Abstract

Fly ash generated from the coal fired thermal power plants is mostly sluiced into ash ponds by wet disposal method. Leachate emanating from the ash pond contaminates the ground water as well as surface water and poses a threat to the eco-system. Stabilization of ash is an effective means to mitigate the problem of leaching. This paper highlights the effect of lime column on the leachate characteristics of pond ash. For this purpose, large scale laboratory model of sedimented pond ash bed was prepared with a centrally installed lime column simulating a field condition. The samples were collected from various radial distances and depths after 30, 90, 180 and 365 days of installation of lime column and subjected to different tests for determination of pH value, hydraulic conductivity and concentration of different elements like Ca, Ni, Pb, Zn, Cu, Cr, Fe in the leachate sample. The leachability of different elements is expressed in terms of leachate load ratio. Further the leachate load ratio of different elements in the leachate sample is correlated to the hydration products, pH value and hydraulic conductivity. From the test results, it is found that lime column treatment is an effective means of reducing the concentration of metals in the leachate emanating from ash ponds.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

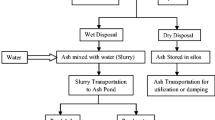

The disposal of fly ash has become a major issue for coal based thermal power plants as it requires a huge disposal area and creates a lot of problems like shortage of useful land, increase in disposal cost and dusting of atmospheric air. Generally, fly ash is disposed by using dry or wet disposal method. In dry disposal method, the fly ash is arrested in electrostatic precipitator and then it is transported to silos through suction or by pressurized air whereas in wet disposal method, fly ash is mixed with water and sluiced to settling ponds or dumping areas near the plant. Most of the power plants adopt wet disposal scheme. This ash contains a number of toxic heavy metals such as arsenic, beryllium, cadmium, barium, chromium, copper, lead, mercury, molybdenum, nickel, radium, selenium, thorium, uranium, vanadium and zinc which can leach out by percolating rain water and contaminate the ground water. Ultimately, it may pose a serious threat to the aquatic as well as human life. The leaching of metals mainly depends on two factors such as pH and hydraulic conductivity. The pH of the pore water plays a pivotal role in reducing the concentration of the elements. Hydraulic conductivity of the material also has a major effect in preventing the leachate from contaminating the ground water. So stabilization of fly ash with proper chemical additives like lime may be one of the promising methods to mitigate the problem of leaching.

2 Literature Review

A good number of literatures are available on the leachate characteristics and hydraulic conductivity of fly ash deposits. Fleming et al. (1996) studied the leach-ability of metals like Cd, Cr, Zn, Pb, Hg and Ag from fly ash generated by a coal‐fired electric plant and a municipal waste incinerator by conducting column leaching experiments under acidic conditions and found that the increase in extraction of metal ions from both type of fly ash occurred at low pH value. Ghosh and Subbarao (1998) found out that the pH value of the pore water was one of the factors which govern the concentration of a metal in the leachate. The ambience of high alkalinity in the pore fluid of the stabilized fly ash was conducive to the precipitation of some of the metals. The concentrations of Cu, Fe, Mg, Ni, and Zn in the leachate flowing out of the stabilized specimens were below allowable limits of drinking water quality, whereas concentrations of As, Cd, Cr, and Pb were above allowable limits, but below threshold limits. Sengupta and Miller (1999) investigated on the contaminants leaching out from the scrap tire material treated with synthetic solution of varying pH and reported that the concentration of contaminants that leach out was dependent on pH of environment. Wang et al. (1999) studied the effect of calcium on arsenic adsorption onto coal fly ash by conducting batch leaching test and reported that addition of calcium significantly reduced the soluble arsenic ratio in the alkaline pH range. Lau and Wong (2001) found that different elements have different leaching behaviors because of differences in elemental properties, the pH of the solution and leaching time. Jankowski et al. (2006) studied the leaching of metals like As, B, Mo and Se in fly ash generated from Australian power stations by conducting batch leaching test and reported that the pH of the leaching solution was the key factor which affected the mobility of these trace elements in the fly ashes. Sushil and Batra (2006) investigated on the heavy metal content in fly ash and bottom ash collected from different thermal power plants in India. The ashes were analyzed for the presence of metals like Cr, Mn, Pb, Zn, Cu, Ni and Co and it was found that the concentration of Cr and Zn were highest while Co concentration was less. Ghosh and Subbarao (2006) worked on stabilization of fly ash with varying percentage of lime (4, 6 and 10 %) and in combination with gypsum (0.5 and 1.0 %) and found that gypsum was effective in reducing the leaching of lime from stabilized fly ash matrix. Prasad and Mondal (2008) investigated on the heavy metals leaching in Indian fly ash. A cascade leaching test was used at liquid-to-solid ratio (L/S) ranging between 20 and 100. The fly ash samples exhibited neutral reactions, as indicated by pH values <11.75 and >7.0 at L/S = 10 and contact time of 10 min. Effect of pH on metals released from ash surface in aqueous solution followed a predictable pattern of decreasing release with increased pH. At pH of 2, maximum leachability of all elements was found. Sridevi et al. (2010) proposed that the concentration of calcium in the leachate increases with an increase in lime content in the fly ash cushion and it depends upon the curing period Lokeshappa and Dikshit (2012) studied on the leachate characteristics of class C and class F laboratory scale ash ponds and found out that the concentration of metals like arsenic, chromium increased with aging of ash ponds containing class F ash while the concentration of all metals deceased in ash pond with class C ash. Guleria and Dutta (2013) studied the effect of treated tire chips on leaching characteristics of fly ash–lime–gypsum composite and found a reduced concentration of leaching metals.

The hydraulic conductivity of the ash bed regulates the amount of leachate migrating from the source. Ghosh and Subbarao (2001) worked on microstructural development in fly ash modified with lime and gypsum and proposed that the hydraulic conductivity was reduced as a result of reduction in interconnectivity of the pore channels due to formation of hydration products. Kalinski and Yerra (2006) proposed that the hydraulic conductivity of compacted Portland cement flyash mixtures was affected by compaction effort. Chand and Subbarao (2007) worked on stabilization of ash ponds by hydrated lime column and studied the improvements in the water content, dry density, particle size distribution, unconfined compressive strength, pH, hydraulic conductivity, and leachate characteristics and found that the concentration of major and trace elements in the leachate were below the threshold limit. Pal and Ghosh (2011) studied the effect of compaction effort on hydraulic conductivity of class F fly ashes by preparing the samples corresponding to their standard Proctor and with modified Proctor compaction energy. From the test results it was found that with increase in compaction effort, maximum dry density (MDD) increased and optimum moisture content (OMC) of the sample decreased. A decreasing trend in hydraulic conductivity values were with increase in MDD of the samples. With increase in flow period, there was also a significant reduction in hydraulic conductivity for all the samples. Behera and Mishra (2012) evaluated the microstructural characteristics of class F fly ash stabilized with (15 and 6 %) lime and found that the concentration of Ni, Cr and Pb in the leachate effluents were below threshold limit. Kishan et al. (2012) found a reduced value of hydraulic conductivity in fly ash due to addition of lime and/or gypsum with increase in curing period.

Scanning thorough the previous research works, it is perceived that most of the researchers have adopted lime stabilization technique to reduce the concentration of elements in the leachate but a limited attempt has been made to study the efficacy of lime column in mitigating the leachate characteristics of pond ash. In addition to this the role of hydraulic conductivity and hydration products on leachability of elements are not investigated in detail. Moreover, mixing of lime in ash pond is practically not a feasible process. Keeping these aspects in mind an effort has been made to study the effect of lime column in mitigating the problems of leaching from the ash pond deposits through large scale laboratory model tests.

3 Experimental Programme

3.1 Materials

The fly ash used in the experimental work was procured from the captive power plant of Rourkela Steel Plant (RSP) Rourkela, India. Its physical properties and chemical composition are given in Table 1. The major constituents of fly ash are silica, alumina and iron oxide. Calcium oxide present in the fly ash is <20 % and hence according to ASTM specification C 618-89 (1992), this fly ash belongs to a class-F category. The commercially available superior grade quick lime was used to prepare lime column. The purity of lime is 90.2 %.

3.2 Methodology

3.2.1 Preparation of Ash Bed and Installation of Lime Column

Figure 1a shows the test set up for sedimentation of ash slurry which consists of a large circular galvanized iron tank of 105 cm diameter and 120 cm height open at the top with a drainage arrangement at the base. About 1 tonne of fly ash sample was used and the amount of water required for the flow-able fly ash slurry was determined from step-by-step water addition, and mixing of fly ash. The optimum moisture content without bleeding of water from fly ash was based on eye judgment and it was found to be 75 %. The slurry was prepared at this moisture content and placed in the tank. A conventional mixer machine was used to prepare the slurry in the laboratory. Before pouring the slurry in the test tank, the bottom of the test tank was covered with a filter bed of highly permeable material such as sand up to a height of 10 cm. Then the ash slurry was allowed to settle in a large circular test tank and it was kept undisturbed for a period of 2 months in order to facilitate sedimentation under the self-weight. At the end of the initial sedimentation period of 2 months, the lime column was installed at the center of the sediment ash in the test tank. The diameter of lime column was 10 cm and 10 kg of quick lime was used for preparation of the column. The difference between the concentration of chemical in the lime column and the pore water elsewhere induce the migration of lime from the central column to the peripheral region.

3.2.2 Sampling Program

The samples were collected from various radial distances from the periphery of the lime column such as 5, 15, 25, 35 and 45 as well as depths like 10, 30, 50, 70, and 90 after 30, 90, 180, and 365 days after installation of the lime column and the pH value, hydraulic conductivity and concentration of different elements in the leachate sample were determined. The details of sampling locations for leachate analysis and hydraulic conductivity test are presented in Figs. 1b and 2 respectively. The nomenclature S1, S2, S3, S4, S5 represents the sampling position at a fixed radial distance of 25 cm and with varying depth of 10, 30, 50, 70 and 90 respectively, whereas S6, S7, S8, S9 represents the sampling position at a fixed depth of 50 cm and radial distances of 5, 15, 35 and 45 respectively (Fig. 1b).

3.3 Details of Test Conducted

3.3.1 pH Test

In order to the know the variation of pH in the test tank, leachate samples are collected from different radial distances and depth of the sedimented fly ash deposits after specified curing periods and the pH test was done in a calibrated pH meter (Sony micro pH system 361).

3.3.2 Leachate Analysis

The total concentration of major and trace elements present in the fly ash is determined by acid digestion method according to Environmental Protection Agency (EPA 3050B method). The leachate characteristics of raw fly ash are determined by extraction method (Toxicity Characteristic Leaching Procedure 1311 method). In this method oven dried raw fly ash sample was taken with liquid to solid ratio (L/S) of 10 and stirred in magnetic stirrer for 24 h. Then it was filtered with Whatman 42 filter paper in order to make the sample free from suspended particles and then subjected to leachate analysis. In order to know effect of lime column on the leachate effluent characteristics of sedimented pond ash deposits, samples are collected from the predetermined locations (Fig. 1b) in the test tank by pipetting method after specified curing periods. The samples were filtered in Whatman 42 filter paper and the concentration of the elements like Ca, Ni, Pb, Zn, Cu, Cr, Fe were found out by atomic absorption spectrometer (Perkin Elmer). The allowable and threshold limits of concentration of metals in drinking water as recommended by World Health Organization (WHO) and Indian Standards (IS-10500) along with the content range in various fly ash samples are presented in Table 2. Table 3 gives the concentration range of metals in the leachate sample of the raw fly ash used in the present experimental work.

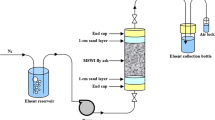

3.3.3 Hydraulic Conductivity

The hydraulic conductivity of test specimens was determined according to the procedure prescribed in IS: 2720 (Part-17; 1986) in a constant head permeameter. In order to know the hydraulic conductivity of stabilized fly ash specimens, the undisturbed samples were collected from different radial distances as well as different depths (Fig. 2a, b) after specified days of curing with the help of thin walled sampling tube having diameter same as the permeability mold and height equal to 15 cm. The collected sample was transferred into the permeability mold. Tap water of pH 7.02 was allowed to flow though the sample and saturate it. The effluents coming from the outlets of hydraulic conductivity molds were collected in measuring cylinders and the hydraulic conductivity of the samples was determined.

3.3.4 Hydration Products and Microstructure

The formation of hydration products and microstructure in cured specimens were studied by different methods likes X-ray Diffraction (XRD) and Scanning Electron Microscopy (SEM) respectively. The XRD tests were done to find out the different phases of hydration peaks that appeared in the specimens after specified days of curing. This is performed with the help of X-ray diffractometer (model Rigaku, Ultima IV). Microscopic studies were undertaken to examine the morphology and microstructure of hydrated specimens. This was done by a JEOL 6480 LV SEM, equipped with an energy dispersive X-ray detector with the Oxford data reference system. After specified periods of curing samples were collected and are soaked in acetone to stop further hydration. These samples were ground to size <75 µm before the tests.

4 Results and Discussion

4.1 pH Value

Figures 3 and 4 represent the pH test results of the samples collected from different radial distances and depths of the test tank after 90, 180 and 365 days of curing. It is observed that at a given depth the pH value follows a decreasing trend with an increase in radial distance and follows an increasing trend with increase in depth from the top surface of the pond ash deposit. This is due to migration of lime to the periphery of tank. As there is high concentration of lime at the location near to the lime column, so pH value is higher for the samples collected adjacent to the lime column. Similarly an increasing trend of pH value with increase in depth from the surface of the tank at a given radial distance is due to migration of lime towards downward direction. Moreover, it is also observed that the pH value increases with the curing period up to 180 days. However, after 180 days of curing, the pH value is found to be reduced. The increase in pH value at initial period of curing is due to the migration of lime from the lime column towards the peripheral region of the tank. Simultaneously the migrated lime also takes part in the pozzolanic reaction to produce the calcium silicate hydrate and calcium aluminate hydrate gels. These hydration products migrates through the capillary pore spaces of the sedimented fly ash deposits and causes a reduction in interconnectivity of the pore channels. The intensification of hydration products with the curing time can be observed from the XRD patterns given in Fig. 11. This reduces the permeability of the bed; particularly in the zone near to the central lime column prohibiting further migration of lime from the lime column. This indicates that the migration of lime continues even up to 180 days, and the amount of lime migrated is higher than the amount of lime consumed in pozzolanic reaction. This leads to a gradual increase in the pH value up to 180 days of installation of lime column and thereafter the same decreases.

4.2 Hydraulic Conductivity

Figures 5, 6 and 7 represent the hydraulic conductivity values of pond ash specimens collected after 90, 180 and 365 days of curing period respectively. From the test results, it is found that the hydraulic conductivity is the highest at a depth of 30 cm. Lower values of hydraulic conductivity is noticed in specimens collected above or below to this depth. Further at a given depth the hydraulic conductivity is found to increase with increase in radial distance from the lime column. This is due to the dispersion of migrated of lime from lime column to the surrounding. As there is high concentration of lime at the location near to the lime column, the hydraulic conductivity is lesser for the samples collected adjacent to the column whereas the hydraulic conductivity is more for the samples collected at a remote area from the lime column. The reduced value of hydraulic conductivity is due to the participation of lime in pozzolanic reaction and formation of hydration products like C–S–H gel which causes reduction of void space and in the interconnectivity of pore channel. The test results show that hydraulic conductivity at depth of 10 cm is lower than that of 30 cm depth. This indicates the presence of finer size particles on the top layer and coarser particles towards to the bottom. Another possible reason for the low permeability on the top layer may be the evaporation of water from the surface of the ash deposit thus increasing the concentration of lime in the pore water. This higher concentration of lime in pore water results in formation of more hydration products thereby reducing the hydraulic conductivity of the ash bed. It is also observed from Fig. 8 that as the curing period increases, significant reduction in hydraulic conductivity occurs in all the depths of sediment pond ash deposit. This indicates that the hydration reaction continues with time for a considerable curing period, generating more amount of hydration products and hence reduction in hydraulic conductivity.

4.3 Leachate Analysis

The leachate analysis results of sample collected on 90, 180 and 365 days curing are given in Tables 4, 5 and 6 respectively. It shows that concentration of all elements in the leachate samples collected from the test tank are much lower than that extracted from raw fly ash (Table 3). It also shows that at early period of curing the concentration of Ca in the leachate sample collected from all the locations of the tank is more than that in the virgin fly ash. The concentration of Ca in the leachate sample continues to increase up to a curing period of 180 days thereafter the same follows a decreasing trend. During initial period there is profuse migration of lime from the lime column towards the surrounding. As curing period increases the migrated lime takes part in pozzolanic reaction producing the C–S–H gel. This gel blocks the capillary pore space of thee ash bed thus prohibiting further migration of lime which results in a decrease in the concentration of Ca in the leachate sample with longer curing period. Further, it is observed that the concentration of Ca in sample follows an increasing trend in the sample collected at same radial distances but varying depth in the order of S1 < S2 < S3 < S4 < S5 due to migration of lime in downward direction, whereas the concentration of Ca in samples follows a decreasing trend in the samples collected at the same depth but different radial distance in the order of S6 > S7 > S3 > S8 > S9 due to distribution of migrated lime over a wider area. It is also observed from the results that the concentration of other major and trace elements in the leachate sample collected adjacent to the lime column is lesser than that of the sample collected at the periphery of the test tank. This is due to the presence of higher concentration of lime at the location adjacent to the lime column which results in higher pH value near the lime column and lower at a remote area from lime column thus, providing an alkaline medium for metal precipitation. The presence of different elements in the leachate sample mostly depends on its solubility, which is governed by the pH of the pore fluid. A detailed solubility curves for elements like Pb, Cd, Zn, Cr, Ni, Cu, Na, K, Ca, and Cl is presented by Quina et al. (2009). It is reported that the solubility of major elements decreases with increase in the pH value except for the amphoteric elements which shows an increase of solubility with the pH value. In addition to this, the higher concentration of lime results in the formation of more amount of C–S–H gel which encapsulates the metal ions and thus, prevents leaching of elements. Moreover, it is observed with increase in curing period, the concentration of elements in the leachate decreases. This is due to the formation of hydration product such as C–S–H gel which encapsulates the elements and prevents leaching. The encapsulation of metal ions by the hydration products has been reported by Zhen et al. (2014). The intensification of hydration products with curing period can be observed in the XRD patterns given in Fig. 11. The SEM image presented in Fig. 13 also confirms the formation of higher amounts of C–S–H gel with increased curing period. This indicates that addition of lime plays a pivotal role in reducing the concentration of elements and with higher curing period the concentration of element reduces even more. The concentration of all the elements was found to be less than threshold limit of WHO and IS-10500 water quality standard (Table 2).

4.3.1 Leachate-Load Ratio

The total amount of a metal in the leachate depends on the hydraulic conductivity of the material and on the concentration of the metal in the leachate. The efficacy of lime column in mitigating the leachate characteristics of pond ash is studied through the term leachate load ratio which is defined as the ratio of the total metal emanating from an unstabilized specimen per unit time to the total metal emanating from a stabilized specimen per unit time. At a given curing period and depth the hydraulic conductivity increases with the radial distance (Fig. 7). Further higher amount of hydration products are formed near to the central lime column than remote areas (Fig. 12). The total metal emanating from the specimen is the product of hydraulic conductivity and concentration of the metal under study. Figure 9 shows that the leachate load ratio of all the elements in the leachate collected on 365 days curing is >1. Therefore, the total metal coming out of the stabilized specimens is less than that of unstabilized specimens. Also this value for each metal is higher in the sample collected near to the lime column than that collected at a greater radial distance. This is due to higher pH of pore water near to the lime column which causes a reduction in the solubility of metal ions. Further, the hydration products formed due to pozzolanic reaction encapsulates the metal ions and prevents its leaching. Figure 10 shows that with increase in curing period the leachate-load ratio increases. This confirms that with increase in curing periods the pozzolanic reaction becomes even more stronger and more amount of C–S–H gel is formed which causes a reduction of hydraulic conductivity and encapsulation of metal ions.

4.4 Hydration Products and Microstructure

The formation of hydration products and its distribution in the surrounding mass is studied with the help of XRD and SEM images. The XRD pattern of fly ash specimens collected on 30 and 365 days curing were shown in Fig. 11. A series of compounds such as calcite, quartz, calcium silicate hydrate (C–S–H), calcium alumininate hydrate (C–A–H) and calcium aluminium silicate hydrate (C–A–S–H) are found in hydrated specimens. It shows that as the curing period increases, hydration products or phases are intensified and the peaks of calcite diminish. The diminished intensity of calcite peaks with an increase in curing time in the cured specimen is an indication of participation of lime in hydration process and formation of more amount of C–S–H gel. Moreover, it is observed from Fig. 12 that at 365 days curig more amount of C–S–H gel is formed in the samples collected near to the lime column. With increase in radial distance the formation of C–S–H gel decreases. This is due to distribution of migrated lime over a wider area. Microstructure of the specimens cured for different periods are studied using scanning electron microscope. Figure 13 shows that at early stage of curing periods (30 days), in some areas, needle like structures of ettringite are formed. However, at later stage of curing, common fibrous type of irregular grains forming a reticular network of C–S–H gel is found. This gel migrates through the pore space causing an reduction in the capillary voids. The presence of hydration products result in reduction of hydraulic conductivity value. The SEM analysis shows the compounds that are identified earlier from XRD analysis.

5 Conclusions

The primary objective of this study is to reduce the concentration of metals in the leachate emanating from the pond ash bed and also to prevent the leachate from contaminating the ground water. So an experimental investigation was carried out in order to study the efficacy of lime column in mitigating the leachate characteristics and hydraulic conductivity of the sedimented pond ash deposit. Based on the findings of experimental investigation, the following conclusions can be drawn.

The leaching of metals majorly depend on two factors; pH and hydraulic conductivity. The pH value was found to be more in the samples collected near to the lime column and decreases with increase in curing period. An increase in curing period results in a significant reduction of hydraulic conductivity value. At a given curing period and depth the hydraulic conductivity is found to increase with increase in radial distance from the lime column. The concentration of Ca in the leachate sample continues to increase up to a curing period of 180 days thereafter the same follows a decreasing trend whereas the concentration of other elements continues to decrease with time. The concentration of all elements in the leachate sample emanating from the stabilized ash bed is below the threshold limit of IS-10500 and WHO water quality standard. The leachate-load ratio of all the elements in the leachate sample collected from different locations of sediment ash bed was found to be >1. The same was found to reduce with increase in radial distance. With increase in curing peiod this value increases even more deue to reduction of hydraulic conductivity and encapsulation of elements in the hydration products. A series of hydration products like calcite, C–S–H, C–A–H and C–A–S–H are found in the cured specimens. As the curing period increases, hydration products or phases are intensified and the peaks of calcite diminishes, indicating the participation of lime in hydration process and formation of more amount of C–S–H gel. SEM analysis shows abundance of needle-like structures in the specimen at initial stage of curing. However, at later stage of curing, common fibrous type of irregular grains forming a reticular network of calcium–silicate–hydrate gel is found. The presence of hydration products result in reduction of hydraulic conductivity value. Thus, lime treatment was found to be an effective means of reducing the hydraulic conductivity and concentration of the metals coming out of the sedimented fly ash specimens.

References

Behera B, Mishra MK (2012) Microstructure and leaching characteristics of fly ash-mine overburden-lime mixtures. In: International conference on chemical, civil and environment engineering (ICCEE’2012), pp 256–260

Chand SK, Subbarao C (2007) In-place stabilization of pond ash deposits by hydrated lime columns. J Geotech Geoenviron Eng 133(12):1609–1616

Fleming LN, Harrison NA, Inyang HI (1996) Leachant pH effects on the leachability of metals from fly ash. J Soil Contam 5(1):53–59

Ghosh A, Subbarao C (1998) Hydraulic conductivity and leachate characteristics of stabilized fly ash. J Environ Eng 124(9):812–820

Ghosh A, Subbarao C (2001) Microstructural development in fly ash modified with lime and gypsum. J Mater Civ Eng 13:65–70

Ghosh A, Subbarao C (2006) Leaching of lime from fly ash stabilized with lime and gypsum. J Mater Civ Eng 18:106–115

Guleria SP, Dutta RK (2013) Durability and leachate analysis of fly ash–lime–gypsum composition mixed with treated tire chips. J Geo-Eng 8(2):33–40

Jankowski J, Ward CR, French D, Groves S (2006) Mobility of trace elements from selected Australian fly ashes and its potential impact on aquatic ecosystems. Fuel 85:243–256

Kalinski ME, Yerra PK (2006) Hydraulic conductivity of compacted cement-stabilized fly ash. Fuel 85(16):2330–2336

Kishan D, Dindorkar N, Shrivastava R (2012) Characteristics of low lime fly ash stabilized with lime and gypsum. In: International conference on future environment and energy, IPCBEE, vol 28, pp 114–118

Lau SSS, Wong WC (2001) Toxicity evaluation of weathered coal fly ash: amended manure compost. Water Air Soil Pollut 128:243–254

Lokeshappa B, Dikshit AK (2012) Fate of metals in coal fly ash ponds. Int J Environ Sci Dev 3(1):43–48

Pal SK, Ghosh A (2011) Compaction and hydraulic conductivity characteristics of Indian fly ashes. In: Proceedings of Indian geotechnical conference, pp 773–776

Prasad B, Mondal KK (2008) The impact of filling an abandoned opencast mine with fly ash on ground water quality: a case study. Mine Water Environ 27(1):40–45

Quina MJ, Bordado JCM, Quinta-Ferreira RM (2009) The influence of pH on leaching behavior of inorganic components from municipal solid waste APC residues. Waste Manag 29:2483–2493

Sengupta S, Miller HJ (1999) Preliminary investigation of tire shreds for use in residential subsurface leaching field systems. Chelsea Center for Recycling and Economic Development, Technical Report #12, University of Massachusetts

Sridevi G, Rao AS, Prasad SSV (2010) Leaching studies of lime-stabilized fly ash mixes. In: Indian geotechnical conference—2010, pp 437–440

Sushil S, Batra VS (2006) Analysis of fly ash heavy metal content and disposal in three thermal power plants in India. Centre for Energy and Environment, TERI school of Advanced studied, New Delhi. doi:10.1016/j.fuel.2006.04.031

Wang Y, Ren D, Zhao F (1999) Comparative leaching experiments for trace elements in raw coal, laboratory ash, fly ash and bottom ash. Int J Coal Geol 40(3):103–108

Zhen S, Dong X, Appiah-Sefah G, Pan M, Zhou D (2014) Analysis of changes in hydration products during solidification/stabilization process of heavy metals in the presence of magnesium potassium phosphate cement. J Appl Sci Eng 17(4):413–421

Acknowledgments

The research work reported in this paper was conducted in the Department of Civil Engineering, National Institute of Technology, Rourkela, India where the first and second authors have been professor and research scholar, respectively, until recently. The authors would like to thank the authorities of NIT Rourkela for extending all co-operation in accomplishing the experimental work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, S.P., Sangita, S. Mitigation of Leaching of Major and Trace Elements from Pond Ash Deposits by Lime Column Treatment. Geotech Geol Eng 34, 2019–2031 (2016). https://doi.org/10.1007/s10706-016-0080-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-016-0080-0