Abstract

The contamination of food commodities with mycotoxins could be a serious health threat to humans and animals. Therefore, identification, quantification and reduction of mycotoxins in food commodities, particularly of aflatoxins (AFs) and ochratoxin A (OTA) in grain foods, is essentially required to guarantee safe food. This study determined the levels of AFs and OTA in 135 maize grains samples belonging to eight salient maize varieties cultivated in Pakistan, and evaluated the usefulness of radiations and adsorbents to reduce their levels. High performance liquid chromatography (HPLC)-based method was validated for the determination of AFs and OTA in maize grains. The results showed that 69 and 61% samples were positive for AFs and OTA, respectively and 54 and 22% of the respective samples had AFs and OTA above the permissible limits set by Pakistan Standards and Quality Control Authority. The concentration of AFs, AFB1and OTA in grains ranged from 14.5 to 92.4, 1.02 to 2.46 and 1.41 to 53.9 μg kg−1, respectively. Among the varieties, Pearl had the highest level of total AFs and OTA, whereas YH-5427 had the highest AFB1 level. The lowest concentration of AFs and OTA was found in Malaka and 30Y87, respectively. The use of 15 kGy gamma irradiation for 24 h, sunlight-drying for 20 h and UV irradiation for 12 h almost completely degraded the mycotoxins. The microwave heating for 120 s resulted in 9–33% degradation of mycotoxins. Moreover, the treatment of grains’ extract with activated charcoal (5% w/w) removed > 96% of total AFs and AFB1, and up to 43% of OTA. The use of bentonite at the same rate removed OTA, total AFs and AFB1 by 93, 73 and 92%, respectively. Thus, it is concluded that contamination of maize grains with mycotoxins was fairly high in the collected maize grain samples in Pakistan, and treatment with radiations and adsorbents can effectively reduce mycotoxins contamination level in maize grains.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pakistan is among many countries with a climate of high temperatures and humidity. These conditions favor the growth of mycotoxigenic molds and the production of mycotoxins in food. Molds can contaminate food grains with mycotoxins at pre- and post-harvest stages and subsequently under poor storage conditions. Among the molds, the filamentous fungi are considered responsible for the occurrence of mycotoxins which are naturally occurring secondary metabolites (Hassan et al., 2020; Iqbal et al., 2016). About 500 mycotoxins have been identified in food commodities, of which a few are seriously hazardous to humans and livestock (Awuchi et al., 2021). Among the most common mycotoxins present in food commodities are aflatoxins (AFs) and ochratoxin A (OTA), which are mainly produced by Aspergillus flavus and Aspergillus parasiticus, respectively (Novas & Cabral, 2002). The aflatoxin B1 (AFB2), aflatoxin B2 (AFB2), aflatoxin G2 (AFG1), and aflatoxin G2 (AFG2) are the four most important types of naturally produced AFs in several crops, foods, feeds, and agricultural products (Ashiq, 2015; De Ruyck et al., 2015; Hassan et al., 2020). AFs are classified as group 1 carcinogens by the International Agency for Research on Cancer (IARC). Moreover, AFs are teratogenic, immunosuppressant and genotoxic (IARC, 1993). The other important mycotoxin is OTA that is produced in cereals by the species of Aspergillus and Penicillium. OTA has been reported as genotoxic, mutagenic, cytotoxic, immunotoxin, teratogenic, and carcinogens (Calado et al., 2018). Therefore, control of mycotoxigenic molds and their mycotoxins in food commodities is of utmost importance: contamination levels must be in the limits of the national and international public health authorities.

The high temperature and humid conditions are the main environmental factors accelerating fungal infection and mycotoxin production (Nesic et al., 2015). The tropical environment of the subcontinent facilitates higher production of AFs and OTA. The rest of mycotoxins such as zearalenone, deoxynivalenol, and T-2 toxins are mostly produced in the temperate regions of the world (Mgbeahuruike et al., 2018). The optimum temperature and relative humidity for the occurrence of AFs are 33 °C and 0.99, and for OTA are 25–30 °C and 0.98, respectively (Milani, 2013). In Pakistan, high temperature, air moisture content and abrupt changes in weather provide a conducive environment for the spread of molds in food crops and their derived products (Iqbal et al., 2016). AFs and OTA have been detected in different cereals of the country including maize (Hassan et al., 2020; Iqbal et al., 2014; Majeed et al., 2013). Maize, which is the 3rd important cereal and 4th largest crop in Pakistan, get contaminated with mycotoxins at pre-harvest and post-harvest stages (Iqbal et al., 2016; Shah et al., 2010). The maximum permissible levels for total AFs, AFB1 and OTA set by Pakistan Standards and Quality Control Authority (PSQCA) and Food and Drug Administration (FDA) are 20, 10 and 20 µg kg−1, respectively (Alexander et al., 2006; Hassan et al., 2020; Makun et al., 2013). However, information regarding total AFs, AFB1 and OTA contents in grains of popular maize varieties at the time of harvest is lacking.

To reduce mycotoxin production and avoid the resulting adverse effect, several types of management measures, such as good agricultural practices, ideal storage conditions and the establishment of legislative limits in cereal grains and feed, have been evaluated (Streit et al., 2012). Different chemical and physical approaches have been employed to reduce levels of mycotoxins in food commodities worldwide (Sarrocco & Vannacci, 2018; Tsitsigiannis et al., 2012). However, chemical treatment of food commodities for mycotoxin removal has low decontamination efficiency (Maxwell et al., 2006). Also does not have a good repute among the scientific community and traders due to the residual effects of the used chemicals including chlorine, hydrogen peroxide, ozone, and bisulfite. In spite of the substantial efforts, complete avoidance of mycotoxin contamination in agricultural commodities has been found impossible. Thus, it is necessary to develop some practicable and effective decontamination techniques. In this regard, employment of physical methods is thought to be the most efficient post-harvest technique to reduce the mycotoxins in food during storage (Karlovsky et al., 2016). One of the most widely used physical practices for mycotoxins reduction is food irradiation (Calado et al., 2014; Di Stefano et al., 2014; Domijan et al., 2019). Irradiation is a safe and effective alternative to chemical treatments for the decontamination of microorganisms and reduction of mycotoxin levels in food and feed (Sebaei et al., 2020). Food irradiation technology is approved and endorsed as a secure and efficient procedure for food processing by World Health Organization (WHO, 1999). Also several adsorbents are used for the reduction of mycotoxins in food commodities (Gan et al., 2019).

Keep in view the above discussion, the current study was planned to determine the levels of AFs and OTA in grains of maize different varieties cultivated in Pakistan, and to evaluate the usefulness of irradiation technique and adsorbents to reduce the level of these mycotoxins in maize grains. We hypothesized that maize grains are significantly contaminated with AFs and OTA, and that application of radiation technique can effectively decontaminate the grains from these mycotoxins.

Materials and methods

Chemicals and reagents

The reference standards of mycotoxins (AFB1, AFB2, AFG1, AFG2, and OTA) and immunoaffinity columns (MycoSep 226 and MycoSep 229) were obtained from Romer Labs (Union, MO, USA). The acetonitrile (HPLC grade), methanol (HPLC grade), trifluoroacetic acid (CAS No. 76–05-1), bentonite (CAS No. 1302–78-9, B-3378), and activated charcoal (CAS No. 7440–44-0, C-2764) were purchased from Sigma-Aldrich (Spruce St. Louis, Missouri, USA).

Collection of maize grain samples

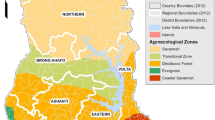

Maize grain samples of eight varieties, including Pearl (n: 15), MMRI yellow (n: 12), Malaka (n: 15), DK-6789 (n: 19), YH-5427 (n: 15), YH-5404 (n: 15), YH-1898 (n: 14), and 30Y87 (n: 20) were collected from different agriculture farms and research stations at the time of harvesting. Agriculture farms were located at Bahawalpur, Dera Ghazi Khan, Faisalabad, Gujranwala, Lahore, Multan, Sahiwal, Sargodha, and Rawalpindi divisions of Punjab, Pakistan (Fig. 1). The research stations were Maize and Millets Research Institute, Nuclear Institute for Agriculture and Biology (NIAB) and University of Agriculture Faisalabad. The standard procedure was followed for the collection of maize grains (about 1 kg) and storage before determining mycotoxins (Hassan et al., 2020; IARC, 2012).

Extraction and purification of mycotoxins

Extraction of mycotoxins (AFs and OTA) from maize grains was done according to the protocol described by Iqbal et al. (2014) with a few modifications. Maize grain samples were ground to fine powder by a high-speed grinding mill (ZM 200, Retsch, Germany). For extraction of AFs and OTA, 25 g ground grains, taken in conical flasks, were suspended in 100 mL of acetonitrile: water (84:16 v/v). Then the flasks were placed on a horizontal shaker (GFL shaker, Gunther & Co., Baltimore, MD USA) at 50 rpm for 60 min. The suspension was filtered using nylon membrane filters (size 0.45 µm, diameter 47 mm) and 9 mL filtrate was reacted with 70 µl acetic acid. For AFs, the mixture was cleaned-up using MycoSep 226 immunoaffinity column, whereas MycoSep 229 immunoaffinity column was used for OTA purification. Two milliliters purified solution of AFs was evaporated to dryness by N2 gas and derivatized with trifluoroacetic acid (TFA). However, purified OTA solution was not derivatized with TFA after drying with N2 gas. The dried mycotoxins were liquefied in 1.95 mL of acetonitrile:water (1:9 v/v). The liquefied samples were saved at 4 °C before quantification of AFs and OTA by HPLC.

Validation of method used for quantification of mycotoxins in maize grains

Performance parameters of HPLC detection method including linearity, limit of detections (LOD), limit of quantifications (LOQ), repeatability and reproducibility of AFB1, AFG1, AFB2, AFG2 and OTA are presented in Table 1. The precision and accuracy of the method were evaluated as repeatability and reproducibility at three different concentrations on the same day with triplicate analysis of spiked samples. For determining recovery efficiency of the method, the maize ground grain samples were spiked with B1 and G1 (0.5, 1.0 and 5 µg kg−1), B2 and G2 (1, 2, and 4 µg kg−1), and OTA (1, 5, and 10 µg kg−1). For linearity, 0.2 to 100 µg kg−1 OTA, 0.5–50 µg kg−1 B1 and G1,, and 0.1–20 µg kg−1 B2 and G2 were tested and values of regression coefficient (R2) were calculated. Moreover, LOD and LOQ for all mycotoxins were determined.

Quantification of mycotoxins

The AFs (AFB1, AFB2, AFG1, and AFG2) and OTA in the extracts of maize grains were quantified by HPLC (LC-10A series, Shimadzu, Japan). The system had LC-10AS delivery pumps, SCL-10A system controller, CTO-10A column oven, CBM-101 communication bus module, RF-530 fluorescence detector, CLASS LC-10 acquisition software, and octadecylsilyl-C18 column (250 × 4.6 mm, 5 μm; Discovery HS, ISupelco Park, USA). All the standards and samples (20 µL) were introduced to the HPLC system using manual syringe in triplicate. For the determination of AFB1, AFB2, AFG1 and AFG2, the mobile phase used comprised of acetonitrile, water, acetic acid in the ratio of 22.5: 22.5: 55, respectively. The column pressure was set as 2702 ± 2 psi, whereas flow rate of mobile phase as 1.5 mL min−1. The analysis was done in isocratic mode at 30 °C. The fluorescent detector was fixed to wavelengths of 365 nm for excitation and 440 nm for emission. The complete separation and analysis were carried out in 15 min. The retention time (Rt) of AFB1, AFB2, AFG1, AFG2 was confirmed by running standards of 25 µg kg−1 and 50 µg kg−1 (Fig. 2).

For OTA estimation, all conditions were similar as described above except mobile phase and detector wavelengths selected for excitation and emission. Mobile phase was acetonitrile: water: acetic acid (50:48:2), and wavelengths were 333 nm for excitation and 470 nm for emission. Rt of OTA was also confirmed by running AFs standards of 25 µg kg−1 and 50 µg kg−1 (Fig. 3).

Use of irradiations to lower level of mycotoxins in contaminated maize grain samples

The contaminated maize grain samples were exposed to gamma, UV, sunlight, and microwave radiations to lower the level of AFs and OTA. Maize grain samples of Pearl variety (100.8 µg kg−1 total AFs, 2.1 µg kg−1 and 60.3 µg kg−1 OTA) were gamma irradiated in a chamber which had 137Cs as the gamma radiation source (3000 Elan, MDS Nordion Ottawa, Canada) having total radioactivity of 99.7 TBq (2.7 kCi). The dose rate at irradiation was 11.40 Gy min−1 with an uncertainty of 2.5% to 95% confidence and irradiation was performed at 25 ºC. Doses of gamma radiation applied were 0, 1, 2, 3, 5, 10, and 15 kGy. The gamma irradiation was applied on three replicates for each radiation dose. In the next batch study, UV irradiation of contaminated maize grain samples was accomplished at 25 °C in a biosafety cabinet type-II (NUAIRE # NU-425–400) equipped with a UV lamp (TUV 30 W, Phillips, Holland). The average dose rate was 84 mW cm−2. The maize samples in zipper plastic bags (0.4 g/cm2) were exposed to UV radiations for 1.5, 3, 6, 9, and 12 h. The UV treatment was applied on three replicates for each exposure time.

For sunlight treatment, samples were spread on a white polythene sheet and exposed to sunlight for 2.5, 5, 10, 15, and 20 h. This activity was performed in the months of May, June and July, 2020. The average light intensity recorded was 685–722 kLux, average temperature 42.5 to 47 °C, relative humidity 48% to 72%, pan evaporation 5.5 to 8.5 mm and sunshine 7.4 to 10.1 h (Adnan et al., 2012). For microwave irradiations, the maize samples were treated with heating frequency 2450 MHz by using 1.5 kW power level (Dawlance, Japan) for 1, 2, 3, 4, and 5 min (Pankaj et al., 2018).

Use of adsorbent to lower the level of mycotoxins in grain extract of Pearl variety

The efficacy of bentonites and activated charcoal was investigated to reduce mycotoxin levels in maize grain extract. Five milliliter maize grain extract was taken in 20 mL glass vials and added with bentonite and charcoal at 0.5, 1, 2, 3, and 5% separately in triplicates. Samples were placed at room temperature (25 °C) for 24 h under static condition. Afterward, samples were centrifuged at 10,000 g and 25 °C for 10 min to get the clear supernatant. The concentration of different mycotoxins was determined in the supernatant as described above.

Statistical analysis

Statistical analyses were performed using Statistix-10 program. One-way ANOVA was applied to test the significance of different types of radiations and adsorbents on lowering mycotoxins in the samples. Least significance difference (LSD) test was used to compare the treatment means at 5% probability level (Steel & Torrie, 1996). Descriptive statistics including means and standard error were calculated by Microsoft Excel 2013 (Microsoft Office).

Results

Quality control and recovery analysis

The method used to quantify different levels of AFB1, AFB2, AFG1, AFG2 and OTA showed high linearity as R2 was above 0.99. The method also showed very good recoveries (88–92%) of the mycotoxins in the spiked in maize grains, with RSD ranging between 4-17%. Moreover, the instrument had highly acceptable limit of detection (LOD, 0.01–0.10 µg kg−1) and limit of quantification (LOQ, 0.03–0.30 µg kg−1), with a high level of precision as shown by RSD of repeatability (9–12%) and reproducibility (9–14%) (Table 1). The Rf of AFB1, AFB2, AFG1, AFG2, and OTA were same at two levels (25 and 50 mg kg−1) of each type of mycotoxins. The chromatograms of mycotoxins standards of 25 and 50 µg kg−1 are shown in Figs. 2 and 3.

Aflatoxins content in maize grains

Out of 135 maize grain samples collected from different areas of the country, 93 samples were found contaminated with AFs (Table 2). It was noteworthy that 54% of contaminated samples had total AFs above the permissible limit of 20 µg kg−1 set by PSQCA. In contrast all the positive samples had AFB1 below the permissible limit of 10 µg kg−1. The average grain concentration of total AFs and AFB1 ranged from 14.51 to 92.36 and 1.03 to 2.46 μg kg−1 in positive samples of different maize varieties. The highest average concentration of total AFs in grains was detected in Pearl variety (92.36 ± 3.70 μg kg−1) while least average AFs level was found in Malaka (14.51 ± 1.11 μg kg−1). Likewise, the highest average concentration of AFB1 in grains was detected in YH-5427 (2.46 ± 0.19) while least average AFB1 level was found in Malaka (1.03 ± 0.07). For each variety of maize, average concentration of AFB2 was higher than AFB1 and AFG1 than AFG2. Overall, AFB2 was detected in much higher levels in maize grains than other AFs.

Ochratoxin-A content in maize grains

Like AFs, high percentages (61%) of collected samples of eight maize varieties were contaminated with OTA (Table 3). More importantly, about 32% samples, regardless of varieties, had level of OTA above EU permissible limit for human consumption. The average concentration of OTA ranged from 1.41 to 53.9 μg kg−1 in maize grain samples. The concentration of OTA was detected in different maize varieties in the order of Pearl > DK-6789 > MMRI-yellow > Malaka > YH-5404 > YH-5427 > YH-1898 > 30Y87.

Degradation of mycotoxins in maize grains by irradiations

Data regarding the effect of irradiation treatments (gamma, sunlight, UV, and microwave) on the degradation of mycotoxins (AFB1, total AFs and OTA) in the maize grains are presented in Fig. 4. The level of all three mycotoxins in maize grains decreased with the dose of gamma irradiation (Fig. 4a). The exposure of maize grains to 1 kG gamma irradiation decreased the level of AFB1, total AFs and OTA by 21, 32 and 3%, whereas 15 kG completely degraded the mycotoxins. Sunlight treatment was also found highly effective in lowering the level of mycotoxins in maize grains (Fig. 4b). OTA was degraded faster than AFs. The sunlight drying of grains for 2.5 h resulted in decreases of 21, 19 and 39% of AFB1, total AFs and OTA, respectively. The complete removal of OTA was achieved after 10 h, while others AFs after 20 h. Likewise, OTA degradation by UV irradiation was quicker than AFs. OTA was completely eliminated after 9 h of UV exposure, whereas similar removal of AFs was achieved in 12 h. However, with microwave irradiation OTA degradation was much less than AFB1 and total AFs at all exposure times. After 10 s of microwave irradiation, AFB1, total AFs, OTA were degraded up to 10, 17, and 0.2%, respectively. The microwave irradiation for 120 s reduced AFB1, total AFs, and OTA by 29, 33, 9%, respectively.

Removal of mycotoxins in maize grain extracts by adsorbents

The effectiveness of activated charcoal to remove AFs and OTA from maize grain extract varied between them (Fig. 5). Activated charcoal at dose rate of 0.5% exhibited 6.51, 7.25 and 0.78% removal of AFB1, total AFs and OTA, respectively after 24 h. The removal efficiency of mycotoxins increased with increase in dose level of activated charcoal. By using 5% activated charcoal, both AFB1 and total AFs were removed above 96% from the aqueous solution, whereas OTA removed up to 43%. In contrast to activated charcoal, bentonite was found more effective for OTA removal than AFs. Bentonite at 0.5% dose rate, removed AFB1, total AFs and OTA by 3.5, 17.8 and 31.1%, respectively. The addition of bentonite to maize extract at 5% resulted in the removal of OTA by 93% and AFs by 73%.

Discussion

Maize is an important crop cultivated two to three times a year in Pakistan. The rains, humidity, inadequate storage facilities, and inappropriate market environment provoke fungal attack. This fungal attack results in the production of AFs and OTA in maize grains (Alshannaq & Yu, 2017). The AFs and OTA are common fungal metabolites formed by Aspergillus, Penicillium and Fusarium genera. In the current study, levels of AFs and OTA were estimated in maize varieties cultivated in different areas of Punjab, Pakistan. Moreover, irradiations and bio-sorbents were used to degrade mycotoxins in maize grains and grain extracts.

It was found that 69% maize grain samples collected at maturity were contaminated with AFs (Table 2). Out of positive samples, 54% had total AFs above the permissible level established by PSQCA. The concentration of AFB1 and total AFs in different cultivars ranged 1.03–2.46 and 14.5–92.4 μg kg−1, respectively. Kamika et al. (2016) found 32% of maize samples, collected from Democratic Republic of Congo, contaminated with AFs during the pre-harvest period. The concentration of 1.5 to 51.2 µg kg−1 AFB1 and 3 to 104 μg kg−1 total AFs were detected. Similarly, high concentrations of AFB1 were also reported by Ogara et al. (2017) from Nigeria, Matumba et al. (2014) from Malawi, Janardhana et al. (1999) from India, Shah et al. (2010) from Pakistan, and Oliveira et al. (2017) from Brazil. However, there are a few reports of other researchers exhibiting low level of AFs in maize grains than observed in the present study (Kara et al., 2015; Majeed et al., 2013; Mtega et al., 2020). The reason of low level of AFB1 in our study may be the dominance of other fungal species over the Aspergillus species responsible for the formation of AFB1. Moreover, the high accumulation of AFB2 is mainly responsible for higher AFs in the maize varieties. The high levels of AFs in maize grains might be associated with the weather conditions during August to January 2018 in Pakistan.

Like AFs, the incidence of OTA in maize crop at pre- and post-harvest stages is a global issue (Iqbal et al., 2013). In the current study, OTA was recorded in 61% maize grain samples of different varieties and 22% had OTA above permissible limit. The concentration of OTA was ranged 1.41 to 53.89 µg kg−1. Previously, researchers reported different ranges of OTA in maize viz. 16 to 73 µg kg−1 by Kamala et al. (2015), not detected to 139.2 µg kg−1 by Makun et al. (2013), and 1.70 to 19.5 µg kg−1 by Girolamo et al. (2017). Similar to our data, co-occurrence of OTA and AFs were also reported by others (Iqbal et al., 2016; Temba et al., 2017).

Use of radiations to increase the storage life of food commodities is getting popularity worldwide. In the present study the exposure of maize grains to 10 kGy gamma radiations decreased the level of AFB1, total AFs and OTA by 93, 89 and 43%, respectively. However, 15 kGy treatment completely degraded all the mycotoxins (Fig. 4). There are a number of reports showing the efficiency of gamma irradiation in reducing mycotoxins in food commodities (Aquino et al., 2005; Assuncao et al., 2015; di Stefano et al., 2014; Ghanem et al., 2008). Aquino et al. (2005) observed the complete removal of AFB1 in maize by 10 kGy exposure. The use of 10 kGy in peanuts, corn, and rice samples exhibited 59, 81 and 88% reduction in AFB1 (Ghanem et al., 2008). Whereas, total AFs level reduction up to 84% in Brazilian nut by 10 kGy gamma irradiation has been reported by Assuncao et al. (2015). In contrast, negligible degradation of AFs and only 24% of OTA occurred in almonds at 15 kGy (Di Stefano et al., 2014). The sunlight drying contaminated sample for 150 min degraded AFB1, OTA and total AFs by 20, 18 and 38%, respectively. The sunlight treatment for 20 h exhibited complete removal mycotoxins (Fig. 4). Herzallah et al. (2008) also found 42 and 40% reduction of AFB1 and total AFs after 3 h of direct sunlight treatment. Adegoke et al. (1996) found that sun drying of pepper (Capsicum annum) showed significant effects on aflatoxin levels. In our study, UV treatment was also found highly effective as it degraded AFB1, total AFs, and OTA up to 37, 49, and 52%, respectively after 180 min and complete degradation achieved in 12 h. Similarly, Garg et al. (2013) reported the complete reduction of AFs in peanuts by UV treatment. The decrease of OTA (100%) was achieved in 8 h by a study carried out by Ameer et al. (2016) in Pakistan and these findings support our results. However, other researcher reported a relatively a low efficiency of this treatment (Mazaheri, 2012). We found that microwave heating was effective in degrading AFs but not OTA. The microwave irradiation for 120 s degraded OTA by only 9%. Similarly, low degradation of OTA has been observed by others (Alkadi & Altal, 2019; Herzallah et al., 2008; Jabłońska & Mańkowska, 2014; Zhang et al., 2020).

The bio-sorbents (activated charcoal and bentonite) were compared for their efficiency to remove mycotoxins from maize extracts. The activated charcoal removed 93% total AFs and 29% OTA at 3% dose rate. At the same dose rate, the bentonites decreased 56% total AFs and 84% OTA of its initial level in aqueous solution. Similar to our results, the complete removal of AFs by activated charcoal at 3% dose rate was observed by Eniola et al. (2019). Khoury et al. (2018) reported 52% removal of OTA after applying 1% activated charcoal in red wine and grape juice. However, the degradation rate of AFs with activated charcoal was found higher than reported by Liu et al. (2011). Bentonites have been used recently for the significant reduction of AFB1, AFs, and OTA in poultry feed, and data recorded are in good agreement with the current findings. Total AFs and AFB1 were reduced by 85 and 66% with bentonite (Mgbeahuruike et al., 2018). Rao and Chopra (2001) have shown that 2% bentonite could adsorb 89% of aflatoxin M1 in naturally contaminated raw milk, supporting the present study's findings. Other researchers showed that bentonites were efficient to degrade AFB1 in fish food (Hassan et al., 2010) and OTA residues in feed (38–84%) (Bhatti et al., 2018; Mgbeahuruike et al., 2018), highlighting the effectiveness of bentonite as compared to charcoal.

Effect of different radiations and absorbents on AFs and OTA showed that radiations were more efficient to decontaminate mycotoxins than absorbents. In contrast, microwave treatment decontaminated AFs and OTA to 33% and 10%, respectively. In radiations, gamma, UV, and sunlight showed a significant reduction of AFs and OTA. From absorbents, bentonite showed a similar decrease in AFs and OTA, whereas 5% activated charcoal showed more reduction of total AFs and AFB1 (100%) than OTA (42%).

Conclusions

The commonly grown maize varieties in Pakistan are vulnerable to mycotoxins contamination. Among the maize varieties, Pearl variety had the highest level of total AFs, and OTA mycotoxins levels were considerably higher than the permissible limits. Irradiation of contaminated samples and application of adsorbents showed high efficiency in reducing mycotoxin; however, their efficacy varied against different toxins. The gamma irradiation at 15 kGy, sunlight treatment for 20 h, and UV exposure for 12 h almost completely degraded AFB, OTA, and total AFs. The charcoal was better for degrading AFB1 and total AFs, while bentonite detoxified OTA. Therefore, physical techniques may be used as a suitable technique to reduce the lethal effects of mycotoxins on humans and animals, which otherwise could lead to massive economic losses for farmers, traders, and consumers.

Availability of data and material

Not applicable.

Abbreviations

- AFs:

-

Aflatoxins

- AFB1:

-

Aflatoxin B1

- AFB2:

-

Aflatoxin B2

- AFG1:

-

Aflatoxin G1

- AFG2:

-

Aflatoxin G1

- ANOVA:

-

Analysis of variance

- LSD:

-

least significance difference

- OTA:

-

Ochratoxin-A

- FDA:

-

Food and drug administration

- PSQCA:

-

Standards and quality control authority

- HPLC:

-

High performance liquid chromatography

- TFA:

-

trifluoroacetic acid

- LOD:

-

limit of detections

- LOQ:

-

limit of quantifications

References

Adegoke, G., Allamu, A., Akingbala, J., & Akanni, A. (1996). Influence of sundrying on the chemical composition, aflatoxin content and fungal counts of two pepper varieties—Capsicum annum and Capsicum frutescens. Plant Foods for Human Nutrition, 49(2), 113–117.

Adnan, S., Khan, A., Haider, S., & Mahmood, R. (2012). Solar energy potential in Pakistan. Journal of Renewable and Sustainable Energy, 4(2012), 032701.

Alexander, J., Autrup, H., Bard, D., Benford, D., Carere, A., Costa, L., Cravedi, J., Di Domenico, A., Fanelli, R., & Fink-Gremmels, J. (2006). Opinion of the scientific panel on contaminants in the food chain on a request from the commission related to ochratoxin A in food. EFSA Journal, 365(2006), 1–56.

Alkadi, H., & Altal, J. (2019). Effect of microwave oven processing treatments on reduction of Aflatoxin B1 and Ochratoxin A in maize flour. European Journal of Chemistry, 10(3), 224–227.

Alshannaq, A., & Yu, J. H. (2017). Occurrence, toxicity, and analysis of major mycotoxins in food. International Journal of Environmental Research and Public Health, 14(6), 632–651.

Ameer, S. G., Hussain, S. Z., Hussain, S. S. T., Nizamani, S., & Mahesar, S. A. (2016). Decontamination of poultry feed from ochratoxin A by UV and sunlight radiations. Journal of the Science of Food and Agriculture, 96(8), 2668–2673.

Aquino, S., Ferreira, F., Ribeiro, D. H. B., Corrêa, B., Greiner, R., & Villavicencio, A. L. C. H. (2005). Evaluation of viability of Aspergillus flavus and aflatoxins degradation in irradiated samples of maize. Brazilian Journal of Microbiology, 36(4), 352–356.

Ashiq, S. (2015). Natural occurrence of mycotoxins in food and feed: Pakistan perspective. Comprehensive Reviews in Food Science and Food Safety, 14(2), 159–175.

Assuncao, E., Reis, T. A., Baquiao, A. C., & Correa, B. (2015). Effects of gamma and electron beam radiation on Brazil nuts artificially inoculated with Aspergillus flavus. Journal of Food Protection, 78(7), 1397–1401.

Awuchi, C. G., Ondari, E. N., Ogbonna, C. U., Upadhyay, A. K., Baran, K., Okpala, C. O. R., Korzeniowska, M., & Guiné, R. P. F. (2021). Mycotoxins affecting animals, foods, humans, and plants: Types, occurrence, toxicities, action mechanisms, prevention, and detoxification strategies—A revisit. Foods, 10(6), 1279.

Bhatti, S. A., Khan, M., Hassan, Z. U., Saleem, M. K., Saqib, M., Khatoon, A., & Akhter, M. (2018). Comparative efficacy of bentonite clay, activated charcoal and Trichosporon mycotoxinivorans in regulating the feed-to-tissue transfer of mycotoxins. Journal of the Science of Food and Agriculture, 98(3), 884–890.

Calado, T., Fernandez-Curzm, M. L., Verde, S. C., Venancio, A., & Abrunhosa, L. (2018). Gamma irradiation effect on ochratoxin A: Degradation, cytotoxicity and application in food. Food Chemistry, 240(2018), 463–471.

Calado, T., Venancio, A., & Abrunhosa, L. (2014). Irradiation for mold and mycotoxin control: A review. Comprehensive Reviews in Food Science and Food Safety, 13(5), 1049–1061.

De Ruyck, K., De Boevre, M., Huybrechts, I., & De Saeger, S. (2015). Dietary mycotoxins, co-exposure, and carcinogenesis in humans: Short review. Mutation Research, 766(2015), 32–41.

Di Stefano, V., Pitonzo, R., & Avellone, G. (2014). Effect of gamma irradiation on aflatoxins and ochratoxin A reduction in almond samples. Journal of Food Research, 3(4), 113–118.

Domijan, A. M., Marjanović Čermak, A. M., Vulić, A., Tartaro Bujak, I., Pavičić, I., Pleadin, J., Markov, K., & Mihaljević, B. (2019). Cytotoxicity of gamma irradiated aflatoxin B1 and ochratoxin A. Journal of Environmental Science and Health, Part B, 54(3), 155–162.

Eniola, O., Flora, O., Sarafadeen, K., & Adebukunolami, O. (2019). View affiliations detoxifying potentials of two indigenous adsorbents: Imarsil and activated charcoal in the reduction of aflatoxin in vegetable oils consumed in Nigeria. Microbiology, 1(1A), 52–58.

Gan, F., Hang, X., Huang, Q., & Deng, Y. (2019). Assessing and modifying China bentonites for aflatoxin adsorption. Applied Clay Science, 168(2019), 348–354.

Garg, N., Aggarwal, M., Javed, S., & Khandal, R. K. (2013). Studies for optimization of conditions for reducing aflatoxin contamination in peanuts using ultraviolet radiations. International Journal of Drug Development and Research, 5(3), 408–424.

Ghanem, I., Orfi, M., & Shamma, M. (2008). Effect of gamma radiation on the inactivation of aflatoxin B1 in food and feed crops. Brazilian Journal of Microbiology, 39(2008), 787–791.

Girolamo, A. D., Ciasca, B., Stroka, J. B. S., Pascale, M., Visconti, A., & Lattanzio, V. M. T. (2017). Performance evaluation of LC-MS/MS methods for multi-mycotoxin determination in maize and wheat by means of international proficiency testing. Trends in Analytical Chemistry, 86(2017), 222–234.

Hassan, A. M., Kenawy, A. M., Abbas, W. T., & Abdel-Wahhab, M. A. (2010). Prevention of cytogenic, histochemical and biochemical alterations in Oreochromic niloticus by dietary supplement of sorbent materials. Ecotoxicology and Environmental Safety, 73(8), 1890–1895.

Hassan, S. W. U., Sadef, Y., Hussain, S., Asi, M. R., Ashraf, M. Y., Anwar, S., & Malik, A. (2020). Unusual pattern of aflatoxins and ochratoxin in commercially grown maize varieties of Pakistan. Toxicon, 182(2020), 66–71.

Herzallah, S. A., Shawabkeh, K., & Fataftah, A. (2008). Aflatoxin decontamination of artificially contaminated feeds by sunlight, g-radiation, and microwave heating. Journal of Applied Poultry Research, 17(4), 515–521.

IARC. (1993). Monographs on the evaluation of the carcinogenic risk of chemicals to humans: some naturally occurring substances-food items and constituents, heterocyclic aromatic amines and mycotoxins. (Vol. 56., pp. 245–521). Lyon, France: IARC.

IARC. (2012). Monographs on the evaluation of the carcinogenic risk of chemicals to humans: Some naturally occurring substances-Chemical agents and related occupations. Lyon, France: IARC., 10, 1143–1144.

Iqbal, S. Z., Asi, M. R., Hanif, U., Zuber, M., & Jinap, S. (2016). The presence of aflatoxins and Ochratoxin-A in rice and rice products; and evaluation of dietary intake. Food Chemistry, 210(2016), 135–140.

Iqbal, S. Z., Asi, M. R., Zuber, M., Akhtar, J., & Saif, M. J. (2013). Natural occurrence of aflatoxins and ochratoxin-A in commercial chili and chili sauce samples. Food Control, 24(1–2), 621–625.

Iqbal, S. Z., Rabbani, T., Asi, M. R., & Jinap, S. (2014). Assessment of aflatoxins, Ochratoxin-A and zearalenone in breakfast cereals. Food Chemistry., 157(2014), 257–262.

Jabłońska, J., & Mańkowska, D. (2014). The influence of UV, X and microwave radiation on the aflatoxin B1 concentration in nuts. Biotechnology and Food Science, 78(2), 111–119.

Janardhana, G. R., Raveesha, K. A., & Shetty, H. S. (1999). Mycotoxin contamination of maize grains grown in Karnataka (India). Food and Chemical Toxicology, 37, 863–868. https://www.ncbi.nlm.nih.gov/pubmed/10506010

Kamala, A., Ortiz, J., Kimanya, M., Haesaert, G., Donoso, S., Tiisekwa, B., & Meulenaer, B. (2015). Multiple mycotoxin co-occurrence in maize grown in three agro-ecological zones of Tanzania. Food Control, 54(2015), 208–215.

Kamika, I., Ngbolua, K. N., & Tekere, M. (2016). Occurrence of aflatoxin contamination in maize throughout the supply chain in the Democratic Republic of Congo. Food Control, 69(2016), 292–296.

Kara, G. N., Ozbey, F., & Kabak, B. (2015). Co-occurrence of aflatoxins and Ochratoxin-A in cereal flours commercialized in Turkey. Food Control, 54(2015), 275–281.

Karlovsky, P., Suman, F., Berthiller, D.-M., & J., Eisenbrand, G., Perrin, I., Oswald, I. P., Speijers, G., Chiodini, A., Recker, T., & Dussort, P. (2016). Impact of food processing and detoxification treatments on mycotoxin contamination. Mycotoxin Research, 32(4), 179–205.

Khoury, R. E., Choque, E., Khoury, A. E., Snini, S. P., Cairns, R., Andriantsiferana, C., & Mathieu, F. (2018). OTA prevention and detoxification by actinobacterial strains and activated carbon fibers: Preliminary results. Toxins (basel), 10(4), 137–144.

Liu, Y. L., Meng, G. Q., Wang, H. R., Zhu, H. L., Hou, Y. Q., & Wang, W. J. (2011). Effect of three mycotoxin adsorbents on growth performance: Nutrient retention and meat quality in broilers fed on mould-contaminated feed. British Poultry Science, 52(2), 255–263.

Majeed, S., Iqbal, M., Asi, M. R., & Iqbal, S. Z. (2013). Aflatoxins and ochratoxin A contamination in rice, corn and corn products from Punjab. Pakistan. Journal of Cereal Science, 58(3), 446–450.

Makun, H. A., Adeniran, A. L., Mailafiya, S. C., Ayanda, I. S., Mudashiru, A. T., Ojukwu, U. J., Jagaba, S. S., Usman, Z., & Salihu, D. A. (2013). Natural occurrence of Ochratoxin-A in some marketed Nigerian foods. Food Control, 31(2), 566–571.

Matumba, L., Sulyok, M., Njoroge, S. M. C., Ediage, E. N., Poucke, C. V., Saeger, S. D., & Krska, R. (2014). Uncommon occurrence ratios of aflatoxin B1, B2, G1, and G2 in maize and groundnuts from Malawi. Mycotoxin Research, 31(1), 57–62. https://doi.org/10.1007/s12550-014-0209-z

Maxwell, C. K. L., Díaz-Liano, G., & Smith. T. K. (2006). Mycotoxins in pet food: A review on worldwide prevalence and preventative strategies. Journal of Agricultural and Food Chemistry, 54, 9623–9635.

Mazaheri, M. (2012). Effect of UV radiation on different concentrations of Aflatoxin B1 in pistachio. International Society for Horticultural Science (ISHS), (963 ed., pp. 41–46). Leuven, Belgium

Mgbeahuruike, A. C., Ejioffor, T. E., Obasi, C., Christian, O. C., Shoyinka, V. C., Karlsson, M., & Nordkvist, E. (2018). Detoxification of aflatoxin-contaminated poultry feeds by 3 adsorbents, bentonite, activated charcoal, and fuller’s earth. Journal of Applied Poultry Research, 27(4), 461–471.

Milani, J. M. (2013). Ecological conditions affecting mycotoxin production in cereals: a review. Veterinary Medicine (Prague, Czech Repub.), 58(8), 405–411.

Mtega, M., Mgina, C. A., Kaale, E., Sempombe, J., & Kilulya, K. F. (2020). Occurrence of aflatoxins in maize and maize products from selected locations of Tanzania and the effects of cooking preparation processes on toxin levels. Tanzania Journal of Science, 46(2), 407–418.

Nesic, K., Milicevic, D., Nesic, V., & Ivanovic, S. (2015). Mycotoxins as one of the foodborne risks most susceptible to climatic change. Procedia Food Science, 5(2015), 207–210.

Novas, M. V., & Cabral, D. (2002). Association of mycotoxin and sclerotia production with compatibility groups in Aspergillus flavus from peanut in Argentina. Plant Disease, 86(3), 215–219.

Ogara, I. M., Zarafi, A. B., Alabi, O., Banwo, O., Ezekiel, C. N., Warth, B., Sulyok, M., & Krska, R. (2017). Mycotoxin patterns in ear rot infected maize: A comprehensive case study in Nigeria. Food Control, 73(2017), 1159–1168.

Oliveira, M. S., Rocha, A., Sulyok, M., Krska, R., & Mallmann, C. A. (2017). Natural mycotoxin contamination of maize (Zea mays L.) in the South region of Brazil. Food Control, 73(2017), 127–132.

Pankaj, S. K., Shi, H., & Keener, K. M. (2018). A review of novel physical and chemical decontamination technologies for aflatoxin in food. Trends in Food Science & Technology, 71(2018), 73–83.

Rao, S. B. N., & Chopra, R. C. (2001). Influence of sodium bentonite and activated charcoal on aflatoxin M1 excretion in milk of goats. Small Ruminant Research, 41(3), 203–213.

Sarrocco, S., & Vannacci, G. (2018). Preharvest application of beneficial fungi as a strategy to prevent postharvest mycotoxin contamination: A review. Crop Protection, 110(2018), 160–170.

Sebaei, A. S., Sobhy, H. M., Fouzy, A. S. M., & Hussain, O. A. (2020). Occurrence of zearalenone in grains and its reduction by gamma radiation. International Journal of Environmental Analytical Chemistry, 2020, 1–9.

Shah, H. U., Simpson, T. J., Alam, S., Khattak, K. F., & Perveen, S. (2010). Mould incidence and mycotoxin contamination in maize kernels from Swat Valley, North West Frontier Province of Pakistan. Food and Chemical Toxicology, 48(4), 1111–1116.

Steel, R. G. D., & Torrie, J. H. (1996). Principles and procedures of Statistics: A biometrical approach (pp. 195–233). NY: Mc Graw-Hill

Streit, E., Schatzmayr, G., Tassis, P., Tzika, E., Marin, D., Taranu, I., Tabuc, C., Nicolau, A., Aprodu, I., Puel, O. & Oswald, I. P. (2012). Current situation of mycotoxin contamination and co-occurrence in animal feed—Focus on Europe. Toxins, 4(10), 788–809.

Temba, M. C., Njobeh, P. B., & Kayitesi, E. (2017). Storage stability of maize-groundnut composite flours and an assessment of aflatoxin B1 and Ochratoxin-A contamination in flours and porridges. Food Control, 71(2017), 178–186.

Tsitsigiannis, D. I., Dimakopoulou, M., Antoniou, P. P., & Tjamos, E. C. (2012). Biological control strategies of mycotoxigenic fungi and associated mycotoxins in Mediterranean basin crops. Phytopathology Research, 51(2012), 158–174.

World Health Organization. (1999). High-dose irradiation: wholesomeness of food irradiatied with doses above 10 kGy (Vol. 890).

Zhang, Y., Li, M., Liu, Y., Guan, E., & Bian, K. (2020). Reduction of aflatoxin B1 in corn by water-assisted microwaves treatment and its effects on corn quality. Toxins, 12(9), 605–618.

Acknowledgements

Authors are highly grateful to the Muhammad Rafique Asi and Director (NIAB), Faisalabad, Pakistan for facilitating laboratory space and analytical equipment’s to carry out research work. Authors also acknowledged the help of Director, MMRI, Sahiwal, Pakistan and farmers for providing the seed of maize varieties.

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Conflict of interest

The authors declare no conflict of interest.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gillani, S.W.u.H.S., Sadef, Y., Imran, M. et al. Determination and detoxification of aflatoxin and ochratoxin in maize from different regions of Pakistan. Environ Monit Assess 194, 613 (2022). https://doi.org/10.1007/s10661-022-10197-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10661-022-10197-3