Abstract

In order to minimise the adverse impacts on the environment, manufacturers, policymakers, and society have all been interested in sustainable manufacturing. Several factors related to Configurable Product, Customer Need, Emerging Technology, Information Technology, Market Performance, Organisation Readiness are being studied by the researchers in this process. Make To Order (MTO), as an approach towards management of manufacturing helps to reduce the over production and thus wastage of the items and helps in sustainable manufacturing along with improving the competitiveness of the organisation. The goal of this study is constructing a sustainability model using a MTO manufacturing system. From the responses of structured questionnaires, PLS-SEM (SMART PLS 4), i.e. Partial Least Squares approach to structural equation modelling has been used to develop the model and determine the strength of the relation between items. The empirical findings demonstrate that all the approaches have a significant effect on MTO manufacturing system. Competitive Advantage acts as a mediator for the relationship between MTO and Sustainable manufacturing. The current literature on sustainable manufacturing initiatives has been extended and improved by these findings, and give researchers a fresh angle from which to further explore this idea.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The strategic objectives of manufacturing organisations are always changing in tandem with the growth of the new competitive market (Li et al., 2020). As per He et al. (2014) manufacturing companies must learn to be adaptable to these rapid shifts in the business environment if they want to endure in the current market. It is well acknowledged that these businesses need to succeed in other ways as well as financially. Instead, they should be devoted to sustainability so that the environment is protected and the well-being of future generations is ensured (Angappa Gunasekaran & Spalanzani, 2012). Many companies are beginning to adopt sustainable practices in the current environment, moving in an innovative direction that is geared towards sustainability (Jones et al., 2016). Sustainability refers to the goal of reducing a company’s negative impact on the environment, societies, and people while consecutively increasing value for customers, stakeholders, and business partners (Luthra et al., 2015). In today’s fiercely competitive market, where many businesses still rely on natural resources while also producing waste and environmental degradation, sustainable manufacturing (SM) has become increasingly important (Bhanot et al., 2015). Role of manufacturing is significant in creating a society that is more sustainable. The constant shift in product types, fluctuating demand, and unforeseen changes in client needs put increasing pressure on manufacturing organisations today. Manufacturing was viewed by (Guo & Wu, 2023) as one of the key indicators of social sustainability. Sustainability has been acknowledged as a critical component to obtain an edge in future competitiveness; as a result, more money is being invested in sustainability, and this innovation is now essential in all sectors of the economy (Khurana et al., 2019). Sustainability has drawn a lot of attention and is an important strategic issue for nations, as well as for specific businesses (Barbosa & Azevedo, 2018). Utilising sustainable business practises can help firms grow their income, brand value, and stakeholder involvement (Kaur, 2017).

This understanding of adaptation for achieving competitive advantage has led to this present study which focuses on the impact of the MTO strategy on Sustainable manufacturing. Several studies have been done to understand the importance and various issues of MTO manufacturing strategy. A few of them have been discussed here. In MTO businesses, for on-time delivery, order acceptance and scheduling are particularly crucial production planning activities (Lödding & Koch, 2020). To address the unique requirements of MTO businesses, Lödding and Koch (2020) suggested a new value stream analysis and design. Taylor et al. (2009) provided the evidence empirically on the unique needs of Production Planning and Control (PPC) needs of small and medium sized MTO enterprises.

Very few studies have shown the contribution of MTO strategy towards competitive advantage of the company and only some of the studies have discussed the impact of MTO over sustainable manufacturing. To effectively implement MTO in an organisation and gain competitive advantage and sustainable manufacturing, it is required to design a model that identifies the aspects a manufacturer must take into account.

Following are the research objectives that have been developed in light of the discussion above.

RQ1: Does MTO help in Sustainable Manufacturing?

RQ2: Does MTO improve Competitive Advantage?

RQ3: What are the factors that influence the enterprise to adopt MTO to achieve sustainable manufacturing?

Considering the above, the aim of the current study is to identify the factors that influence the integration of MTO, Competitive Advantage and sustainable manufacturing. Manufacturing sectors in India that see a potential in adaptation of MTO, need a manufacturing model to boost competitive advantage over rivals as well as achievement of sustainable manufacturing.

The following objectives for the current study have been defined in light of the aforementioned research questions.

-

To conduct a thorough literature analysis and identify factors for the implementation of MTO manufacturing system.

-

To develop a sustainability model with MTO system and considering the mediating effect of competitive advantage on attaining sustainable manufacturing.

Thus it can be said that this study’s objective is to empirically fill the gaps in implementing MTO with an aim to achieve competitive advantage (CA) and sustainable manufacturing (SM). With the use of PLS-SEM (SMART PLS 4) factors have been related (depicted as items in the tool) with three other items, i.e. MTO, CA and SM. The organisation of the paper is as follows. Section 2 includes Systematic Literature review and Hypothesis development. Section 3 represents research methodology, while Sect. 4 shows Analysis and Results. Finally, the conclusion and limitations of the study are being mentioned in Sects. 5 and 6, respectively.

2 Theoretical background and hypothesis development

The current study’s objective is to address the aforementioned research questions. Although the field of sustainable manufacturing is one that is fast emerging, there aren’t many reliable reports on how prevalent it is currently among business operations (Despeisse et al., 2012). Therefore, a thorough detailed literature review is conducted to find the key elements that would motivate firms to adopt MTO strategy for achieving competitive advantage and sustainable manufacturing. Also, a detailed literature review has been done to select PLS-SEM as the tool for measuring relationship between different constructs. PLS-SEM was first introduced by Herman Wold in 1966, and since then, it has undeniably grown in popularity for survey research (Akter et al., 2017). PLS-SEM is a causal prediction method for SEM that emphasises forecasting when assessing measurable models with constructs intended to provide causal explanations (Hair et al., 2018). PLS-SEM emerged as a result of the lack of factor indeterminacy, the advantages of distributional assumptions, and models with more parameters than observations (Dijkstra & Henseler, 2015). Certainly, it works best with complex models, especially when prediction is the main goal, a lot of variables need to be explained, and the sample size is limited (Akter et al., 2017; Hulland et al., 2010).

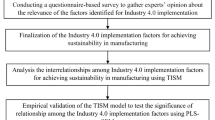

The hypotheses offered in the current study consider factors that are critical for MTO approach and further reinforced by examining relationship between MTO ability for competitive advantage and Sustainable Manufacturing (Fig. 1). MTO is also directly linked to three pillars of sustainability, i.e. Social, Economical and Environmental (Garetti & Taisch, 2012; Sari et al., 2021) and two other effects of supply chain manufacturing; sustainable supply chain and sustainable product design (Garetti & Taisch, 2012). Table 1 presents the constructs, related to measurement items.

A thorough review of the literature is conducted out to identify the important factors influencing the implementation of MTO to achieve sustainable manufacturing. A thorough analysis helps to acquire a sense of the research being done by researchers in the subject of sustainable manufacturing. The literature for the concept of sustainable manufacturing, Competitive Advantage and MTO has been reviewed. Expert’s opinion has also been taken. Accordingly, six factors each having further sub factors strengthening the sustainable manufacturing implementation in companies have been determined. These factors are given below:

2.1 Configurable product (CP)

The development of configurable products is based on in-depth expertise and methodology (Custódio et al., 2018). For creating MTO capability, manufacturing sector has to deliver huge product variety (Haskose et al., 2004). Due to competition in the market for product variety, various organisations use MTO strategy for offering a variety of items and prevent multiplication of product (Vidyarthi et al., 2009). Customer needs are given top consideration because they have an impact on MTO’s entire manufacturing system (Rabbani & Dolatkhah, 2017; Zennaro et al., 2019). A. Gunasekaran & Ngai (A. Gunasekaran & Ngai, 2005) highlighted that product innovation helps MTO companies to be successful and competitive. Easton & Moodie (Easton & Moodie, 1999) pointed out that for successful MTO enterprises, shorter and more precise lead times are preferred. Modular product design, which allows for easy assembly using a common set of components, is another crucial consideration. (Zennaro et al., 2019). The MTO business must provide a wide range of items, typically in less numbers, varying from a selection of conventional products to all requests as required by a customised product (Haskose et al., 2004). MTO businesses must provide their goods faster than the whole lead time for production in order to remain competitive (Gonçalves Filho & Marçola, 2001). The two main competitive advantages in MTO circumstances are the ability to specify assured delivery dates and quick delivery periods. (Ebadian et al., 2008)

Hypothesis H1

Configurable Product is positively related to MTO ability.

2.2 Information technology (IT)

IT is a tool made to add value and that value comes from improved productivity, a competitive advantage, cost savings, better supplier relationships, etc. Process improvements and improved organisational performance occur when the appropriate technology is applied within the proper business process (Dalcher, 2016). Despite the fact that applying IT to enhance company performance requires little organisational changes (Mcafee, 2002), successful IT implementation frequently results in major organisational change (Cooper et al., 2000); Brynjolfsson et al., 2002); Moody, 2020) including organizational structure and culture, workplace policies and practices. On-time shipping (Mcafee, 2002), customer satisfaction (Devaraj & Kohli, 2000), and inventory turnover (Barua et al., 1995) are just a few examples of business processes performance measures that have been employed in earlier IT business value research. The entire system will be affected by any information update or change, saving time, energy, and money (Sahin & Robinson, 2005). In order to successfully manage orders and payments, Zennaro et al. (Zennaro et al., 2019) underlined the role of IT as a centralised online system. There is an increasing requirement for seamless task coordination and real-time information transfers across various nodes of product development life cycle (Eswaran & Bahubalendruni, 2022). IT is valuable because it offers a wide range of possible advantages, from increased flexibility and improved quality to lower costs and higher production. (Dalcher, 2016)

Hypothesis H2

Information Technology is positively related to MTO ability.

2.3 Market performance (MP)

Numerous businesses are using MTO manufacturing processes as a result of the growing trend of customization in consumer market. (Fakhrzad & Mohagheghian, 2019). Variables like retail price, selling price, etc. are impacted by factors like technological improvement in the market competition (Fakhrzad & Mohagheghian, 2019; Garmdare et al., 2018). In cases when there is a high likelihood of product obsolescence or perishability, a preference for MTO systems is greater (Rafiei & Rabbani, 2009; Zaerpour et al., 2009; Hemmati & Rabbani, 2010). Market penetration is another significant factor which affects the market performance of any kind product and in this case it’s customised product. The uncertainty surrounding the uptake of electric vehicles in the American market was highlighted by Noori & Tatari (Noori & Tatari, 2016). Propfe et al. (Propfe et al., 2013) conducted an EV (electric vehicle) market analysis for the German passenger automobile market until 2030. Gong et al. (Gong et al., 2020) also reviewed penetration of EVs in Australian market and studied the impact of government incentives on it. According to studies conducted by Jo et al. (Jo et al., 2003) effective global manufacturing that results in cost advantages is dependent upon a strong brand image. Essoussi & Merunka (Essoussi & Merunka, 2007) analysed the outcome of brand image on Consumer’s product evaluations in emerging markets. Towers et al. (Towers et al., 2013) studied Scottish industry to determine the beneficial effects of SSCM (Sustainable Supply Chain Management) on brand image and social responsibility performance. As per Accenture, by creating sustainable supply chains, companies could save costs, enhance risk management, explore new revenue streams, and elevate brand value (Hong et al., 2018).

Hypothesis H3

Market Performance is positively related to MTO ability.

2.4 Customer need (CN)

Using MTO strategy is essential if consumers have a broad range of customization needs (Hemmati & Rabbani, 2010). The correlations among sharing of real-time information, consumer focus, buying behaviour, and buyback behaviour were investigated by Mujahid et al. (Mujahid et al., 2021). Adopting technology to communicate real-time information to clients is viewed as a strategic tool (Meadows & Dibb, 2012; Jabbar et al., 2019). System performance suffers dramatically when real-time information about items that are available in the Work in Process is ignored (Calle et al., 2016). It would be impossible to offer a large product variety and the amount of customisation that the consumer requires on a system other than MTO (Hemmati & Rabbani, 2010). In many industries, mass customization is starting to become popular. As a result, businesses are implementing the MTO production method to make it easier to produce different product variants. (Fakhrzad & Mohagheghian, 2019)

Hypothesis H4

Customer need is positively related to MTO ability.

2.5 Organisation readiness (OR)

Organisation Readiness is associated with Flexible manufacturing processes. Analysing the amount of time needed to switch a system from one type of job to another will depend on how flexible the production processes are (Pramod & Garg, 2006). Due to the utilisation of multipurpose machinery or equipment, MTO demands a significant amount of skilled labour (H. Li & Womer, 2012; Khakdaman et al., 2015). Kidwell (Kidwell, 2005) highlighted Flat organisation structure, i.e. organisation has fewer employees and less hierarchical management, as another important factor to be considered. It is also important to take into account MTO’s capacity without raising manufacturing costs. To reduce total cost, various factors and resources need to be taken into account and examined (He et al., 2014; Salamati-Hormozi et al., 2018; Pan et al., 2014; Rafiei & Rabbani, 2009). The key characteristic of MTO is lower carrying or storage costs (Wang et al., 2019). Also, Reduced stock holding costs result from a wide range of customization requirements (Hemmati & Rabbani, 2010).

Hypothesis H5

Organisation Readiness is positively related to MTO ability.

2.6 Emerging technologies (ET)

With the advent of immersive technologies, the manufacturing industry is currently going through its fourth revolution, with a heavy focus on flexible production and human–machine interaction. Utilising technology during the manufacturing process can eliminate the barriers to creating a variety of goods with unchanged quality in the shortest possible period of time (Eswaran & Bahubalendruni, 2022).

Industry 4.0, Internet of Things (IOT), Artificial Intelligence (AI), Big Data, these terms describe a variety of ideas, instruments, and techniques that have the potential to fundamentally alter contemporary industry and society (Osterrieder et al., 2020). Industry 4.0 incorporates information exchange, Smart Supply Chain, and production coordination with vendors to lower time of delivery and alterations of information that cause “bullwhip effects.“ Customised products and additive manufacturing are two favourable technology of the Industry 4.0 concept (Frank et al., 2019). These technologies can enhance MTO system using real-time data and can be used for optimization of production processes, reduce lead times, and improve quality.

Industry 4.0 is regarded as a new industrial stage where a number of developing technologies are combining to offer digital solutions. Industry 4.0 is dependent on the use of digital technology to collect data in real-time, analyse it, and provide meaningful information to the industrial system. The cyber-physical system concept of Industry 4.0 was made possible by the emergence of the Internet of Things (IoT), cloud services, big data, and analytics. (Frank et al., 2019) listed the base technologies for Industry 4.0 as Internet of Things (IoT), Cloud computing, Big data and Analytics (Wang et al., 2015; Zhong et al., 2017).

The Internet of Things (IoT) has arose as a key topic in the context of advanced manufacturing (Durão et al., 2018). The Internet of Things (IoT) gives up-to-the-minute information on happenings in the real world, by connecting virtual data environment and the physical devices (Domingos et al., 2014). Improvements in productivity, lower production costs, and more efficient resource use are all achieved by industrial IoT. It aims to create seamless connectivity between industrial resources and various control systems. (Wan et al., 2018). In order to achieve customisation for various product versions, the manufacturing sectors have given a lot of attention to Augmented Reality (AR) and Virtual Reality (VR) immersive technologies (Eswaran & Bahubalendruni, 2022). Eswaran & Bahubalendruni, (Eswaran & Bahubalendruni, 2022) demonstrated the progress of AR/VR technologies for product design and evaluation, assembly, repair and maintenance, quality control, warehouse management, CNC simulation and plant planning. AR VR provides support, simulation and assistance in improving processes of industries before they are actually implemented in production. This will save money on reworks and changes to manufacturing tasks like product design, process planning, machining, and other related ones (Yuan et al., 2005; Zhang et al., 2012).

3D Printing (3DP) has gained international recognition of a disruptive technology that can transform manufacturing and design. The design and manufacture of items are being fundamentally altered by 3DP (Corsini et al., 2022). Recent developments in fused material deposition (FMD) and additive manufacturing (AM) methods have led to the commercialization and extensive use of 3DP (Bassett et al., 2015). 3DP is a relatively new industrial technology that may have significant positive effects on sustainable development (Gebler et al., 2014). It simplifies the manufacturing process by minimising the number of required processes (Corsini et al., 2022). Additionally, it promotes environmentally friendly manufacturing by lowering carbon emissions, energy use, and material waste. Researchers are examining various techniques to obtain natural materials for 3DP, including cellulose-chitin material, coffee grounds, and algae. This will enable more sustainable production (Nadagouda et al., 2020). (Gebler et al., 2014) carried out a descriptive sustainability assessment to identify the qualitative effects of the 3DP on the three sustainability dimensions of economy, environment, and society. It is a manufacturing technique with a lot of sustainability potential, especially if it can be used in mass production markets and if social consequences are completely taken into account. It is linked to a significant reduction in the amount of money and energy used in production, which lowers the price of goods and reduces CO2 emissions. The future impact of 3DP on the spare parts business is another significant industrial market segment. This means that when a component breaks and the industry is no longer producing its replacement part, the entire item must be discarded, having a negative influence on the environment. However, if the replacement part can be printed, the item will last longer, which is excellent from a sustainability perspective. A quantitative analysis of the sustainability effects of 3D printing on costs, energy use, and CO2 emissions reveals that there are sustainability potentials throughout the full life cycle of 3D-printed products.

Hypothesis H6

Emerging Technologies is positively related to MTO ability.

2.7 Make to Order (MTO)

Customers often anticipate speedy delivery, which is an order winner for businesses, therefore if the lead time of product delivery is lengthy, it will be difficult to use the MTO strategy and could lead to in backorder cost (Hemmati & Rabbani, 2010). Increase in varieties: Using MTO strategy is essential if consumers have a broad range of customization needs (Hemmati & Rabbani, 2010). Many businesses are attempting to capitalise on this trend by employing MTO production processes that provide greater product diversity and flexibility in response to the increased interest in product variants. (Fakhrzad & Mohagheghian, 2019). Today’s manufacturing companies must produce different items for a range of different customers because of the rise of customised production (Kim & Van Oyen, 2021). In MTO situations, timely work delivery and total delivery cost are the two performance metrics that are most frequently taken into account. (Tang et al., 2019)

Hypothesis H7

MTO is positively related to Competitive Advantage.

2.8 Competitive advantage (CA)

Consumers typically want quick deliveries, which is a competitive advantage for businesses (Hemmati & Rabbani, 2010). MTO manufacturing allows firms to offer customised products and services, which can differentiate them from their competitors and provide a competitive advantage. It is observed that the literature available does not properly value employee satisfaction for MTO manufacturing. Employee satisfaction and its effect on productivity are both strongly influenced by the workplace environment (Sukdeo, 2017).

Hypothesis H8

Competitive Advantage is positively related to sustainable Manufacturing.

2.9 Sustainable manufacturing (SM)

The U.S department of commerce defines sustainable manufacturing as the “creation of manufactured products which use processes that minimise negative environmental impacts, conserve energy and natural resources, are safe for employees, communities, and consumers and are economically sound” (Ebrahimi et al., 2021). This study considers three pillars of sustainability (Garetti & Taisch, 2012; Sari et al., 2021) and two other effects of supply chain manufacturing; sustainable supply chain and sustainable product design. Sustainability concerns will have an impact on all facets of human life, including the economic, political, social, and environmental spheres (Garetti & Taisch, 2012).

Sustainability has emerged as a crucial concern in all walks of life. The early idea of sustainability is driven by the necessity for economic growth, with its social and economic goals, to take conservation into consideration by taking resource constraints and ecosystem carrying capacity into account (Purvis et al., 2018). The “general model” of sustainable development that appears in the literature underlines trade-offs between economic expansion, worsening environmental conditions, and a drop in the standard of living (Macnaghten & Jacobs, 1997). The authors (Macnaghten & Jacobs, 1997) proposed a model in which “economic welfare” is a factor of “quality of life,“ which is in turn limited by “environmental limits.“ Numerous authors have seen such a nested model as superior to a “Venn diagram” of trade-offs because it emphasises how the three systems represented by the pillars cannot be separated and are actually subsystems of one another. From both a “quality of life” or social standpoint and an ecological perspective, the concept of “sustainable development” emerged here as a double critique of the previously prevalent idea of “economic development” (Purvis et al., 2018).

Sustainability in manufacturing and services has been a tactical tool used to achieve success not only economically but also environmentally and socially. The goal of sustainability is to prevent manufacturing and service organisations from exploiting natural resources for their own productivity and competitiveness. Environmental friendly manufacturing has attracted the attention of businesses worldwide (Angappa Gunasekaran & Spalanzani, 2012). Sustainable business practises enable organisations innovate by developing innovative, environmentally friendly goods and services, decrease risk, prevent creating waste, and boost material and energy efficiency (Angappa Gunasekaran & Spalanzani, 2012). This will support an organization’s efforts to meet social and environmental goals and requirements in addition to improving its financial success. To achieve sustainability, a sustainable design strategy for new products and services with significantly improved environmental (sustainable) performance would be essential. Businesses are utilising a variety of approaches and technologies to evaluate the economic, social, and environmental effects of their products and supply chains as they adapt to the challenging future of sustainable manufacturing. For assessing the environmental impact of assets across their full life cycle, life cycle assessment (LCA) and life cycle costing (LCC) are being utilised more frequently (Garetti & Taisch, 2012).

It has become necessary to develop and pursue manufacturing activities in order to maximise economic and social benefits while minimising environmental impact. This is because the ongoing trend of rising demand for materials and energy is severely limiting the availability of natural resources like fossil fuels, water, minerals and land, driving up energy and commodity prices, and making the country’s momentum unsustainable (Bhanot et al., 2015). Increased energy use results in air pollution, which harms the ecosystem and biodiversity and ultimately undermines sustainable economic growth (Ali et al., 2023). In order to achieve a more sustainable energy and economic transformation, the global economies must take the initiative to increase the use of renewable and alternative resources (Kamran et al., 2022). Manufacturers by developing newer method of production can greatly reduce the consumption of materials and the discharge of effluents thus contributing to the sustainability. This will also reduce the cost of the products and services.

Manufacturing, will be significantly impacted by sustainability challenges and will be crucial in constructing a sustainable future. Manufacturing enterprises face a number of challenges, including the depletion of natural resources, tougher laws and regulations, economic stagnation, and consumer demands for improved product quality. The paradigm of sustainable manufacturing has drawn a lot of interest in the last ten years as a new production strategy designed to help businesses overcome these challenges and help them stand out in today’s cutthroat marketplace (Franciosi et al., 2020). (Garetti & Taisch, 2012) grouped the challenges of sustainable manufacturing as business processes and models, Asset and product life cycle management, energy and resource management and enabling technologies.

Almost all manufacturing models in use today are based on the outdated paradigm. In light of the fact that manufacturing is entirely dependent on technology, if humanity wishes to prevent a return to the primitive past, it should rely on the technology’s obvious contribution to sustainability (Garetti & Taisch, 2012). In their study of the relationship between business performance and sustainable supply chain management (SSCM) practises, (Hong et al., 2018) analysed the mediation effect of the dynamic capacities of the supply chain (SC). According to (Bhanot et al., 2017) SM has been a key component of a sustainable supply chain, which essentially covers product-related activities like design, production, and recovery operations up until the product’s end of life.

Hypothesis H9

MTO is positively related to Sustainable Manufacturing.

3 Research methodology

For developing a sustainability model with MTO system and considering the mediating effect of competitive advantage on attaining sustainable manufacturing, a three stage process was used. The initial stage examined the important factors influencing the implementation of MTO to achieve sustainable manufacturing. In the second stage of the process, a questionnaire was created based on these factors. In the third phase, PLS-SEM was used and the validity was accessed to analyse the influence of the factors.

3.1 Design of questionnaire and its reliability

Following a thorough assessment of the literature, the questionnaire was created as a research tool. There were three sections in the questionnaire. The demographics of the respondents, the industry in which they are employed, and number of employees (company size) and revenue are all covered in the first section of the questionnaire. The questions in the next section examine how the respondents perceived their level of MTO skill. It had thirty-seven variables that were measured using a Likert scale using a five-point scale. The questionnaire utilised the five-point Likert scale since it is easy for respondents to read out and provides a comprehensive list of scale descriptors (Dawes, 2008; Sari et al., 2021). A panel of experts reviewed the questionnaire to make sure it was clear and accurate (Mendes & Machado, 2015). Ten experts who were particularly briefed on the concept of research and its scope were a part of this panel. It was finalised through individual discussions with six manufacturing industry experts who held positions such as managers, vice presidents, general managers, and assistant general managers, as well as two consultants with extensive experience. It also included two experts from academics. Further, two experts were from the area of environment, three were concerned with area of manufacturing cost and three experts were social scientist. The expert screening procedure was designed so that the panel of assessors could identify items with overly similar wording (Maklan, 2011). As suggested by Forza, (Forza, 2002) a pilot survey is carried out with a small sample size (15 respondents) to test the questionnaire (Sari et al., 2021).

3.2 Target organisations and target respondents

Respondent lists were gathered from reliable sources such alumni associations, trade associations, and chambers of business and industry. The most crucial requirements, restrictions, and challenges were to find responders with potential expertise to answer questions about knowledge from a range of areas covered by diverse domains (Valase & Raut, 2019). The survey was carried out in the processing and manufacturing sectors of India. The responders were chosen from businesses that used or had experience with such technology.

3.3 Collection of data

The questionnaire was disseminated both offline and online in order to get answers from possible respondents. Respondents were asked to set up an appointment in advance for the offline mode. For online mode, the questionnaire was produced as a Google form, along with an additional background note on MTO so they could better understand all of its various components and around 300 concerned professionals received it in the mail. After two weeks, a follow-up email was sent to all the experts involved. After receiving the responses through offline and online mode, the surveys were analysed to see if the respondents provided meaningful input.

3.4 Demographic of respondents

A total of 192 questionnaires out of the 300 disseminated questionnaires were finished and submitted. Outliers and missing data were explored in the questionnaires (Schreiber et al., 2013). All of the respondents have a diploma as a minimum qualification. The maximum of them hold Master’s Degree (42.8%), holders of graduation came second (41.4%), and those holding doctorate were third (5.9%), followed by diploma holders (5.3%) and post doctorate (4.6%) (Fig. 2).

According to the respondents’ sample characteristics, top management made up 19.1% of respondents, followed by middle management (64.5%), administrative staff (3.3%), technical staff (6.6%), and academicians (6.6%) (Fig. 3). As per the different departments, Marketing/Sales made up 27% of the respondents, R& D constituted 23% of the respondents, followed by 10.5% of Supply Chain/Procurement, 10.5% of Project management, 8.6% of Production department, 0.7% of Retailer and 19.7% of others (Fig. 4). Concerning the years of experience, 32.9% of respondents had work experience of more than 20 years, 28.3% of employees had work experience of 15 to 20 years, followed by 10 to 15 years (18.4%), 0–5 years (11.2%) and 5–10 years of experience (9.2%) (Fig. 5).

4 Result and analysis

In this study, the complicated, hierarchical research model including mediating effects was estimated using PLS-SEM. To quantify the relationship between constructs in this study’s data analysis, the PLS-SEM method was applied using the SmartPLS 4 software. Comparing PLS-SEM to covariance-based SEM, it is more capable of handling formative and reflective underlying paths (Hair et al., 2014; Sarstedt et al., 2019).

4.1 The empirical results of the measurement model

4.1.1 Reliability analysis and convergent validity

Convergent validity measures the level of correlation between various variables within similar framework (Hair et al., 2014). Table 1 displays the findings of the reliability and convergent validity analyses conducted for this study. Furthermore, all constructs’ Cronbach’s alpha values were above the threshold, ranging from 0.847 to 0.917. The composite reliability (CR) values varied from 0.848 to 0.917, and the average variance extracted (AVE) values ranging from 0.567 to 0.734. To demonstrate that the tool is reliable and valid, the recommended values for Cronbach’s alpha and CR should be greater than 0.7 and AVE should be greater than 0.5, respectively (Shahzad et al., 2020; Hair et al., 2014; Larcker, 1981). Therefore, results demonstrate that the convergent validity and reliability of the data utilised of current study remain unaffected, and they can be used for subsequent structural analysis.

4.1.2 Discriminant validity

The level of empirical difference between variables is described by discriminant validity. Discriminant validity evaluation is known for widely acknowledged platform for examining the relationship between potential factors (Hair et al., 2014). The distinctiveness of a construct is measured by Discriminant validity (Hair et al., 2020). In this work, discriminant validity was evaluated using two different techniques. Heterotrait Monotrait ratio of correlations (HTMT) and Fornell Larcker criterion. HTMT should be used for Discriminant validity (Larcker, 1981; Hair et al., 2014; Henseler et al., 2015; Shahzad et al., 2020). Also, the predominant method for testing discriminant validity is the Fornell Larcker criterion (Henseler et al., 2015; Shahzad et al., 2020). Table 2 shows the Fornell Larcker criterion, which is based on inter-construct correlations and the square root of AVE, was used to assess the instrument’s discriminant validity. The diagonal values in Table 2 show that the square root of AVE values are larger than the coefficients of the correlations of all variables. This suggests strong discriminant validity.

Because the HTMT ratio is nearer to 1, it can be concluded that the path analysis does not have discriminant validity (Larcker, 1981). HTMT should be less than 1 in order to differentiate the two components clearly (Henseler et al., 2016; Henseler et al., 2015). The data in Table 3 show that the highest value is 0.895, which is below the aforementioned cutoff point and demonstrates that the discriminant validity of the present investigation is sufficient.

4.1.3 The empirical results of the structural model

In order to test the hypothetical relationship between constructs using standardised routes (Hair et al., 2014; Henseler et al., 2016) the reliability, convergent validity, and discriminant validity of the study model were examined. This was done using the SmartPLS 4 programme. The values of the path coefficient are shown in Fig. 6.

Henseler and Sarstedt ( 2013) claim that the quality of the structural model and its capacity for prediction are determined by the standardised path coefficients and R2 values of endogenous latent variables. The direction, strength, and significance of the hypothesised route coefficient are tested using the bootstrap approach with 5000 subsamples in SmartPLS 4 software. PLS-SEM indices for goodness of fit include SRMR = 0.044 (< 0.08), d_ULS = 1.463, d_G = 1.07, Chi-square = 987.277, NFI = 0.822 (Table 4) demonstrate a significantly adequate and reliable fit (Henseler et al., 2016).

Explanatory variation, or the R-squared value of a finding, is a measure of a research model’s descriptive power (Shahzad et al., 2020). The value of the adjusted R square of SP is 0.663, indicating that selected variables show 66.3% of the variation. Meanwhile, the adjusted R square values of CA and MTO are 0.341 and 0.685 respectively, indicating 34.1% and 68.5% of effective involvement of selected factors. According to the SEM results displayed in Fig. 1, all of the exogenous constructs in this investigation are significantly and favourably connected to the endogenous constructs. Table 5 provides the specific path coefficient values, direct effect significance, and bootstrapping path analysis. It reveals that the T-statistics values are higher above the cutoff point of 1.96, proving the importance of the connection between the proposed variables (Leguina, 2015; Streukens & Leroi-Werelds, 2016). Also, the p-value is provided to support the relevance.

4.1.4 Hypothesis results

p Values are used to draw a conclusion about all the hypotheses and indicate that they are all supported. The p value for the path of hypothesis 1 of Configurable Product (CP) and MTO ability is 0.002, which is less than 0.05, therefore the hypothesised path between CP and MTO is significant. Similarly, the path of hypothesis 2 between Information Technology (IT) and MTO ability has a p value of 0.001 (< 0.05), indicating that it is significant. The p value for the path of Hypothesis 3 of Market Performance (MP) and MTO ability is 0 (< 0.05), hence this is significant. The p value for the hypothesised path 4 of Customer need (CN) and MTO ability is 0.005 (< 0.05), hence it is significant. Further, the p value for the path of Hypothesis 5 of Organisation Readiness (OR) and MTO ability is 0.026, which is less than 0.05, therefore the hypothesised path between OR and MTO is significant. The p value for the path of Hypothesis 6 of Emerging Technologies (ET) and MTO ability is 0.004 (< 0.05); thus, this is significant. The path of Hypothesis 7 of MTO and Competitive Advantage (CA) has the p value as 0 (< 0.05), and so the hypothesised path between MTO and CA is significant. The p value for the path of Hypothesis 8 of Competitive Advantage (CA) and Sustainable Manufacturing is 0.001 (< 0.05); therefore, the hypothesised path between CA and SM is significant. The path of Hypothesis 9 of MTO and Sustainable Manufacturing (SM) has p value of 0 (< 0.05); thus, this path is also significant.

5 Conclusion

Being the first study of its kind, this one has a lot to offer the manufacturing sector in terms of applying sustainability concepts. In the industrial sector there is little doubt that sustainable production practices are being adopted. This study fills in a blind hole by demonstrating how to operationalize sustainable manufacturing concepts. Extending the study’s theoretical and managerial contributions is made possible by the use of PLS-SEM. The results of the testing of the hypotheses, using PLS-SEM software, showed that all nine of them were supported. The study incorporates some of the most important factors for attainment of Competitive advantage and sustainable manufacturing through MTO strategy. Overall the results of this study show that configurable product, customer need, emerging technology, information technology, market performance, organisation readiness have a positive influence on MTO system, which further significantly impacts sustainable manufacturing. This research has examined the importance of Competitive Advantage as the mediator between MTO and Sustainable manufacturing.

6 Limitations of the study

Despite the substantial theoretical and practical contributions made by this research, it has some limitations. The factors have been selected from the literature after a thorough review, although there is still plenty of opportunity for improvement. Nine different construct categories with a total of 38 factors were taken into account. After the initial set of research was completed, several factors from the original selected constructs were eliminated. The current study has solely looked at manufacturing sector. It is possible to look at other industries to see if implementing MTO would be appropriate there as well to attain sustainability via competitive advantage.

Data availability

Data will be made available as desired by the journal.

References

Akter, S., Fosso Wamba, S., & Dewan, S. (2017). Why PLS-SEM is suitable for complex modelling? An empirical illustration in big data analytics quality. Production Planning and Control, 28(11–12), 1011–1021. https://doi.org/10.1080/09537287.2016.1267411.

Ali, A., Ramakrishnan, S., Faisal, F., Akram, T., Salam, S., & Rahman, S. U. (2023). Bibliometric analysis of finance and natural resources: Past trend, current development, and future prospects. Environment Development and Sustainability, 25(11), 13035–13064. https://doi.org/10.1007/s10668-022-02602-1.

Barbosa, C., & Azevedo, A. (2018). Towards a hybrid multi-dimensional simulation approach for performance assessment of MTO and ETO manufacturing environments. Procedia Manufacturing, 17, 852–859. https://doi.org/10.1016/j.promfg.2018.10.137.

Barua, A., Kriebel, C. H., & Mukhopadhyay, T. (1995). Information technologies and Business Value: An Analytic and. Information Systems Research, 6(1), 3–23.

Bassett, K., Carriveau, R., & Ting, D. S. K. (2015). 3D printed wind turbines part 1: Design considerations and rapid manufacture potential. Sustainable Energy Technologies and Assessments, 11, 186–193. https://doi.org/10.1016/j.seta.2015.01.002.

Bhanot, N., Rao, P. V., & Deshmukh, S. G. (2015). Enablers and barriers of sustainable manufacturing: Results from a survey of researchers and industry professionals. Procedia CIRP, 29, 562–567. https://doi.org/10.1016/j.procir.2015.01.036.

Bhanot, N., Rao, P. V., & Deshmukh, S. G. (2017). An integrated approach for analysing the enablers and barriers of sustainable manufacturing. Journal of Cleaner Production, 142, 4412–4439. https://doi.org/10.1016/j.jclepro.2016.11.123.

Brynjolfsson, E., Hitt, L. M., & Yang, S. (2002). Intangible assets: Computers and organizational capital. Brookings Papers on Economic Activity, 2002(1), 137–198. https://doi.org/10.1353/eca.2002.0003.

Calle, M., González-R, P. L., Leon, J. M., Pierreval, H., & Canca, D. (2016). Integrated management of inventory and production systems based on floating decoupling point and real-time information: A simulation based analysis. International Journal of Production Economics, 181, 48–57. https://doi.org/10.1016/j.ijpe.2016.08.001.

Cooper, B. L., Watson, H. J., Wixom, B. H., & Goodhue, D. L. (2000). Data warehousing supports corporate strategy at First American Corporation. MIS Quarterly: Management Information Systems, 24(4), 547–567. https://doi.org/10.2307/3250947.

Corsini, L., Aranda-Jan, C. B., & Moultrie, J. (2022). The impact of 3D printing on the humanitarian supply chain. Production Planning and Control, 33(6–7), 692–704. https://doi.org/10.1080/09537287.2020.1834130.

Custódio, D. T., Vaccaro, R., Nunes, G. L., Vidor, F. L., G., & Chiwiacowsky, L. D. (2018). Variant product configuration of industrial air handling units in a MTO environment. International Journal of Advanced Manufacturing Technology, 95(1–4), 1025–1037. https://doi.org/10.1007/s00170-017-1171-7.

Dalcher, D. (2016). Novel approaches to Organizational Project Management Research: Translational and transformational. Project Management Journal, 47(1), e2–e2. https://doi.org/10.1002/pmj.21567.

Dawes, J. (2008). Do data characteristics change according to the number of scale points used ? An experiment using 5-point, 7-point and 10- point scales. 50(1), 1–10.

Despeisse, M., Mbaye, F., Ball, P. D., & Levers, A. (2012). The emergence of sustainable manufacturing practices. Production Planning and Control, 23(5), 354–376. https://doi.org/10.1080/09537287.2011.555425.

Devaraj, S., & Kohli, R. (2000). Information technology payoff in the health-care industry: A longitudinal study. Journal of Management Information Systems, 16(4), 41–67. https://doi.org/10.1080/07421222.2000.11518265.

Dijkstra, T. K., & Henseler, J. (2015). Consistent and asymptotically normal PLS estimators for linear structural equations. Computational Statistics and Data Analysis, 81, 10–23. https://doi.org/10.1016/j.csda.2014.07.008.

Domingos, D., Martins, F., Cândido, C., & Martinho, R. (2014). Internet of things aware WS-BPEL business processes - context variables and expected exceptions. Journal of Universal Computer Science, 20(8), 1109–1129.

Durão, L. F. C. S., Carvalho, M. M., Takey, S., Cauchick-Miguel, P. A., & Zancul, E. (2018). Internet of things process selection: AHP selection method. International Journal of Advanced Manufacturing Technology, 99(9–12), 2623–2634. https://doi.org/10.1007/s00170-018-2617-2.

Easton, F. F., & Moodie, D. R. (1999). Pricing and lead time decisions for make-to-order firms with contingent orders. European Journal of Operational Research, 116(2), 305–318. https://doi.org/10.1016/S0377-2217(98)00101-5.

Ebadian, M., Rabbani, M., Jolai, F., Torabi, S. A., & Tavakkoli-Moghaddam, R. (2008). A new decision-making structure for the order entry stage in make-to-order environments. International Journal of Production Economics, 111(2), 351–367. https://doi.org/10.1016/j.ijpe.2007.01.004.

Ebrahimi, A., Khakpour, R., & Saghiri, S. (2021). Sustainable setup stream mapping (3SM): A systematic approach to lean sustainable manufacturing. Production Planning and Control, 0(0), 1–24. https://doi.org/10.1080/09537287.2021.1916637.

Essoussi, L. H., & Merunka, D. (2007). Consumers’ product evaluations in emerging markets: Does country of design, country of manufacture, or brand image matter? International Marketing Review, 24(4), 409–426. https://doi.org/10.1108/02651330710760991.

Eswaran, M., & Bahubalendruni, M. V. A. R. (2022). Challenges and opportunities on AR/VR technologies for manufacturing systems in the context of industry 4.0: A state of the art review. Journal of Manufacturing Systems, 65, 260–278. https://doi.org/10.1016/j.jmsy.2022.09.016.

Fakhrzad, M. B., & Mohagheghian, E. (2019). A nash game in multi-period planning of make-to-order production system across the supply chain. International Journal of Industrial Engineering and Production Research, 30(1), 231–246.

Forza, C. (2002). Survey research in operations management: a process-based perspective. https://doi.org/10.1108/01443570210414310.

Franciosi, C., Voisin, A., Miranda, S., Riemma, S., & Iung, B. (2020). Measuring maintenance impacts on sustainability of manufacturing industries: From a systematic literature review to a framework proposal. Journal of Cleaner Production, 260, 121065. https://doi.org/10.1016/j.jclepro.2020.121065.

Frank, A. G., Dalenogare, L. S., & Ayala, N. F. (2019). Industry 4.0 technologies: Implementation patterns in manufacturing companies. International Journal of Production Economics, 210(September 2018), 15–26. https://doi.org/10.1016/j.ijpe.2019.01.004.

Garetti, M., & Taisch, M. (2012). Production Planning & Control: The Management of Operations Sustainable manufacturing : trends and research challenges. Taylor & Francis, June 2013, 37–41.

Garmdare, H. S., Lotfi, M. M., & Honarvar, M. (2018). Integrated model for pricing, delivery time setting, and scheduling in make-to-order environments. Journal of Industrial Engineering International, 14(1), 55–64. https://doi.org/10.1007/s40092-017-0205-y.

Gebler, M., Uiterkamp, A. J. M. S., & Visser, C. (2014). A global sustainability perspective on 3D printing technologies. Energy Policy, 1–10. https://doi.org/10.1016/j.enpol.2014.08.033.

Gonçalves Filho, E. V., & Marçola, J. A. (2001). Annualized hours as a capacity planning tool in make-to-order or assemble-to-order environment: An agricultural implements company case. Production Planning and Control, 12(4), 388–398. https://doi.org/10.1080/09537280152005012.

Gong, S., Ardeshiri, A., & Rashidi, T. H. (2020). Impact of government incentives on the market penetration of electric vehicles in Australia. Transportation Research Part D, 83, 102353. https://doi.org/10.1016/j.trd.2020.102353.

Gunasekaran, A., & Ngai, E. W. T. (2005). Build-to-order supply chain management: A literature review and framework for development. Journal of Operations Management, 23(5), 423–451. https://doi.org/10.1016/j.jom.2004.10.005.

Gunasekaran, A., & Spalanzani, A. (2012). Int. J. Production Economics sustainability of manufacturing and services : Investigations for research and applications. Intern Journal of Production Economics, 140(1), 35–47. https://doi.org/10.1016/j.ijpe.2011.05.011.

Guo, R., & Wu, Z. (2023). Social sustainable supply chain performance assessment using hybrid fuzzy – AHP – DEMATEL – VIKOR: A case study in manufacturing enterprises. Environment Development and Sustainability, 25(11), 12273–12301. https://doi.org/10.1007/s10668-022-02565-3.

Hair, J. F., Sarstedt, M., Hopkins, L., & Kuppelwieser, V. G. (2014). Partial least squares structural equation modeling (PLS-SEM): An emerging tool in business research. European Business Review, 26(2), 106–121. https://doi.org/10.1108/EBR-10-2013-0128.

Hair, J. F., Risher, J. J., Sarstedt, M., & Ringle, C. M. (2018). The results of PLS-SEM article information. European Business Review, 31(1), 2–24.

Hair, J. F., Howard, M. C., & Nitzl, C. (2020). Assessing measurement model quality in PLS-SEM using confirmatory composite analysis. Journal of Business Research, 109(August 2019), 101–110. https://doi.org/10.1016/j.jbusres.2019.11.069.

Haskose, A., Kingsman, B. G., & Worthington, D. (2004). Performance analysis of make-to-order manufacturing systems under different workload control regimes. International Journal of Production Economics, 90(2), 169–186. https://doi.org/10.1016/S0925-5273(03)00052-5.

He, N., Zhang, D. Z., & Li, Q. (2014). Agent-based hierarchical production planning and scheduling in make-to-order manufacturing system. International Journal of Production Economics, 149, 117–130. https://doi.org/10.1016/j.ijpe.2013.08.022.

Hemmati, S., & Rabbani, M. (2010). Make-to-order/make-to-stock partitioning decision using the analytic network process. International Journal of Advanced Manufacturing Technology, 48(5–8), 801–813. https://doi.org/10.1007/s00170-009-2312-4.

Henseler, J., & Sarstedt, M. (2013). Goodness-of-fit indices for partial least squares path modeling. 565–580. https://doi.org/10.1007/s00180-012-0317-1.

Henseler, J., Ringle, C. M., & Sarstedt, M. (2015). A new criterion for assessing discriminant validity in variance-based structural equation modeling. 115–135. https://doi.org/10.1007/s11747-014-0403-8.

Henseler, J., Hubona, G., & Ash, P. (2016). Using PLS path modeling in new technology research: updated guidelines. https://doi.org/10.1108/IMDS-09-2015-0382.

Hong, J., Zhang, Y., & Ding, M. (2018). Sustainable supply chain management practices, supply chain dynamic capabilities, and enterprise performance. Journal of Cleaner Production, 172, 3508–3519. https://doi.org/10.1016/j.jclepro.2017.06.093.

Hulland, J., Ryan, M. J., & Rayner, R. K. (2010). Modeling customer satisfaction: A comparative performance evaluation of Covariance structure analysis Versus partial least squares. 307–325. https://doi.org/10.1007/978-3-540-32827-8.

Jabbar, A., Akhtar, P., & Dani, S. (2019). Real-time big data processing for instantaneous marketing decisions: A problematization approach. Industrial Marketing Management, November 2018, 0–1. https://doi.org/10.1016/j.indmarman.2019.09.001.

Jo, M., Nakamoto, K., & Nelson, J. E. (2003). The shielding effects of brand image against lower quality countries-of-origin in global manufacturing. 56, 637–646. https://doi.org/10.1016/S0148-2963(01)00307-1.

Jones, J., Corral, G., & Zubielqui, D. (2016). Technological Forecasting & Social Change Doing well by doing good: A study of university-industry interactions, innovationess and fi rm performance in sustainability-oriented Australian SMEs. Technological Forecasting & Social Change. https://doi.org/10.1016/j.techfore.2016.07.036.

Kamran, M., Hai, K., Trinh, H., & Ullah, I. (2022). Sustainable economic activities, climate change, and carbon risk : An international evidence. Environment Development and Sustainability, 24(7), 9642–9664. https://doi.org/10.1007/s10668-021-01842-x.

Kaur, A. (2017). Social sustainability in supply chain decisions: Indian manufacturers. Environment, Development and Sustainability. https://doi.org/10.1007/s10668-017-9961-5.

Khakdaman, M., Wong, K. Y., Zohoori, B., Tiwari, M. K., & Merkert, R. (2015). Tactical production planning in a hybrid make-to-stock-make-to-order environment under supply, process and demand uncertainties: A robust optimisation model. International Journal of Production Research, 53(5), 1358–1386. https://doi.org/10.1080/00207543.2014.935828.

Khurana, S., Haleem, A., & Mannan, B. (2019). Determinants for integration of sustainability with innovation for Indian manufacturing enterprises: Empirical evidence in MSMEs. Journal of Cleaner Production, 229, 374–386. https://doi.org/10.1016/j.jclepro.2019.04.022.

Kidwell. (2005). Journal of Applied Management and Entrepreneurship. The Journal of Applied Management and Entrepreneurship, 10(3), 87–96.

Kim, E., & Van Oyen, M. P. (2021). Joint admission, production sequencing, and production rate control for a two-class make-to-order manufacturing system. Journal of Manufacturing Systems, 59(March), 413–425. https://doi.org/10.1016/j.jmsy.2021.03.010.

Larcker, C. F. (1981). and D. F. Unobservable Variables and Measurement Error: Algebra and Statistics. XVIII(August), 382–388.

Leguina, A. (2015). International Journal of Research & Method in Education A primer on partial least squares structural equation modeling (PLS-SEM). February. https://doi.org/10.1080/1743727X.2015.1005806.

Li, H., & Womer, K. (2012). Optimizing the supply chain configuration for make-to-order manufacturing. European Journal of Operational Research, 221(1), 118–128. https://doi.org/10.1016/j.ejor.2012.03.025.

Li, Y., Haleem, F., Cheng, Y., & Farooq, S. (2020). The management of Operations the impact of corporate social responsibility practices on sustainability performance in manufacturing networks: The moderating effect of interplant coordination. Production Planning and Control, 0(0), 1–15. https://doi.org/10.1080/09537287.2020.1856955.

Lödding, H., & Koch, C. (2020). The management of Operations Value stream analysis and design for make-to- order companies. Production Planning and Control, 0(0), 1–13. https://doi.org/10.1080/09537287.2020.1735008.

Luthra, S., Garg, D., & Haleem, A. (2015). An analysis of interactions among critical success factors to implement green supply chain management towards sustainability: An Indian perspective. Resources Policy, 1–14. https://doi.org/10.1016/j.resourpol.2014.12.006.

Macnaghten, P., & Jacobs, M. (1997). Public identification with sustainable development Investigating cultural barriers to. 3780(96).

Maklan, S. (2011). Customer experience Are we measuring the right things ? 53(6), 771–792. https://doi.org/10.2501/IJMR-53-6-771-792.

Mcafee, A. (2002). The impact of enterprise information technology adoption on operational performance: An empirical investigation. Production and Operations Management, 11(1), 33–53. https://doi.org/10.1111/j.1937-5956.2002.tb00183.x.

Meadows, M., & Dibb, S. (2012). Progress in customer relationship management adoption: a cross-sector study. October 2014, 37–41. https://doi.org/10.1080/0965254X.2012.671337.

Mendes, L., & Machado, J. (2015). Employees’ skills, manufacturing fl exibility and performance: A structural equation modelling applied to the automotive industry. International Journal of Production Research, 53(13), 4087–4101. https://doi.org/10.1080/00207543.2014.993772.

Moody, W. B. (2020). Beyond computation. The Arithmetic Teacher, 22(1), 22–26. https://doi.org/10.5951/at.22.1.0022.

Mujahid, A., Akhtar, P., Haq, M. A., Mani, V., Arsenyan, G., & Meyer, M. (2021). Technological forecasting & Social Change Real-time information sharing, customer orientation, and the exploration of intra-service industry differences : Malaysia as an emerging market. Technological Forecasting & Social Change, 167(February), 120684. https://doi.org/10.1016/j.techfore.2021.120684.

Nadagouda, M. N., Ginn, M., & Rastogi, V. (2020). ScienceDirect A review of 3D printing techniques for environmental applications. Current Opinion in Chemical Engineering, 28, 173–178. https://doi.org/10.1016/j.coche.2020.08.002.

Noori, M., & Tatari, O. (2016). Development of an agent-based model for regional market penetration projections of electric vehicles in the United States. Energy, 96, 215–230. https://doi.org/10.1016/j.energy.2015.12.018.

Osterrieder, P., Budde, L., & Friedli, T. (2020). International Journal of Production Economics The smart factory as a key construct of industry 4. 0 : A systematic literature review. Intern. Journal of Production Economics, 221(August 2019), 107476. https://doi.org/10.1016/j.ijpe.2019.08.011.

Pan, T., Zhang, Z. H., & Cao, H. (2014). Collaborative production planning with production time windows and order splitting in make-to-order manufacturing. Computers and Industrial Engineering, 67(1), 1–9. https://doi.org/10.1016/j.cie.2013.10.006.

Pramod, M., & Garg, S. (2006). Analysis of flexibility requirements under uncertain environments. Journal of Modelling in Management, 1(3), 196–214. https://doi.org/10.1108/17465660610715203.

Propfe, B., Kreyenberg, D., Wind, J., & Schmid, S. (2013). Market penetration analysis of electric vehicles in the German passenger car market towards 2030. International Journal of Hydrogen Energy, 38(13), 5201–5208. https://doi.org/10.1016/j.ijhydene.2013.02.049.

Purvis Ben, Y. Mao, & Darren, R. (2018). Three pillars of sustainability: in search of conceptual origins. Sustainability Science, 5. https://doi.org/10.1007/s11625-018-0627-5.

Rabbani, M., & Dolatkhah, M. (2017). Simultaneous production planning of make-to-order (MTO) and make-to-stock (MTS) products using simulation optimization. Case study: Soren Restaurant. International Journal of Advanced Logistics, 6(1), 30–44. https://doi.org/10.1080/2287108x.2017.1361290.

Rafiei, H., & Rabbani, M. (2009). Order partitioning in hybrid MTS/MTO contexts using fuzzy ANP. World Academy of Science Engineering and Technology, 58, 467–471. https://doi.org/10.5281/zenodo.1332109.

Sahin, F., & Robinson, E. P. (2005). Information sharing and coordination in make-to-order supply chains. Journal of Operations Management, 23(6), 579–598. https://doi.org/10.1016/j.jom.2004.08.007.

Salamati-Hormozi, H., Zhang, Z. H., Zarei, O., & Ramezanian, R. (2018). Trade-off between the costs and the fairness for a collaborative production planning problem in make-to-order manufacturing. Computers and Industrial Engineering, 126, 421–434. https://doi.org/10.1016/j.cie.2018.09.044.

Sari, E., Ma’aram, A., Shaharoun, A. M., Chofreh, A. G., Goni, F. A., Klemeš, J. J., Marie, I. A., & Saraswati, D. (2021). Measuring sustainable cleaner maintenance hierarchical contributions of the car manufacturing industry. Journal of Cleaner Production, 312(March), https://doi.org/10.1016/j.jclepro.2021.127717.

Sarstedt, M., Hair, J. F., Cheah, J., Becker, J., & Ringle, C. M. (2019). How to specify, estimate, and validate higher-order constructs in. Australasian Marketing Journal (AMJ), 27(3), 197–211. https://doi.org/10.1016/j.ausmj.2019.05.003.

Schreiber, J. B., Nora, A., Stage, F. K., Barlow, E. A., & Schreiber, J. B. (2013). Modeling and Confirmatory Factor Analysis Results: A Review. September 2013, 37–41. https://doi.org/10.3200/JOER.99.6.323-338.

Shahzad, F., Du, J., Khan, I., Shahbaz, M., & Murad, M. (2020). Untangling the influence of organizational compatibility on green supply chain management efforts to boost organizational performance through information technology capabilities. Journal of Cleaner Production, 266, 122029. https://doi.org/10.1016/j.jclepro.2020.122029.

Streukens, S., & Leroi-Werelds, S. (2016). Bootstrapping and PLS-SEM: A step-by-step guide to get more out of your bootstrap results. European Management Journal, 34(6), 618–632. https://doi.org/10.1016/j.emj.2016.06.003.

Sukdeo, N. (2017). The effect of the working environment on employee satisfaction and productivity: a case study in a clothing manufacturing factory. 1112–1121.

Tang, L., Chen, F. L., Tang, L., Li, F., & Chen, Z. (2019). INFORMS Journal on Computing Integrated Scheduling of production and two-stage delivery of make-to-Order products: Offline and Online Algorithms Integrated Scheduling of Production and two-stage delivery of make-to-Order products : Of fl ine and online A. August.

Taylor, P., Land, M. J., & Gaalman, G. J. C. (2009). Production Planning & Control: The Management of Operations Production planning and control in SMEs : time for change. November 2014, 37–41. https://doi.org/10.1080/09537280903034230.

Towers, N., Perry, P., Chen, R., Towers, N., Perry, P., & Chen, R. (2013). Corporate social responsibility in luxury manufacturer supply chains An exploratory investigation of a Scottish cashmere garment manufacturer. https://doi.org/10.1108/IJRDM-05-2013-0100.

Valase, K., & Raut, D. N. (2019). Mediation analysis of multiple constructs in the relationship between manufacturing and technology and environmental constructs in structural equation model for sustainable manufacturing. International Journal of Advanced Manufacturing Technology, 101(5–8), 1887–1901. https://doi.org/10.1007/s00170-018-2979-5.

Vidyarthi, N., Elhedhli, S., & Jewkes, E. (2009). Response time reduction in make-to-order and assemble-to-order supply chain design. IIE Transactions (Institute of Industrial Engineers), 41(5), 448–466. https://doi.org/10.1080/07408170802382741.

Wan, J., Chen, B., Imran, M., Tao, F., Li, D., Liu, C., & Ahmad, S. (2018). Toward dynamic resources management for IoT-based manufacturing. IEEE Communications Magazine, 56(2), 52–59. https://doi.org/10.1109/MCOM.2018.1700629.

Wang, S., Wan, J., Zhang, D., Li, D., Zhang, C., Wan, J., Zhang, D., Li, D., & Zhang, C. (2015). Towards Smart Factory for Industry 4.0: A Self-organized Multi-agent System with Big Data Based Feedback and Coordination. 2016. https://doi.org/10.1016/j.comnet.2015.12.017.

Wang, Z., Qi, Y., Cui, H., & Zhang, J. (2019). A hybrid algorithm for order acceptance and scheduling problem in make-to-stock/make-to-order industries. Computers and Industrial Engineering, 127(February), 841–852. https://doi.org/10.1016/j.cie.2018.11.021.

Yuan, M. L., Ong, S. K., & Nee, A. Y. C. (2005). A generalized registration method for augmented reality systems. Computers and Graphics (Pergamon), 29(6), 980–997. https://doi.org/10.1016/j.cag.2005.09.014.

Zaerpour, N., Rabbani, M., Gharehgozli, A. H., & Tavakkoli-Moghaddam, R. (2009). A comprehensive decision making structure for partitioning of make-to-order, make-to-stock and hybrid products. Soft Computing, 13(11), 1035–1054. https://doi.org/10.1007/s00500-008-0377-x.

Zennaro, I., Finco, S., Battini, D., & Persona, A. (2019). Big size highly customised product manufacturing systems: A literature review and future research agenda. International Journal of Production Research, 0(0), 1–24. https://doi.org/10.1080/00207543.2019.1582819.

Zhang, J., Ong, S. K., & Nee, A. Y. C. (2012). Design and development of an in situ machining simulation system using augmented reality technology. Procedia CIRP, 3(1), 185–190. https://doi.org/10.1016/j.procir.2012.07.033.

Zhong, R. Y., Xu, X., Klotz, E., & Newman, S. T. (2017). Intelligent Manufacturing in the context of industry 4. A Review Engineering, 3(5), 0. https://doi.org/10.1016/J.ENG.2017.05.015.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Upadhyay, S., Garg, S.K. & Sharma, R. Unlocking competitive edge and sustainability through Make-to-Order manufacturing: an empirical investigation. Environ Dev Sustain (2023). https://doi.org/10.1007/s10668-023-04255-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10668-023-04255-0