Abstract

Natural fiber reinforced green composites have been attracting high attention nowadays, as the green movement in the world forced companies to use green materials instead of synthetic fibre reinforced composites. In this respect, the aim of the study is to investigate usage possibility of undervalued Chrysanthemum morifolium stem fibers as a new reinforcement of composite materials. Chemical, thermal, crystallographic, density, mechanical and morphological characterizations of the C. morifolium fibers were examined. Crystallinity Index, density and tensile strength values were found as 65.18%, 1.33 g/cm3 and 65.12 MPa, respectively. Chrysanthemum morifolium has a low cellulose content of 32.9% while the thermal resistance temperature was determined as 267.5 °C. Although its cellulose content is low, C. morifolium fiber can be a good alternative for many other reinforcement plant fibers in terms of tensile strength. The high tensile strength of the fiber can be attributed to the high crystallinity index and fiber morphology advantage (low lumen diameter and thick cell wall). Hollow fiber morphology can increase the insulation and absorption properties of the fibers and can also create a usage area in lightweight composites by providing low density. This study suggests a novel sustainable ecological reinforcement fiber for green polymer composites with low density, reasonable tensile strength, high surface hydrophobicity and high surface roughness.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Since the early ages, metallic materials based on ferrous and non-ferrous have been used in the production of advanced technology vehicles such as aircraft from the simplest equipment. The need for lighter and stronger materials led to the development of composite materials after the discovery of polymers with low-density (Karthi et al. 2020).

The green movement in the world forced automotive companies to use bio-composite green materials instead of synthetic fibre reinforced composites (Ganapathy et al. 2019; Senthamaraikannan and Kathiresan 2018). Due to high cost-effectivity, sustainability, recyclability of the natural fiber-reinforced composites, high demand occurred in the last 20 years for natural fiber-reinforced polymeric composites in the fields of building and industrial panels, false ceilings, storage devices, automobile body panels, interiors and partition boards (Karthi et al. 2020; Kilinc et al. 2016; Seki et al. 2019a).

Natural fiber reinforced green composites provide biodegradable nature, lightweight, low tool wear, less energy utilization during processing and machining, less hazardous and easy to fabrication properties compared to traditional composites reinforced by artificial fibers (Senthamaraikannan and Kathiresan 2018). Thanks to these features, green composites used in many applications including sports equipment, building materials, aircraft parts, naval applications, household appliances and automobile parts (Senthamaraikannan and Kathiresan 2018). These popular applications forced researchers to explore new natural fibres with appropriate properties (Ganapathy et al. 2019). Accordingly, new natural fibers such as Conium maculatum (Kilinc et al. 2018b), Hierochloe Odarata (Dalmis et al. 2020), Furcraea foetida (Manimaran et al. 2018b), aerial roots of banyan tree (Ganapathy et al. 2019), Coccinia grandis.L (Senthamaraikannan and Kathiresan 2018), Lygeumspartum L. (Belouadaha et al. 2015) Cissusquadrangularis (Indran and Raj 2015) Althea Officinalis L. (Kilinc et al. 2018a) and Phoenix dactylifera L (Alotaibi et al. 2019) fibers were characterized. In addition, many modification studies have been carried out to give optimum properties to these fibers for possible utilization as reinforcement (Seki et al. 2018, 2019b). Many polymer-based green composites reinforced with natural fibers including coir, sisal, jute, and banana have being developed (Senthilkumar et al. 2019; Siakeng et al. 2019). Due to environmental and ecological advantages of green composites, it is very important to find alternative natural fibers suitable for them (Amroune et al. 2019; Saaidia et al. 2015; Sanjay et al.2019; Senthilkumar et al. 2018). Under the light of this trend, the characterization of the Chrysanthemum morifolium fiber for the polymer-based green composites is aimed in the present study for the first time.

C. morifolium is known as an important horticulture crop belongs to the Asteraceae family, among the 30 flowering species in the C. genus (Nissim-Levi et al. 2019). C.s are native to Asia and north-eastern Europe and are grown for flowering pots and cut for flower industry (Nissim-Levi et al. 2019). C. morifolium has a very important state in the world flower industry due to the fact that this plant is one of the ten most popular traditional flowers in China and one of the four most popular cut flowers in the world (Sun et al. 2010a, b; Wang et al. 2014). Taking advantage of the stem of such a popular flower will provide great economic value.

In this respect, the aim of the study is to characterize C. morifolium stem fibers as a novel natural fiber for the green polymeric composites. Structural, morphological and mechanical properties of the C. morifolium fibers are characterized by the help of Fourier Transform Infrared Spectroscopy (FTIR), X-Ray Photoelectron Spectroscopy (XPS), Thermogravimetric Analysis (TGA), X-Ray Diffraction Analysis (XRD), Scanning Electron Microscope (SEM), Archimedes density method, determination of chemical composition, and single fiber tensile tests.

Materials and methods

Fiber extraction

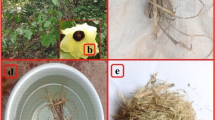

Chrysanthemum morifolium plants presented in Fig. 1 were harvested from Bahadırlı village of Çanakkale which is located about the northwest part of Turkey. The harvested C. morifolium plants were roughly cleaned from their branches and leaves. Separated stems were washed in distilled water to clean any dirt and dust afterward cut into parts of about 300 mm. The conventional water retting process was carried out for separation of C. morifolium fibers from the stem. In order to let microbial degradation, stem parts were immersed in a plastic tub filled by tap water and kept for 4 weeks for easy separation of fibers. Then, fibers were manually separated from the stem by brushing with a metal comb. Finally, the obtained fibers were washed with distilled water and dried in an oven at 60 °C for overnight to depart moisture.

Characterization methods

Density measurement

As the density measurement method, ASTM D8171-18, based on Archimedes Law (Method B) was used. Approximately 1 g of specimen was measured with 3 replications. Eq. (1) shows the density measurement formula.

where d represents the density, Wd and Ws are dry weight, and the effective mass of samples submerged in deionized water, respectively.

Chemical analysis

The fiber samples were oven-dried at 105 °C before chemical analysis. After removing the excess moisture from the fiber sample, cellulose and hemicellulose contents of Chysantemum fiber were determined in accordance with the previous study (Kilinc et al. 2018b).

Fourier transform infrared analysis

Fourier Transform Infrared (FTIR) analysis was used to identify functional groups of C. morifolium fibers with the aid of the Perkin Elmer Spectrum BX instrument. Data was recorded with a scan rate of 40 scans per minute and at a resolution of 2 cm−1 in the range of 650–4000 cm−1 wavenumber.

Thermogravimetric analysis

To investigate the thermal stability of C. morifolium, thermogravimetric analysis was conducted by using a Shimadzu DTG-60H instrument. The investigation was performed from room temperature to 800 °C at a rate of 10 °C/min. To prevent oxidation, the analysis was conducted under a nitrogen atmosphere with a flow rate of 100 ml/min. 10 mg of C. morifolium fibers were used for the test.

X-ray photoelectron spectroscopy analysis

The chemical states and surface compositions of C. morifolium fibers were determined with aid of Thermo Scientific instrument. Al-Kα (1486.7 eV) X-ray source was applied in the range of 1350 and 10 eV with a resolution of 1 eV. The surface of the sample was sputtered with ionic Ar gas before the analysis.

X-ray diffraction analysis

Crystallinity index and crystallite size calculations were performed by the help of the data obtained from X-Ray diffraction pattern of the fibers by using Rigaku Ultima 3 device with Cu–Kα radiation (λ-Kα1 = 1.54 Å). In order to put fibres on specimen holder, fibres were cut into small pieces. XRD device was set to 40 kV and 30 mA power, and scanning was done between 5° and 80° range with 2°/min scan rate.

The crystallinity index (CI) was determined by using the empirical formula [Eq. (2)] by Segal et al. (Segal et al. 1959).

where I200 represents the peak at the maximum intensity that relates to the (200) lattice plane between 22° and 23°, and Iam is the minimum intensity value between the highest two peaks, which is at a 2θ angle between 18° and 19° (French 2014; Seki et al. 2013). Crystallite size (L) of fibers were also obtained from the XRD pattern and calculated by using the Scherrer’s Equation [Eq. (3) (Warren 1990)]

where L is the crystallite size, K is the Scherrer constant (0.94), \(\lambda\) is the wavelength of the x-ray beam, and β is the peak full width half maximum (FWHM).

Single fiber tensile test

The tensile tests of C. morifolium were conducted using INSTRON 4411 universal testing machine equipped with 1 kgf load cell. The loading rate was 1 mm/min with a gauge length of 20 mm. Pneumatic grips which were used for clamping the fibre have of 0.5 MPa pressure. Ten fiber samples were tested to determine tensile properties of C. morifolium fiber. All tests were performed at standard atmospheric conditions (20 ± 2 °C ambient temperature and 65 ± 4% relative humidity) in accordance with ASTM D 3822 standard.

Morphological characterization

A JEOL-JJM 6060 model scanning electron microscope (SEM) was used for the characterization of the surface and cross-sectional morphologies of C. morifolium fibers. Scanning electron images were taken with an accelerating voltage of 5 kV. In order to obstruct electron charging effects during the examination, C. morifolium fibers were coated with Au–Pd alloy by sputter coating prior to characterization.

Results and discussion

Density results

The density of C. morifolium bast fibres was calculated by using Eq. (1) and found as 1.336 g/cm3. It can be easily seen from Table 1, that the density of C. morifolium is very similar to the density of many common natural fibers like sisal, jute, and banana fibers. But there are also lighter fibers obtained from other plants, for example, Hierochloe Oderata, and coir. As lightweight is one of the main properties that a natural fiber needs to have, because of its low density C. morifolium becomes a good option for use in composites.

Chemical composition

Cellulose, hemicellulose and lignin are the chief components of the lignocellulosic fibers (Rowell and Stout 2006). The chemical composition of cellulosic fiber is reportedly affected by extraction methods, soil properties, age and origin of the plant (Baskaran et al. 2018). The chemical compositions of C. morifolium some recently characterized lignocellulosic fibers are compared from the available data and listed in Table 2.

Chemical analysis of C. morifolium showed low cellulose content of 32.9% in comparison with fibers from Hierochloe Odarata, Sida Cordfolia, Epipremnum Aurem and Cereus Hildmannianus (Dalmis et al. 2020; Maheshwaran et al.2018; Manimaran et al. 2018b; Subramanian et al. 2019). Besides, C. morifolium has comparable cellulose content with Tridax Procumbens, Juncus Effusus, coir and bagasse fibers (Justiz-Smith et al. 2008; Maache et al. 2017; Vijay et al. 2019). The extensive hydrogen bonds between cellulose chains may increase crystallinity and enhance mechanical properties of the fibers (Silva et al. 2019). The hemicellulose content (13.8%) is comparable with jute, flax and coir fibers (Bulut and Aksit 2013; Justiz-Smith et al. 2008; Nilsson and Gustafsson 2007). High level content of hemicellulose may lead to the disintegration of cellulose micro fibrils (Indran and Raj 2015). Hemicellulose is responsible from moisture content of the fiber possibly due to its amorphous region. The content of the rest of the components including lignin, oils, and waxes is experimentally 53.3%. To summarize, it is possible to indicate that C. morifolium can be a candidate as a reinforcement fiber regarding to chemical composition data.

FTIR analysis

To clarify the main component of natural fiber (lignin, cellulose, and hemicellulose), and their functional groups (ester, ketone, and alcohol) FT-IR spectroscopy was utilized for characterization (De Rosa et al. 2010; Fan et al. 2011). The functional groups of C. morifolium fibers are given in Fig. 2 with the range of 4000–650 cm−1. As seen from the spectrum a broad peak observed at 3340 cm−1 related to characteristic O–H stretching vibrations of cellulose (Porras et al. 2015). The peak located at 2922 cm−1 is assigned of the C–H stretching vibrations of CH and CH2 in cellulose and hemicellulose (Oh et al. 2005). The peak located at 1737 cm−1 can be related to stretching vibration of the C=O group in the ester group of hemicellulose or carboxylic acid in lignin and the distinct absorption peak at 1628 cm−1 can be ascribed to H–O–H bending vibration of water in fiber (De Rosa et al. 2010, 2011). The small peak located at nearly 1510 cm−1 corresponds to the C= stretching of aromatic lignin in the fiber(Kilinc et al. 2018b). The peaks detected at 1428 cm−1 correspond to the symmetric bending of CH2 in cellulose (Sgriccia et al. 2008b). The two peaks located at 1377 and 1330 C–H cm−1 can be associated with the C–O bending vibrations of aromatic rings of hemicellulose and lignin (Jonoobi et al. 2009; Sreenivasan et al. 2011). The peaks located at 1250 cm−1 are associated with C–O stretching vibration of the acetyl groups in lignin (Tawakkal et al. 2016). The intense peak nearly at 1028 cm−1 is related to the C–O and O–H stretching vibrations in fiber (Dalmis et al. 2020). The band at 896 cm−1 is related to the β-glycosidic linkages between the monosaccharides (Mwaikambo and Ansell 2002). These results can indicate the existence of the main components of natural fiber (lignin, cellulose, and hemicellulose) similar to the most utilized natural fibers such as jute (Saha et al. 2010), hemp (Sawpan et al. 2011), kenaf (Keshk et al. 2006).

Thermogravimetric analysis

Investigation of the thermal behavior of natural fiber is important because the fabrication of polymer composite generally executed at relatively high temperatures. To manufacture composite without any degradation of natural fiber at relatively high-temperature and to utilize its properties at a maximum rate we need to understand the thermal behavior of fibers. Natural fiber generally consists of lignin, cellulose, and hemicellulose, which can possibly affect the thermal stability of natural fibers. Finding the degradation temperature of C. morifolium fibers can help to learn about the thermal behavior these fibers (Belouadah et al. 2015; Sarikanat et al. 2014). In this respect, TGA analysis was used to investigate the thermal behavior of the C. morifolium fibers. TG/DTG curves of the fibers are given in Fig. 3. The first weight loss with 8.978% occurred between 25 and 100 °C due to the evaporation of water (Ridzuan et al. 2016). The next degradation was observed at 267.5 °C with the 16.3% weight loss which corresponds to the decomposition of hemicellulose in fibers (Saravanakumar et al. 2013). This temperature also indicates the decomposition onset temperature of fibers (Yao et al. 2008). The last degradation was recorded at 350 °C with major weight loss (48.12%) associated with the decomposition of cellulose and lignin in fiber (Baskaran et al. 2018; Mahmood et al. 2016) which indicates the maximum degradation temperature of C. morifolium fibers. Similar maximum decomposition temperatures related to the decomposition of cellulose were observed at different studies examining sisal, jute, and flax at 340 °C (Manfredi et al. 2006), 365 °C (Alvarez et al. 2006), and 345 °C (Manfredi et al. 2006), respectively (Indran and Raj E. 2015; Saravanakumar et al. 2013). Also, C. morifolium fibers decompose at higher temperatures as compared with some recently characterized cellulosic fibers such as Chloris Barbata (324.6 °C) (Balasundar et al. 2018), Heteropogon Contortus (337.7 °C) (Rajesh Jesudoss Hyness et al. 2018), Acacia Leucophloea (346.8 °C) (Arthanarieswaran et al. 2015) and Thespesia populnea (323.8 °C) (Kathirselvam et al. 2019).

Also, the high crystallinity index of C. morifolium fiber with 65.18% compatible with the high maximum degradation temperature of fibers (Jonoobi et al. 2009). The measurement was conducted to the 800 °C and after major decomposition, 8.54% weight loss recorded, which is related to the residual content in the fiber (Balasundar et al. 2018). Thermal analysis indicates that C. morifolium fiber is thermally stable up to 267.5 °C which is higher than the onset temperature of the most utilized natural fibers such as hemp (205.1 °C), kenaf (219 °C), jute (205.1 °C) (Yao et al. 2008). This result indicates that C. morifolium fiber can be proper reinforcement for polymer matrix composites because of high onset temperature considering the manufacturing temperature of the polymer composite, without any degradation under its onset temperature (267.5 °C) (Belouadah et al. 2015; Sarikanat et al. 2014).

XPS analysis

The chemical states and surface compositions of C. morifolium fibers were investigated using XPS. The elemental compositions of C. morifolium fiber surface were listed in Table 3. The main component of the fiber surface is carbon that is followed by oxygen. Concentrations of carbon and oxygen were determined as 66.33% and 27.45%, respectively. To determine the surface hydrophilic or hydrophobic character of fibers, Carbon/Oxygen (C/O) and Oxygen /Carbon (O/C) ratios of fibers were calculated using XPS data. The O/C ratio of C. morifolium (0.41) is higher than the most known cellulosic fibers such as flax (0.156) (Csiszar et al. 2013), hemp (0.27), sisal (0.29) (Seki et al. 2019a, b) and Henequen fibers (0.25) (Sgriccia et al. 2008a). However, the value is lower than that of Luffa Cylindrica (0.61), oil palm mesocarp fiber (1.00) and oil palm kernel shell (1.07) (Sabil et al. 2013). In general, a high C/O ratio is associated with the hydrophobic surface characteristic in fibers and this parameter is important for cellulose-based fiber-reinforced composite materials (Sernek et al. 2004).

As compared to common fibers such as such as jute (2.09) and kenaf (2.38) (Sgriccia et al. 2008a) taking into account surface C/O ratio, C. morifolium can be used as a reinforcement in green composites with a high C/O ratio (2.40).

In order to determine the content of the functional groups, deconvolution analysis was used for C1s and O1s peaks. The high-resolution XPS spectra of C1s and O1s peaks are given in Fig. 4. The main peak at 285.52 eV is the most prominent peak in all represents C–C, C–H bonds which can indicate the presence of cellulose or ether (Pandey et al. 2020). The 532.25 eV peak is of cellulosic or cyanoethyl cellulose peak which is having C–O–C bond and signifies the presence of cellulose in material (Pandey et al. 2020).

XRD analysis

The XRD pattern of C. morifolium is shown in Fig. 5. There is a broad amorphous part showing peak intensities between 13.36° and 18.66°, which is contributed to the two peaks of cellulose-I, that (110) and (\(1\overline{1}0\)) lattice planes overlap (Manimaran et al. 2018b). At 18.72° the minimum intensity between these peaks can be seen for measuring the crystallinity index. The main peak seen in XRD pattern is related with cellulose (200) lattice plane, which is at 21.94°. Also a weak peak at 34° can be assigned to the (004) plane (Oh et al. 2005). Crystallinity Index (CI) of C. morifolium fibers calculated by Segal formula is 65.18%, which is comparatively higher than many natural fibers extracted from different plant sources (see Table 4). With increasing crystallinity, the cellulosic chains become more regularly aligned and helps to increase the tensile properties of the fibers (Ehrenstein2012). Therefore, as a reinforcement higher crystallinity helps the production of high-strength composites. Thermal degradation temperature of natural fibers is also improved with increasing crystallinity (Kim et al. 2010).

The crystallite size of C. morifolium fibers is shown in Table 4. Crystallite size is a measure of coherency of the related XRD peak which is (200) lattice plane of cellulose (French 2014). With the increasing crystallite size, the amount of amorphous structure becomes diminished and this increases the CI value of the cellulose (Kim et al. 2010).

Single fiber tensile properties

The mechanical properties of natural fibers highly depend on their structure and chemical composition. When the literature is analyzed, it is seen that there is a wide distribution for the reported mechanical values of cellulose-based fibers. This variability is due to some reasons such as test conditions, plant characteristics, extraction, maturity, growing conditions, harvesting period, degree of retting, irregular cross-section, section measurements, defects on the fiber surface and etc. (Fidelis et al.2013; Kilinc et al. 2018b; Owonubi et al. 2019). On the other hand, it is known that high cellulose content provides better tensile strength and modulus values because cellulose possesses specific characters such as high degree of polymerization and its linear orientation (Baskaran et al. 2018; Senthamaraikannan et al. 2019; Thakur and Singha 2010). The cellulose content and mechanical properties of C. morifolium and some lignocellulosic fibers are listed in Table 5. When the values are examined, it is seen that although the cellulose content of C. morifolium is lower than Veldt-grape stem (VSF), Palm leaf stalk (WLF), banyan tree, Catharanthus roseus, coconut tree leaf sheath, and Grewia tilifolia fibers, C. morifolium fibers have comparable and even higher tensile strength values (Ganapathy et al. 2019; Indran and Raj 2015; Jayaramudu et al. 2010; Mayandi et al. 2015; Vinod et al. 2019). The fact that the fibers exhibit high strength despite the low cellulose ratio can be attributed to the more regular formation of the cellulosic chains due to the high crystallinity as mentioned in the crystallinity characterizations (Ehrenstein 2012). Furthermore, the elongation values of C. morifolium is also quite good. It is known that the mechanical properties of fiber-reinforced composites depend on some other parameters such as matrix composition, mechanical properties of matrix, fiber orientation angle, fiber-matrix shear strength and adhesion and also mechanical properties of reinforcement fiber (Goda et al. 2009; Saheb and Jog 1999; Shesan et al. 2019). In addition, it is thought that this fiber can be a good alternative for green composites with reasonable mechanical properties and similar properties to other reinforcement plant fibers such as palm and coconut. The stress–strain curve of C. morifolium fiber is given in Fig. 6 that a sudden decrease in stress value indicates the nature of the brittle failure.

Morphological characterizations

The morphology of the C. morifolium fibers was examined according to Fig. 7, where the longitudinal and cross-sectional SEM images are presented. Surface morphology can be interpreted from the longitudinal fiber section in Fig. 7a. It is seen that the fiber sample has a diameter of about 118 µm. It can be concluded that C. morifolium fibers are thinner than Banana pseudo-stem, coir, sisal, and palmyra fibers while thicker than pineapple leaf fiber, considering the average diameter of the fibers (Asmanto and Chafidz 2018). It is very clear that C. morifolium fibers have many particles [might be wax, lignin or impurities (Senthamaraikannan and Kathiresan 2018)] and porosities on the surface. These irregularities increase the surface roughness of the fibers. Increased surface roughness is a big advantage for composite systems due to providing better adherence to the fiber with the matrix (Indran and Raj 2015). Moreover, Zhang et al. (2018) have mentioned that rough surface can improve interfacial bonding between fiber and matrix by the means of mechanical interlocking.

When cross-sectional SEM images of the C. morifolium fibers are examined from Fig. 7b, elementary fibers can be observed. It can be concluded that similar to the other natural fibers, C. morifolium fibers consist of many several elementary fibers bound together by pectin or other non-cellulosic compounds (Kilinc et al. 2018b). Empty spaces (called lumen) in the center of the fibers corresponding to the channels, where nutrients and water flow take place throughout the fiber can be observed from cross-sectional images (Sanjay et al. 2018). The observed central hole explains why C. morifolium natural fiber has a low density. Furthermore, the hollow structure due to the lumen phenomenon, provides good insulation and absorbance properties to the fiber (Asmanto and Chafidz 2018). Cross-sectional SEM images showed up that elementary fibers have a diameter of 10 µm, while the cell wall thickness is about 3 µm and lumen diameter is about 4 μm. The natural fibers generally have similar morphology, but they differ from each other by factors including wall thickness, lumen, and fiber diameters. That's why it is important to compare some of these properties of the new fiber with popular natural fibers. For example, Fidelis et al. found that strength and Young's modulus could be increased by low lumen area and high cell-wall thickness (Fidelis et al. 2013). When compared to this study, the lumen diameter of the C. morifolium fiber is equal to that of the curaua fiber and smaller than the jute and sisal fibers (Fidelis et al. 2013). Also, C. morifolium fiber has higher cell wall thickness than jute and sisal fibers while lower than curaua fiber (Fidelis et al. 2013). In the previous section, it was stated that high crystallinity helps the C. morifolium fibers to have good strength despite low cellulose ratio. It is thought that morphological advantages of C. morifolium fiber such as low lumen range and thick cell wall contribute to this situation.

Conclusion

This study aimed to investigate whether C. morifolium fiber properties are suitable for use in green composites as a new potential reinforcement material. Thermal resistance temperature is analyzed to be 267.5 °C that can facilitate extrusion of polymer-based composites. Main components of C. morifolium fiber such as cellulose, hemicellulose and lignin was determined by FTIR and XPS analyses like other cellulosic fibers. Surface C/O ratio is found to be relatively high (2.4), which is a desired feature for the natural fiber reinforcements for helping to improve fiber/matrix compatibility. Cellulose content of C. morifolium fiber is analysed to be 32.9% which is quite low comparing with other fibers. Tensile strength as 65.12 MPa supports the claim that C. morifolium fiber can be a good alternative for many reinforcement fibers. The relatively high tensile strength of the fiber can be attributed to the high crystallinity index (65.18%) and characteristic fiber morphology (low lumen diameter and thick cell wall) associated with XRD and SEM results. In addition, hollow fiber morphology can increase the insulation and absorption properties of the fibers and can create an application area in lightweight composites by providing low density such as 1.33 g/cm3. In summary, C. morifolium fiber is a good natural reinforcement candidate for green composites with high thermal resistance, high hydrophobicity, reasonable tensile strength, low density, and rough surface. The development of C. morifolium fiber-reinforced green composites can be aimed for future studies.

References

Alotaibi MD, Alshammari BA, Saba N, Alothman OY, Sanjay MR, Almutairi Z, Jawaid M (2019) Characterization of natural fiber obtained from different parts of date palm tree (Phoenix dactylifera L.). Int J Biol Macromol 135:69–76

Alvarez V, Rodriguez E, Vazquez A (2006) Thermal degradation and decomposition of jute/vinylester composites. J Therm Anal Calorim 85(2):383–389

Amroune S, Bezazi A, Dufresne A, Scarpa F, Imad A (2019) Investigation of the date palm fiber for green composites reinforcement: thermo-physical and mechanical properties of the fiber. J Nat Fibers, pp 1–18

Arthanarieswaran VP, Kumaravel A, Saravanakumar SS (2015) Characterization of new natural cellulosic fiber from bark. Int J Polym Anal Charact 20(4):367–376

Asmanto S, Chafidz A (2018) Banana pseudo-stem fiber: Preparation, characteristics, and applications. In: Banana Nutrition-Function and Processing Kinetics, IntechOpen

Balasundar P, Narayanasamy P, Senthamaraikannan P, Senthil S, Prithivirajan R, Ramkumar T (2018) Extraction and characterization of new natural cellulosic chloris barbata fiber. J Nat Fibers 15(3):436–444

Baskaran PG, Kathiresan M, Senthamaraikannan P, Saravanakumar SS (2018) Characterization of new natural cellulosic fiber from the bark of dichrostachys cinerea. J Nat Fibers 15(1):62–68

Belouadah Z, Ati A, Rokbi M (2015) Characterization of new natural cellulosic fiber from Lygeum spartum L. Carbohyd Polym 134:429–437

Belouadaha Z, Atib A, Rokbi M (2015) Characterization of new natural cellulosic fiber from Lygeumspartum L. Carbohydr Polym 134:439–437

Bulut Y, Aksit A (2013) A comparative study on chemical treatment of jute fiber: potassium dichromate, potassium permanganate and sodium perborate trihydrate. Cellulose 20(6):3155–3164

Csiszar E, Fekete E, Toth A, Bandi E, Koczka B, Sajo I (2013) Effect of particle size on the surface properties and morphology of ground flax. Carbohyd Polym 94(2):927–933

Dalmis R, Koktas S, Seki Y, Kilinc AC (2020) Characterization of a new natural cellulose based fiber from Hierochloe Odarata. Cellulose 27(1):127–139

De Rosa IM, Kenny JM, Maniruzzaman M, Moniruzzaman M, Monti M, Puglia D, Santulli C, Sarasini F (2011) Effect of chemical treatments on the mechanical and thermal behaviour of okra (Abelmoschus esculentus) fibres. Compos Sci Technol 71(2):246–254

De Rosa IM, Kenny JM, Puglia D, Santulli C, Sarasini F (2010) Morphological, thermal and mechanical characterization of okra (Abelmoschus esculentus) fibres as potential reinforcement in polymer composites. Compos Sci Technol 70(1):116–122

Ehrenstein GW (2012) Polymeric materials: structure, properties, applications. Carl Hanser Verlag GmbH Co KG

Fan, M., Dai, D., Huang, B. 2011. Fourier Transform Infrared Spectroscopy for Natural Fibres. in: Fourier transform-materials analysis, pp. 45–68.

Fidelis M, Pereira T, Gomes O, Silva F, Toledo Filho R (2013) The effect of fiber morphology on the tensile strength of natural fibers. J Mater Res Technol 2:149–157

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21(2):885–896

Ganapathy T, Sathiskumar R, Senthamaraikannan P, Saravanakumar SS, Khan A (2019) Characterization of raw and alkali treated new natural cellulosic fibres extracted from the aerial roots of banyan tree. Int J Biol Macromol 138:573–581

Goda K, Takagi H, Netravali AN (2009) Fully biodegradable green composites reinforced with natural fibers. In: Natural fibre reinforced polymer composites, Old City Publishing, pp. 329–360

Holbery J, Houston D (2006) Natural-fiber-reinforced polymer composites applications in automotive. Jom 58(11):80–86

Ilangovan M, Guna V, Hu C, Nagananda GS, Reddy N (2018) Curcuma longa L. plant residue as a source for natural cellulose fibers with antimicrobial activity. Ind Crops Prod 112:556–560

Indran S, Raj E, R. (2015) Characterization of new natural cellulosic fiber from Cissusquadrangularis stem. Carbohyd Polym 117:392–399

Indran S, Raj RE (2015) Characterization of new natural cellulosic fiber from Cissus quadrangularis stem. Carbohyd Polym 117:392–399

Jabli M, Tka N, Ramzi K, Saleh TA (2018) Physicochemical characteristics and dyeing properties of lignin-cellulosic fibers derived from Nerium oleander. J Mol Liq 249:1138–1144

Jayaramudu J, Guduri BR, Rajulu AV (2010) Characterization of new natural cellulosic fabric Grewia tilifolia. Carbohyd Polym 79(4):847–851

Jonoobi M, Harun J, Shakeri A, Misra M, Oksman K (2009) Chemical composition, crystallinity, and thermal degradation of bleached and unbleached kenaf bast (Hibiscus cannabinus) pulp and nanofibers. BioResources 4(2):626–639

Justiz-Smith NG, Virgo GJ, Buchanan VE (2008) Potential of Jamaican banana, coconut coir and bagasse fibres as composite materials. Mater Charact 59(9):1273–1278

Karthi N, Kumaresan K, Sathish S, Gokulkumar S, Prabhu L, Vigneshkumar N (2020) An overview: natural fiber reinforced hybrid composites, chemical treatments and application areas. Materials today: proceedings

Kathirselvam M, Kumaravel A, Arthanarieswaran VP, Saravanakumar SS (2019) Isolation and characterization of cellulose fibers from Thespesia populnea barks: a study on physicochemical and structural properties. Int J Biol Macromol 129:396–406

Keshk S, Suwinarti W, Sameshima K (2006) Physicochemical characterization of different treatment sequences on kenaf bast fiber. Carbohyd Polym 65(2):202–206

Kilinc AC, Atagur M, Ozdemir O, Sen I, Kucukdogan N, Sever K, Seydibeyoglu O, Sarikanat M, Seki Y (2016) Manufacturing and characterization of vine stem reinforced high density polyethylene composites. Compos Part B Eng 91:267–274

Kilinc AC, Koktas S, Atagur M, Seydibeyoglu MO (2018a) Effect of Extraction Methods on the Properties of Althea Officinalis L. Fibers. J Nat Fibers 15(3):325–336

Kilinc AC, Koktas S, Seki Y, Atagur M, Dalmis R, Erdogan UH, Goktas AA, Seydibeyoglu MO (2018b) Extraction and investigation of lightweight and porous natural fiber from Conium maculatum as a potential reinforcement for composite materials in transportation. Compos Part B Eng 140:1–8

Kim UJ, Eom SH, Wada M (2010) Thermal decomposition of native cellulose: Influence on crystallite size. Polym Degrad Stab 95(5):778–781

Kommula VP, Reddy KO, Shukla M, Marwala T, Rajulu AV (2013) Physico-chemical, tensile, and thermal characterization of napier grass (Native African) fiber strands. Int J Polym Anal Charact 18(4):303–314

Kulkarni AG, Satyanarayana KG, Rohatgi PK, Vijayan K (1983) Mechanical-properties of banana fibers (Musa-Sepientum). J Mater Sci 18(8):2290–2296

Maache M, Bezazi A, Amroune S, Scarpa F, Dufresne A (2017) Characterization of a novel natural cellulosic fiber from Juncus effusus L. Carbohyd Polym 171:163–172

Madsen B, Brøndsted P, Andersen TL (2013) Biobased composites: materials, properties and potential applications as wind turbine blade materials. Advances in wind turbine blade design and materials. Woodhead Publishing, Cambridge, pp 363–386

Maheshwaran MV, Hyness NRJ, Senthamaraikannan P, Saravanakumar SS, Sanjay MR (2018) Characterization of natural cellulosic fiber from Epipremnum aureum stem. Journal of Natural Fibers 15(6):789–798

Mahmood H, Moniruzzaman M, Yusup S, Akil HM (2016) Pretreatment of oil palm biomass with ionic liquids: a new approach for fabrication of green composite board. J Clean Prod 126:677–685

Manfredi LB, Rodriguez ES, Wladyka-Przybylak M, Vazquez A (2006) Thermal degradation and fire resistance of unsaturated polyester, modified acrylic resins and their composites with natural fibres. Polym Degrad Stab 91(2):255–261

Manimaran P, Prithiviraj M, Saravanakumar SS, Arthanarieswaran VP, Senthamaraikannan P (2018a) Physicochemical, tensile, and thermal characterization of new natural cellulosic fibers from the stems of Sida cordifolia. J Nat Fibers 15(6):860–869

Manimaran P, Senthamaraikannan P, Sanjay MR, Marichelvam MK, Jawaid M (2018b) Study on characterization of Furcraea foetida new natural fiber as composite reinforcement for lightweight applications. Carbohyd Polym 181:650–658

Mayandi K, Rajini N, Pitchipoo P, Sreenivasan VS, Jappes JTW, Alavudeen A (2015) A comparative study on characterisations of Cissus quadrangularis and Phoenix reclinata natural fibres. J Reinf Plast Compos 34(4):269–280

Mohanty AK, Misra M, Drzal LT (2005) Natural fibers, biopolymers, and biocomposites. CRC Press, Boca Raton

Mwaikambo LY, Ansell MP (2002) Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J Appl Polym Sci 84(12):2222–2234

Nilsson T, Gustafsson PJ (2007) Influence of dislocations and plasticity on the tensile behaviour of flax and hemp fibres. Compos Part A Appl Sci Manuf 38(7):1722–1728

Nissim-Levi A, Kitron M, Nishri Y, Ovadia R, Forer I, Oren-Shamir M (2019) Effects of blue and red LED lights on growth and flowering of Chrysanthemum morifolium. Sci Hortic 254:77–83

Oh SY, Yoo DI, Shin Y, Seo G (2005) FTIR analysis of cellulose treated with sodium hydroxide and carbon dioxide. Carbohyd Res 340(3):417–428

Owonubi JS, Agwuncha CS, Anusionwu GC, Revaprasadu N, Rotimi SE (2019) Improving the mechanical properties of natural fiber composites for structural and biomedical applications. In: Renewable and sustainable composites, IntechOpen

Pandey R, Sinha MK, Dubey A (2020) Cellulosic fibers from Lotus (Nelumbo nucifera) peduncle. J Nat Fibers 17(2):298–309

Porras A, Maranon A, Ashcroft IA (2015) Characterization of a novel natural cellulose fabric from Manicaria saccifera palm as possible reinforcement of composite materials. Compos Part B Eng 74:66–73

Ridzuan MJM, Majid MSA, Afendi M, Kanafiah SNA, Zahri JM, Gibson AG (2016) Characterisation of natural cellulosic fibre from Pennisetum purpureum stem as potential reinforcement of polymer composites. Mater Des 89:839–847

Rowell RM, Stout HP (2006) Jute and kenaf in handbook of fiber chemistry. CRC Press, Boca Raton

Saaidia A, Bezazi A, Belbah A, Amroune S, Scarpa F (2015) Evaluation of mechanical properties of jute yarns by two- and threeparameters weibull method. INTEGRITET I VEK KONSTRUKCIJA 15(3):157–162

Sabil KM, Aziz MA, Lal B, Uemura Y (2013) Effects of torrefaction on the physiochemical properties of oil palm empty fruit bunches, mesocarp fiber and kernel shell. Biomass Bioenerg 56:351–360

Saha P, Manna S, Chowdhury SR, Sen R, Roy D, Adhikari B (2010) Enhancement of tensile strength of lignocellulosic jute fibers by alkali-steam treatment. Biores Technol 101(9):3182–3187

Saheb DN, Jog JP (1999) Natural fiber polymer composites: A review. Adv Polym Technol 18(4):351–363

Sanjay MR, Madhu P, Jawaid M, Senthamaraikannan P, Senthil S, Pradeep S (2018) Characterization and properties of natural fiber polymer composites: a comprehensive review. J Clean Prod 172:566–581

Sanjay MR, Siengchin S, Parameswaranpillai J, Jawaid M, Pruncu CI, Khan A (2019) A comprehensive review of techniques for natural fibers as reinforcement in composites: Preparation, processing and characterization. Carbohyd Polym 207:108–121

Saravanakumar SS, Kumaravel A, Nagarajan T, Sudhakar P, Baskaran R (2013) Characterization of a novel natural cellulosic fiber from Prosopis juliflora bark. Carbohyd Polym 92(2):1928–1933

Sarikanat M, Seki Y, Sever K, Durmuskahya C (2014) Determination of properties of Althaea officinalis L. (Marshmallow) fibres as a potential plant fibre in polymeric composite materials. Compos Part B Eng 57:180–186

Sathishkumar TP, Navaneethakrishnan P, Shankar S, Rajasekar R (2013) Characterization of new cellulose sansevieria ehrenbergii fibers for polymer composites. Compos Interfaces 20(8):575–593

Sawpan MA, Pickering KL, Fernyhough A (2011) Effect of various chemical treatments on the fibre structure and tensile properties of industrial hemp fibres. Compos Part A Appl Sci Manuf 42(8):888–895

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29(10):786–794

Seki Y, Kilinc AC, Dalmis R, Atagur M, Koktas S, Goktas AA, Celik E, Seydibeyoglu MO, Onay AB (2018) Surface modification of new cellulose fiber extracted from Conium maculatum plant: a comparative study. Cellulose 25(6):3267–3280

Seki Y, Kilinc AC, Dalmis R, Koktas S, Celik E (2019a) Characterization of Flax, Jute, and Sisal Fibers after Sodium Perborate Modification. Aatcc J Res 6(6):25–31

Seki Y, Koktas S, Kilinc AC, Dalmis R (2019b) Green alternative treatment for cellulosic fibers: ionic liquid modification of Abelmoschus esculentus fibers with methyl-tri-n-butyl ammonium methyl sulphate. Mater Res Express 6(8):085104

Seki Y, Sarikanat M, Sever K, Durmuskahya C (2013) Extraction and properties of Ferula communis (chakshir) fibers as novel reinforcement for composites materials. Compos Part B Eng 44(1):517–523

Senthamaraikannan P, Kathiresan M (2018) Characterization of raw and alkali treated new natural cellulosic fiber from Coccinia grandis. L Carbohydrate Polymers 186:332–343

Senthamaraikannan P, Sanjay MR, Bhat KS, Padmaraj NH, Jawaid M (2019) Characterization of natural cellulosic fiber from bark of Albizia amara. J Nat Fibers 16(8):1124–1131

Senthilkumar K, Saba N, Chandrasekar M, Jawaid M, Rajini N, Alothman OY, Siengchin S (2019) Evaluation of mechanical and free vibration properties of the pineapple leaf fibre reinforced polyester composites. Constr Build Mater 195:423–431

Senthilkumar K, Saba N, Rajini N, Chandrasekar M, Jawaid M, Siengchin S, Alotman OY (2018) Mechanical properties evaluation of sisal fibre reinforced polymer composites: a review. Constr Build Mater 174:713–729

Sernek M, Kamke FA, Glasser WG (2004) Comparative analysis of inactivated wood surfaces. Holzforschung 58(1):22–31

Sgriccia N, Hawley MC, Misra M (2008a) Characterization of natural fiber surfaces and natura fiber composites. Compos Part A 39:1632–1637

Sgriccia N, Hawley MC, Misra M (2008b) Characterization of natural fiber surfaces and natural fiber composites. Compos Part A Appl Sci Manuf 39(10):1632–1637

Shesan OJ, Stephen AC, Chioma AG, Neerish R, Rotimi SE (2019) Improving the mechanical properties of natural fiber composites for structural and biomedical applications. In: Renewable and sustainable composites, IntechOpen

Siakeng R, Jawaid M, Ariffin H, Sapuan SM, Asim M, Saba N (2019) Natural fiber reinforced polylactic acid composites: A review. Polym Compos 40(2):446–463

Silva AMBD, Luz SMD, Siva I, Jappes JTW, Amico SC (2019) An overview on plant fiber technology: an interdisciplinary approach. Sustainable polymer composites and nanocomposites. Springer, Berlin, pp 977–999

Sreenivasan VS, Somasundaram S, Ravindran D, Manikandan V, Narayanasamy R (2011) Microstructural, physico-chemical and mechanical characterisation of Sansevieria cylindrica fibres—An exploratory investigation. Mater Des 32(1):453–461

Subramanian SG, Rajkumar R, Ramkumar T (2019) Characterization of natural cellulosic fiber from cereus hildmannianus. J Nat Fibers, pp 1–12

Sun CQ, Chen FD, Teng NJ, Liu ZL, Fang WM, Hou XL (2010a) Factors affecting seed set in the crosses between Dendranthema grandiflorum (Ramat.) Kitamura and its wild species. Euphytica 171(2):181–192

Sun CQ, Chen FD, Teng NJ, Liu ZL, Fang WM, Hou XL (2010b) Interspecific hybrids between Chrysanthemum grandiflorum (Ramat.) Kitamura and C. indicum (L.) Des Moul and their drought tolerance evaluation. Euphytica 174(1):51–60

Tawakkal ISMA, Cran MJ, Bigger SW (2016) Interaction and quantification of thymol in active PLA-based materials containing natural fibers. J Appl Polym Sci, 133(2)

Thakur VK, Singha AS (2010) Natural fibres-based polymers: part I-mechanical analysis of Pine needles reinforced biocomposites. Bull Mater Sci 33(3):257–264

Vijay R, Singaravelu DL, Vinod A, Sanjay MR, Siengchin S, Jawaid M, Khan A, Parameswaranpillai J (2019) Characterization of raw and alkali treated new natural cellulosic fibers from Tridax procumbens. Int J Biol Macromol 125:99–108

Vinod A, Vijay R, Singaravelu DL, Sanjay MR, Siengchin S, Moure MM (2019) Characterization of untreated and alkali treated natural fibers extracted from the stem of Catharanthus roseus. Mater Res Express 6(8):085406

Wambua P, Ivens J, Verpoest I (2003) Natural fibres: can they replace glass in fibre reinforced plastics? Compos Sci Technol 63(9):1259–1264

Wang F, Zhang FJ, Chen FD, Fang WM, Teng NJ (2014) Identification of Chrysanthemum (Chrysanthemum morifolium) Self-Incompatibility. Sci World J

Warren BE (1990) X-ray diffraction. Courier Corporation

Yao F, Wu QL, Lei Y, Guo WH, Xu YJ (2008) Thermal decomposition kinetics of natural fibers: Activation energy with dynamic thermogravimetric analysis. Polym Degrad Stab 93(1):90–98

Zhang K, Wang FX, Liang WY, Wang ZQ, Duan ZW, Yang B (2018) Thermal and Mechanical Properties Of Bamboo Fiber Reinforced Epoxy Composites. Polymers, 10(6)

Acknowledgments

Authors would like to thank Dokuz Eylul University, Center for Fabrication and Application of Electronic Materials.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dalmis, R., Kilic, G.B., Seki, Y. et al. Characterization of a novel natural cellulosic fiber extracted from the stem of Chrysanthemum morifolium. Cellulose 27, 8621–8634 (2020). https://doi.org/10.1007/s10570-020-03385-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-020-03385-2