Abstract

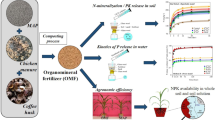

The circular nutrient economy repurposes organic (formerly alive, containing organic carbon) and inorganic (mineral) recycled materials as fertilisers and soil ameliorants, and halving nitrogen (N) waste is a global goal. Our focus was unavoidable food waste and garden waste (FOGO food organics garden organics) as suitable feedstock for compost and use for cropping. We hypothesised that to realise benefits of compost, organic and organo-mineral fertilisers (OF/OMF) must be optimised for target crops and biophysical environments. We explored compost and organic recyclates (dried bacterial biomass PPB, chicken litter manure) as N sources for vegetable, fruit and grain crops in controlled experiments with single or combinations of contrasting N release and carbon-to-N ratios of 20, 13.5 (compost), 13.5 (poultry manure), 6.1 (PPB) and 0.5 (mineral N). With standardised N input (0.5–1 g N/pot and plant), compost as the sole N source resulted in less yield than all other N sources, while suitable mixtures of organic recyclates with/without added mineral N matched the yield of crops grown with mineral N. Adding 5% compost to sand growth substrate modulated crop growth and phenology, increased tillering and panicle production, or accelerated fruit ripening. This confirmed effects beyond nutrient supply, likely crop-growth modulating substances are present. Exploring effects of crop species, N source and water supply confirmed statistically significant interactions on yield, biomass and N use efficiency (NUE). This means a robust strategy for optimising OF/OMF is testing target crops with compost and recyclates to identify crop-specific responses. We recommend that applying such strategy allows manufacturers targeting N-efficient OF/OMF to service the expanding market for recyclate-based organo-mineral fertilisers and soil ameliorants for the circular N economy.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The circular nitrogen (N) economy has been singled out as one of five United Nations Environment Assembly’s (UNEA) priority goals to transition from “N pollution to circular N economy”, and “halving N waste by 2030” is the goal of the 2019 Columbo declaration (Sutton et al. 2021; Gu et al. 2023). Nitrogen is quantitatively the most important plant nutrient, accounting for over 60% of the soil-derived nutrients that crops acquire and is a major driver of yield. Global farmlands receive on average twice as much N fertiliser than is absorbed by crops (Zhang et al. 2015), demanding strategies for responsible N use (Udvardi et al. 2021). Nitrogen losses from fertilisers and wastes are the main reason for the more than doubling of reactive N in the biosphere that exceeds the safe planetary boundaries, impacts biodiversity, generates greenhouse gas emissions and contributes to the human disease burden (Steffen et al. 2015). The circular N economy recycles N from solid and liquid wastes to reuse as fertilisers and soil ameliorants.

We focussed on organic fertiliser (OF) in which N is derived from organic sources (i.e., recyclates that contain organic carbon (C), N and other nutrients), and organo-mineral fertiliser (OMF) that has mineral N fertiliser added. Current limits to a widespread use of OF/OMF include availability of suitable materials, appropriate formulations, manufacturing and logistics (De Corato 2020), tentative adoption by farmers (Bouhia et al. 2022) and insufficient government regulatory policy resulting in uncertainty for businesses (Australian Organics Recycling Association 2021). Transitioning to the circular N economy demands advancing OF/OMF for high production cropping. There is evidence that OF/OMF can match or outperform mineral fertilisers by improving crop nutrient supply, soil aeration, pH and water holding capacity, disease suppression and microbiomes (Paustian et al. 2016; De Corato 2020; Khan et al. 2023). However, claims of all-encompassing benefits are unwarranted as crop yields can be compromised with organic formulations including compost (Timsina 2018; Zhao et al. 2022). This points to a need to improve the design of OF/OMF and motivated our study, with a focus on how organic recyclates are best formulated to satisfy crop N demand.

Apart from the need to implement the circular N economy and boost the efficiency of crop N nutrition, a third motivation is that the fate of organic wastes as landfill is undesirable. Landfills can be high emitters of greenhouse gases with the anaerobic decay of organic matter (Brown 2016; Maasakkers et al. 2022), and alternative uses of organic wastes are sought. Composting is a highly suitable alternative to burying organic wastes in landfill (Lou and Nair 2009), being a long-established technology that converts organic wastes into stabilised organic matter through a controlled aerobic process in which bacteria, Archaea and fungi metabolise soluble and easily degradable biomolecules (e.g., sugars, proteins) and carbon-rich macromolecules (e.g., cellulose, lignin) into more stable organic humic substances and humus.

The properties of a compost determine its value for soil and crops and depend inter alia on feedstocks and processing. Composts vary in macronutrient content (e.g., C/N, C/phosphorus), pH, salt content and microbial composition among other (Cassity-Duffey et al. 2020) and although compost is increasingly valued in agriculture, it is often a generic product not designed for target crops or specific biophysical conditions (De Corato 2020). This was confirmed in a recent global meta-analysis demonstrating compost-grown crops produced on average 10% less yield, while compost + mineral fertiliser achieved on average 16% more yield compared to crops with mineral fertiliser (Zhao et al. 2022). This means yield often profits from nutrient-ameliorated compost and N was identified as key yield limiting factor. Promisingly, it was estimated that the benefits of a global ‘precision compost strategy’ that optimises composts for target crops and biophysical settings has the potential to increase major cereals yield by 96.3 Tg (4% above current global production) and store 19.5 Pg organic carbon in topsoil, ~ 26.5% of current soil carbon levels (0–20 cm of soil) (Zhao et al. 2022).

A knowledge gap is how to implement the precision compost strategy, which we addressed by testing the interactions between crops and N supplied as FOGO compost, dried bacterial biomass, poultry litter and mineral fertiliser. Valorising FOGO is attractive as a highly suitable feedstock with accelerating global production, but manufacturers must demonstrate that compost-based fertilisers are a viable alternative to mineral fertilisers (Paustian et al. 2016; De Corato 2020). Mineral N fertilisers are immediately crop available, rapidly releasing N ions into the aqueous phase, while organic materials release N at different speeds (Cassity-Duffey et al. 2020), which is driven by nutrient density including C/N ratio, biophysical conditions, microbial processes and a crop’s ability to access organic nutrients (e.g., exuding N-mobilising enzymes and biochemicals, attracting N-mobilising rhizosphere microbes, Paungfoo-Lonhienne et al. 2012, Kuzyakov and Razavi 2019). Previous research successfully supplied crops with N from combinations of N-dense microalgae, chicken manure and mineral N (Rupawalla et al. 2021; Ngo et al. 2022), indicating that suitable ratios of organic and mineral N can supply crops. We also tested purple phototrophic bacteria (PPB) as N fertiliser. PPB are fast-growing anoxygenic photoheterotrophs that efficiently recover nutrients from wastewater (Batstone et al. 2015; Hülsen et al. 2018). PPB concentrate macronutrients in their biomass (10% N, 1–2% P, C/N ~ 5) with over 60% protein content (Capson-Tojo et al. 2020). This is comparable to biosolids (e.g., waste-activated sludge), but PPB wastewater treatment facilities produce twice as much microbial biomass per gram chemical oxygen demand (COD) without dissipating carbon dioxide (CO2) and dinitrogen (N2) or losing P in metal-bound sludge destined for landfill. In current applications, PPB-biomass serves as fishmeal substitute and as fertiliser (Zarezadeh et al. 2019; Delamare-Deboutteville et al. 2019). Further, we used poultry manure as N-dense recyclate because manures from intensive livestock production have much potential as fertilisers when formulated correctly (Lim et al. 2023).

Seven crops (vegetable, fruit, grain) were grown with organic recyclates (FOGO compost, dried PPB, poultry manure) and/or added mineral N in controlled glasshouse conditions with matching N supply. Further, we explored FOGO compost as a growth substrate ameliorant that can module plant growth responses through bioactive compounds including phytohormones (Ravindran et al. 2016) or improved water use efficiency as observed with amino acid-supplied tree seedlings (Krishnan et al. 2023). In collaboration with an industry partner who generates FOGO compost and aims to optimise it for crops, we explored design principles for OF/OMF in standardised growth conditions to identify how best to supply N to target crops across settings that included single or mixed N sources and different N supply and water regimes.

Materials and methods

Experimental conditions and material characteristics

All experiments were carried out in glasshouses with natural lighting at The University of Queensland (St Lucia campus, Australia, 153.01369 E, − 27.497502 S) from November 2019 to March 2021. Glasshouse temperatures ranged from 25 to 45 °C in summer and 19–28 °C in winter with ~ 80% ambient light intensity. The glasshouses were cooled with vents and relative humidity averaged 90 and 60% in summer and winter, respectively. Vegetable, fruit and grain crops were grown with single N sources or mixtures of organic and organo-mineral N sources. Controls included treatments without N or supplied with mineral N. To ensure a low N background and accurate dosing of N, crops were grown in sand mixed with peat or vermiculite. All other essential nutrients were supplied as a N-free nutrient solution. The same harvest and analysis protocol was used for all experiments. Aboveground biomass (leaves and stems), belowground biomass (roots carefully washed free of growth substrate) and crop yield (shoots—leafy green vegetables, fruit—watermelon and tomato; panicle—sorghum) were quantified with fresh and dry weights (60 °C for 3–10 days in drying oven). To quantify tissue N, plant matter was ground to a fine powder with a ball mill (Retsch MM-2, Haan, Germany). Nitrogen and C contents were determined by dry combustion and infrared detection (CNS-2000, LECO Corporation, MI, USA). All other macronutrients were analysed in the organic materials after digestion in nitric acid via ICP-OES (Perkin Elmer, Optima 8300, USA).

Organic nitrogen sources

Compost Loose and/or pelletised (extruded) FOGO compost generated from food and green wastes (household and council wastes was manufactured at Peats Soil & Garden Supplies Ltd Pty, https://www.peatssoil.com.au). In experiments 1–3, FOGO compost was used to deliver N to crops, in experiment 4, it was used as soil ameriorant (see below). Macroelement analyses were performed as outlined above. Loose compost consisted of 24% C, 1.2% N, 0.26% phosphorus (P), 1.55% potassium (K), 1.73% calcium (Ca), 0.48% magnesium (Mg), 0.27% sulopjur (S). Compost pellets contained 23.1% C, 1.71% N, 0.8% P, 1.65% K, 5.79% Ca, 0.69% Mg, 0.29% S. C/N ratios of loose and pelletised compost were 20 and 13.5, respectively. Compost pellets had a 30% higher N content than loose compost and the first experiment showed that neither compost type adequately supplied N to crops, and Only one compost type was used in subsequent experiments as indicated below.

Purple phototrophic bacteria (PPB)—The PPB used here were grown on poultry-processing wastewater pre-treated in an industrial, dissolved air flotation unit, followed by a fermenter with 1-day hydraulic retention time prior to entering a flat plate photobioreactor. The photobioreactor was operated outdoors at the processing facility in Brisbane, Australia. The system is described elsewhere (Hülsen et al. 2022), the basic characteristics of the photobioreactor were as follows: the unit was 9.76 m long with a total volume of 953 L and a working volume of 900 L. The reactor walls, outer bottom, and roof were covered with an ultraviolet–visible (UV–Vis) absorbing foil (Lee filter ND 1.2 299) to limit light input from non-NIR wavelengths and favour PPB over phototrophic algae and cyanobacteria. The photobioreactor was operated for 253 days and biomass harvested over the first 160 days of operation. The microbial composition varied over time with a relative PPB abundance of 40–60%, dominated by species of Rhodopseudomonas. PPB biomass was harvested via centrifugation from the bottom of the bioreactor on five occasions and transported on ice to the laboratory before drying at 70 °C for ~ 24 h (Sunbeam Food Lab Electronic Dehydrator). PPB had a C/N ratio of 6.1 and a dry biomass macroelement composition of 53% C, 8.66% N, 1.13% P, 0.57% K, 1.85% Ca, 0.27% Mg, 0.67% S.

Poultry manure. In experiment 4, we used commercial poultry manure (Fine Farm, Bunnings, Australia) as a N source. The poultry manure had a C/N ratio of 13.52 and element composition of 32.47% C, 2.4% N, 1.0% P, 2.09% K, 5.6% Ca, 0.46% Mg, 2.09% S.

Crop growth experiments

All experiments had different aims but followed the same setup as randomised block design and cultivating 1 plant per pot (pot sizes differed to accommodate different crop sizes) in growth media with low N background (sand, peat, vermiculite), and in Experiment 4 with 5% FOGO compost (see below, the term compost is used in the following). All nutrients except N were supplied as nutrient solution. Nitrogen was added to pots as recyclate/s at the start of the experiment or, in the case of mineral N controls, as regular additions of N solution to match the amount provided by recyclates at the end of the experiment. Daily watering ensured that plants were well supplied (except water limited plants in Experiment 2) without leaching from pots. We quantified harvest product (fruit, grain or above ground biomass), shoot and root biomass with roots washed carefully to remove growth medium, and N content after drying and grinding.

Experiment 1 tested single N sources (compost, compost pellets, dried bacterial biomass (PPB), mineral N; November to January, 12 weeks) with a fruit, grain and vegetable crop from three plant families. Sorghum (Sorghum bicolour var. Buster, Poaceae), watermelon (Citrullus lanatus, var. ‘Sugarbaby’, Curcurbitaceae) and tomato (Lycopersicon esculentum, var. Arcadia, Solanaceae) were grown from seed for 12 weeks in 4 L (sorghum) or 2.8 L pots (watermelon, tomato) with sand:peat (50:50 v:v) growth medium. Four N treatments (compost, compost pellets, PPB, mineral N) received 1 g N pot−1 with 10 replicates for each crop and treatment, no-N control plants were grown without added N. Pots were filled to 75% capacity with growth medium. Organic recyclates were added as single materials (83.3 g compost, 58.5 g compost pellets, 11.5 g PPB) and mixed with the remaining growth medium to fill the pots (standardised to 2.6 kg for 2.8 L pots and to 3.8 kg for 4 L pots). Pots were arranged in a randomised block design and watered to field capacity before sowing seeds (3 seeds pot−1, thinned to one seedling after emergence). Initially, 100 mL of deionised water were added to the pots daily, once seedlings produced true leaves, a no-N nutrient solution (2 mM K2SO4, 2 mM MgSO4, 2 mM CaCl2, 0.085 mM K2HPO4, 0.914 mM KH2PO4, 200 µM Fe EDTA, 10 µM MnSO4, 10 µM H3BO3, 1 µM CuSO4, 2.5 µM ZnSO4, 0.35 µM Na2MoO4) was added 3 days/week. The mineral N treatment received 5 mM NH4NO3 as nutrient solution. After 2 weeks, nutrient solution was supplied five times per week to supply a total of 1 g N at the end of the experiment. Aboveground biomass was removed and roots carefully washed to remove substrate before processing as described above.

Experiment 2 tested compost together with PPB or mineral N (June to August, 6 weeks) with congeneric species kale and pak choi (Brassica oleracea var. acephala; Brassica rapa var. chinensis, Brassicaceae; both Mr. Fothergill’s Seeds Pty. Ltd, NSW, Australia). In addition to different N treatments, interactions between N and water supply were tested with adequate or undersupply of water. Sand and vermiculite (70:30 v:v) was the growth medium in 1.9 L pots and OF/OFM were added as outlined in Experiment 1. Pot weight was standardised to 2.6 kg. Recyclate treatments received 0.5 g N pot−1 with five replicates per species and treatment with negative control (no N added), positive control (100% mineral N), 100% compost pellets (30 g pot−1), 50% compost pellets (15 g) and 50% PPB (3 g), 50% compost pellets (15 g) and 50% mineral N (0.25 g). Pots were watered to field capacity with 500 mL deionised water before sowing crop seeds (3 seeds per pot, thinned to 1 seedling after emergence). Pots were well watered until seedling emergence and grown for 2 weeks. After 2 weeks of seedling growth, watering treatments converted to 40 or 80% field capacity, weighing pots daily to maintain the required soil moisture. No-N nutrient solution (see Experiment 1) was added to the treatments three times per week for the first 2 weeks. The mineral N treatment received mineral N (2 mM NH4NO3) at the start of the experiment which was gradually increased to 5 mM N. Addition of nutrient solution was increased from three to five times per week for all treatments from week 2. At the end of 6 weeks, plants were harvested and processed as outlined above.

Experiment 3 tested compost in combination with one or two additional N sources (April to May, 4 weeks) with spinach and silver beet (Spinacia oleracea Amaranthaceae, Beta vulgaris var. cicla, Amaranthaceae, Mr. Fothergill’s Seeds Pty Ltd., NSW, Australia). Plants were cultivated from seeds in the same growth medium as Experiment 1 in 1.9 L pots. Five nutrient treatments with six replicates per treatment and crop species received 1 g N pot−1. Treatments included two controls (no N, mineral N), 25% compost pellet and 75% mineral N, 50% compost pellets and 50% PPB, 50% compost pellets and 25% PPB and 25% mineral N, 25% compost pellets and 25% PPB and 50% mineral N. Pots were filled to 75% capacity with sand:vermiculite medium (see Experiment 2) and OF/OFM were added and mixed with the remaining growth medium and all pots standardised to 2.7 kg weight. Pots were watered to field capacity before sowing crop seeds (3 seeds per pot, thinned to one seedling after emergence). Until seedling emergence, 100 mL of deionised water was added to pots daily. Once seedlings emerged and had produced true leaves, no-N or complete nutrient solution (see above) was added (~ 100 mL) every 3–5 days to the control treatments, while all other treatments received N-free nutrient solution. Nitrogen was supplied to treatments receiving mineral N in combination with compost and/or PPB as 2 mM NH4NO3. Plants grew faster than expected and the experiment was completed after 4 weeks, and mineral-N grown plants received 250 mg N pot−1 (spinach) and 320 mg N pot−1 (silverbeet). Plants were harvested and processed as outlined above.

Experiment 4 tested compost as a growth substrate ameliorant with tomato and sorghum (same cultivars as Experiment 1, October to January, 12 weeks tomato, 14 weeks sorghum). Plants were grown in either sand or sand:compost mixture (95:5, weight:weight). Pots (4 L) were filled to 75% capacity either with sand or sand + compost. OF/OMF were mixed with the potting media and pots filled to the rim to 5.6 kg weight. The sand:compost substrate received 5% (265 g) compost (C/N 20:1). Pots were watered with deionised water to field capacity before sowing (3 seeds pot−1 seeds for sorghum, 5 seeds pot−1 seeds for tomato). All treatments contained 2 g N pot−1 as one of the following treatments: 100% mineral N, 100% poultry litter, 50% mineral N and 50% poultry litter, 50% poultry litter and 50% PPB, 50% mineral N and 50% PPB. Upon seedling emergence, mineral fertiliser solution was added (100–200 mL) at low concentration (no-N solution as in Experiment 1 or complete solution with 2 mM NH4NO3) for a week. All treatments were given similar amounts of deionised water (100–200 mL) 5 days/weeks at the start of seedling growth. Once seedlings were > 20 cm tall, concentration and amount of nutrient solution or water were increased to 300–400 mL day−1. Sorghum and tomato plants were harvested as outlined above.

Statistics

For each experiment, two-way analysis of variance (ANOVA) determined the significance of each fixed effect and the interaction of each model (Table 1). In Experiment 1, the effect of crop and N treatments was determined for fruit fresh weight, shoot and root biomass, and N use efficiency (NUE = g N in whole plant/g N applied * 100). In Experiment 2, models for the effect of water supply and N treatment on total biomass, N uptake and NUE were developed separately for spinach and silver beet. In Experiment 3, effects of crop, N treatments on shoot dry weight, N uptake and NUE were determined. In Experiment 4, models for the effect of substrate and N treatment on yield, total biomass and NUE were developed individually for sorghum and tomato. Quantile plots were generated from the models to assess the distributions of the residuals for the assumption of normality. Response variables for models were transformed accordingly to meet the assumptions of normality. Post-hoc Tukey analyses were conducted to determine pairwise differences within fixed effects for each response variable. All analyses were conducted on R Statistical Computing (version 4.2.2). Linear models were created using the package ‘nlme’, post-hoc tests were run using ‘emmeans’ (R Core Team 2022). All graphs were created with GraphPad Prism version 9.5.1 (733).

Results

A series of four experiments explored crop growth and yield with single or mixed N sources, and, in the last experiment, also using compost as growth substrate ameliorant. Focussing on N, we standardised N supply, supplied all other nutrients and used growth substrate with low background of biological activity. Experiments were carried out with summer and winter crops to quantify how N sources affect yield, N uptake and NUE. Significant (P ≤ 0.05) effects and interactions were observed for tested variables (Table 1). NUE was significantly affected by individual variables (crop, N source, water supply, substrate) with significant interactions in experiment 1 (crop, single N source), experiment 2 (kale only, source, water supply), experiment 3 (crop, N source), but not in experiment 4.

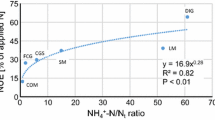

Experiment 1, evaluating effects of single N sources on crops, showed significant (P ≤ 0.05) effects of crop, N source and their interactions (Table 1). Watermelon, sorghum and tomato grown with compost or compost pellets as the sole N source (0.5 or 1 g N pot−1) produced little biomass and yield (Fig. 1). With PPB as the sole N source, watermelon produced relatively more fruit (76% yield) than sorghum (46% yield) and tomato (1.4% yield) compared to mineral N supplied plants (100%), and similar patterns with biomass.

Crops grown with a single N source supplied as compost, compost pellets, PPB (dried biomass of purple phototrophic bacteria) or mineral N. Control plants received no N, all N treatments received 1 g N pot−1. Bars show average harvest product per plant (gram fresh weight (FW) or dry weight (DW), averages and standard deviations, n = 10 (see Table 1 for statistical information). Photos show fruits or grains of the productive treatments

Experiment 2, testing single and dual N sources and water supply, showed significant effects and interactions on kale and pak choi (Brassicaceae) (Table 1). N source and water supply had significant effects on NUE, but a significant interaction on NUE was only observed with kale (Tables 1 and 2). Water-limited kale grown with OMF had 67% N of mineral N supplied plants, and pak choi had 67% and 56% N of mineral N plants in the two water treatments, respectively (Fig. 2).

Kale and pak choi grown with single or dual N sources and under water limiting or water replete conditions. Compost pellets were used as the compost source. Bars show biomass (g dry weight (DW) of whole plant, averages and standard deviations, n = 5) and N uptake (g pot−1, 0.5 g N supplied per plant indicated by the dotted line). Photos show representative plants of each N treatment in water limited and replete (well-watered)conditions, for statistical information see Table 1

Experiment 3, evaluating the response of shoot biomass (yield) and N uptake with up to three N sources confirmed significant effects of crop on shoot biomass and N source on N uptake but no interactions (Table 1). In this experiment, silverbeet and spinach (Amaranthaceae) were grown with N oversupply (1 g N pot−1) and harvested as ‘young greens’ after acquiring ~ 10% of the supplied N (Fig. 3, Table 2). Significant effects on NUE were observed with N source and the interaction between crop and N source (Table 1).

Shoot biomass and nitrogen (N) uptake of silverbeet and spinach grown with mineral N or combinations of organic and mineral N. Abbreviations: com (compost pellets), PPB (dried bacterial biomass), mineral, min (mineral N). Averages and standard deviations (n = 6) are shown. Photos show representative plants for each treatment, for statistical information see Table 1

Experiment 4, testing effects of 5% compost in the growth substrate and N sources showed significant effects and interactions on yield of sorghum and tomato (Table 1, Fig. 4). Sorghum tiller numbers (data not shown) followed a similar pattern as panicle numbers (Fig. 4), indicating that compost increased tillering and panicles. Grown with compost, tomato fruit mostly ripened faster than in sand with 10 to 38% of fruit red at the time of harvest compared to no ripe fruit in sand-grown plants (except poultry manure + mineral N with 12% red fruit) (Fig. 4).

Sorghum and tomato grown in sand or sand:compost (95:5) substrate with organic and/or mineral N sources (single source or 50:50). Averages and standard deviations are shown (n = 6). Photos show representative panicles and tomato fruit. Average sorghum panicle numbers and tomato fruit are shown, as well as % ripe tomato fruit, for statistical information see Table 1

Discussion

Organic recyclate-based fertilisers and soil ameliorants can deliver comprehensive benefits and disruptive innovation central to repurposing nutrient-rich wastes and implementing the circular nutrient economy. OF/OMF can contribute to recarbonising soils and slow the rising atmospheric carbon dioxide levels as charted in the 4 per 1000 initiative but can also be problematic when not optimised for yield and for supressing greenhouse gas emissions (Minasny et al. 2017; Zhao et al. 2022; Zhou et al. 2017). Our study focussed on N as a major yield limiting factor and tested how different crops access N from organic sources with higher to lower C/N ratios to expand knowledge on how to formulate OF/OMF as fertiliser. Effective and standardised products are needed that facilitate delivering high yields, quality food and feed. Key findings are that (i) crops differed in their ability to access N from organic recyclates and convert to biomass and yield, (ii) combinations of recyclates with/without added mineral N achieved yield parity with mineral N, (iii) OF/OMF and compost as soil ameliorant modulated crop growth, ripening and yield, and (iv) the tested variables affected NUE. A robust approach for designing OF/OMF that deliver sufficient N to crops is combining recyclates with different N release rates and testing target crops with OF/OMF formulations to ensure customised products that deliver maximal benefit.

Organic and organo-mineral fertilisers support crop yield and efficiency gains

Transitioning to a circular N economy, and implementing the Sustainable Development Goals, sets a new agenda that requires repurposing of organic recyclates to partially replace current synthetic N fertiliser. Appropriate blends of two or three materials (compost, PPB, poultry litter, mineral N) matched the yields of mineral-N grown crops. When crops acquired all supplied mineral N (Experiment 2), kale and pak choi produced the same biomass with mineral and compost + mineral N but accumulated ~ 40–50% less N in the latter. Similarly, when crops accumulated less than 20% of supplied N (Experiment 3), silverbeet produced the same biomass with compost + PPB or mineral N but accumulated 47% less N. Such higher NUE defined as biomass per tissue N content has been documented in organic versus mineral N supplied plants (Franklin et al. 2017) even though in this experiment it is unresolved if lower N accumulation is caused by a lower N availability of recyclates (i.e., crops took up N only from mineral N) or an effect of organic N supply.

No obvious benefits were derived from OF/OMF in crops grown with water limitation. This contrasts findings of higher water use efficiency in tree seedlings supplied with organic versus mineral N, as organic N more effectively regulated stomatal conductance to convey greater drought resilience (Krishnan et al. 2023). Water limitation can reduce the uptake of mineral N through decreased mobility of nitrate (Araus et al. 2020), and lower N accumulation with OF/OMF grown crops is of interest when crops store excess N as nitrate. We did not analyse nitrate in plant tissues, but previous research showed that spinach grown with microalgae biomass as N source accumulated less nitrate than with mineral N, which is desirable as high nitrate consumption is a health risk for humans and domestic livestock (Rupawalla et al. 2021 and references cited therein). Similarly, salad from organic crop production (no mineral N fertiliser) contained less nitrate (1.45–6.40 mg kg−1 fresh weight) than conventionally produced salad (10.5–45.19 mg kg−1 FW, Aires et al. 2013). A flipside of lower crop N accumulation can be an undesirable reduced protein content, as was detected in wheat from organic farms that had not optimised their N management (Casagrande et al. 2009). However, N oversupply is at the forefront of the discussion due to high costs for farmers and environment, and N efficiency underpins sustainable uses (Udvardi et al. 2021). Understanding how organic recyclates and mineral N supply crops, individually and in combination, will advance successful formulation of OF/OMF, bearing in mind that both N sources can be converted to organic and inorganic forms in the soil-microbe-plant continuum (Schmidt et al. 2014).

Promisingly, compost can generate higher yield than mineral fertiliser when formulated to optimally supply target crops. Currently in 61% of field experiments globally, average crop yield was 10% lower with compost than with mineral fertiliser, while in 76% of experiments with compost + mineral fertiliser, yield was 15.7% higher than with mineral fertiliser (Zhao et al. 2022). Studies show that composts and other biofertilisers benefit crop growth (e.g., Weber et al. 2014; Tahiri et al. 2022), while OF/OMF in our experiments did not have a yield advantage over mineral N. Likely reasons include that we controlled N losses and water supply, provided all other essential nutrients and the growth substrate minimised other negative conditions (e.g., low pH, pathogens). Thus the experiments contrast real world settings where reasons for higher yields with OF/OMF include lower N losses from soil compared to conventional mineral fertiliser, improved soil physicochemical conditions including soil structure, pH, water infiltration and water storage, and soil biology (Forge et al. 2016; Hoover et al. 2019).

Organic substrates can alter crop growth and phenology—including faster fruit ripening

Compost as an ameliorant in sand growth substrate altered crop growth. Sorghum increased tiller and panicle numbers but had lower yield at harvest due to slower ripening than no-compost control plants. In contrast, tomatoes ripened faster and produced more yield than the no-compost control. Phytohormones and other bioactive substances have been detected in composts, inherent to the input materials and/or generated by soil microbes, and are a likely cause for the observed effects as they can enhance root growth and nutrient absorption, ameliorate crop stress and disease resistance, and delay crop aging (Klimas et al. 2016; Pant et al. 2012). Some bacteria, including PPB, produce plant growth promoting phytohormones (e.g., auxins) and beneficial growth regulators (e.g., 5-aminolevulinic acid, Sakarika et al. 2020). Quantifying plant growth promoting substances in organic recyclates will assist with formulating OF/OMF to harness beneficial effects (e.g., faster ripening) and avoid undesirable effects (e.g., excessive tillering, delayed grain ripening). While sorghum and tomato generated similar yield with OF/OMF as with mineral N, rice yields benefitted from the use of vermicompost, inorganic N and beneficial bacteria (Jeyabal and Kuppuswamy 2001). Similarly, poultry manure compost and municipal organic waste-based vermicompost increased tomato yield (Wang et al. 2017; Mengistu et al. 2017), although the precise causes for the observed benefits remain unknown.

A possible reason for the observed altered plant growth here includes the sources of N supplied to crops. Compared to ammonium or urea as an N source, nitrate enhanced tillering in barley and wheat, and tiller numbers were positively correlated to root-to-shoot translocation of endogenous cytokinins (Bauer and von Wirén 2020). A reason why compost can boost tillering is the presence of nitrate in compost (Cáceres et al. 2018) but this is an unlikely reason here as both mineral N treatments received regular doses of ammonium nitrate. Rather, we observed that organic N modulated crop growth. Similarly, spent brewer’s yeast increased shoot growth in tomato and tillering in sugarcane (Lonhienne et al. 2014). Taken together, the results confirm the notion that phenology-modulating substances can occur with compost and other recyclates (Ravindran et al. 2016).

Realising organic and organo-mineral fertilisers

Recyclates, such as those tested here, spanning C/N ratios from 6.1 to 20, are ingredients for OF/OMF. Converting organic wastes into effective fertilisers and soil ameliorants should consider combining recyclates with lower C/N ratio, such as microbial biomass and manures, with higher C/N recyclates such as FOGO compost, as well as mineral N. Retrieving N from wastes, including humanure, will enable the transition to a circular N economy with organic and mineral N sources (Koskue et al. 2022). We show here that testing different proportions of recyclates, without or with added mineral N, allows a thorough assessment of crop responses, including phenology and yield. Future research should systematically evaluate the variables that drive N release including abiotic (temperature, water, soil) and biotic factors (crop, microbial activity). To advance OF/OMF, laboratory incubations can quantify N release rates (Cassity-Duffey et al. 2020) and in situ soil microdialysis can quantify diffusive N fluxes to generate a baseline of N release rates from organic materials (Buckley et al. 2020). Optimising OF/OMF can include the addition of functional materials to moderate excessive initial N release. For example, added zeolite or biochar attenuated ammonium release from organic recyclates to better match crop uptake capacity (Chin et al. 2018), and amending poultry litter with bentonite nearly halved the emissions of nitrous oxide from fields fertilised with conventional poultry litter (Westermann et al. 2021). Lastly, ensuring high quality OF/OMF will require collaboration between growers, regulators, the organics recycling and fertiliser industries.

Conclusions

As Environmental Protection Agencies and other regulatory bodies are codifying policies for implementing the SDGs and national sustainability goals, recycled organics-based fertilisers will deliver on multiple fronts. Supplementing or replacing mineral N while ensuring crop N sufficiency contributes to N circularity for a world without waste and pollution. Key is that OF/OMF are developed with scientific principles to maximise benefits. On-farm, key goals are crop N sufficiency, avoiding N oversupply, and recarbonising degraded soils. Off-farm, goals include curbing greenhouse gas emissions from organic waste disposal and N losses during processing. Coupling high-throughput testing of OF/OMF in controlled conditions with on-farm experiments will advance the circular N economy to increase the value of compost and other recyclates as fertilisers and soil ameliorants.

References

Aires A, Carvalho R, Rosa EAS, Saavedra JM (2013) Effects of agriculture production systems on nitrate and nitrite accumulation on baby-leaf salads. Food Sci Nutr 1:3–7

Araus V, Swift J, Alvarez JM, Henry A, Coruzzi GM (2020) A balancing act: how plants integrate nitrogen and water signals. J Exp Bot 71:4442–4451

Australian Organics Recycling Association (2021) Vision 2031: the 10 year roadmap for australia’s world leading organics recycling industry. AORA. https://www.aora.org.au/sites/default/files/uploaded-content/website-content/AORA%20Vision%202031%20Roadmap%20web.pdf (Accessed 29 Jun 2023)

Batstone DJ, Hülsen T, Mehta CM, Keller J (2015) Platforms for energy and nutrient recovery from domestic wastewater: a review. Chemosphere 140:2–11

Bauer B, von Wirén N (2020) Modulating tiller formation in cereal crops by the signalling function of fertilizer nitrogen forms. Sci Rep 10:20504

Bouhia Y, Hafidi M, Ouhdouch Y, Boukhari MEME, Mphatso C, Zeroual Y, Lyamlouli K (2022) Conversion of waste into organo-mineral fertilizers: current technological trends and prospects. Rev Environ Sci Bio/technol 21:425–446

Brown S (2016) Greenhouse gas accounting for landfill diversion of food scraps and yard waste. Compost Sci Util 24:11–19

Buckley S, Brackin R, Jamtgård S, Näsholm T, Schmidt S (2020) Microdialysis in soil environments: current practice and future perspectives. Soil Biol Biochem 143:107743

Cáceres R, Malińska K, Marfà O (2018) Nitrification within composting: a review. Waste Manag 72:119–137

Capson-Tojo G, Batstone DJ, Grassino M, Vlaeminck SE, Puyol D, Verstraete W, Kleerebezem R, Oehmen A, Ghimire A, Pikaar I, Lema JM, Hülsen T (2020) Purple phototrophic bacteria for resource recovery: challenges and opportunities. Biotechnol Adv 43:107567

Casagrande M, David C, Valantin-Morison M, Makowski D, Jeuffroy M-H (2009) Factors limiting the grain protein content of organic winter wheat in south-eastern France: a mixed-model approach. Agron Sustain Dev 29:565–574

Cassity-Duffey K, Cabrera M, Gaskin J, Franklin D, Kissel D, Saha U (2020) Nitrogen mineralization from organic materials and fertilizers: predicting N release. Soil Sci Soc Am J 84:522–533

Chin A, Schmidt S, Buckley S, Pirie R, Redding M, Laycock B, Luckman P, Batstone DJ, Robinson N, Brackin R (2018) Sorbents can tailor nitrogen release from organic wastes to match the uptake capacity of crops. Sci Total Environ 645:1474–1483

De Corato U (2020) Agricultural waste recycling in horticultural intensive farming systems by on-farm composting and compost-based tea application improves soil quality and plant health: a review under the perspective of a circular economy. Sci Total Environ 738:139840

Delamare-Deboutteville J, Batstone DJ, Kawasaki M, Stegman S, Salini M, Tabrett S, Smullen R, Barnes AC, Hülsen T (2019) Mixed culture purple phototrophic bacteria is an effective fishmeal replacement in aquaculture. Water Res X 4:100031

Forge T, Kenney E, Hashimoto N, Neilsen D, Zebarth B (2016) Compost and poultry manure as preplant soil amendments for red raspberry: Comparative effects on root lesion nematodes, soil quality and risk of nitrate leaching. Agric Ecosyst Environ 223:48–58

Franklin O, Cambui CA, Gruffman L, Palmroth S, Oren R, Näsholm T (2017) The carbon bonus of organic nitrogen enhances nitrogen use efficiency of plants. Plant Cell Environ 40:25–35

Gu B, Zhang X, Lam SK, Yu Y, van Grinsven HJM, Zhang S, Wang X, Bodirsky BL, Wang S, Duan J, Ren C, Bouwman L, de Vries W, Xu J, Sutton MA, Chen D (2023) Cost-effective mitigation of nitrogen pollution from global croplands. Nature 613:77–84

Hoover NL, Law JY, Long LAM, Kanwar RS, Soupir ML (2019) Long-term impact of poultry manure on crop yield, soil and water quality, and crop revenue. J Environ Manag 252:109582

Hülsen T, Hsieh K, Lu Y, Tait S, Batstone DJ (2018) Simultaneous treatment and single cell protein production from agri-industrial wastewaters using purple phototrophic bacteria or microalgae – A comparison. Biores Technol 254:214–223

Hülsen T, Züger C, Gan ZM, Batstone DJ, Solley D, Ochre P, Porter B, Capson-Tojo G (2022) Outdoor demonstration-scale flat plate photobioreactor for resource recovery with purple phototrophic bacteria. Water Res 216:118327

Jeyabal A, Kuppuswamy G (2001) Recycling of organic wastes for the production of vermicompost and its response in rice–legume cropping system and soil fertility. Eur J Agron 15:153–170

Khan N, Bolan N, Jospeh S, Anh MTL, Meier S, Kookana R, Borchard N, Sánchez-Monedero MA, Jindo K, Solaiman ZM, Alrajhi AA, Binoy Sarkar BB, Basak HW, Wong JWC, Manu MK, Kader MA, Wang Q, Li R, Ok YS, Withana PA, Qiu R (2023) Chapter One - Complementing compost with biochar for agriculture, soil remediation and climate mitigation. In: Sparks DL (ed) Advances in Agronomy. Academic Press, Cambridge, pp 1–90

Klimas E, Szymańska-Pulikowska A, Górka Bogusława M, Wieczorek P (2016) Presence of plant hormones in composts made from organic fraction of municipal solid waste. J Elementol Polskie Towarzystwo Magnezol 21:1043–1053

Koskue V, Pyrhönen V-P, Freguia S, Ledezma P, Kokko M (2022) Modelling and techno-economic assessment of (bio) electrochemical nitrogen removal and recovery from reject water at full WWTP scale. J Environ Manag 319:115747

Krishnan V, Robinson N, Firn J, Herbohn J, Schmidt S (2023) Organic nitrogen improves the water use of tropical tree seedlings cultivated for restoration plantings. Plants People Planet 5:437–448

Kuzyakov Y, Razavia BS (2019) Rhizosphere size and shape: Temporal dynamics and spatial stationarity. Soil Biol Biochem 135:343–360

Lim T, Massey R, McCann L, Canter T, Omura S, Willett C, Roach A, Key N, Dodson L (2023) Increasing the value of manure for farmers, AP-109, U.S. Department of Agriculture, Economic Research Service

Lonhienne T, Mason MG, Ragan MA, Hugenholtz P, Schmidt S, Paungfoo-Lonhienne C (2014) Yeast as a biofertilizer alters plant growth and morphology. Crop Sci 54:785–790

Lou XF, Nair J (2009) The impact of landfilling and composting on greenhouse gas emissions–a review. Biores Technol 100(16):3792–3798

Maasakkers JD, Varon DJ, Elfarsdóttir A, McKeever J et al (2022) Using satellites to uncover large methane emissions from landfills. Sci Adv 8:eabn9683

Mengistu T, Gebrekidan H, Kibret K, Woldetsadik K, Shimelis B, Yadav H (2017) The integrated use of excreta-based vermicompost and inorganic NP fertilizer on tomato (Solanum lycopersicum L.) fruit yield, quality and soil fertility. Int J Recycl Org Waste Agric 6:63–77

Minasny B, Winowiecki L et al (2017) Soil carbon 4 per mille. Geoderma 292:59–86

Ngo HTT, Watts-Williams SJ, Panagaris A, Baird R, McLaughlin MJ, Cavagnaro TR (2022) Development of an organomineral fertiliser formulation that improves tomato growth and sustains arbuscular mycorrhizal colonisation. Sci Total Environ 815:151977

Pant AP, Radovich TJK, Nguyen V, Hue R, Paul E (2012) Biochemical properties of compost tea associated with compost quality and effects on pak choi growth. Sci Hortic 148:138–146

Paungfoo-Lonhienne C, Visser J, Lonhienne TGA, Schmidt S (2012) Past, present and future of organic nutrients. Plant Soil 359:1–18

Paustian K, Lehmann J, Ogle S, Reay D, Robertson GP, Smith P (2016) Climate-smart soils. Nature 532:49–57

R Core Team (2022) R: a language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria. https://www.R-project.org/

Ravindran B, Wong JWC, Selvam A, Sekaran G (2016) Influence of microbial diversity and plant growth hormones in compost and vermicompost from fermented tannery waste. Biores Technol 217:200–204

Rupawalla Z, Robinson N, Schmidt S, Li S, Carruthers S, Buisset E, Roles J, Hankamer B, Wolf J (2021) Algae biofertilisers promote sustainable food production and a circular nutrient economy - an integrated empirical-modelling study. Sci Total Environ 796:148913

Sakarika M, Spanoghe J, Sui Y, Wambacq E, Grunert O, Haesaert G, Spiller M, Vlaeminck SE (2020) Purple non-sulphur bacteria and plant production: benefits for fertilization, stress resistance and the environment. Microb Biotechnol 13:1336–1365

Schmidt S, Näsholm T, Rentsch D (2014) Organic nitrogen. New Phytol 203:29–31

Steffen W, Richardson K, Rockström J, Cornell SE, Fetzer I, Bennett EM, Biggs R, Carpenter SR, de Vries W, de Wit CA, Folke C, Gerten D, Heinke J, Mace GM, Persson LM, Ramanathan V, Reyers B, Sörlin S (2015) Planetary boundaries: guiding human development on a changing planet. Science 347:1259855

Sutton MA, Howard CM, Kanter DR, Lassaletta L, Móring A, Raghuram N, Read N (2021) The nitrogen decade: mobilizing global action on nitrogen to 2030 and beyond. One Earth 4:10–14

Tahiri A, Meddich A, Raklami A, Alahmad A, Bechtaoui N, Anli M, Göttfert M, Heulin T, Achouak W, Oufdou K (2022) Assessing the potential role of compost, PGPR, and AMF in improving tomato plant growth, yield, fruit quality, and water stress tolerance. J Soil Sci Plant Nutr 22:743–764

Timsina J (2018) Can organic sources of nutrients increase crop yields to meet global food demand? Agronomy 8:214

Udvardi M, Below FE, Castellano MJ, Eagle AJ, Giller KE, Ladha JK, Liu X, Maaz TM, Nova-Franco B, Raghuram N, Robertson GP, Roy S, Saha M, Schmidt S, Tegeder M, York LM, Peters JW (2021) A research road map for responsible use of agricultural nitrogen. Front Sustain Food Syst 5:660155

Wang X-X, Zhao F, Zhang G, Zhang Y, Yang L (2017) Vermicompost improves tomato yield and quality and the biochemical properties of soils with different tomato planting history in a greenhouse study. Front Plant Sci 8:1978

Weber J, Kocowicz A, Bekier J, Jamroz E, Tyszka R, Debicka M, Parylak D, Kordas L (2014) The effect of a sandy soil amendment with municipal solid waste (MSW) compost on nitrogen uptake efficiency by plants. Eur J Agron 54:54–60

Westermann M, Brackin R, Robinson N, Salazar Cajas M, Buckley S, Bailey T, Redding M, Kochanek J, Hill J, Guillou S, Freitas JCM, Wang W, Pratt C, Fujinuma R, Schmidt S (2021) Organic wastes amended with sorbents reduce N2O emissions from sugarcane cropping. Environments 8:78

Zarezadeh S, Moheimani NR, Jenkins SN, Hülsen T, Riahi H, Mickan BS (2019) Microalgae and phototrophic purple bacteria for nutrient recovery from agri-industrial effluents: influences on plant growth, rhizosphere bacteria, and putative carbon- and nitrogen-cycling genes. Front Plant Sci 10:1193

Zhang X, Davidson EA, Mauzerall DL, Searchinger TD, Dumas P, Shen Y (2015) Managing nitrogen for sustainable development. Nature 528:51–59

Zhao S, Schmidt S, Gao H, Li T, Chen X, Hou Y, Chadwick D, Tian J, Dou Z, Zhang W, Zhang F (2022) A precision compost strategy aligning composts and application methods with target crops and growth environments can increase global food production. Nat Food 3:741–752

Zhou M, Zhu B, Wang S, Zhu X, Vereecken H, Brüggemann N (2017) Stimulation of N2O emission by manure application to agricultural soils may largely offset carbon benefits: a global meta-analysis. Glob Change Biol 23:4068–4083

Funding

The Funding statement were provided by Fight Food Waste Cooperative Research Centre, Advanced Queensland Industry Research Fellowship, Rural R&D for Profit Program.

Author information

Authors and Affiliations

Contributions

SS designed the experiments, HG carried out the experiments and analyses, VK performed the statistics, SS and VK drafted the manuscript. PW provided compost and guidance on the needs of compost producers. TH and PJ provided PPB and input into the manuscript; MW, JW, BD and NR contributed insights and edits of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors SS, VK, HG, MW, TH, JW, PJ, BD, NR declare that they have no known competing financial interests in the research presented. Peter Wadewitz (PW) is the owner of Peats Soil and Garden Supply Pty Ltd, a compost business in South Australia. The work has been supported by the Fight End Waste Cooperative Research Centre whose activities are funded by the Australian Government’s Cooperative Research Centre Program, together with PW. PPB aspects of the project were supported by Meat & Livestock Australia, through funding from the Australian Government Department of Agriculture, Water and the Environment as part of its Rural R&D for Profit program, and the partners. PPB biomass was grown by TH as part of an Advanced Queensland Industry Research Fellowship. We acknowledge the Queensland Government, GHD, Ridley, Aquatec Maxcon and Ingham for their financial support for the PPB project.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Schmidt, S., Krishnan, V., Gamage, H. et al. Enabling the circular nitrogen economy with organic and organo-mineral fertilisers. Nutr Cycl Agroecosyst (2024). https://doi.org/10.1007/s10705-024-10380-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10705-024-10380-7