Abstract

Based uniaxial compression tests of altered granite, the weakening laws of rock strength and energy mechanism of rock failure for altered granite subjected to wet–dry cycles are analyzed. Results show that: (1) with increasing number of wet–dry cycles, the rock weakening coefficient and damage variables increase gradually. The maximum weakening coefficient of altered granite-1 was 50.22%, and the damage variable was up to 63.84%. The maximum weakening coefficient of altered granite-2 was 43.22%, and the damage variable was up to 44.00%. (2) The total energy of rock increases gradually with the number of wet–dry cycles. Elastic strain energy in the rock increases first then decreases. The energy storage limit decreases gradually, showing a linear or exponential relationship with the number of wet–dry cycles. (3) The rock damage energy mechanism under wet–dry cycles is obtained via the rock dissipation energy. The rock dissipation energy increases gradually as the number of wet–dry cycles increases. Wet–dry cycles causes irreversible damage to the rock internal structure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Water flow commonly weakens the mechanical properties of rock and soil. For example, water level variations in a hydropower station or tailings reservoir can reduce the rock strength. At present, the weakening of rock strength caused by water–rock interaction are analyzed by many research results (Akcanca and Aytekin 2014; Zhao et al. 2017; Kassab and Weller 2015; Waragai 2016). The weakening of mechanical properties, such as uniaxial compressive strength, elastic modulus, shear strength parameters, and the sensitivity of water rock interactions varies for different types of rocks (Sharma et al. 2017; Zhao et al. 2017; Liu et al. 2014a, b, 2016; Qin et al. 2018). The rock deformation and failure is the damage of the internal structure of the rock essentially. The weakening of macroscopic rock strength is an external characterization of the internal rock structure. The primary research methods for examine rock damage cause by water include scanning electron microscopy (SEM), computed tomography (CT) scanning, and nuclear magnetic resonance (NMR), which are used to observe the internal structure of rock specimens under water–rock interaction, and qualitatively analyze the internal structural damage caused by water–rock interactions. Relevant numerical analysis software, such as particle flow code (PFC), is used to examine internal fractures propagation (Chen and Gong 2018; Özbek 2014; Khanlari and Abdilor 2015; Yao et al. 2016; Bian et al. 2019). Existing research methods for examining macro–meso damage caused by water–rock interactions are mainly qualitative analysis or quantitative characterization from mechanical tests and some meso-mechanical tests. Rock energy dissipation is the essential attribute of rock deformation and failure, mainly reflecting the generation, continuous development, weakening and ultimate loss of micro-defects inside the rock. The energy dissipation of rock can reflect the internal structural damage in the rock.

In this contribution the reduction of rock strength due to wet–dry cycles was examined, and energy damage mechanisms were analyzed from the perspective of energy dissipation to analyze the rock damage characteristics related to wet–dry cycles.

2 Uniaxial Compression Test

2.1 Test Design Method

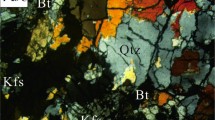

The rock samples were processed into cylindrical samples through core drilling and sawing, standard cylindrical samples (50 mm diameter × 100 mm length) were obtained. One drying–wetting cycles was defined as, the rock specimens were placed into a soaking box for 24 h at room temperature, after which they were placed into a drying box (at 105 °C) for 12 h. The testing procedure was shown in Fig. 1.

2.2 Uniaxial Compression Test Curve

In order to simulate the influence of the water level fluctuation on the rock, the wet–dry cycles test was designed to carry out during uniaxial compression testing. The strength weakening coefficient and degree of deterioration were defined according to the uniaxial compression test results (Fig. 2).

The uniaxial compression stress–strain curve shows five distinct stages, including internal defect closure stage, linear elastic deformation stage, unsteady rupture stage, plastic yield stage and strain softening stage.

-

1.

Internal defect closure stage (OA): Due to mineralization and alteration of gold deposits as well as axial stress loading, the surrounding granite develops internal pores and fissures. The average elastic modulus of the closed section of the rock specimen decreases gradually with increasing number of wet–dry cycles. The internal rock structure was damaged, and the primary pores and fractures expanded.

-

2.

Linear elastic deformation stage (AB): Once the internal defects of the specimen are closed and compacted, the rock stress–strain curve shows an approximately linear change, and the elastic modulus remains basically unchanged. The elastic modulus of the elastic phase is selected as the eclipse (Fig. 3).

-

3.

Unsteady rupture stage (BC): The curve shows an obvious concave shape, and the rock undergoes plastic deformation. Primary fractures continue to develop, the secondary pores and fractures sprouting. The stress of point C represents the yield stress (Fig. 2);

-

4.

Plastic yield stage (CD): With application of the axial load, fractures and pores continuously expand and finally penetrated the specimen to form a shear failure surface. The peak strength is at which shear failure occurs.

-

5.

Strain softening stage (DE): After the specimen passes the peak stress, the strength gradually decreases; however, a certain residual strength still exists, the residual strength decreases with increasing number of wet–dry cycles.

According to the uniaxial compression stress–strain curve, the peak strength and elastic modulus of the rock under different wet–dry cycles can be obtained, and the Poisson’s ratio is obtained via the longitudinal and radial deformation (Table 1).

2.3 Uniaxial Compression Strength Degradation Law

The peak strength and elastic modulus of the rock gradually decrease with increasing number of wet–dry cycles, while Poisson’s ratio changes little. To quantitatively characterize the degree of rock strength deterioration, the rock weakening coefficient and the rock damage variable are defined in Eqs. (1) and (2):

where λ is the rock weakening coefficient; Rt0 is the initial compressive strength of the natural rock; Rtn is the compressive strength of rock after N number of wet–dry cycles; De is the damage variable; E0 is the initial elastic modulus of the natural rock; EN is the elastic modulus of rock after N number of wet–dry cycles.

The rock compressive strength and elastic modulus degraded because of wet–dry cycles (Table 2). As for the altered granite-1, the maximum weakening coefficient is 50.22%, and the maximum deterioration degree is 63.84%. For altered granite-2, the maximum weakening coefficient is 43.22%, and the maximum deterioration degree is 44.00%. The effect of wet–dry cycles on elastic modulus is greater, and altered granite-1 is more susceptible to the wet–dry cycles.

The relationships between rock weakening coefficient, damage variable and the number of wet–dry cycles follows an exponential function (Fig. 4).

3 Rock Energy Evolution of Wet–Dry Cycles

3.1 Rock Damage Energy Change

Rock deformation and failure is caused by damage to the rock internal structure, which can be characterized by a change in energy. The process of rock failure is composed of energy input, elastic strain energy accumulation and energy dissipation. The dissipation of rock energy is primarily manifested in the development and expansion of internal fractures, and energy release is the essential cause of sudden rock failure (Xie et al. 2004). The composition of energy is shown in Fig. 5.

It is assumed that there is no heat exchange or closed system in the indoor test process. For a unit volume of rock mass under the an external force, the total input energy is the same, and the rock energy composition relationship is shown in Eqs. (3) and (4) (Xie et al. 2005):

where Wd is the dissipated energy, \(W^{e}\) is the released elastic strain energy, and the rock mass release strain energy, is shown in Eq. (5) (Zhang and Gao 2012):

where \(\sigma_{i}\) is the principal stress of the space element, and \(\varepsilon_{i}^{e}\) is the elastic principal strain of the three principal stress spaces. Given by Einstein’s peace agreement (Fan et al. 2014):

Equation (7) is the simplified version of Eq. (6) representing uniaxial compression:

3.2 Energy Evolution Under Wet–Dry Cycles

From the perspective of energy evolution, the rock deformation and failure process is accompanied by changes in total energy, releasable elastic strain energy and dissipated energy. The natural rock is not only affected by external loads, but also may be affected by environmental conditions. The internal structure of the rock is constantly changing under the influence of various external environmental factors, causing rock damage and instability. By analyzing energy changes during the rock deformation under the wet–dry cycles, the total energy in the rocks at different cycles can be obtained (Fig. 6).

The total energy of altered granite-1 is obviously different at different cycles. The rock total energy in the initial rock is the highest. Total energy decreases gradually as the number of wet–dry cycles increases. For the altered granite-2, the total energy also decreases with increasing number of wet–dry cycles, but the magnitude of the decrease is small.

Rock failure was derived from the release of elastic strain energy during the loading process. The elastic strain energy change process includes an energy storage stage and energy release stage. Elastic strain energy of the granite changed gradually, and the elastic strain energy growth rate decreased with increasing number of wet–dry cycles. In the energy release stage, the elastic strain energy of the altered granite decreased gradually, and the elastic strain energy release rate did not differ much with an increasing number of wet–dry cycles (Fig. 7).

The maximum elastic strain energy of the rock is called the energy storage limit (Fan et al. 2014). The rock energy storage limit under different cycles is shown in Fig. 8.

The rock energy storage limit decreases with increasing number of wet–dry cycles. As for altered granite-1, the energy storage limit decreases linearly with the number of wet–dry cycles, and the energy storage limit of altered granite-2 decreases exponentially with the number of wet–dry cycles. The reduction in rock energy storage limit indicates when the energy generated by the external load is accumulates inside the rock mass, the energy storage limit is exceeded in the rock mass, and the wet–dry cycles accelerates the energy release process.

3.3 Energy Mechanism of Rock Failure

It is known from the laws of thermodynamics that rock energy dissipation is the essential property of rock failure, which mainly reflects the generation, continuous development, weakening and eventually loss of internal micro-defects. The rock energy dissipation of two kinds of altered granites under different cycles is shown in Fig. 9.

It can be concluded that rock energy dissipation is mainly used in the development and expansion of internal fractures, and rock energy dissipation increases with increasing strain. For altered granite-1, when strain exceeds 6.0 × 103 m, energy dissipation decreases gradually as the number of wet–dry cycles increases, and internal fractures development and expansion accelerates. For altered granite-2, when the number of dry and wet cycles are 0, 5, and 15, energy dissipation values do not vary significantly; however, when strain exceeds 8.0 × 103 m, energy dissipation varies significantly. The rock specimens subjected to wet–dry cycles were more prone to fractures propagation until failure.

Rock energy dissipation results show that the wet–dry cycles causes damage to the rock’s internal structure, to some extent weakens the bond between rock particles, and promotes initiation, development and expansion of fractures. Weakening of macroscopic strength is only the external representation of the internal structural damage. Energy dissipation reflects the generation, continuous development and weakening of the internal micro-defects. The final loss process is a quantitative representation of the damage of the internal structure of the rock.

Energy dissipation is directly related to the change of rock strength. The relationship between stress and rock dissipation energy under different wet–dry cycles is shown in Fig. 10.

-

1.

Segment OA: corresponds to the closing phase of rock internal defects. The rock structure becomes denser due to the gradual closure of primary pores and fractures inside the rock. Most of the energy absorbed by the rock is stored in the form of elastic strain energy. Point A is the elastic phase transition point.

-

2.

Segment AB: corresponds to the elastic deformation stage. As internal defects in the rock are closed and compacted, the energy absorbed by the rock is converted into elastic strain energy. The rock dissipation energy hardly changes, and point B represents the elastic phase transition to the elastoplastic phase.

-

3.

Segment BC: corresponds to the unsteady rupture stage. Primary fractures in the rock continue to develop, the secondary pores and fissures sprouting, and rock energy dissipation increases gradually. As the wet–dry cycles increases, the rock energy dissipation value increases significantly, and rock internal structure damage intensifies.

-

4.

Segment CD: corresponds to the plastic yielding stage. Internal fractures and pores in the rock continuously expand, and finally penetrate, until failure. Point C indicates the sudden release of the elastic strain energy.

4 Conclusions

-

1.

Based uniaxial compression test results, rock strength weakening characteristics after being subjected to wet–dry cycles are analyzed. The weakening coefficient and damage variable of the altered granite gradually increased with increasing number of wet–dry cycles. The rock strength weakening coefficient can reach 50.22%, and the damage variable can reach up to 63.84%. The effect of wet–dry cycles on the elastic modulus is significant, and altered granite-1 is more susceptible to the effects of wet–dry cycles.

-

2.

Based on the evolution of rock energy characteristics, the effect of wet–dry cycles on rock failure was analyzed. The total energy increases with increasing strain, and as the number of wet–dry cycles increases, the total energy of the rock increases gradually. The elastic strain increases first and then decreases. The rock energy storage limit is gradually reduced, and it has a linear or exponential relationship with the number of wet–dry cycles.

-

3.

Based on dissipative energy characteristics, the energy mechanism of rock damage under wet–dry cycles is determined. The change in rock dissipative energy mainly reflects damage of rock internal structure. As strain increases, the dissipated energy increases gradually. Stress and dissipative energy curves show four stages related to the rock deformation. As the number of wet–dry cycles increases, rock dissipation energy increases gradually, indicating that wet–dry cycles causes irreversible damage to the rock’s internal structure.

Data Availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

Akcanca F, Aytekin M (2014) Impact of wetting–drying cycles on the hydraulic conductivity of liners made of lime-stabilized sand–bentonite mixtures for sanitary landfills. Environ Earth Sci 72(1):59–66

Bian K, Liu J, Zhang W (2019) Mechanical behavior and damage constitutive model of rock subjected to water-weakening effect and uniaxial loading. Rock Mech Rock Eng 52:97–106. https://doi.org/10.1007/s00603-018-1580-4

Chen X, Gong Y (2018) Features of shear strength parameters reflecting damage to rock caused by water invasion-loss cycles. Geotech Geol Eng 2018:1–11. https://doi.org/10.1007/s10706-018-0733-2

Fan Y, Lu W, Zhou Y et al (2014) Study on energy release process of high energy storage rock mass induced by excavation unloading. Chin J Rock Mech Eng 33(2):296–308

Kassab MA, Weller A (2015) Study on P-wave and S-wave velocity in dry and wet sandstones of Tushka region, Egypt. Egypt J Pet 24(1):1–11

Khanlari G, Abdilor Y (2015) Influence of wet–dry, freeze-thaw, and heat-cool cycles on the physical and mechanical properties of Upper Red sandstones in central Iran. Bull Eng Geol Environ 74(4):1287–1300

Liu X, Zhang L, Fu Y (2014a) Experimental study of mechanical properties of argillaceous sandstone under wet and dry cycle in acid environment. Rock Soil Mech 35(2):45–52

Liu X, Zhang L, Fu Y et al (2014b) Mechanical properties of argillaceous sandstone under wet and dry cycle in acid environment. Electron J Geotech Eng 19(1):1433–1446

Liu X, Wang Z, Fu Y et al (2016) Macro/microtesting and damage and degradation of sandstones under dry–wet cycles. Adv Mater Sci Eng 1:1–16

Özbek A (2014) Investigation of the effects of wetting–drying and freezing–thawing cycles on some physical and mechanical properties of selected ignimbrites. Bull Eng Geol Environ 73(2):595–609

Qin Z, Chen X, Fu H (2018) Damage features of altered rock subjected to wet–dry cycles. Adv Civ Eng 1(5):1–10

Sharma K, Kiyota T, Kyokawa H (2017) Effect of slaking on direct shear behaviour of crushed mudstones. Soils Found 57(2):288–300

Waragai T (2016) The effect of rock strength on weathering rates of sandstone used for Angkor temples in Cambodia. Eng Geol 207:24–35

Xie H, Peng R, Ju Y (2004) Energy dissipation of rock deformation and fracture. Chin J Rock Mech Eng 23(21):1360–1364

Xie H, Ju Y, Li LY (2005) Criteria for strength and structural failure of rocks based on energy dissipation and energy release principles. Chin J Rock Mech Eng 24(17):3003–3010

Yao Q, Chen T, Ju M et al (2016) Effects of water intrusion on mechanical properties of and fractures propagation in coal. Rock Mech Rock Eng 49(12):4699–4709

Zhang Z, Gao F (2012) Experimental research on energy evolution of red sandstone samples under uniaxial compression. Chin J Rock Mech Eng 31(5):953–962

Zhao Z, Guo T, Ning Z et al (2017) Numerical modeling of stability of fractured reservoir bank slopes subjected to water–rock interactions. Rock Mech Rock Eng 51(8):2517–2531

Acknowledgements

This paper are supported by Shandong Provincial Natural Science Foundation (ZR2017BEE014), Scientific Research Foundation of Shandong University of Science and Technology for Recruited Talents (2017RCJJ050). The financial aids are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, X., He, P. & Qin, Z. Strength Weakening and Energy Mechanism of Rocks Subjected to Wet–Dry Cycles. Geotech Geol Eng 37, 3915–3923 (2019). https://doi.org/10.1007/s10706-019-00881-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-019-00881-6