Abstract

This study uses farm models to analyze the effect of farm size on farm-level costs of adoption of reduced soil cultivation systems. In an empirical study in the Kulunda Steppe in Russia, we examine the farm-level economics of three crop cultivation technologies: old Soviet intensive tillage technology (OS), modified Soviet reduced-tillage technology (MS), and modern Canadian no-till technology (MC). We consider economies of size by considering three farm sizes (small = 500 ha, medium = 5000 ha, and large = 15,000 ha). Based on the general approach to cost and activity accounting, we sequentially compute gross cost–benefit measurement to assess the economic performance of the different systems. The study utilizes two data sources: (1) experts’ estimates regarding the input requirements and yield impacts of reduced-tillage systems in the marginal ecosystem of the Kulunda Steppe and (2) market prices in 2014 and 2015. According to the model calculations, OS is inferior to MC and MS tillage systems in all farm sizes if we adopt a medium- to long-term perspective and consider residual income. If we adopt a very short-term perspective and consider only the difference between sales and direct costs, the MC tillage system would rank first across all modeled farm sizes. However, because farms in the Kulunda Steppe are heterogeneous, our results cannot replace management decisions based on farm-specific calculations that consider the conditions of the respective farm.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Today, more than 50% of the agricultural land in the Kulunda Steppe in southwest Siberia is affected by different types of degradation (Frühauf 2013). The main problems are wind erosion, salinization, acidification, and water erosion. To reverse soil degradation processes and the negative environmental consequences thereof, cultivation technologies that address the exigencies of the marginal ecosystem steppe must be adopted. Agronomy and soil scientists recommend reduced-tillage systems as a sustainable way of cultivating soils endangered by degradation (e.g., Dammann et al. 2011; Knowler and Bradshaw 2007; López et al. 1998; Llewellyn et al. 2012; Meinel 2002; Thomas et al. 2007). However, it must also be noted with respect to sustainability that the mechanical herbicide control achieved through tillage is often replaced by increased herbicide inputs in reduced-tillage systems (e.g., Gray et al. 1996; Zentner et al. 2002). A broader approach to crop production sustainability that involves reduced tillage is known as conservation agriculture.

Conservation agriculture is characterized by three linked principles (FAO 2015), namely:

-

1.

Continuous minimum mechanical soil disturbance.

-

2.

Permanent organic soil cover.

-

3.

Diversification of crop species grown in sequences and/or associations.

Over the last 30 years, conservation agriculture has become a fast-growing production system worldwide. Conservation agriculture is fairly widespread, mainly in marginal ecosystems in North and South America and in Australia and Asia. Whereas conservation agriculture covered only 2.8 M ha worldwide in 1973/74, approximately 157 M ha was cultivated using conservation agriculture in 2013 (Kassam et al. 2015). In Russia, the area covered by conservation tillage (according to the FAO definition) is estimated to be approximately 4.5 M ha (Kassam et al. 2015), which represents 3.8% of the total arable land area of Russia.

Many studies analyze factors that affect farmer adoption of conservation technologies such as no tillage (e.g., D’Emden et al. 2008; Gray et al. 1996; Llewellyn et al. 2012; Pannell et al. 2014). Gray et al. (1996) distinguish between factors that the influence short-run profitability (i.e., yield and cost differences between conventional and reduced-tillage systems) and factors that produce long-term agronomic benefits (e.g., the improvement of soil quality). Llewellyn et al. (2012) use a slightly different classification, distinguishing between economic factors (e.g., changes in herbicide and machinery costs, learning costs, etc.) and factors related to the management of the natural resource of land (e.g., soil erosion, salinization, etc.). Moreover, because soil erosion has public implications, institutional and policy factors also affect the adoption of no-tillage technologies. Pannell et al. (2014) stress the importance of financial and production risks, as well as the uncertainty created by the lack of knowledge about or confidence in technology performance. Resource-poor farmers, whose livelihood may be quickly endangered, are especially averse to adopting practices that may cause a reduction in short-term income, even if these practices will bring about long-term benefits (Pannell et al. 2014). Also Russian scholars have studied effects of implementation of different tillage systems in Russia on soil quality and yield (Karakulev et al. 2004; Markovskaya and Yudina 2009; Pykhtin and Gostev 2012). The only study on the farm-level economics of reduced till we found in Russian settings is that by Polyanskaya (2012).

To overcome this gap in the literature, we concern ourselves in this study with the socioeconomic determinants of farmers’ land use choices. We recognize that the success of government interventions—such as soil protection and carbon sequestration projects—depends on the following factors: (1) if the corresponding change in land use increases the profitability of farming, farmers must be convinced of the economic benefits and professionally enabled to realize those benefits (capacity building); and (2) if farmers perceive that the change in land use reduces the profitability of farming, society’s willingness-to-pay (WTP)(cf. e.g., Hanemann 1991) must exceed farmers’ willingness-to-accept (WTA), i.e., the compensation payment must be greater than the perceived losses caused by the new technology.

Bavorova et al. (2018) use the farm optimization model (linear programming) to provide systematic analysis of factors influencing the performance of the crop production systems for a real farm in the Kulunda Steppe, together with expert estimations. The results of the optimization model show that under optimal management and climatic conditions, the expert MC no-till technology outperforms the farm mini-till technology, but this is not the case for suboptimal conditions with lower yields.

The present study develops the previous case study in many aspects. Differently as in the previous study, in this study, we apply farm models approach. This approach allows to analyze the effect of farm sizes on the performance of reduced cultivation practices.

We analyze the farm-level economics of three crop cultivation technologies used in the Kulunda Steppe: old Soviet intensive tillage technology (OS), modified Soviet reduced-tillage technology (MS), and modern Canadian no-till technology (MC).

Empirically, no-tillage is often associated with large farms due to the necessary investments in machinery, the profitability of which depends on its use over a large crop area (D’Emden et al. 2006; Fuglie and Kascak 2001). To examine the effect of farm size on farm economics, we model three farm sizes (500 ha, 5000 ha, and 15,000 ha).

The method we use provides empirical evidence, especially regarding the question: Does the farm size affect the economic performance of the considered cultivation technologies?

The calculations are based on experts’ estimates regarding the requirements for adopting reduced-tillage systems in the marginal ecosystem of the Kulunda Steppe and the impacts of such adoption on farming profitability.

In the second section of this paper, we provide a short overview of studies that focus on the economic viability of production technologies in semiarid and arid areas and describe crop production in the Kulunda Steppe. In section three, we describe the methodology, different technologies and data. Section four presents the results and discussion. The paper concludes with a discussion of the limitations of this study and recommendations for further work.

2 Agricultural production in semiarid areas and in the Kulunda Steppe

2.1 Environmental characteristics and farm structure in the Kulunda Steppe

2.1.1 Environmental characteristics

The Kulunda Steppe extends over the western part of Altai krai (region). The specialization of agricultural production is determined by soil types and climatic conditions. Based on climate and soil characteristics, the Kulunda Steppe may be divided into three environmental sub-types. The forest steppe extends over the northwestern portion of Altai region. In the forest steppe, precipitation is approximately 350–400 mm/year, and the average annual temperature is + 2 °C. The typical steppe is located between Voltshicha, Rodino, and Blagoveshenka in the west and Mamontovo and Baijevo in the east. In this area, precipitation is approximately 300–350 mm/year and the average annual temperature is + 3 °C. In the dry steppe that lies in the southwest portion of Altai krai, close to the Kazakh border, precipitation is below 300 mm/year and the average annual temperature is + 4 °C.

Due to their respective climatic conditions, the potential for arable farming is highest in the forest steppe and lowest in the dry steppe. Therefore, we present herein calculations of the profitability of farm models under forest steppe conditions. The frequent early-summer droughts in the dry steppe make agricultural production more difficult, as do the high temperatures and strong winds and storms. The wind dries out the soil, especially in the dry, heavily mechanically cultivated areas.

In addition to the climatic factors, in very rare cases, the soils of the Kulunda Steppe, in their original natural condition, can be limiting factors for crop production. The Kulunda Steppe consists of dark and light chestnut soils. The soils have a small humus content and light mechanical structure and are easily affected by wind erosion. The banks of numerous lakes, such as Kulundinskoe (728 km2), Kuchukskoe (181 km2), Gorkoe (140 km2), Bolshoe topolnoe (76 km2), and Bolshoe yarovoe 66.7 km2), and potholes have meadow licks and meadow-steppe soils as well as salt marshes. Derno-podzolic soils are formed near piny woods with steppificated grass canopies. The soils of Priobskoye Plateau are haplic and leached chernozems.

The chernozems have high yield potential due to their high water-retention capacity, good nutrient supply, good physical characteristics, and large-surface expansion. In parts of the dry regions of the Kulunda Steppe, the high salinity of the soils’ surface makes crop production very difficult (solonized chernozems by the valleys of Kulunda and Burla).

2.1.2 Farm structure

The study focuses on the agricultural enterprises with the legal forms of individual entrepreneurs with full liability (Private (Peasant) Farm (PPF) or Individual Entrepreneur (IE)), and agricultural organizations (Liability Limited Company (LLC), Joint Stock Company (JSC), Agricultural Productive Cooperative (APC) and State Agricultural Organisations). Subsistence plots are excluded from the analysis in this study.

According to statistical data for Altai krai, average sown area of PPF or IE covered 986 hectares in 2015 (2031 farms cultivated 2003 thousand hectares). Average sown area of an agricultural organization (LLC, JSC or APC etc.) equaled 4.3 thousand hectares (781 organizations cultivated 3321 thousand hectares) in 2015 (REESTR 2012–2015; ROSSTAT 2019).

2.2 Economic viability of reduced tillage—the overall view

Agricultural economists emphasize that economic decisions are intended to maximize profits based on existing physical input–output relationships (i.e., production functions) and price relations (e.g., Knowler and Bradshaw 2007, Llewellyn et al. 2012; Pannell et al. 2014). Most studies in the area of reduced-tillage economics examine the profitability of cropping systems for selected regions, cultivation technologies and crops, abstracting from whole farm consideration (e.g., Meyer-Aurich et al. 2006; Ozpinar and Ozpinar 2011; Singer et al. 2010; Zentner et al. 2002). The reason for this approach is that economic outcomes of conservation agriculture are farm specific, due to the heterogeneity of regions, institutional factors, interest rates, farm size, risk attitudes, access to markets (for inputs and outputs), resource endowments, farming systems, and farm management skills which makes generalizability of the results very difficult. In the following literature review, we provide examples of studies that examine effect of various reduced-tillage technologies and crop rotations on farm economics. Particularly, we consider the results on effect of soil tillage on risk, costs of labor, fuel, machinery and chemicals and residual income. Meyer-Aurich et al. (2006) examined the effectiveness of eastern Canadian cropping systems using the results of a 20-year field trial that included 15 cropping systems. The systems varied by crop choice and tillage system (mouldboard and chisel plow). The net returns identified in the study were affected by tillage and rotation, as well as by the interaction between tillage and rotation. Furthermore, the level of diversification of rotations reduced the volatility of net returns. This finding makes diversified rotations more attractive to risk-averse producers.

Ozpinar and Ozpinar (2011) compared three tillage systems in a semiarid region of Turkey: (1) rototiller (shallow) tillage, (2) conventional tillage with mouldboard plow, and (3) chisel tillage. They found that labor input varies across tillage systems. The highest labor input for wheat was with mouldboard plow, and the lowest was with chisel. Labor savings from reduced tillage have also been found in other studies (Raper et al. 1994; Weersink et al. 1992). The total cost savings from using chisel and rototiller tillage instead of mouldboard plow were found to be approximately 17%, due to the reduced number of field operations and thus reduced labor, fuel and machinery costs. These findings contradict those of studies in dry environments, which have found that the total cost of producing crops using reduced-tillage systems is higher than that of conventional tillage systems (Sánchez-Girón et al. 2004; Zentner et al. 2002). For instance, Zentner et al. (2002) examined the economic performance of different rotations and tillage systems in the sub-humid black soil zone of Saskatchewan. The study included three crop rotations and three methods of tillage: (1) conventional tillage, (2) minimum tillage, and (3) zero-tillage. Although annual production costs for crop rotation systems went up with cropping intensity and diversity, these costs were not influenced by the tillage system. This resulted from the fact that the cost savings for labor, fuel, and machinery were more than offset by the higher herbicide costs.

Becker (1997) analyzes the economics of soil cultivation systems for different farm sizes in Germany. He compares the economics of four cultivation systems (1. conventional tillage with mouldboard plowing, 2. conservation tillage with loosening, 3. conservation tillage without loosening, and 4. direct drilling). He compares four farm models (75 ha, 150 ha, 500 ha, and 2000 ha) and calculates the residual income for the four cultivation systems. The conservation tillage without soil loosening produces the highest residual income. For Russian conditions, Polyanskaya (2012) investigated the profitability of (1) traditional tillage, (2) min-till, and (3) no-till systems for winter wheat in Nizhegorodskaya oblast. The author found that fuel costs were 4% and 48.4% lower for min-till and no-till technologies, respectively, compared to the traditional tillage system. Furthermore, profitability with the conventional tillage system was 51% and 19% lower than profitability with zero-till and min-till technologies, respectively. Although labor costs and depreciation were reduced in the min-till and zero-till systems, the yield was same for the tillage systems. Karakulev et al. (2004) show that in the forest steppe of Orenburgskoy oblast spring wheat yield increased with the zero-tillage system. Pykhtin and Gostev (2012) discuss reduced-tillage systems in Russia and conclude that outcomes of tillage systems are farm specific and depend on the natural regional conditions.

The majority of the above-cited studies found that in min-till and zero-till technologies the costs of labor, fuel, machinery, and repair are lower than the costs of conventional tillage. According to some studies, this effect is thwarted by the increased herbicide costs of min-till and zero-till soil cultivation technologies. The studies show that yields are strongly dependent on site-specific natural conditions (precipitation, soil quality, etc.).

3 Methodological approach and data

The main aims of this chapter are to describe different crop cultivation systems in the Kulunda Steppe and to present the profitability measurements and data used in the analysis.

3.1 Analyzed tilling systems and farm sizes in the farm models

A number of crop cultivation systems are currently used in the Kulunda Steppe. The main differences among them are the frequency of mechanical cultivation, its depth, the use and frequency of spraying, the use of fertilizers, and crop rotation. No statistics exist regarding the systems used in this area. The no-till system is a new system that has emerged in the last several years, and rough estimations are that only 2–5% of farmers are using it. Off-farm experts recommend reduced tilling to address the problems of erosion and soil degradation specific to the Kulunda region, as well as the global problem of climate change.

The defined farm models use three technologies in the studied forest area of the Kulunda Steppe: (1) old Soviet intensive tillage technology (OS), (2) modified Soviet reduced-tillage technology (MS), and (3) modern Canadian no-till technology (MC). Both the modified Soviet and modern Canadian technologies use reduced tillage to prevent soil erosion. We define two types of plant rotation commonly implemented for these three technologies. Plant rotation in the old Soviet system differs from plant rotation in the other two systems. In the old Soviet system, only wheat is cultivated and fallow is used after 2 years of wheat cultivation.

In the forest steppe, OS entails deep cultivation in fall and chisel cultivation in spring (Table 1). Neither spraying nor fertilizer is used in this system. The crop rotation is wheat–wheat–fallow.

The modified Soviet tilling system (MS) is a reduced-till cultivation method in which a chisel cultivator and drill are used before seeding. Spraying in fall is regularly necessary, but spraying in spring is conducted only in cases of weed pressure. In addition, fertilizers are spread while sowing. The crop rotation is wheat–field pea–wheat–sunflower.

In the adapted modern Canadian no-till technology (MC), spraying in fall is obligatory, whereas spraying in spring is conducted only in cases of weed pressure. Fertilizers are spread while direct seeding. The crop rotation is wheat–field pea–wheat–sunflower.

We constructed farm models with three arable land areas (500 ha, 5000 ha, and 15,000 ha). The area of 500 ha was chosen because it represents a typical acreage of private peasant farms (PFs) and individual entrepreneur farms (IEs). The 5000-ha area represents medium-scale private peasant farms (PFs) and individual entrepreneur farms (IEs), as well as smaller agricultural organizations (AO). Large farms (primarily agricultural organizations) are also important in the Kulunda Steppe region. Therefore, the acreage of the third farm models is 15,000 ha. 15,000-ha farm is a management unit that is usually managed centrally without separate smaller management units. Instead, spatial plant rotation over the farm’s total acreage is adjusted to fit the transport of machinery. The plant rotation in all three farm models is same.

3.2 Profitability measurements and data

To compare the economic competiveness of the tillage systems under investigation, we need a measurement of profitability (performance measurement) that is as simple as possible but includes all of the costs and benefits that vary depending on the tillage system used. We emphasize that the subordinate performance measurements, such as yields or sales, on which non-economists occasionally focus, are not capable of informing us about the economic performance of the various systems. We use the measurement residual income to measure and compare the economic performance of the different tillage systems and associated production programs. When calculating the residual income, we do not consider fixed costs (such as the farm manager’s salary) that are not affected by the choice of tillage system and production program.

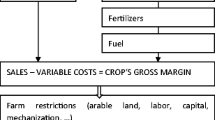

Based on the general approach to cost and activity accounting, we sequentially compute gross cost–benefit measurements to assess the economic performance of the different systems (Table 2).

Beginning with the likely yields and sales, the first step is to deduct the direct costs (seeding costs, plant protection costs, etc.) including fuel and calculate an initial cost–benefit measurement (margin) called sales free of direct costs. The sales free of direct costs performance measurement is an imperfect proxy of the (short-term) operating income because variable labor and machinery costs are not yet deducted. For labor, we cannot distinguish between fixed (e.g., permanent labor) and variable (e.g., seasonal labor) components. Regarding the machinery cost, we only have a total expert estimate, i.e., without the detailed information if machinery is used, for example, above depreciation level or below. Because we are unable to separate the variable components of labor and machinery costs from their fixed counterparts, we cannot compute the conventional gross margin (sales free of all variable costs). Instead, in one additional step, we deduct all labor and machinery costs from the sales free of direct costs. We call the resulting performance measurement residual income. The residual income incorporates all the long-term consequences of choosing one tillage system over another. All costs and benefits that vary depending on the choice of the tillage system are considered. Hence, residual income is an adequate performance measurement and decision calculus for farmers who must choose among the different systems. In this context, it should be noted that the identification of an adequate performance measurement does not eliminate the uncertainty of future outcomes. The reliability of the rank order of the different systems will thus depend critically on the forecasting quality of the data and expert estimates that are used in the computation of residual income.

In the following section, we describe the calculation of the profitability measurements and identify the data sources used.

3.2.1 Sales free of direct costs

We first calculate the sales free of direct costs. We present the sequential approach to this calculation because it allows us to compare the parameters that affect the income of different cultivation systems.

Crop yield was assessed by two experts: one GermanFootnote 1 and one Russian,Footnote 2 based on average weather conditions and a very good management system. Crop prices were obtained from the Agroserver (2015) website for the year 2014.

Direct costs were calculated using cost data for seeds, herbicides, fungicides, insecticides, seed treatment, fertilizers, and fuel. The German1 and Russian2 experts assessed the production parameters of the different technologies in the forest steppe. The assessment of both experts differed in some estimations. Therefore, the first author of this paper met both experts and confronted them with the differences. The experts discussed these differences, and at the end they adapted the estimations of production parameters so that both agreed upon.

The fuel costs per ha for the three technology systems were estimated separately for each crop. Fuel costs were estimated only for the 15,000-ha farm. We used this estimation for the 5000-ha farm as well. For the 500-ha farm, we added 25% to the costs of the 15,000-ha farm because fuel costs increase for smaller acreage plots.

3.2.2 Residual income

To quantify the effects of the selected technologies on profitability, the effect of each technology on labor and machinery costs must be taken into consideration, which is done in the calculation of residual income:

The labor costs per ha for the three technology systems were estimated by an expert (T. Meinel) separately for each crop. The expert estimated labor costs only for the 15,000 ha farm. Thus, we adjusted the costs for the 5000-ha and 500-ha farms because labor costs increase for smaller acreage plots. For the 5000-ha farm, we multiplied the expert’s estimation by 1.3, and for the 500 ha farm, we multiplied the estimation by 1.7, as suggested by the German expert.

The average annual costs of machinery are usually calculated as the sum of a) depreciation, b) interest claim, and c) annual operation costs associated with the use of the machine (repairs, consumables, and insurance).

-

(a)

Average annual depreciation We determined the useful life of all machines according to farm size as 12 years (500 ha), 10 years (5000 ha), and 8 years (15,000 ha), with no residual value at the end of the machine’s useful life. We calculated the average annual depreciation of both imported western machinery and Russian machinery. Because the exchange rate changed dramatically over the last 3 years (1.1.2013—40.19 RUB/€, 1.1.2015—71.93 RUB/€, and 27.10.2015—69.06 RUB/€), we calculated the prices of imported western machines based on an exchange rate of 60 RUB/€.

-

(b)

Average interest claim We used an interest rate of 12% p.a. (interest rate—interest rate subsidies) in the calculation, an average fixed capital of 50% of the machinery acquisition price (which is typically used for machinery), and a residual value of zero.

-

(c)

Annual operation costs associated with the use of the machine (repairs, consumables, and insurance) were not considered in this calculation because we could not obtain reliable data on these costs. The experts denied assessing this cost with the argument that it varies tremendously.

We determined the average annual depreciation and the average interest claim per hectare of farm.Footnote 3 In the Altai region, farmers are using Russian machinery and imported western machinery. The price of imported machinery is significantly higher than the price of local machinery. The price of imported machinery has increased recently due to the depreciation of the ruble. The lower price of Russian machinery is also due to state subsidies for these purchases. Therefore, in our model, we are calculating the costs based on two sets of machinery (Russian and imported). In reality, farms use a combination of imported and domestic machines.

The German expert assessed machinery needs for 500-ha, 5000-ha, and 15,000-ha farms in the forest steppe in Altai krai and provided us with prices (in euros) for imported western machinery since the beginning of 2015. The 015 prices of machines produced in Russia were taken from the Rosagroleasing website (in Russian rubles). To compare the prices of imported machinery and Russian machinery, we calculated the price in euros using the average exchange rate in 2014 (60 RUB = 1€). In the farm models, varying machines sizes are used to account for varying farm models’ size. The numbers of machines used in the different farm model technologies according to expert knowledge and their market prices are presented in Table 11 in “Appendix.”Footnote 4

There are numerous similar machines in the market from different producers and at different price levels. We selected the cheapest new Russian machines that we found in the market. There are certain size differences between imported and Russian machines. For instance, to our knowledge, Russian-produced direct pneumatic seeding machines have a maximum size of 3 m, whereas imported machines have a maximum size of 6 m. Regarding the list of required Russian machines, we had to substitute the imported pneumatic direct seeding machine with two Russian machines. In addition, we found that the maximum size of sprayers in the Russian market is 4000 l/28 m. Thus, for the largest farm (15,000 ha), we took two units of this machine. Furthermore, two machines on the list of imported machines (the mechanical seed drill (7.2 m) and deep-tiller (ripper) PG 3–5, 3 m) were replaced with Russian machines because the expert explained that imported machines are not used in the studied region. However, several machines on the list (such as the direct pneumatic seeding machine 18 m, combination strip tiller with seedbed conditioner—8 and 12 rows, and trailed sprayer 11,200 l/30 m) are not produced in Russia. Therefore, we had to replace them with imported machines in the Russian machine set.

Additionally to the residual income calculated based on the estimated yield for optimal conditions, we carry out a critical yield analysis and determine the critical yield level as a percentage share of the original estimation at which MS and MC would break even with OS and produce an identical residual income.

4 Results and discussion

In this section, we present the results and discuss the effect of technology and farm size on sales free of direct costs and on residual income.

4.1 Sales free of direct costs

In this subchapter, we present the results for sales free of direct costs. We also present the intermediary results (for sales and direct costs) to determine how cultivation system and farm size affect each parameter.

4.1.1 Sales

Experts estimated that under optimal weather conditions and management systems, the yield for all studied crops is higher with an input-intensive MC tillage system than with the other tillage systems. In particular, wheat yield with an MC system is three times higher than wheat yield with the input-extensive OS tillage system. We must note that we abstracted from the yield the difference in yields between wheat planted after fallow and wheat planted after wheat in the OS system. There is also a difference in yield between the MC and MS tillage systems. For instance, the yields for peas and sunflowers are 30% and 25% % higher, respectively, under the MC system than under the MS tillage system (Table 3). However, the effect of reduced-tillage systems on yield is highly variable depending on agro-ecological conditions (Giller et al. 2009; Gray et al. 1996; Hernanz et al. 1995). For instance, Rusinamhodzi et al. (2011) found that in low-rainfall areas, conservation agriculture practices have increased maize yield over time. Several scholars have found that under zero-tillage systems, yield can decrease initially but then increase after several years (Baudron et al. 2011; Fowler and Rockstrom 2001). Anecdotal evidence suggests that in the Kulunda Steppe, the yield during wet years is higher when the traditional cultivation system is used, but in very dry years, the yield is the highest when a no-tillage system is used. According to local farmers who use a no-tillage system, in very dry years, the yield is often zero when the traditional system is used, but this is not the case when a no-tillage system is used.

In the model farms, reduced-tillage systems significantly increase the revenues derived from higher yields compared with traditional tillage systems. The highest revenues are observed for sunflowers cultivated with an MC tillage system, due to the high average price for sunflowers. In contrast, the lowest revenues are observed for peas cultivated with the MC tillage system, because of low yield and low price. Price volatility for agricultural products is high in Altai krai and has a significant effect on crop sales.

4.1.2 Direct costs

The direct costs of each tillage system and for each type of farm are presented in Table 4. The highest direct costs are observed for the MC tillage system, mainly because of the high cost of chemicals. The total chemical cost includes costs for herbicides, fungicides, insecticides, seed treatment, and N + P fertilizers. 1750 RUB/ha of fertilizer costs is estimated for the MC system and 700 RUB/ha for the MS. In the OS system, no fertilizers are used and the follow is used to accumulate nitrogen.

The pesticides costs for OS are close to zero because pesticides are usually not used (or are used in very small amounts) in this system in the Kulunda Steppe. In contrast, the herbicides costs for wheat production under the MC system are as high as 2200 RUB/ha. When discussing no-tillage systems with farmers in the Kulunda Steppe, high herbicide costs are often mentioned as a reason why the no-tillage method is not used. Some farmers are also concerned about the ecological effect of using large amounts of pesticide. These results are consistent with the findings of Sánchez-Girón et al. (2004), who argue that because of high herbicide costs, total production costs in reduced-tillage systems are higher than those in conventional practices. The same results are obtained by Gray et al. (1996) for Canadian conditions. These authors simulated an increase in the price of glyphosate that had a dramatic effect on the relative profitability of zero and conventional tills. They stress that the profitability of no-tillage technology depends on the purchase of particular herbicides at reasonable prices. In Australia, the substantial fall in the price of glyphosate has played a significant role in the increase of no-till adoption (D’Emden et al. 2006). D’Emden et al. (2006) stress the importance of the glyphosate-to-diesel price ratio for the adoption of no-tillage systems and note the growing problem with glyphosate resistance, which could negatively affect the adoption of no-tillage technology.

In the farm models, the fuel costs per hectare are significantly higher with OS, followed by the MS and MC tillage systems. Farm size affects fuel costs primarily due to plot size. Specifically, fuel consumption per hectare is higher for smaller plots. Gray et al. (1996) showed in their farm simulation that if fuel prices increase, zero-tillage systems become relatively more feasible, although the effect is relatively small. This finding is supported by Ward et al. (2010), who showed that the energy crisis of the 1970s was an important factor in the early adoption of no-tillage technology on the Canadian prairies.

If we look at direct costs of specific crops, we see that total direct costs for wheat range from 4144 to 10,675 RUB/ha, reflecting the differences between tillage systems and farm sizes. The highest direct costs for wheat production are observed with MC tillage system, followed by MS and OS tillage systems. Direct costs for peas range from 4879 to 10,675 RUB/ha. On average, direct costs for peas under the MS tillage system are 1.6 times less than the costs of the MC system. However, the costs for sunflower production are on average two times less for the MS tillage system than for the MC tillage system. Sales free of direct costs Sales free of direct costs are depicted in Table 5. For all model farm sizes, the result for MC technology is highest, followed by MS technology. The result for OS technology is considerably lower than those for the other two technologies.

4.2 Residual income

In this subchapter, we present the residual income results. We also present the intermediary results (for labor and machinery costs) to show how they are affected by cultivation system and farm size. We compare labor and machinery costs for different technologies with those obtained in studies from other regions. Finally, we provide a critical yield analysis for the considered technologies.

4.2.1 Labor costs

Labor costs per hectare are provided in Table 6. For a 500-ha farm, the labor cost per hectare in a MC tillage system is 4% and 44% lower than the labor costs of the MS and OS tillage systems, respectively. The indirectly involved labor cost (e.g., administration and management) was not involved in the calculation. These differences are similar for larger farm sizes. If we compare the labor costs of an MC tillage system across different farms, we see that the cost of labor is lowest for the 15,000-ha farm. Similar cost savings are observed for the MS and OS tillage systems.

These results are supported by other scholars. For example, Gray et al. (1996) and Smart and Bradford (1999) report that plowless tillage systems reduce the number of field operations, which in turn decreases labor costs. The no-tillage system is more complex, and its implementation requires a certain level of knowledge. The need for more specialized and more expensive workers thus increases. In the Kulunda Steppe region, out-migration of young specialists and a lack of skilled labor are prevalent (Bednaríková et al. 2016; Sergienko et al. 2013; Shibaeva 2012). This deficiency can hinder the implementation of no-tillage systems in the area and make no-tillage systems more expensive.

4.2.2 Machinery costs (depreciation and interest)

Table 7 presents machinery costs (depreciation and interest) for each farm size and cultivation system. For 500-ha farms, depreciation costs for imported machines with MS tillage systems are 48% and 0.3% lower than with MC and OS tillage systems, respectively. These differences increase if Russian machines are used. Specifically, the use of Russian machinery with an MS tillage system reduces depreciation costs by 109% and 43% relative to MC and OS tillage systems, respectively. With an MS tillage system, the depreciation costs of Russian machines are almost three times lower than the depreciation costs of imported machines. Because interest costs depend on machine price,Footnote 5 the interest costs for the respective tillage systems are ranked the same order. In other words, the lowest interest cost is observed for MS tillage systems using imported or Russian machines.

Compared to small farms, 5000-ha farms using MC tillage systems have lower depreciation and interest costs. In our farm model, if imported machines are used, the depreciation cost is nearly 31% and 103% lower under a MC tillage system than under the MS and OS systems, respectively. If Russian machines are used, the depreciation cost for an MC tillage system is 22% and 39% lower than for MS and OS systems, respectively. Because the interest cost is correlated with machine price, the lowest interest costs are observed in the MC tillage system. Under all tillage systems, the depreciation costs of Russian machines are nearly two times lower than the depreciation cost of imported machines.

Regarding the 15,000-ha farm, the depreciation and interest costs are lowest with the MC tillage system. The depreciation costs of MS and OS tillage systems with imported (Russian machines) are 30% (25%) and 44% (40%) higher than depreciation cost of the MC system, respectively. Thus, the interest cost is also the lowest under the MC tillage system. When we compare Russian and imported machines, we see that for all tillage systems, the use of Russian machines decreases the depreciation cost by approximately two times.

The machinery used for no-tillage systems, especially the seeding equipment, is more sophisticated and specialized and farmers often cite increased costs as an impediment to the adoption of no-tillage systems (Llewellyn and D’Emden 2010). Our results show that in Altai krai, this limitation is especially relevant for smaller farmers. This impediment can become less important when machinery is due to be replaced and new machines must be bought (Llewellyn et al. 2012).

4.2.3 Residual income

The residual income (sales free of direct costs, labor costs, and machinery costs) of the analyzed crops with the three tillage systems and three types of farms is presented in Table 8. In 500-ha farms, the highest residual income per hectare is observed under the MS tillage system for both domestic and imported machines. The results for the MC and OS tillage systems show negative residual income with imported machines. The highest residual income with imported machines is achieved under the MS tillage system. The residual income under the OS tillage system is negative. If Russian machines are used, residual income is approximately 1.4 and 5.2 times higher under the MS tillage system than under the MC and OS systems, respectively. If the 500-ha farm uses the MS tillage system with Russian machines, its residual income per hectare is 4.8 times higher than it is if the MS tillage system is implemented with imported machines.

The results for the 5000-ha and 15,000-ha farms are similar. When considering the benefits of the three tillage systems in terms of residual income if imported machines are used, we found that the MC tillage system generates the highest residual income—10,949 RUB/ha and 10,410 RUB/ha—for the 5000-ha and 15,000-ha farm models, respectively. Use of the OS tillage system results in the lowest residual income for the 5000-ha farm (1344 RUB/ha); for the 15,000-ha farm, the residual income is actually negative (− 109 RUB/ha) if imported technology is used. The highest residual income was found for MC tillage systems using Russian machinery.

The high residual income generated by the MC tillage system in 5000-ha and 15,000-ha farms is due primarily to the high yield and reduced input costs for items such as fuel, labor, and depreciation. Also other scholars have found that compared with conventional tillage systems reduced-tillage systems can increase residual income (Raper et al. 1994; Smart and Bradfor 1999). Impact of farm size on residual income has been found. Llewellyn et al. (2012) argue that there is a greater value generated by new seeding machinery across a larger crop area. Also this is the factor why larger farms are often associated with the adoption of no-tillage systems. For larger farms, even labor and fuel costs per hectare are lower than for smaller farms.

4.2.4 Critical yield

Additionally to the residual income calculated based on the expert estimates for yield under optimal climatic and management conditions, we provide a critical yield analysis (Table 9). We determine the critical yield level as a percentage share of the original expert estimates at which MS and MC would break even with OSFootnote 6 and produce an identical residual income.

The critical yield level in the MS technology amounts to 61% of the original expert estimate for yield for the 500-ha farm and to 67% for the larger farm models. Looking at MC no-till technology gives a different picture. When using Russian machinery, the critical yields amount to 80% of the estimated yield for the 500-ha farm and to 68–69% for the larger farm models. When using imported western machinery (as this is used in the no-till system in the area) for the 500-ha farm, the critical yields are 16% higher than the expert estimates. For both larger farm models, the critical yield level amounts to 77% of the expert estimate for yield.

Considering the wheat yields (wheat is the most cultivated crop in the region), the residual income of MS min-till technology per hectare breaks even with OS when the yield amounts to ca. 1.5 t/ha for all farm sizes. Considering the MC no-till technology with Russian machinery, the critical wheat yield for the 500-ha farm model is 2.4 t/ha and for the larger farms ca. 2.0 t/ha. For MC no-till technology with imported machinery, the critical yield is higher for the 500-ha farm model (3.5 t/ha wheat) than for the larger farm models (2.3 t/ha wheat).

5 Summary of the results and conclusions

In this study, we examine the farm-level economics of three crop cultivation technologies in the southwest Russian Kulunda Steppe. We answer the following research question: Does the farm size affect the economic performance of the considered cultivation technologies?

Table 10 presents a summary of the cost and residual income results for imported and Russian machinery. The results show that under optimal weather conditions and management systems, reduced-tillage systems have the potential to contribute to the welfare of farmers in the Altai region. If we look at the sales free of direct costs, we see that the MC tillage system has more benefits for each type of farm. Moreover, labor costs are lower for MC technology compared with the other tillage systems. Although depreciation costs per hectare are very low for medium and large farms under the MC tillage system, the results show that depreciation costs for small farms are higher with zero-tillage technology than with the other tillage systems. Finally, the residual income results of our farm models demonstrate that for 500-ha farms, the MS tillage system is the most profitable, whereas for 5000-ha and 15,000-ha farms, the MC tillage system generates the highest residual income.Footnote 7

The results based on expert estimates show that both reduced-tillage technologies (MS and MC) are more profitable than the old Soviet intensive technology under the assumption of optimal climatic and management conditions. This gives rise to the question of whether the original expert estimates are realistic proxies for annual average yields in the region. This question is especially important since yield volatility is quite high in the region and the average wheat yield in Altai krai amounted to 1.4 t/ha in 2011–2015 (own unpublished results).Footnote 8 Unfortunately, long-term field experiments that would facilitate reliable assumption regarding annual average yields for different tillage systems are still missing.

To put the results based on the original expert estimates into perspective, we carried out a critical yield analysis. The MS min-till technology outperforms the OS conventional technology (expert estimates for wheat yield 2.0 t/ha) if the yield is higher than ca. 1.5 t/ha for all farm sizes. The MS min-till technology breaks even through considerable lower critical yields (especially in the 500-ha farm) than the MC system. It must be noted that the critical yield level for all variants using capital-intensive imported machinery does not give a complete picture of the respective variant’s competitiveness. This is due to our cost calculations in which we used the subsidized interest rate that has been made available to farmers by the government. Using the real costs of capital ( = non-subsidized interest rate) would increase costs and therefore increase the critical yield levels at which the capital-intensive systems break even with OS.

The results of this study show positive effect of using modern cropping technologies on farm economics in Altai krai. There are also other factors besides the economic ones that support the decision to use modern technologies with reduced-tillage and diversified crop rotation. For the dry region of Kulunda Steppe in southwest Siberia, the adoption of these modern technologies by more farmers would help to reverse soil degradation processes particularly the erosion and the negative environmental consequences thereof such as dust bowls. Also, the reduced tillage would increase water-retention capacity of soil. Further, the fact that no-tillage seeding requires less seeding days and thus prevents the yield decrease through late seeding may make it superior to other tillage systems.

Rational farmers would adopt the modern technologies if they would be aware of both their positive effect on farm economics and soil quality. The use of old soviet technology in the area indicates that the farmers do not have enough information about the modern technologies. To increase the adoption rates of new technologies among farmers, the governmental extension services should provide farmers with up-to-date information about the effects of modern technologies and support them by the conversion to the conservation practices. The anecdotal evidence says that it is not the case nowadays. When interpreting the findings, it should be noted that like most farms, the farms in the Kulunda Steppe are very heterogeneous in terms of factor endowment, natural conditions, and market environment. Therefore, our model calculations cannot replace management decisions based on farm-specific calculations that take into account the conditions of the farm at issue, including soil quality, soil degradation status, micro-climatic conditions, the availability of capital and other inputs, crop rotation requirements, and management and labor skills.

Even though we selected the experts very carefully, the main limitation of this paper is that we had to use the experts’ estimations as there were no reliable long-term field trials in the area. The statistical business data could not be used as the farmers in the area usually use a mix of various soil cultivation systems.

Notes

Dr. Meinel has studied soil cultivation in the Altai krai for approximately 15 years.

Prof. Belayev (Professor at the Farm Mechanisation Department at the Agrarian University in Barnaul) has investigated soil cultivation technologies in Altai krai for two decades.

With regard to machinery requirement for follow, it must be noted that the mechanical follow is cultivated six times during the vegetation period: once using a deep cultivation and five times using flat cultivation by harrow.

As mentioned previously, machinery prices have changed significantly due to the depreciation of the Russian ruble. Thus, machinery costs were calculated based on the exchange rates that prevailed before (40 RUB/€ exchange rate) and after the crisis (60 RUB/€ exchange rate). However, only the more current results are presented here. Data regarding the cost of machinery before the exchange rate crisis are available upon request.

The bank interest rate on the purchase of both imported and Russian machines is 12%.

OS is the conventional technology that usually uses Russian machinery. We therefore assume Russian machinery equipment when calculating the costs of OS.

Similar results were also obtained using the pre-crisis exchange rate (40 €/RUB), although residual income with the pre-crisis exchange rate is higher than residual income with the exchange rate that prevailed during the crisis (60 €/RUB). These results are available upon request.

A total of 92 farms were investigated in the Altai Krai between February 2015 and July 2016. We collected the data through quantitative face-to-face questionnaire surveys. When selecting the farms, our aim was to have at least one large and medium or small farm from each rayon in our sample. We closely achieved this aim as we covered 52 rayons from 59.

References

Agroserver. (2015). Rosiyskiy agorpromishlenniy server. Retrieved April 9, 2018 www.agroserver.ru.

Baudron, F., Corbeels, M., Andersson, J. A., Sibanda, M., & Giller, K. E. (2011). Delineating the drivers of waning wildlife habitat: The predominance of cotton farming on the fringe of protected areas in the Zambezi Valley, Zimbabwe. Biological Conservation, 144(5), 1481–1493.

Bavorova, M., Imamverdiyev, N., & Ponkina, E. (2018). Farm-level economics of innovative tillage technologies: The case of no-till in the Altai Krai in Russian Siberia. Environmental Science and Pollution Research, 25(2), 1016–1032.

Becker, C. (1997). Dauerhaft pfluglose Bodenbearbeitungssysteme und Betriebsgröße – eine pflauzenbaulich-ökonomische Analyse. Dissertation, Georg-Auguns-Universität Göttingen.

Bednaříková, Z., Bavorová, M., & Ponkina, E. V. (2016). Migration motivation of agriculturally educated rural youth: The case of Russian Siberia. Journal of Rural Studies, 45, 99–111.

D’Emden, F. H., Llewellyn, R. S., & Burton, M. P. (2008). Factors influencing adoption of conservation tillage in Australian cropping regions. Australian Journal of Agricultural and Resource Economics, 52(2), 169–182.

Dammann, S., Meinel, T., Beljaev, V. I., & Frühauf, M. (2011). Einfluss verschiedener Bodenbearbeitungsmethoden auf Bodenwasserhaushalt und Pflanzenproduktion in Trockengebieten. Hallesches Jahrbuch für Geowissenschaften, 32(33), 33–48.

D’Emden, F. H., Llewellyn, R. S., & Burton, M. P. (2006). Adoption of conservation tillage in Australian cropping regions: An application of duration analysis. Technological Forecasting and Social Change, 73, 630–647.

FAO. (2015). What is conservation agriculture? Retrieved September 2, 2018 http://www.fao.org/ag/ca/1a.html.

Fowler, R., & Rockstrom, J. (2001). Conservation tillage for sustainable agriculture: An agrarian revolution gathers momentum in Africa. Soil and Tillage Research, 61(1), 93–108.

Frühauf, M. (2013). KULUNDA—How to prevent the next “Global Dust Bowl”? Retrieved August 5, 2016 http://www.youtube.com/watch?v=1E3kpFIQTWA.

Fuglie, K. O., & Kascak, C. A. (2001). Adoption and diffusion of natural-resource-conserving agricultural technology’. Review of Agricultural Economics, 23, 386–403.

Giller, K. E., Witter, E., Corbeels, M., & Tittonell, P. (2009). Conservation agriculture and smallholder farming in Africa: The heretics’ view. Field Crops Research, 114(1), 23–34.

Gray, R. S., Taylor, J. S., & Brown, W. J. (1996). Economic factors contributing to the adoption of reduced tillage technologies in central Saskatchewan. Canadian Journal of Plant Science, 76(4), 661–668.

Hanemann, W. M. (1991). Willingness to pay and willingness to accept: How much can they differ? The American Economic Review, 81(3), 635–647.

Hernanz, J. L., Giro´n, V. S., & Cerisola, C. (1995). Long-term energy use and economic evaluation of three tillage systems for cereal and legume production in central Spain. Soil and Tillage Research, 35(4), 183–198.

Karakulev, V. V., Bakirov, F. G., & Vibe, V. D. (2004). Effektivnost’ resursosberegayushchikh sistem osnovnoy obrabotki pochvy pri vozdelyvanii yarovoy pshenitsy (Vol. 4, pp. 14–16). Orenburg: Izvestiya Orenburgskogo gosudarstvennogo agrarnogo universiteta.

Kassam, A., Friedrich, T., Derpsch, R., & Kienzle, J. (2015). Overview of the worldwide spread of conservation agriculture. Field actions science reports. The Journal of Field Actions Science Reports, 8, 1–11.

Knowler, D., & Bradshaw, B. (2007). Farmers’ adoption of conservation agriculture: A review and synthesis of recent research. Food Policy, 32(1), 25–48.

Llewellyn, R. S., D’Emden, F. H., & Kuehne, G. (2012). Extensive use of no-tillage in grain growing regions of Australia. Field Crops Research, 132, 204–212.

Llewellyn, R., & D’Emden, F. (2010). Successful adoption down under. In W. Lindwall & B. Sonntag (Eds.), Landscape transformed: The history of conservation tillage and direct seeding (pp. 163–172). Saskatoon: Knowledge Impact in Society.

López, M. V., Sabre, M., Gracia, R., Arrúe, J. L., & Gomes, L. (1998). Tillage effects on soil surface conditions and dust emission by wind erosion in semi-arid Aragón (NE Spain). Soil & Tillage Research, 45, 91–105.

Markovskaya, G. K., & Yudina, V. (2009). Vliyaniye razlichnykh sposobov osnovnoy obrabotki pochvy na yeye biologicheskuyu aktivnost’ v usloviyakh lesostepnoy zony samarskoy oblasti. Dostizheniya Nauki i Tekhniki APK, 3, 21–23.

Meinel, T., 2002. Die geoökologischen Folgewirkungen der Steppenumbrüche in den 50er Jahren in Westsibirien. Ein Beitrag für zukünftige Nutzungskonzepte unter besonderer Berücksichtigung der Winderosion. Dissertation, Martin-Luther-Universität Halle-Wittenberg.

Meinel, T. (2012). Major trials KULUNDA 2013–2017. Unpublished.

Meyer-Aurich, A., Janovicek, K., Deen, W., & Weersink, A. (2006). Impact of tillage and rotation on yield and economic performance in corn-based cropping systems. Agronomy Journal, 98(5), 1204–1212.

Ozpinar, S., & Ozpinar, A. (2011). Influence of tillage and crop rotation systems on economy and weed density in semi-arid region. Journal of Agricultural Science and Technology, 13, 769–784.

Pannell, D. J., Llewellyn, R. S., & Corbeels, M. (2014). The farm-level economics of conservation agriculture for resource-poor farmers. Agriculture, Ecosystems & Environment, 187, 52–64.

Polyanskaya, N. A. (2012). Povysheniye effektivnosti proizvodstva zerna na osnove resursosberegayushchikh tekhnologiy. Vestnik NGIEI, 5, 77–93.

Pykhtin, I. G., & Gostev, A. V. (2012). Sovremennyye problemy primeneniya razlichnykh sistem i sposobov osnovnoy obrabotki pochvy. Dostizheniya nauki i tekhniki APK, 1, 3–5.

Raper, R. L., Reeves, E. W., Burt, E. C., & Torbert, H. A. (1994). Conservation tillage and traffic effects on soil conditions. Transaction of the ASAE, 37(3), 763–768.

REESTR. (2012–2015). Reestr selskohozyaystvennyih predpriyatiy. 2012-2015. Upravlenie selskogo hozyaystva Altayskogo kraya. (Reestr of Agricultural Enterptises in Altai Krai. The Main Department of Agrikulture in Altai Krai). Retrieved July 24, 2019 http://www.altagro22.ru/management/docs/?ELEMENT_ID=52075.

Rosagroleasing. (2015). Yediny prays list na tekhniku po federal’nomu lizingu. Retrieved November 4, 2018 www.rosagroleasing.ru.

ROSSTAT. (2019). Federalnaya sluzhba gosudarstvennoy statistiki. Edinaya mezhvedomstvennaya informatsionno – statisticheskaya sistema (EMISS). (Federal State Statistics Service. United Informational Statistics System). Retrieved July 24, 2019 http://www.gks.ru/wps/wcm/connect/rosstat_main/rosstat/ru/statistics/databases/emiss/.

Rusinamhodzi, L., Corbeels, M., van Wijk, M., Rufino, M. C., Nyamangara, J., & Giller, K. E. (2011). A meta-analysis of long-term effects of conservation agriculture on maize grain yield under rain-fed conditions. Agronomy for Sustainable Development, 31(4), 657–763.

Sánchez-Girón, V., Serrano, A., Hernanz, J. L., & Navarrete, L. (2004). Economic assessment of three long-term tillage systems for rainfed cereal and legume production in semiarid central Spain. Soil and Tillage Research, 78(1), 35–44.

Sergienko, A.M., Anisimova, M.M., Ivanova, O.A., Perekarenkova, Y.A., Rzaeva, S.V., Reshetnikova S.A., & Rodionova, L.V. (2013). Bednost celskoy Rosii v usloviyach modernizacii ekonomiki: Processy i mechanizmy formirovaniya i preodoleniya. Barnaul.

Shibaeva, E. E. (2012). Russian village in the thick of the demographic crisis: Political aspect. Teoriya i Praktika Obshestvenogo Razvitiya, 9, 198–200.

Singer, J. W., Chase, C. A., & Kohler, K. A. (2010). Profitability of cropping systems featuring tillage and compost. Agronomy Journal, 102(2), 450–456.

Smart, J. R., & Bradford, J. M. (1999). Conservation tillage corn production for a semiarid, subtropical environment. Agronomy Journal, 91(1), 116–121.

Thomas, G. A., Titmarsh, G. W., Freebairn, D. M., & Radford, B. J. (2007). No-tillage and conservation farming practices in grain growing areas of Queensland–a review of 40 years of development. Animal Production Science, 47(8), 887–898.

Ward, B., Smith, D., Shaw, G., Haak, D., & Fredette, J. (2010). Policy and program response to land management issues. In C. Lindwall & B. Sonntag (Eds.), Landscapes transformed: The history of conservation tillage and direct seeding (pp. 15–22). Saskatchewan: Knowledge Impact in Society.

Weersink, A., Walker, M., Swaton, C., & Shaw, J. E. (1992). Cost of conventional and conservation tillage systems. Journal of Soil and Water Conservation, 47(4), 328–334.

Zentner, R. P., Lafond, G. P., Derksen, D. A., & Campbell, C. A. (2002). Economics of crop diversification and soil tillage opportunities in the Canadian prairies. Agronomy Journal, 94(2), 216–230.

Acknowledgements

The authors would like to thank Dr. Tobias Meinel and Lars Grünwald (experts on introduction of no-till system from the agricultural machinery manufacturer Amazon in Kazakhstan and Russia and co-founders of farmers’ extension organization on reduced till introduction in Altai Krai) as well as Prof. Belayev (professor from the Farm Mechanization Department at the Agrarian University in Barnaul and co-founder of farmers’ extension organization on reduced till introduction in Altai Krai) for their valuable estimations. Without their knowledge input, this analysis would not have been possible. The authors acknowledge the KULUNDA Project, part of the BMBF research program ‘Sustainable Land Management’, for completion of this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Rights and permissions

About this article

Cite this article

Bavorova, M., Ponkina, E.V., Imamverdiyev, N. et al. Effect of adoption of sustainable crop production systems on farm economics. Environ Dev Sustain 22, 6961–6984 (2020). https://doi.org/10.1007/s10668-019-00522-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-019-00522-1