Abstract

Microbially produced biosurfactants are fast catching up due to their environment-friendly approach over chemical surfactants. But their commercial production is restricted due to poor economy of the production process which could be improved by using high yielding microbial strains and optimizing the process parameters. The present research was directed to optimize the biosurfactant production monitored in terms of oil displacement and emulsification (E24) index, using a promising yeast Meyerozyma guilliermondii YK32. Maximum oil displacement equaling 7.5 cm was obtained with olive oil at 8% (v/v) concentration as carbon source under shaking conditions (150 rpm). Diesel being a complex hydrocarbon was not utilized easily by yeast and showed poor biosurfactant production. Yeast extract at 1.5% (w/v) concentration yielded maximum biosurfactant as evident from maximum oil displacement and E24 index equal to 8.1 cm and 52.6%, respectively. Sodium chloride at the rate of 3% (w/v) supported maximum oil displacement (8.8 cm) using the production broth containing optimized carbon and nitrogen sources. Any increase beyond this level negatively influenced the biosurfactant production. The yield was at its maximum at 30 °C as a shift in temperature either to 35 °C or 25 °C decreased the oil displacement from 8.8 to 5.2 or 7.6 cm, respectively. At 40 °C, oil displacement was decreased to 2.5 cm. Biosurfactant production appeared to be sensitive to varying pH as evident from the E24 index as high as 67.3% at pH 6.0 as compared with 60.2%, 60.1%, and 52.4% at pH 5.0, 5.5, and 7.0, respectively. Yeast biomass yield equivalent to 10.3 g/L and 8.3 g/L was recorded at pH 6 and 7, respectively, during the production process. Elimination of shaking reduced the E24 index from 67.3 to 34.8% under optimized conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Biosurfactants are naturally occurring tensio-active compounds exhibiting pronounced surface and emulsifying activities. Many microbial species are known to produce biosurfactants extracellularly or as part of the cell membrane. These are frequently grouped as glycolipids, lipopeptides, phospholipids, fatty acids, neutral lipids, and polymeric and particulate compounds (Mulligan 2005). Biosurfactants offer several advantages over chemical surfactants, such as low toxicity, improved biodegradability, and ecological acceptability. Glycolipids produced by Rhodococcus species 413A, for instance, were 50% less toxic as compared with Tween 80 as indicated by naphthalene solubilization tests (Kanga et al. 1997), thus making them more suitable for applications in food, pharmaceutical, and cosmetic industries (Desai and Banat 1997). Besides, these biological compounds also find application in bioremediation, enhanced oil recovery, and agriculture (Pacwa-Płociniczak et al. 2011). These are significant for biosurfactant-producing microorganisms themselves in facilitating nutrient transport and host–microbe interactions and showing biocidal and antimicrobial activities against human pathogens such as Escherichia coli, Candida albicans, and Staphylococcus aureus (Khopade et al. 2012). The increasing efforts for the search and development of new drugs that can replace traditional antibiotics may represent biosurfactants as a tremendously favorable agent that ought to be explored further. Biosurfactant production among bacteria is well explored nominating Pseudomonas aeruginosa, P. putida, P. stutzeri (Joshi and Shekhawat 2014), Bacillus subtilis, B. pumilus, B. licheniformis, Lactococcus lactis (Rodrigues et al. 2006), Lactobacillus spp., Streptococcus thermophilus, and Nocardioides spp. (Khopade et al. 2011) as some of the promising candidates known for producing biosurfactants mainly rhamnolipid in nature (Rahman et al. 2002). Contrary to this, relatively fewer fungi such as Aspergillus ustus (Kiran et al. 2009), Ustilago maydis (Alejandro et al. 2011), Trichosporon ashii (Chandran and Das 2010) Candida bombicola (Felse et al. 2007), C. lipolytica (Sarubbo et al. 2007), C. ishiwadae (Thanomsub et al. 2004), C. batistae (Konishi et al. 2008), and C. antarctica (Hua et al. 2003) are known to produce biosurfactants. Yeasts, being eukaryotic in cell organization, have cell wall comparatively rigid and less prone to damage by biosurfactants and therefore, can produce biosurfactant in higher concentrations (Cooper and Paddock 1984). This makes the application of yeast economically more feasible at industrial level for production of biosurfactants. Other challenges that could have been addressed towards development of economically more viable bioprocesses are isolation of novel strain, utilization of cheaper raw material, and optimization of fermentative parameters along with exploitation of effective methods for extraction of crude biosurfactant. The present investigation focuses on optimization of process parameters for the improvement of the biosurfactant production by yeast Meyerozyma guilliermondii YK32 retrieved from a hydrocarbon-polluted site (Kaur et al. 2017).

Materials and methods

Chemicals and ingredients

All the chemicals, reagents, and media ingredients were purchased from Hi-Media or E. Merck. Diesel oil was purchased from petrol pump, CCS Haryana Agricultural University, Hisar, whereas olive oil was purchased from the local market in Hisar. Waste mobile oil discarded during washing and repair of engine parts was obtained from local automarket, Hisar.

Preparation of yeast inoculum

Yeast M. guilliermondii strain YK32 was obtained from a previous study (Kaur et al. 2017) and was maintained on yeast extract peptone dextrose (YEPD) medium at 4 °C. It was grown under shaking conditions (150 rpm) in 100 mL of Bushnell Haas (BH) broth (Bushnell and Haas 1941) of pH 5.5. For biosurfactant production, 100 mL BH broth supplemented with different carbon and nitrogen sources was inoculated with 0.25 g wet biomass of M. guilliermondii strain YK32 and incubated at 30 ± 2 °C for 6 days in a rotary flask shaker at 150 rpm. The optimization of fermentation broth was conducted in a series of experiments by changing one variable at a time while keeping others unchanged. Among the chemical parameters, optimization of carbon sources (glucose, diesel, and olive oil), nitrogen sources (ammonium sulphate, yeast extract, and urea), and NaCl was conducted. Among the physical parameters, temperature, pH, shaking, and incubation time were optimized.

Biosurfactant monitoring

Samples were withdrawn from each fermentation treatment after every 24 h and centrifuged at 10,000 rpm for 15 min in a cooling centrifuge at 4 °C. The pellets obtained were used to estimate biomass production during the biosurfactant production after drying to a constant weight at 50–60 °C in a hot air oven. The culture supernatant was used to estimate biosurfactant production in terms of oil displacement and emulsification (E24) index. The oil displacement technique used here was adopted from Rodrigues et al. (2006) with slight modification. Fifty milliliters of distilled water in a glass Petri plate (14.5 cm diameter) was overlayered with 1 mL of mobile oil. Mobile oil was taken on purpose to visualize clearly, the displacement of oil, in a colored background. Forty-microliter culture supernatant was dropped gently on the oil surface and the diameter of the zone of oil displacement was recorded and compared with 0.2% SDS and distilled water as positive and negative controls, respectively.

Emulsification index of culture supernatant was determined using diesel oil as described by Aparna et al. (2012). Equal volume (2 mL) of cell-free supernatant and diesel was mixed in a test tube, vertexed for 2 min, and allowed to stand for 24 h at room temperature. The height (cm) of the emulsified layer thus formed at the interface of diesel and cell-free supernatant was recorded. The E24 index was expressed as percent height of emulsified layer by total height of liquid column. The results obtained were compared with 0.2% SDS and distilled water as positive control and negative control, respectively. The results of oil displacement and E24 index were statistically analyzed using ANOVA (analysis of variance) performed using computer software, OPSTAT, available at the official website of CCS Haryana Agricultural University, Hisar (http://www.hau.ac.in).

Results and discussion

Microbes can be incredible and highly potent agents for biosurfactant production. The microbes inhabiting the hydrocarbon-polluted environments possess improved ability of biosurfactant production as compared with those residing in general habitat (Batista et al. 2006). Yeast M. guilliermondii YK 32 was isolated from a soil sample obtained from automarket Hisar (Haryana), India (latitude 29° 10′,7.92″ N and longitude 75° 43′,30.13″ E), in a previous study (Kaur et al. 2017) and identified as Meyerozyma guilliermondii on the basis of 18S rDNA analysis. M. guilliermondii was reported as a promising producer of biosurfactant related to sophorolipid class, especially under acidic condition (Camargo et al. 2018). In the present study, efforts were made to improve the yield of biosurfactant by M. guilliermondii YK32 through optimization of different parameters of the production process. Supernatant obtained from the production broth was used as source of biosurfactant which was measured in terms of oil displacement and E24 index. The oil displacement technique indirectly measures the surface activity of a surfactant under test on oil, where a larger zone symbolizes higher surface activity (Rodrigues et al. 2006). E24 index measures the ability of biosurfactant to emulsify hydrocarbon under test.

Optimization of biosurfactant production

Carbon source

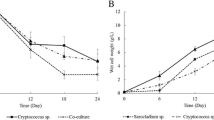

Carbon sources viz. carbohydrates (glucose), hydrocarbons (diesel), and vegetable oil (olive oil) at different concentrations [2–8%(w/v) or (v/v)] were used to supplement production broth. Since glucose is a readily utilizable carbon source, it gets exhausted comparatively faster, especially at lower concentrations [2–6%(w/v)], thereby, did not support increment in biosurfactant production beyond 3–4 days. Higher concentrations [8%(w/v)], however, increased the level of biosurfactant production up to the fifth day of incubation; afterwards, the increase was not found to be statistically significant (Table 1). Diesel being a complex petroleum hydrocarbon did not support biosurfactant production especially at concentrations beyond 2%(v/v) which clearly indicated the inability of yeast M. guilliermondii YK32 to metabolize diesel as a carbon source (Table 2). Yeast like Rhodotorula babjevae was found to be favoring diesel for glycolipid production as evident from E24 index of 70% (Guerfali et al. 2019). Biosurfactant produced on 8% olive oil as carbon source resulted in maximum 7.50 cm oil displacement (Table 1) and 46.2% E24 index (Table 2) which are significantly higher as compared with the oil displacement (6.6 cm) and E24 index (37.5%) generated by a positive control, 0.2% SDS, and is at par with other carbon sources. Biosurfactant produced using diesel was increased by 42.9% with glucose which was further amplified by 7.14% with olive oil as carbon source as monitored in terms of oil displacement, at 8% concentration of each of the carbon sources after 5 days of incubation. The biosurfactant yield of M. guilliermondii YK32 was fairly improved as indicated by the total area under oil displacement that equaled to 44.16 cm2 after 5 days of incubation, using 8%(v/v) olive oil as carbon source (Table 1). A thermotolerant yeast Pichia anomala PY1 preferred 4% soybean oil as carbon source (Thaniyavarn et al. 2008). In the present study, olive oil also supported maximum concomitant production of biomass by M. guilliermondii YK32 equaling 6.4 g/L followed by 6.1 g/L in case of glucose at 8% concentration (Fig. 1) during the production process. Eight percent olive oil was thus selected as a carbon source in further tests for optimality.

Nitrogen source

The impact of different concentrations of three nitrogen sources namely ammonium sulphate, yeast extract, and urea was tested on biosurfactant production by M. guilliermondii YK32. The production broth containing olive oil [8%(v/v)] was supplemented with the given nitrogen sources at different concentrations [0–5% (w/v)], inoculated with the yeast, and incubated at 30 °C under shaking conditions (150 rpm). Biosurfactant production increased with increasing concentrations of all the nitrogen sources from 0.5 to 1.5% and decreased abruptly at 2% level (Tables 3 and 4). The incorporation of ammonium sulphate at a lower concentration [0.5%(w/v)] did not quite add to the production of biosurfactant but its incorporation at the rate of 1.5% in the production media increased the oil displacement and E24 index from 7.6 cm and 40.8% to 7.9 cm and 48.2%, respectively. A further increase in the concentration of ammonium sulphate to 2.0% negatively influenced the biosurfactant production by reducing the oil displacement and E24 to 6.0 cm and 32.6% after 5 days of incubation. The most promising increase in biosurfactant yield measured in terms of oil displacement (8.1 cm) and E24 index (52.6%) was recorded after 5 days of using yeast extract at concentration of 1.5% (Tables 3 and 4). Urea, at similar concentration, supported higher oil displacement (8.0 cm) than ammonium sulphate (7.9 cm) but lagged behind yeast extract (8.1 cm). Further, the increase in oil displacement using yeast extract as nitrogen source was also found to be statistically significant. Konishi et al. (2018) reported urea as the leading nitrogen supplement among the tested sources viz. ammonium nitrate, potassium nitrate, sodium nitrate, and ammonium sulphate, for biosurfactant production using yeast Candida floricola. Biomass production by M. guilliermondii YK32, however, kept on increasing up to 2% yeast extract (7.6 g/L) as opposed to 7.4 g/L obtained at 1.5% after 6 days of incubation (Fig. 1). These results are in agreement with Cooper and Paddock (1984) where biosurfactant production declined but biomass production increased up to 9.1 g/L with increasing concentration of yeast extract beyond optimum concentration of nitrogen source. In another study, Guerfali et al. (2019) obtained a cell biomass of 8.3 ± 0.4 g/L in the presence of yeast extract as the only nitrogen source for biosurfactant production using yeast Rhodotorula babjevae. Yeast extract was thus selected for further optimization studies, although the concentration required was higher as compared with the reports available in literature. Cooper and Paddock (1984), for instance, advocated incorporation of 0.5%(w/v) yeast extract for biosurfactant production.

Salt concentration

Sodium chloride at different concentrations (0–5%) was investigated for biosurfactant production using production broth supplemented with optimized carbon and nitrogen sources. Biosurfactant production increased with increasing salt concentrations up to 3% and then decreased sharply. Incorporation of NaCl at 3% concentration significantly increased the biosurfactant production, as revealed by increments of 7.95% and 12.48% in oil displacement and E24 index, respectively (Tables 5 and 6), as compared with the control lacking NaCl (Table 3). Maximum oil displacement and E24 index of 8.8 cm (Table 5) and 60.1% (Table 6) were observed in the presence of 3%(w/v) NaCl after 5 days of incubation. Further increment in the salt concentrations, however, influenced the biosurfactant production adversely as evidenced by 20.45% and 52.27% reduction in oil displacement at 4% and 5% NaCl concentrations, respectively (Table 5). Similarly, the E24 indices observed at 4% and 5% salt concentrations were found to be decreasing to 50.4% and 46.8%, respectively as compared with 60.1% as observed in the presence of 3% NaCl concentration (Table 6). Three percent concentration of NaCl supported 8.5 g/L biomass production after 5 days of incubation (Fig. 2). Our results agree well with the requirement of 2–3% NaCl by Yarrowia lipolytica NCIM 3589 for generating emulsification activity over 3 U/mL (Zinjarde and Pant 2002).

Temperature and pH

Production broth supplemented with optimized concentrations of carbon, nitrogen, and salt was used to optimize temperature for biosurfactant production by yeast M. guilliermondii YK32 keeping 30 °C as a control. Any deviation in the temperature significantly decreased the biosurfactant production as revealed by the reduction in oil displacement from 8.8 cm at 30 °C to 7.6 cm and 5.2 cm at 25 °C and 35 °C, respectively. Further, the decline was more severe (2.5 cm) on the increase in temperature to 40 °C (Table 5) after 5 days of incubation. Similarly, E24 index was also found to be maximum 60.1% at 30 °C and minimum 32.3% at 40 °C after 5 days of incubation (Table 6). Similarly, biomass production also declined from 8.7 to 4.3 g/L on increasing temperature from 30 to 40 °C (Fig. 2) after 5 days of incubation; while maximum biosurfactant was reported at 30 °C in Pichia anomala (Thaniyavarn et al. 2008), 35 °C was found optimum in Rhodotorula muciliginosa and Candida rugosa (Chandran and Das 2011). Morita et al. (2008) also examined the effect of temperature on biosurfactant production by Pseudozyma siamensis CBS 9960, and observed over 7 g/L yield of biosurfactant at 25 °C which was reduced to around 6 g/L and 4 g/L as the temperature shifted to 20 °C or 30 °C, respectively. Interestingly, they reported a complete elimination of biosurfactant production at 35 °C contrary to our reports of 5.2 cm oil displacement at this temperature after 5 days of incubation (Table 5). Clearly, 30 °C was selected as the optimum temperature for further studies.

Biosurfactant production by yeast M. guilliermondii YK32 was found to be highly sensitive to pH. An increase in pH from 5.5 to 6.0 increased the oil displacement and E24 index to 10.4 cm (Table 5) and 67.3% (Table 6), respectively. Also a maximum of 10.3 g/L biomass was obtained at pH 6 (Fig. 2) after 6 days of incubation. Shifts in pH to 5 and 7 significantly affected the biosurfactant production as indicated by the reduced E24 indices equivalent to 60.2% and 52.4%, respectively (Table 6). Correspondingly, values of oil displacement were also found to decline by 27.88% and 29.80%. An increased pH from 6 to 7 reduced biomass production from 10.1 to 8.0 g/L after 6 days of incubation. This clearly indicated that the pH indirectly influenced biosurfactant production via simply reducing the cell biomass (Fig. 2). In general, yeast preferred an acidic pH as indicated by the maximum biosurfactant production at an initial pH of 6 (Deshpande and Daniels 1995) and 5.5 (Thaniyavarn et al. 2008) by Candida bombicola and Pichia anomala PY1, respectively. It was also stated that any variation in pH values towards acidity or alkalinity caused an appreciable drop in biosurfactant production.

Shaking/stationary conditions

Complete omission of shaking significantly decreased the biosurfactant production in terms of reduced oil displacement from 10.4 to 5.3 cm and E24 index from 67.3 to 34.2% (Table 7) after 5 days of incubation. Similar was the impact on biomass production which declined from 10.3 g/L to 4.4 g/L after 6 days of incubation (Fig. 2).

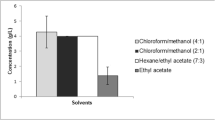

Taken all together, biosurfactant production after 5 days by yeast Meyerozyma guilliermondii YK32 emerged to a maximum of 84.90 cm2 area under oil displacement using optimized medium-containing olive oil (8%), yeast extract (1.5%), and NaCl (3%). This yield was achieved under shaking conditions (150 rpm) at pH 6 and an incubation temperature of 30 °C. The same set of conditions produced 67.3% E24 index which was found to be significantly higher than 42.8% as reported by Camargo et al. (2018) by M. guilliermondii (accession number KX455858) using residual soybean oil under acidic conditions. Thaniyavarn et al. (2008) obtained 69.43 cm2 area under oil displacement by a thermostable yeast Pichia anomala PY1 using 4% soybean oil as carbon source at pH 5.5 and temperature 30 °C. Maximum biomass (10.3 g/L) produced by M. guilliermondii YK32 in the present study was found comparable with the biomass generated using C. antarctica (12–19 g/L) as reported by Adamczak and Bednarski (2000).

Conclusion

The ability of Meyerozyma guilliermondii YK32 to produce biosurfactant with significant emulsification properties suggests its commercialization potential. However, fine tuning of optimization parameters along with exploration of cheaper raw materials for the purpose besides scale-up evaluation would be desirable. Further, characterization and cytotoxicity assessment of the final product would be inevitable in order to clearly assign an application to the final fermentation product. After addressing the gaps in research, the product or the producing organism can efficiently be directed towards mobilization of agrochemicals, synthesis of nanoformulations, or removal of heavy metals from the sewage sludge.

References

Adamczak, M., & Bednarski, W. (2000). Influence of medium composition and aeration on the synthesis of biosurfactants produced by Candida antarctica. Biotechnology Letters, 22(4), 313–316.

Alejandro, C. S., Humberto, H. S., & María, J. F. (2011). Production of glycolipids with antimicrobial activity by Ustilago maydis FBD12 in submerged culture. African Journal of Microbiology Research, 5, 2512–2523.

Aparna, A., Srinikethan, G., & Smitha, H. (2012). Production and characterization of biosurfactant produced by a novel Pseudomonas sp. 2B. Colloids and Surfaces B: Biointerfaces, 95, 23–29.

Batista, S. B., Mounteer, A. H., Amorim, F. R., & Totola, M. R. (2006). Isolation and characterization of biosurfactant/bioemulsifier-producing bacteria from petroleum contaminated sites. Bioresource Technology, 97, 868–875.

Bushnell, L. D., & Haas, H. F. (1941). The utilization of certain hydrocarbons by microorganisms. Journal of Bacteriology, 41(5), 653–673.

Camargo, F. P., Menezes, A. J. D., Tonello, P. S., Dos Santos, A. C. A., & Duarte, I. C. S. (2018). Characterization of biosurfactant from yeast using residual soybean oil under acidic conditions and their use in metal removal processes. FEMS Microbiology Letters, 365(10), fny098.

Chandran, P., & Das, N. (2010). Biosurfactant production and diesel oil degradation by yeast species Trichosporon asahii isolated from petroleum hydrocarbon contaminated soil. International Journal of Engineering, Science and Technology, 2, 6942–6953.

Chandran, P., & Das, N. (2011). Characterization of sophorolipid biosurfactant produced by yeast species grown on diesel oil. International Journal of Science and Nature, 2, 63–71.

Cooper, D. G., & Paddock, D. A. (1984). Production of a biosurfactant from Torulopsis bombicola. Applied and Environmental Microbiology, 47, 173–176.

Desai, J. D., & Banat, I. M. (1997). Microbial production of surfactants and their commercial potential. Microbiology and Molecular Biology Reviews, 61(1), 47–64.

Deshpande, M., & Daniels, L. (1995). Evaluation of sophorolipid biosurfactant production by Candida bombicola using animal fat. Bioresource Technology, 54, 143–150.

Felse, P. A., Shah, V., Chan, J., Rao, K. J., & Gross, R. A. (2007). Sophorolipid biosynthesis by the yeast Candida bombicola from industrial fatty acid residues. Enzyme and Microbial Technology, 40(2), 499–504.

Guerfali, M., Ayadi, I., Mohamed, N., Ayadi, W., Belghith, H., Bronze, M. R., Ribeiro, M.H. and & Gargouri, A. (2019). Triacylglycerols accumulation and glycolipids secretion by the oleaginous yeast Rhodotorula babjevae Y-SL7: structural identification and biotechnological applications. Bioresource Technology, 273, 326-334.

Hua, Z., Chen, J., Lun, S., & Wang, X. (2003). Influence of biosurfactants produced by Candida antarctica on surface properties of microorganism and biodegradation of n-alkanes. Water Research, 3, 4143–4150.

Joshi, P. A., & Shekhawat, D. B. (2014). Screening and isolation of biosurfactant producing bacteria from petroleum contaminated soil. European Journal of Experimental Biology, 4(4), 164–169.

Kanga, S., Bonner, J., Page, C., Mills, M., & Autenrieth, R. (1997). Solubilization of naphthalene and methyl-substituted napthalanes from crude oil using biosurfactants. Environmental Science & Technology, 31, 556–561.

Kaur, K., Sangwan, S., & Kaur, H. (2017). Biosurfactant production by yeasts isolated from hydrocarbon polluted environments. Environmental Monitoring and Assessment, 189(12), 603.

Khopade, A., Biao, R., Liu, X., Mahadik, K., Zhang, L., & Kokare, C. (2011). Production and stability studies of the biosurfactant isolated from marine Nocardiopsis spp. B4. Desalination, 285, 198–204.

Khopade, A., Ren, B., Liu, X. Y., Mahadik, K., Zhang, L., & Kokare, C. (2012). Production and characterization of biosurfactant from marine Streptomyces species B3. Journal of Colloid and Interface Science, 367, 311–318.

Kiran, G. S., Hema, T. A., Gandhimathi, R., Selvin, J., Thomas, T. A., Rajeetha Ravji, T., & Natarajaseenivasan, K. (2009). Optimization and production of a biosurfactant from the sponge-associated marine fungus Aspergillus ustus MSF3. Colloids and Surfaces B: Biointerfaces, 73, 250–256.

Konishi, M., Fukuoka, T., Morita, T., Imura, T., & Kitamoto, D. (2008). Production of new types of sophorolipids by Candida batistae. Journal of Oleo Science, 57, 359–369.

Konishi, M., Morita, T., Fukuoka, T., Imura, T., Uemura, S., Iwabuchi, H., & Kitamoto, D. (2018). Efficient production of acid-form sophorolipids from waste glycerol and fatty acid methyl esters by Candida floricola. Journal of Oleo Science, 67(4), 489–496.

Morita, T., Konishi, M., Fukuoka, T., Imura, T., & Kitamoto, D. (2008). Production of glycolipid biosurfactants, mannosylerythritol lipids, by Pseudozyma siamensis CBS 9960 and their interfacial properties. Journal of Bioscience and Bioengineering, 105, 493–502.

Mulligan, C. N. (2005). Environmental applications for biosurfactants. Environmental Pollution, 133, 183–198.

Pacwa-Płociniczak, M., Płaza, G. A., Piotrowska-Seget, Z., & Cameotra, S. S. (2011). Environmental applications of biosurfactants: recent advances. International Journal of Molecular Sciences, 12(1), 633–654.

Rahman, K. S. M., Banat, I. M., Thahira, J., Thayumanavan, T., & Lakshmanaperumalsamy, P. (2002). Bioremediation of gasoline contaminated soil by a bacterial consortium amended with poultry litter, coir pith, and rhamnolipid biosurfactant. Bioresource Technology, 81(1), 25–32.

Rodrigues, L. R., Teixeira, J. A., Mei, H. C., & Oliveira, R. (2006). Physiochemical and functional characterization of a biosurfactant produced by Lactococcus lactis 53. Colloids and Surfaces B: Biointerfaces, 49, 79–86.

Sarubbo, L. A., Farias, C. B., & Campos-Takaki, G. M. (2007). Co-utilization of canola oil and glucose on the production of a surfactant by Candida lipolytica. Current Microbiology, 54(1), 68–73.

Thaniyavarn, J., Chianguthai, T., Sangvanich, P., Roongsawang, N., Washio, K., Morikawa, M., & Thaniyavarn, S. (2008). Production of sophorolipid biosurfactant by Pichia anomala. Bioscience, Biotechnology, and Biochemistry, 72, 2061–2068.

Thanomsub, B., Watcharachaipong, T., Chotelersak, K., Arunrattiyakorn, P., Nitoda, T., & Kanzaki, H. (2004). Monoacylglycerols: glycolipid biosurfactants produced by a thermotolerant yeast, Candida ishiwadae. Journal of Applied Microbiology, 96, 588–592.

Zinjarde, S. S., & Pant, A. (2002). Emulsifier from a tropical marine yeast, Yarrowia lipolytica NCIM 3589. Journal of Basic Microbiology, 42, 67–73.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sharma, P., Sangwan, S. & Kaur, H. Process parameters for biosurfactant production using yeast Meyerozyma guilliermondii YK32. Environ Monit Assess 191, 531 (2019). https://doi.org/10.1007/s10661-019-7665-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10661-019-7665-z