Abstract

The accumulation of dust pollution on the photovoltaic (PV) module can have a significant effect on the productivity and efficiency of PV systems in different locations in the world. Dust which accumulated over time on the PV module and is based on weather conditions led to the reduction in the effectiveness of solar cells. The aim of this research was to experimentally investigate the effect of the natural dust and the effects of environmental parameters on PV performance. The experiments were conducted to propose a model for the current, voltage, power and efficiency and to simulate the effect of environmental parameters on PV performance. The natural dust investigated consisted of different compounds: SiO2 (45.53 %), CaO (24.62 %), Al2O3 (10.83 %), Fe2O3 (10.46 %), MgO (6.33 %), K2O (0.87 %), TiO2 (0.45 %), SO3 (0.24 %), MnO2 (0.21), Cr2O3 (0.23 %), SrO (0.13 %) and NiO (0.09 %). It was found that the most accurate correlation is a polynomial from seventh degree for current, voltage, power and efficiency, fourth degree for solar radiation and temperature, cubic degree for humidity and wind velocity. The coefficients of general model are 0.6343, 0.0110, 0.0 and 0.0001 for PV module, respectively, with 0.0011 fitting factor. The proposed model has been validated using models in the literature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Energy is a prerequisite in the construction and development operations. The request for energy is necessary for the development of growth at a quicker rate in the future, partly due to the intensifying increase in the world’s population. The production of energy can be divided into three types: fossil fuels, nuclear resources and renewable resources. Photovoltaic systems are one of the renewable energy resources which include the wind, biomass, hydropower and geothermal (Manzano-Agugliaro et al. 2013). Photovoltaic systems as part of renewable energy play a significant role in terms of paying for the move toward low-carbon development growth to reduce greenhouse gas emissions increasing technology diversification and hedging any opposition to fuel price instability by increasing supply adequacy (Gupta and Purohit 2013).

A PV cell is a simple device that can directly convert sunlight into electrical energy. Direct methods of conversion of solar energy into electrical energy avoid the creation of pollutants through processes and reduce global warming. A significant increase in the petrochemical fuels price and a rapid decrease in the price of the solar cell caused increments in the demand for PV systems. Previously, in contrast, PV systems were considered attractive only for special applications in remote and isolated areas. At present, many countries are interested in this technology as a result of the simple and easy way in which they can be setup (Lo Brano et al. 2010). PV modules operate in an outdoor environment with numerous fluctuations in wind, ambient temperature, irradiation intensity, humidity and dust pollutants. These factors lead to deterioration in the output power of the PV modules (Jiang et al. 2012). The dust pollution effect strongly depends on the local area where the PV system is mounted and site’s local environmental conditions (i.e., climate), so it is hard to apply a general model in all cases (Kaldellis and Kapsali 2011; Darwish et al. 2015; Said and Walwil 2014; Sayyah et al. 2014). Dust is the term referring to particulate contaminate with the diameter <500 µm (Mani and Pillai 2010). The impact of dust appears in various places in the world, usually during the summer when huge quantities of dust and sand are raised and carried by the dry fresh wind. Deserts surrounds most of the Arab Gulf states such as the United Arab Emirates, Kingdom of Saudi Arabia, Oman, Qatar Bahrain and Kuwait which are covered lands’ surfaces with sediment limestone loose, which is a mixture of gravel, sand, silt and clay. Territories of these countries lack the protective cover of vegetation, and besides they are also vulnerable to strong winds (Saidan et al. 2016). Dust storms in these countries are the big challenge which is reflected in the PV performance. So the dust deposition on the surface of the PV modules reduces the amount of incident radiation on the panel and creates a shadow. It means when the dust accumulation increases, the power of electricity generation reduces. This reduction depends on the dust properties, e.g., size of the dust particle, density and type of dust deposited (Rao et al. 2014; Urrejola et al. 2016; Kaldellis and Kokala 2010; Kaldellis et al. 2011; Kumar and Chaurasia 2014; Mohamed and Hasan 2012; Molki 2010). El-Shobokshy and Hussein were among the pioneers investigating the effect of the physical and chemical properties of dust particles on the PV modules. In their study, the experiment was conducted with artificial dust including cement, limestone and carbon particulates (El-Shobokshy and Hussein 1993). The study shows the effect of cement particles to be the most important, deposition of cement with a 73 g/m2 deposition resulting in an 80 % drop in PV short- circuit voltage. Many studies conducted in Arab Gulf focus on the effect of dust using different solar energy technologies. Sayigh et al. (1985) in 1985 studied effects of the dust on a photovoltaic panel located in Kuwait and found the reduction in power of 2, 14 and 30 % after one, thirteen and thirty-two days, respectively, without cleaning the surface of the panel. Nimmo et al. (1981) found the efficiency reduction of 26 and 4 % from the solar collector and PV module, respectively, after six months in Saudi Arabia. A study on the effect of sand dust deposition on PV glass conducted by Hassan and Sayigh (1992) for six months found the efficiency of 33.5 and 65.8 % after one month and six months, respectively. El-Nashar (2003, 2009) studied the impact of dust acclamation on solar collector at the United Arab Emirates for one year and found that the transmittance reduced from 0.98 to 0.7 and the power of dusty surface reduced between 14 and 18 %. Precisely, dust caused reduction in output power from PV between 2 and 50 % in different areas (Maghami et al. 2016). The main objective of this work is to study the effect of natural dust pollutant type on the performance of solar PV module. Most of the studies conducted previously neglected the components of the dust, which vary from one area to another. Also, to propose an accurate model, the effect of environmental parameters on PV performance based on experimental data should be taken into consideration.

2 Methodology

2.1 Dust properties

The first step is to collect and analyze the dust sample from the location. For this purpose, dust which accumulated on a horizontal glass surface for the period from the beginning of September 2013 to the end of December 2013 was collected. The studied dust was collected from Sharjah City in the United Arab Emirates, the location in Wadi Al Helo, which lies near the border of Oman. The location is an agricultural area relying on the clean water free of salt (no salt water). Then, the sample was subject to milling for the purpose of obtaining a homogeneous sample. A Retsch PM100 ball mill instrument has been used for this purpose.

Mineralogical analysis of dust particulates collected in glass cups has been performed by X-ray diffraction (XRD) (Bruker D8 Advance) and X-ray fluorescence (XRF) (Horiba XGT-7200). An analysis was conducted to provide qualitative and quantitative materials characterization for detection and analysis. Table 1 illustrates testing and measuring instruments used in this study. The main results achieved from the study XRF are depicted in Fig. 1. The sample of dust was analyzed and found to consist of different compounds. The compounds are SiO2 (45.53 %), CaO (24.62 %), Al2O3 (10.83 %), Fe2O3 (10.46 %), MgO (6.33 %), K2O (0.87 %), TiO2 (0.45 %), SO3 (0.24 %), MnO2 (0.21 %), Cr2O3 (0.23 %), SrO (0.13 %) and NiO (0.09 %).

2.2 Monitoring system

Different sensors, data acquisition and accessories have been used in monitoring systems for these experiments. The monitoring system comprised the following sets of units:

-

Data Acquisition System: 16 Analogue Channels, REAM—(4–20 mA, 0–5 V, 0–10 V and 0–24 V).

-

Computer: Dual-Core Atom, NISE 104—D2550 1.86 GHz, 2 GB RAM, 32 GB SSD 17″ IP65 1024 × 768 Touch Screen.

-

Software: DART (Data Acquisition Real Time).

-

Solar radiation transmitter detector: WE300—Rugged (4–20 mA). Range: 0–1500 W/m2; spectral response: 400–1100 nm; 75-ft cable.

-

PV Panel backside surface temperature sensor: WE710, type: 100 Ohm.

-

Platinum class a RTD: Output: 4–20 ma, (−50 to +85 °C), Accuracy: ±0.5 °f (±0.25 °C); 75-ft. cable.

-

Air temperature sensor: WE700 + WE770, with solar shield temperature sensor type: precision RTD, output: 4–20 mA, range: −50 to +50 °C, 75-ft. cable.

-

CTH Current Transformer—Through Hole Core Type 1-DC (20A)—Output 4–20 mA.

-

PTH Potential Transformer: Output 12–40 V.

The system was used to monitor the voltages and currents of the one PV system. Also, solar radiation, temperature and back panel temperature sensors have been used for weather measurements. The monitoring system records the measurements which take place every second.

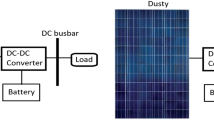

2.3 PV module

The PV module was connected to monitoring by a cable and mounted on the roof of the Faculty of Engineering—Sohar University in Oman (see Fig. 2), and the panel was adjusted to a 27° optimum tilt angle as claimed by the author (Kazem et al. 2013). It is worth mentioning that Oman’s latitude and longitude are 21°00′N and 57°00′E, and Sohar s’ latitude and longitude are 24°20′N and 56°40′E. One PV module of the array was tested in this experiment; the final setup of this system is shown in Fig. 3. The collected dust has been used in these experiments. The parameters of the polycrystalline module are given in Table 2.

2.4 Data collection

The global solar radiation for Sohar City is shown in Fig. 4 for horizontal plane. The annual average of solar radiation in this area is 5.59 KhW/m2/day. The lower values of solar radiation were observed in November, December and January, while the maximum values were observed in May, June and July. This information about solar radiation in this city is very important to design solar PV systems. So the experiments were conducted every day for 150 min and repeated at the same time for three months from May to July, and average of the data has been taken.

3 Results and discussion

3.1 Environmental parameters

The reduction in the performance of the PV module is due to the dust accumulation on its surface. Many environmental conditions caused the dust particles to vary in phase, sort and chemical and physical properties. Climate conditions such as wind speed, air temperature and humidity play a significant role in defining accumulated dust and how it will be deposited the cell (Darwish et al. 2013; Ahmed et al. 2013).

Figure 5 shows the changes in wind speed, temperature, solar radiations and humidity during the experiment with time. It was found that the wind speed changed randomly between 2.5 and 5 m/s. Relative humidity ranged from 79.8 to 84.4 %. Also, it was found that the temperature ranged between 31.7 and 32 °C, while the solar radiation increased from 697 to 713 W/m2.

4 Effect of dust on current, voltage, power and efficiency

The impact of the natural dust added on PV system caused by variables such as current, voltage, power and efficiency was investigated. The masses of the naturally added dust on the surfaces of PV module were collected and measured by the monitoring system. Dust masses added ranged 10–100 g (11.11–111.11 g/m2) during the period from 11 AM to 13:30 PM; the time between two readings was about 13.63 min. All the data were recorded by data acquisition; the experiment was repeated every day at the same time for three months, and then the average of readings has been taken. Figure 6 shows the quantity of the added mass density of dust pollution on the surface of the PV module as a function of time. The field test declared that the dust added during the date of experiment period amounted to about 100 g (111.11 g/m2).

Figure 7a, b presents the variation of current (I), voltage (V), power (P) and efficiency (E) with different dust deposition densities. The outcomes obtained from these data defined the highest values of current and voltage as 4.23 A and 16.4 V representing the clean PV module case. However, the power and efficiency were found to be 69.5 W and 11.1 %, respectively.

Figure 8 illustrates the normalized current I Polluted /I Clean and voltage V Polluted /V Clean of the module for different dust deposition densities. For the dust deposition, mass varied from 0 to 10 g/m2, the reduction in current was 6 %, and the reduction in voltage was 2 %. The maximum reduction in current is 10 %, while that in the voltage is 7 % during the period of the experiment. Table 4 illustrates data statistics for normalized current and voltage. Figure 9 depicts the decrease in the output efficiency with different masses added to the surface of the PV module. The normalized efficiency reduction was calculated using the following equation:

where E clean and E polluted represented the output efficiencies of PV module before the dust was added and after it, respectively. It was found that when the dust accumulation mass increased from 0 to 100 g, the resultant of output efficiency increased from 0 to 18 %. Dust accumulation has a significant impact on the produced performance of PV module. Furthermore, in nature, the dust accumulated randomly on the PV module surface and varied from one cell to another, so this led to the nonhomogeneous distribution of dust among the cells. It means that the difference in the reduction in solar cells productivity and then in the PV module is not clear. The correlation between reduction in PV module efficiency and dust mass added was found to be linear by fitting the normalized data of efficiency with different dust deposition masses, as in Fig. 9. The correlation is represented by linear equation:

where k is the fitting factor for the module and is equal to 0.0011 and d is the dust deposition density.

Jiang et al. (2011) evaluated the reduction in efficiency for three types of PV: monocrystalline silicon (mono-c), polycrystalline silicon (poly-c) and amorphous silicon (a-Si). The fitting factor k was used for the fine test dust (ISO 12103-1 A2, Powder Technology Inc.). The fitting factor k is 0.0115, 0.015 and 0.0139 for mono- c, poly-c and a-Si, respectively. Although the differences among the three modules are not distinct, polycrystalline module shows relatively the highest trend of efficiency reduction and amorphous module contributes to the lowest as in Fig. 10.

Variation of output efficiency calculated by Jiang (Saidan et al. 2016)

Jiang conducted the fitting of experiment data using the equation:

Both Eqs. 2 and 3 show the trend of increase in the reduction in efficiency with increase in the dust deposition densities. Figure 11 displays a comparison between the present work and Jiang experiments using both equations. There is a significant difference in the slope which means that there is a difference in the reduction in the efficiency of the present work and Jiang experiment results. These differences refer to variations in the size of panels and surface material. Other parameters affecting the efficiency are irradiance, ambient temperature, the period of test and dust deposition densities. Different polynomials have been proposed for PV module current, voltage, power and energy based on experimental results.

where d is the density mass (mass/area) of the dust added on the surface of PV module and a 0 to a 10 are the coefficients of the polynomial, and all the values are mentioned in Appendix.

Curves (a, b, c and d) in Fig. 12 depict a comparison between correlation equation and experimental study of current, voltage, power and efficiency. It was found that there is a mismatch between the theoretical and practical results, which is clearly given in Table 3.

With respect to finding a correlation between environment variable, solar radiation, humidity, temperature and wind velocity as a function of time, it was difficult to choose the equation of fitting. The problem refers to the polynomial which is roughly conditioned. As a result, too high sensitive random errors appeared. So improving the accuracy of the proposed model is useful to convert the predictors by normalizing their center and scale, which is presented by computing the z-scores.

where x is the predictor data, μ is the mean of x, and σ is the standard deviation of x. The data are centered at 0, with a standard deviation of 1. After centering and scaling, model coefficients are computed from the data of solar energy (S), humidity (H), temperature (T) and wind velocity (W) as a function of z in the following equations:

where z is centered and scaled and the coefficients p 1 = 1.2576, p 2 = 0.53679, p 3 = −4.6739, p 4 = 4.4524, p 5 = 709.22, mean = 11.264 and standard deviation = 0.11039.

where p 1 = −0.048484, p 2 = 0.61003, p 3 = 0.81529, p 4 = 80.001, mean = 11.264 and standard deviation = 0.11039.

where p 1 = −0.078217, p 2 = −0.055051, p 3 = 0.097972, p 4 = 0.070728, p 5 = 31.926, mean = 11.264 and standard deviation = 0.11039.

where p 1 = 0.80949, p 2 = 0.16959, p 3 = −0.99148, p 4 = 3.6986, mean = 11.264 and standard deviation = 0.11039.

The curves (a, b, c and d) in Fig. 13 show the solar energy, humidity, temperature and wind velocity calculated from proposed model equations compared with experiment results. Table 4 proves the success of the correlations for solar radiation, humidity, temperature and wind velocity that have been processed by z-score.

To check the validity of Eqs. 9, 10, 11 and 12 which are related to Fig. 12 and depending on the information in Table 4, the R-square statics can measure the closeness of the association between the measured and calculated values for solar energy, humidity, temperature and wind velocity. It was found that the R-square for solar radiation between measured and calculated values is 0.9434, humidity = 0.9399, temperature = 0.6156 and wind velocity = 0.1337.

The second attempt to build a model was to find a relationship between the efficiency of the PV module and some environment factors such as solar radiation and temperature. The simulation of the aforementioned random variables means the success of the correlation. The simulation of these elements gives more relying power on the current and voltages. The model will be based on the data in Table 5 or the data from the correlations that were used for comparison with the results of the experiment.The multiple linear regressions can be readily used to fit data in Table 5 to higher-order polynomial, and the matrix form could be used as follows

where

a represents the coefficients of the equation in the final model to calculate the efficiency in the following equation.

where d is the density of mass, S solar radiation and T ambient temperature. This model is simple to justify a reduction in efficiency according to random changes in the temperature and solar irradiance beside the dust. The model was tested by the experimental data and correlation data. It was found that the results of the proposed model are acceptable when compared to experimental results. The data deduced from the correlation equation for efficiency are listed in Table 6.

4.1 Model validation and comparison with the literature

The focus was on finding the correlation between eight parameters in the previous section. Four parameters: current, voltage, power and efficiency, are related directly to the PV performance, and other parameters: solar radiation, humidity, ambient temperature and wind velocity, are associated with the environment factors . All correlations succeeded in simulating eight paraThe model in meters as a function of dust deposition density and time according to scientific criteria as ordinary residuals, mean, the standard deviation of data and minimum value and the maximum value of data. According to these criteria, a high-degree polynomial for four parameters was chosen to avoid the random errors. While a lower-degree polynomial was selected for environment parameters because it is very sensitive to random errors. It was found in the literature that researchers used the same correlation but did not mention the criteria that lead to the selection of polynomial degree. Benatiallah et al. (2012) used three correlations to simulate the dust deposition density on the current, power and efficiency as follows.

It was found that these models are valid only for small values for dust deposition density. As an example, when d = 10 g/m2 degree, the current is (−24.7 A), power = −222.57 W and the efficiency = −0.57. These results are abnormal, and the selection of the degree of the polynomial in each was not subjected to the standards previously mentioned. When using Eqs. 4, 6 and 7 to calculate current, power and efficiency with the same value of d = 10 g/m2, the results were found to be positive and accurate. So, this outcome promotes all our equations which were selected to simulate the current, power and efficiency.

The model in Eq. (15) correlates the solar radiation, temperature and the dust deposition density with the efficiency of PV model. Naturally, it is associated with the relative humidity, but the real condition is more complicated. For example, low relative humidity and high temperature usually alternate with periods of much lower temperature and higher relative humidity on a daily cycle (Brown et al. 2012). For this purpose, the model in Eq. (15) was examined by making some changes. When the time was replaced instead of dust deposition density and solar radiation by humidity, the model became as follows:

where t is time (sec), T temperature (°C) and H relative humidity (%).

The proposed model has been tested with data held in a desert environment in Qatar State (Touati et al. 2012; 2013), and the results were found to be satisfactory to confirm the success of the proposed model as in Table 7.

Table 7 shows the comparison between efficiency for two types of photovoltaic systems: monocrystalline PV and semiflexible PV measured in Qatar and the proposed model. It was found that the values of coefficients for the model are: a(1) = 0.6343, a(2) = 0.0110, a(3) = 0.0 and a(4) = 0.0001 for monocrystalline PV and for semiflexible are: a(1) = 0.1057, a(2) = 0.0293, a(3) = 0.0 and a(4) = −0.0001.

5 Conclusions

This study investigated the effect of dust pollutant accumulation on photovoltaic performance. Outdoor experiments used natural dust that contains MgO, Al2O3, SiO2, SO3, K2O, CaO, TiO2, Cr2O3, MnO2, Fe2O3, NiO and SrO. The most important conclusions can be summarized as follows:

-

1

A mathematical correlation for eight variables which control the PV performance was proposed. The variables concerned are current, voltage, power, efficiency, solar radiation, humidity, ambient temperature and wind velocity.

-

2

A mathematical simulation model of the efficiency of PV module which was related to some environmental factors such as solar radiation, ambient temperature and dust deposition density was fulfilled. The proposed model proved its success in a desert environment data of practical measurements and tests conducted in Qatar State.

-

3

The study shows that the selected correlation equation to simulate any variable like current, power must be subjected to some standards. From these standards, normal residuals of data, mean, median, minimum and maximum data to reduce the random errors in the coefficient of correlation need to be taken into consideration. When comparing this recent study with the literature, it appeared that choosing a small degree of the polynomial to simulate the current and voltage led to illogical results for high dust deposition density values.

-

4

It has been noted that selecting the polynomial to simulate the correlation of temperature, humidity, solar radiation and wind velocity made the coefficient of the polynomial very sensitive to random errors. So to increase the degree of the polynomial to reduce random errors, we solved this problem by normalizing the center and scale data by computing the z-scores.

-

5

It was found that the correlation between reduction in PV module efficiency and dust deposition density is linear. The linearization is done by fitting the normalized data of efficiency with different dust deposition densities; the fitting factor k was 0.0011. The slope of the linear relationship highly depends on the model accuracy.

-

6

The authors recommended investigating the effect of dust pollutant type separately indoors to know the effect of every kind of pollutant contribution and to evaluate the performance of photovoltaic systems accurately.

References

Ahmed, Z., Kazem, H. A., & Sopian, K. (2013).Effect of dust on photovoltaic performance: Review and research status. Latest Trends in Renewable Energy and Environmental Informatics 193–9.

Benatiallah, A., Ali, A. M., Abidi, F., Benatiallah, D., Harrouz, A., & Mansouri, I. (2012). Experimental study of dust effect in Mult-Crystal PV solar module. International Journal of Multidisciplinary Sciences and Engineering, 3, 3.

Brown, K., Narum, T., & Jing, N. (2012). Soiling test methods and their use in predicting performance of photovoltaic modules in soiling environments. In Photovoltaic Specialists Conference (PVSC), 2012 38th IEEE (pp. 001881-001885).

Darwish, Z. A., Kazem, H. A., Sopian, K., Alghoul, M., & Chaichan, M. T. (2013). Impact of some environmental variables with dust on solar photovoltaic (PV) performance review and research status. Int J Energ Environ, 7(4), 152–159.

Darwish, Z. A., Kazem, H. A., Sopian, K., Al-Goul, M., & Alawadhi, H. (2015). Effect of dust pollutant type on photovoltaic performance. Renewable and Sustainable Energy Reviews, 41, 735–744.

El-Nashar, A. M. (2003). Effect of dust deposition on the performance of a solar desalination plant operating in an arid desert area. Solar Energy, 75, 421–431.

El-Nashar, A. M. (2009). Seasonal effect of dust deposition on a field of evacuated tube collectors on the performance of a solar desalination plant. Desalination, 239, 66–81.

El-Shobokshy, M. S., & Hussein, F. M. (1993). Degradation of photovoltaic cell performance due to dust deposition on to its surface. Renewable Energy, 3, 585–590.

Gupta, S. K., & Purohit, P. (2013). Renewable energy certificate mechanism in India: A preliminary assessment. Renewable and Sustainable Energy Reviews, 22, 380–392.

Hasan, A., & Sayigh, A. (1992). The effect of sand dust accumulation on the light transmittance, reflectance, and absorbance of the PV glazing (pp. 461–466). Oxford: Renewable Energy Technology and the Environment Pergamon Press.

Jiang, H., Lu, L., & Sun, K. (2011). Experimental investigation of the impact of airborne dust deposition on the performance of solar photovoltaic (PV) modules. Atmospheric Environment, 45, 4299–4304.

Jiang, J.-A., Wang, J.-C., Kuo, K.-C., Su, Y.-L., Shieh, J.-C., & Chou, J.-J. (2012). Analysis of the junction temperature and thermal characteristics of photovoltaic modules under various operation conditions. Energy, 44, 292–301.

Kaldellis, J., Fragos, P., & Kapsali, M. (2011). Systematic experimental study of the pollution deposition impact on the energy yield of photovoltaic installations. Renewable Energy, 36, 2717–2724.

Kaldellis, J., & Kapsali, M. (2011). Simulating the dust effect on the energy performance of photovoltaic generators based on experimental measurements. Energy, 36, 5154–5161.

Kaldellis, J., & Kokala, A. (2010). Quantifying the decrease of the photovoltaic panels’ energy yield due to phenomena of natural air pollution disposal. Energy, 35, 4862–4869.

Kazem, Hussein A., Khatib, Tamer, & Sopian, K. (2013). Sizing of a standalone photovoltaic/battery system at minimum cost for remote housing electrification in Sohar, Oman. Elsevier-Energy and Building, 6C, 108–115.

Kumar, S., & Chaurasia, P. (2014). Experimental study on the effect of dust deposition on solar photovoltaic panel in Jaipur. International Journal of Science and Research (IJSR), 3, 1690–1693.

Lo Brano, V., Orioli, A., Ciulla, G., & Di Gangi, A. (2010). An improved five-parameter model for photovoltaic modules. Solar Energy Materials and Solar Cells, 94, 1358–1370.

Maghami, M. R., Hizam, H., Gomes, C., Radzi, M. A., Rezadad, M. I., & Hajighorbani, S. (2016). Power loss due to soiling on solar panel: A review. Renewable and Sustainable Energy Reviews, 59, 1307–1316.

Mani, M., & Pillai, R. (2010). Impact of dust on solar photovoltaic (PV) performance: Research status, challenges and recommendations. Renewable and Sustainable Energy Reviews, 14, 3124–3131.

Manzano-Agugliaro, F., Alcayde, A., Montoya, F., Zapata-Sierra, A., & Gil, C. (2013). Scientific production of renewable energies worldwide: An overview. Renewable and Sustainable Energy Reviews, 18, 134–143.

Mohamed, A. O., & Hasan, A. (2012). Effect of dust accumulation on performance of photovoltaic solar modules in Sahara environment. Journal of Basic and Applied Scientific Research, 2, 11030–11036.

Molki, A. (2010). Dust affects solar-cell efficiency. Physics Education, 45, 456–458.

Nimmo, B., & Said, S. A. (1981). Effects of dust on the performance of thermal and photovoltaic flat plate collectors in Saudi Arabia-Preliminary results. In Alternative energy sources II (Vol. 1, pp. 145–152).

Rao, A., Pillai, R., Mani, M., & Ramamurthy, P. (2014). Influence of dust deposition on photovoltaic panel performance. Energy Procedia, 54, 690–700.

Said, S. A., & Walwil, H. M. (2014). Fundamental studies on dust fouling effects on PV module performance. Solar Energy, 107, 328–337.

Saidan, M., Albaali, A. G., Alasis, E., & Kaldellis, J. K. (2016). Experimental study on the effect of dust deposition on solar photovoltaic panels in desert environment. Renewable Energy, 92, 499–505.

Sayigh, A., Al-Jandal, S., & Ahmed, H. (1985). Dust effect on solar flat surfaces devices in Kuwait. In Proceedings of the workshop on the physics of non-conventional energy sources and materials science for energy (pp. 2–20).

Sayyah, A., Horenstein, M. N., & Mazumder, M. K. (2014). Energy yield loss caused by dust deposition on photovoltaic panels. Solar Energy, 107, 576–604.

Touati, F., Al-Hitmi, M., & Bouchech, H. (2012). Towards understanding the effects of climatic and environmental factors on solar PV performance in arid desert regions (Qatar) for various PV technologies. In Renewable Energies and Vehicular Technology (REVET), 2012 First International Conference on (pp. 78–83).

Touati, F., Massoud, A., Hamad, J. A., & Saeed, A. (2013). Effects of environmental and climatic conditions on PV efficiency in Qatar. Renewable Energy and Power Quality Journal, ISSN.

Urrejola, E., Antonanzas, J., Ayala, P., Salgado, M., Ramírez-Sagner, G., Cortés, C., et al. (2016). Effect of soiling and sunlight exposure on the performance ratio of photovoltaic technologies in Santiago, Chile. Energy Conversion and Management, 114, 338–347.

Acknowledgments

The research leading to these results has received Research Project Grant Funding from the Research Council of the Sultanate of Oman, Research Grant Agreement No. ORG SU EI 11 010. The authors would like to acknowledge support from the Research Council of Oman. The authors would like to thank Mr Mohammed Shameer, the supervisor of X-ray center for material analysis at the University of Sharjah in U.A.E, for assisting in the analysis of dust samples. Finally, thanks go to Mr Miqdam T Chaichan from University of Technology, Iraq.

Author information

Authors and Affiliations

Corresponding author

Appendix A

Appendix A

See Table 8.

Rights and permissions

About this article

Cite this article

Darwish, Z.A., Kazem, H.A., Sopian, K. et al. Experimental investigation of dust pollutants and the impact of environmental parameters on PV performance: an experimental study. Environ Dev Sustain 20, 155–174 (2018). https://doi.org/10.1007/s10668-016-9875-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-016-9875-7