, S.B., Nudelman, E., Arao-Tomono, Y., Hakomori, S.: Blood group A glycolipid (Ax) with globo-series structure which is specific for blood group A1 erythrocytes: one of the chemical bases for A1 and A2 distinction. Biochem. Biophys. Res. Commun. 124, 523–529 (1984)

Ito, K., Shiraishi, R., Higai, K.: Globo-A binds to the recombinant natural cytotoxicity receptor NKp44. Biol. Pharm. Bull. 41, 1480–1484 (2018)

Breimer, M.E., Jovall, P.A.: Structural characterization of a blood group A heptaglycosylceramide with Globo-series structure: the major glycolipid based blood group A antigen of human kidney. FEBS Lett. 179, 165–172 (1985)

Fenderson, B.A., Andrews, P.W., Nudelman, E., Clausen, H., Hakomori, S.: Glycolipid core structure switching from globo- to lacto- and ganglio-series during retinoic acid-induced differentiation of TERA-2-derived human embryonal carcinoma cells. Dev. Biol. 122, 21–34 (1987)

Lindsted, R., Larson, G., Falk, P., Jodal, U., Leffler, H., Svanborg, C.: The receptor repertorie defines the host range for attaching Escherichia coli strains that recognize Globo A. Infect. Immun. 59, 1086–1092 (1991)

Chiang, P.Y., Adak, A.K., Liang, W.L., Tsai, C.Y., Tseng, H.K., Cheng, J.Y., Hwu, J.R., Yu, A.L., Lin, C.C.: Chemoenzymatic synthesis of Globo-series glycosphingolipids and evaluation their immunosuppressive activities. Chem. Asian J. 15, e202200403 (2022)

Wen, L., Edmunds, G., Gibbons, C., Zhang, J., Gardi, M.R., Zhu, H., Fang, J., Liu, X., Kong, Y., Wang, P.G.: Toward automated enzymatic synthesis of oligosaccharides. Chem. Rev. 118, 8151–8187 (2018)

Yu, H., Chen, X.: One-pot multienzyme (OPME) systems for chemoenzymatic synthesis of carbohydrates. Org. Biomol. Chem. 14, 2809–2818 (2016)

Yi, W., Shen, J., Zhou, G., Li, J., Wang, P.G.: Bacterial homologue of human blood group A transferases. J. Am. Chem. Soc. 130, 14420–14421 (2008)

Li, P.J., Huang, S.Y., Chiang, P.Y., Fan, C.Y., Guo, L.J., Wu, D.Y., Angata, T., Lin, C.C.: Chemoenzymatic synthesis of DSGb5 and sialylated globo-series glycans. Angew. Chem. Int. Ed. 58, 11273–11278 (2019)

Cai, L., Guan, W., Kitaoka, M., Shen, J., Xia, C., Chen, W., Wang, P.G.: A chemoenzymatic route to N-acetylhexosamine-1-phosphate analogues: substrate specificity investigations of N-acetylhexosamine 1-kinase. Chem. Commun. 2944–2946 (2009)

Guan, W., Cai, L., Wang, P.G.: Highly efficient synthesis of UDP-GalNAc/GlcNAc analogues with promiscuous recombinant human UDP-GalNAc pyrophosphorylase AGX1. Chem. Eur. J. 16, 13343–13345 (2010)

Seto, N.O.L., Palcic, M.M., Hindsgaul, O., Bundle, D.R.: Expression of a recombinant human glycosyltransferase from a synthetic gene and its utilization for synthesis of the human blood group B trisaccharide. Eur. J. Biochem. 234, 323–328 (1995)

Zhong, K., Ye., J., Zhu, X., Cao, H., Liu, C.C.: Highly efficient biocatalytic cascade for the diversity-oriented synthesis of complex blood group Sd antigens. Green Chem. 22, 8002–8011 (2020)

Zhang, J., Liu, D., Saikam, V., Gadi, M.R., Gibbons, C., Fu, X., Song, H., Yu, J., Kondengaden, S.M., Wang, P.G., Wen, I.: Machine-driven chemoenzymatic synthesis of glycopeptide. Angew. Chem. Int. Ed. 59, 19825–19829 (2020)

Fang, J., Li, J., Chen, X., Zhang, Y., Wang, J., Guo, Z., Zhang, W., Yu, L., Brew, K., Wang, P.G.: Highly efficient chemoenzymatic synthesis of α-galactosyl epitopes with a recombinant α (1,3)-galactosyltransferase. J. Am. Chem. Soc. 120, 6635–6638 (1988)

Siddiqui, B., Hakomori, S.I.: A revised structure for the Forssman glycolipid hapten. J. Biol. Chem. 264, 5766–5769 (1971)

Ångstrçm, J., Karlsson, H., Karlsson, K.A., Larson, G., Nilson, K.: GalNAcβ1,3 terminated glycosphingolipids of human erythrocytes. Arch. Biochem. Biophys. 251, 440–449 (1986)

Young, W.W., Hakomori, S.I., Levine, P.: Characterization of anti-Frossman (anti-Fs) antibodies in human sera: Their specificity and possible changes in patients with cancer. J. Biol. Chem. 123, 92–96 (1979)

Smorodin, E.P., Kurtenkov, O.A., Sergeyev, B.L., Afanasyev, V.P.: The relation of serum anti-(GalNAc beta) and -para-Frossman disaccharide IgG levels to the progression and histological grading of gastrointestinal cancer. Exp. Oncol. 29, 61–66 (2007)

Tanaka, H., Takeuchi, R., Jimbo, M., Kuniya, N., Takahashi, T.: Synthesis and biological evaluation of the Frossman antigen pentasaccharide and derivatives by a one-pot glycosylation procedure. Chem. Eur. J. 19, 3177–3187 (2013)

Nunomura, S., Mori, M., Ito, Y., Ogawa, T.: A total synthesis of Frossman glycolipid, globopentaosyl ceramide IV3GalNAcαGb4Cer. Tetrahedron. Lett. 30, 6713–6716 (1989)

Houliston, R.S., Bernatchez, S., Karwaski, M.F., Mandrell, R.E., Jarrell, H.C., Wakarchuk, W.W., Gilbert, M.: Complete chemoenzymatic synthesis of the Frossman antigen using novel glycosyltrasnferases identified in Campylobacter jejuni and Pasteurella multocida. Glycobiology 19, 153–159 (2009)

Feng, J., Hevey, R., Ling, C.C.: Synthesis of a Frossman antigen derivative for use in a conjugate vaccine. Carbohydr. Res. 346, 2650–2662 (2011)

Nunomura, S., Mori, M., Ito, Y., Owaga, T.: A total synthesis of para-Frossman glycolipid isolated from human erythrocyte membrane. Tetrahedron. Lett. 30, 5619–5622 (1989)

Fu, X., Gadi, M.R., Wang, S., Han, J., Liu, D., Chen, X., Yin, J., Li, L.: General tolerance of galactosyltransferases toward UDP-galactosamine expands their synthetic capability. Angew. Chem. Int. Ed. 60, 26555–26560 (2021)

Malekan, H., Fung, G., Thon, V., Khedri, Z., Yu, H., Qu, J., Li, Y., Ding, L., Lam, K.S., Chen, X.: One-pot multi-enzyme (OPME) chemoenzymatic synthesis of sialyl-Tn-MUC1 and sialyl-T-MUC1 glycopeptides containing natural or non-natural sialic acid. Bioorg. Med. Chem. 21, 4778–4785 (2013)

Tseng, H.K., Su, Y.Y., Chang, T.W., Liu, H.C., Li, P.J., Chiang, P.Y., Lin, C.C.: Acceptor-mediated regioselective enzyme catalyzed sialylation: chemoenzymatic synthesis of GAA-7 ganglioside glycan. Chem. Commun. 57, 3468–3471 (2021)

Anwar, M.T., Kawade, S.K., Huo, Y.R., Adak, A.K., Sridharan, D., Kuo, Y.T., Fan, C.Y., Wu, H.R., Lee, Y.S., Angata, T., Lin, C.C.: Sugar nucleotide regeneration system for the synthesis of bi- and triantennary N-glycans and exploring their activities against siglecs. Eur. J. Med. Chem. 232, 114146 (2022)

Li, S. P., Hsiao, W. C., Yu, C.C., Chien, W.T., Lin, H.J., Huang, L.D., Lin, C.H., Wu, W.L., Wu, S.H., Lin, C.C.: Characterization of Meiothermus taiwanensis galactokinase and its use in the one‐pot enzymatic synthesis of uridine diphosphate‐galactose and the chemoenzymatic synthesis of the carbohydrate antigen stage specific embryonic antigen‐3. Adv. Synth. Catal. 356, 3199–3213 (2014)

Nishimoto, M., Kitaoka, M.: Identification of N-acetylhexosamine 1-kinase in the complete lacto-N-biose I/galacto-N-biose metabolic pathway in Bifidobacterium longum. Appl. Environ. Microbiol. 73, 6444–6449 (2007)

Litterer, L., Schnurr, J., Plaisance, K., Storey, K., Gronwald, J., Somers, D.: Characterization and expression of Arabidopsis UDP-sugar pyrophosphorylase. Plant Physiol. Biochem. 44, 171–180 (2006)

Bourgeaux, V., Piller, F., Piller, V.: Two-step enzymatic synthesis of UDP-N-acetylgalactosamine. Bioorg Med. Chem. Lett. 15, 5459–5462 (2005)

Randriantsoa, M., Drouillard, S., Breton, C., Samain, E.: Synthesis of globopentaose using a novel β1, 3-galactosyltransferase activity of the Haemophilus influenzae β1, 3-N-acetylgalactosaminyltransferase LgtD. FEBS Letts. 58, 2652–2656 (2007)

Bernatchez, S., Gilbert, M., Blanchard, M.C., Karwaski, M.F., Li, J., DeFrees, S., Wakarchuk, W.W.: Variants of the β1, 3-galactosyltransferase CgtB from the bacterium Campylobacter jejuni have distinct acceptor specificities. Glycobiology 17, 1333–1343 (2007)

Acknowledgements

This research was funded by the National Tsing Hua University, Academia Sinica (AS-GC-111-M03), the National Science and Technology Council of Taiwan (110-2113-M-007-010-MY3, 111-2114-M-007-001, and 111-2113-M-007-021), the Ministry of Education of Taiwan (111QR001I5), and Frontier Research Center on Fundamental and Applied Sciences of Matters (111B0017I5).

Author information

Authors and Affiliations

Contributions

C.-C.L. supervised the study. Y.-C.C., C.-Y.W., and P.-Y.C. performed experiments. A.K.A., and C.-C.L. wrote the manuscript with input from all authors. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interests.

Additional information

In memory of Professor Roland Schauer.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chiang, YC., Wu, CY., Chiang, PY. et al. A concise chemoenzymatic total synthesis of neutral Globo-series glycosphingolipids Globo A and Globo B, and Forssman and para-Forssman antigens. Glycoconj J 40, 551–563 (2023). https://doi.org/10.1007/s10719-023-10133-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10719-023-10133-8