Abstract

The extraordinary nature of the bacterial cellulose (BC) biopolymer gives it potential for diverse applications; however, the low BC yield of many indigenous cellulose-producing bacteria is a persistent problem in its synthesis. In this study, the BC yield of Komactobacter intermedius (BCRC 910677) was optimized by modifying culture media. The optimal culture period, type of carbon, and nitrogen sources were evaluated using the one-factor-at-a-time approach prior to the optimization study. The optimization was done by using the response surface methodology (RSM). In RSM optimization study, a Box–Behnken design with three parameters is applied; the three parameters include fructose concentrations (X1), peptone concentrations (X2), and pH values (X3). Our optimal culture media combined 41 g/L of fructose, 38 g/L peptone, and a pH of 5.2. The predicted BC yield from the RSM model is 4.012 g/L, while BC yield of 3.906 g/L is obtained from the experiment using the optimized medium; that is only 2.64% difference. An increase in BC production of 3.82-fold (compared to the culture in HS medium) was obtained after 6-days culture. The K. intermedius investigated in this study show great potential for commercial BC productions and as feedstock. The RSM can be a promising approach to enhance BC yield since the parameters were well correlated.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Bacterial cellulose (BC) is a versatile biopolymer produced from the metabolic activity of cellulose-producing bacteria or acetic acid bacteria (AAB); such as Agrobacterium, Rhizobium, Sarcina, and Komagataeibacter (Toda et al. 1997; Iguchi et al. 2000; Lin et al. 2013). Cellulose produced by bacteria has very high purity so that making other purification processes (such as delignification), which is very energy-consuming for plant cellulose, is unnecessary (Brown 1886). Cellulose synthesized by bacteria has a chemical composition similar to plant cellulose; however, thanks to its structural arrangements, BC has remarkable physical properties. A study by Lin and the group showed that BC possesses high tensile strength, high crystallinity, high hydrophilicity, and excellent biocompatibility (Lin et al. 2013).

The applicative properties of BC stimulate its application in fields of industry; one of the most famous is the production of nata de coco (Lin et al. 2013). BC applications have competed with plant cellulose, where BC has also penetrated into the production of sophisticated materials; such as artificial skin, wound dressing, battery membrane, and desalination membrane (Hassan et al. 2017; Lin et al. 2017; Wu et al. 2018; Lo et al. 2019; Santoso et al. 2019). However, many AABs only produce BC in low yields; this is often a major obstacle in BC applications in the industry. Many attempts have been made to improve BC yield of AABs, which is by modifying AAB genetically, modifying fermentation techniques, and modifying fermentation reactors. The modifications mentioned can be further optimized if AAB is fermented in media with the proper nutritional compositions. Nutritional requirements are very different between each AAB species (Basu et al. 2019). Proper nutrition ratios in the preparation of fermentation media are one of the crucial factors in maximizing BC yield. In this study, we sought to optimize the composition of culture media (derived from HS media (Hestrin and Schramm 1954)) for a novel BC-producing strain, Komagataeibacter (Komactobacter) intermedius BCRC 910677; abbreviated as K. intermedius. The success of this optimization study provides the proper nutritional composition for BC production by K. intermedius so that other modifications can be more easily done in the future. Furthermore, there are still no optimization studies conducted for this indigenous BC strain, where this strain can be a potential industrial feedstock. Previously, we have successfully isolated this strain from fermented fruit juice (Lin et al. 2016). The strain shows the level of BC production that is comparable to the common BC-producing strain, Gluconacetobacter xylinus (G. xylinus). The strain, K. intermedius, possesses interesting characteristic that is higher BC yield at high pH in HS medium; meanwhile, common BC-producing strains have higher yield under lower pH (Lin et al. 2016).

The characteristics of BC produced by K. intermedius, as well as its yield, were discussed. The optimization of the fermentation media (HS media) using the Box–Behnken design (BBD) with three factors was performed. Three factors such as carbon, nitrogen sources, and pH values were evaluated; and finally, the response surface method (RSM) was carried out to identify the composition of the optimized medium. A one-factor-at-a-time approach was used before evaluating the significant effects of the three factors investigated. Multivariate techniques are available for experimental designs, in addition to BBD, which is central composite design (CCD), and Doehlert matrix (DM) (Box et al. 2005). In terms of design efficiency (calculated as the number of coefficients divided by the number of runs), BBD and DM are more efficient compared to CCD. However, BBD is better than DM (also CCD) in avoiding unsatisfactory results, especially during extreme conditions; this is because BBD does not have a combination where all the independent variables are simultaneously at the highest or lowest level (Ferreira et al. 2007).

Materials and methods

Preparation of bacterial stock solutions

K. intermedius (BCRC 910677) was previously isolated from fermented fruit juice, according to a previous study (Lin et al. 2016). K. intermedius stock solutions were prepared by hydrolyzing the BC pellets produced using cellulase from Trichoderma reesei (ATCC 26921) at 28 °C for 72 h. After hydrolysis, the supernatant was separated using 7000 rpm centrifugation for 5 min. The obtained bacterial pellets were washed with sterile deionized water, for 2 times. Finally, 1 mL of 20% glycerol solution was added to the pellet and then stored under − 80 °C.

Preparation of the culture media

The composition of culture media was adopted from the composition of Hestrin-Schramm’s (HS) media (Hestrin and Schramm 1954); specifically, 20 g glucose, 5 g peptone, 5 g yeast extract, 2.7 g disodium phosphate (Na2HPO4) and 1.15 g citric acid, dissolved in 1 L of deionized water. Modification of HS media was done by replacing glucose with other carbon sources, while yeast extract and peptone were substituted with different nitrogen sources. Sucrose, fructose, mannitol, or glycerol were used as a substitute for a carbon source. Yeast extract/peptone (YE/P), malt extract (ME), or ammonium sulfate (AS) were used as a substitute for the nitrogen source. Subsequently, the proper pH and culture period were investigated.

Bacteria culture and BC production

The stored bacteria stock solution was thawed at room temperature and then added to a 250 mL culture flask filled with 50 mL of HS (or modified) media. The static fermentation technique was used throughout the study. The propagation of bacteria was performed under aerobic incubation at 28 °C for 72 h. During this propagation step, the bacteria are eventually covered in the BC that is produced. BC containing bacteria were collected aseptically and pureed using a Waring Blender 7011HS. The bacteria puree was added into another 250 mL flask filled with 100 mL of HS (or modified) media and then incubated under the same condition for various culture periods. The resulting BC was harvested and cleaned-twice by immersing BC in 0.1 N NaOH for 30 min at 80 °C. Subsequently, BC was rinsed using double-deionized water for 30 min, at 80 °C, until translucent BC was obtained. BC dry weight was weighted after lyophilization.

Optimization study

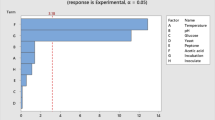

The response surface methodology (RSM) using the Box–Behnken design (BBD) was performed in the optimization study. Three variables, including carbon source concentration, nitrogen source concentration, and pH, were optimized from a set of experiments; in this case, 15 runs were involved in building the model and predicting the optimal point. Three levels of design were introduced; that is low, medium, and high, which coded as − 1, 0, and 1 (Table 1). A Minitab (version 19) software was used to predict the optimal value of the three variables according to the following second-order polynomial equation (Montgomery 1991; Panesar et al. 2012):

where Y is the dependent variable represents the predicted response on BC production yield (g/L); B0 represents the fitted response at the design’s center point; Bi, Bii, and Bij are the coefficient for linear, quadratic, and cross-product regression; Xi and Xj (with j = i + 1) are the coded independent variables (X1 = carbon source concentration, X2 = nitrogen source concentration, and X3 = pH).

A preliminary experiment using a one-factor-at-a-time approach was conducted before determining the range and corresponding levels for each variable, as shown in Table 1. The experimental design by BBD is presented in Table 2. The interactions and the response between the three tested variables were analyzed using analysis of variance (ANOVA). The confidence values for each set of measurements were determined using the least significant difference (LSD) test and paired t test by the correlation coefficient R2. The probability value (P value) of the tested statistical model was used to determine the level of confidence in the fitting, where the proper fitting is appointed for P < 0.05. The statistical significance of the regression coefficient was also obtained from ANOVA as the Fisher value (F value).

BC morphological observation

Lyophilized BC membranes were stored in a desiccator to prevent contact with air moisture before undergoing a Scanning Electron Microscopy (SEM) examination. Prior to taking the SEM images, BC samples were platinum-coated with a JEOL JEC-300FC Quick coater. SEM imaging was performed using a JEOL JSM-7800F (Tokyo, Japan) Prime field emission scanning electron microscope at an accelerating voltage of 10 kV. SEM images were then analyzed using a Java-based image processing and analysis program (Schneider et al. 2012), namely ImageJ, to determine the fiber diameter. ImageJ can assess the density of each pixel of the image; the density measurements reflect the actual Hounsfield unit values. ImageJ generates a 16-bit density histogram (Fig. S2), which can be used to calculate the diameter of BC fibers for each region of interest (Irving et al. 2007).

BC crystallinity measurement

To determine crystallinity of the produced BCs, XRD patterns were collected on an x-ray powder diffractometer (X Pert PRO model, Nalytical, Almelo, Netherlands) using a copper X-ray source. Scans were collected at 4 deg per minute from 5° to 40° 2θ. BCs were lyophilized overnight by using a freeze dryer (SFD-25 model, Chang Juing Machinery, Kaohsiung, Taiwan) and pressed into a thin and flat layer for analysis. The relative crystallinity of samples was calculated by Peakfit software (Jandel Scientific, San Rafael, CA, USA). A peak fit calculation was acquired when five peaks were selected for the fitting. Four of the peaks were associated with the characteristic cellulose I, and the fifth peak at around 20.5◦ was assigned to the amorphous region. The crystallinity degree was calculated utilizing XRD deconvolution method (Park et al. 2010).

Results and discussion

One-factor-at-a-time analysis

Effect of different culturing times in BC production

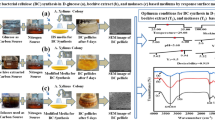

It was noted that a more extended culture period results in more BC accumulation. However, extending the duration of culture causes a reduction in efficiency and yield (Trovatti et al. 2011; Mohite et al. 2013; Lin et al. 2013). Different culture periods (0–15 days) were tested to evaluate the effect of culturing time on BC yield; a general HS medium was used for the evaluation; this is to determine the ideal time frame for BC production. As shown in Fig. 1a, the 6-day culture gave the highest BC yield (1.023 g/L). A more extended culture period does not provide a significant increase in BC production yield. Thus, in this study, a 6-day culture was selected as the ideal time frame for BC production. The kinetics of product formation (dP/dt) can be determined from the data in Fig. 1a (López-Meza et al. 2016); it was obtained that the maximum product formation rate is 0.206 g/L day (0.009 g/L h).

Determination of optimal BC production based on a culture period; b various C source, that is glucose (Glc), sucrose (Suc), Fructose (Fru), Mannitol (Man), glycerol (Gly); and, c various N source, that is yeast extract and peptone (YE/P), peptone (P), yeast extract (YE), malt extract (ME), ammonium sulfate (AS). All the measurements were done in triplicates. Different letter of each column represents significant difference (P < 0.05)

Effect of different carbon source in BC production

The effect of 5 different carbon (C) sources in enhancing BC production was evaluated; the investigated C source is glucose (Glc), sucrose (Suc), fructose (Fru), mannitol (Man), and glycerol (Gly). Those C sources are selected since they found to be suitable in promoting bacteria growth. Masaoka et al. (1993) have proven that Glu is the most effective C source for A. xylinum (IFO 13693) in terms of BC production, followed by Gly and Fru. Other bacteria that have been known to favor Glu over other C sources are including G. sacchari (Trovatti et al. 2011) and Gluconacetobacter sp. (Jahan et al. 2012). However, in another study, Fru is also known to be the most suitable C source for A. xylinum (ATCC 700178) than that of Suc, maple syrup and Glu (Cheng et al. 2009; Lin et al. 2016). Gly can be supplied as waste Gly from the biodiesel industries, and it has the potential of being a cost-effective C source for BC medium (Johnson and Taconi 2007). Gly showed high BC yield in certain strains, which is Acetobacter sp. V6 (Jung et al. 2010), G. xylinus (CGMCC 2955) (Zhong et al. 2013). Culture medium with addition of Man as the C source results in the highest BC production by G. xylinus (PTCC 1734) (Mohammadkazemi et al. 2015) and G. xylinus (ATCC 53524) (Ruka et al. 2012).

In this study, K. intermedius can grow in the selected C sources. As shown in Fig. 1b, culture in Man (as C source) produces the highest BC yield, followed by Fru > Glc > Gly > Suc. The BC production is more optimal by using Man as C source due to the least amount of gluconic acid produced, compared to Glu as C source (Gullo et al. 2019). Glu, as a C source, can encounter a dehydrogenation that transforms it into gluconic acid instead of cellulose (Zhong et al. 2013). Furthermore, certain alcohols are known to act as stimulants for BC synthesis, and Man is one of them (Lu et al. 2011). However, in the study by Fernández and co-researchers, Man is known to inhibit the production of BC by K. xylinus. A further study needs to be performed before understanding the difference in Man metabolic pathway for K. intermedius and K. xylinus (Fernández et al. 2019).

We have demonstrated that Man provided the highest BC yield. However, the use of Man is not commercially feasible. Man has very low solubility due to its low hygroscopicity; Man can only pick up water at a humidity level of 98%; this can be a technical issue, especially for extensive (industrial) scale Man dissolution. Man solubility in water (at 25 °C) is only 216 g/L, which is much lower compare to Fru (4000 g/L) (Yalkowsky and Dannenfelser 1992). Nevertheless, it is more likely that Man is first converted into Fru for further metabolism (Mamlouk and Gullo 2013). As from the production cost, Man is more expensive than Fru; therefore, the use of Fru can reduce cost (Ohrem et al. 2013). Many attempts have been made to reduce the cost of BC production, such as by using agricultural waste as nutritional sources. For instance, industrial waste has been used as culture media for BC, such as citrus peel beverage industry waste (Fan et al. 2016), waste beer yeast (Lin et al. 2014), wine industry waste (Wu and Liu 2012), and candied-jujube waste (Li et al. 2015). However, often, the use of waste as nutrition cannot be immediate but must be preceded by pretreatment; for example, heat and acid treatment. Although the source used is cheap, but there are additional costs for the pretreatment process (Li et al. 2015). Therefore, the use of cheap source nutrients still needs to be optimized and requires further study.

Effect of different nitrogen source in BC production

Yeast extract (YE) and/or peptone (P) are usually used as the nitrogen (N) sources for a typical HS medium (Cheng et al. 2009; Lin et al. 2016). In this study, we attempted to use different N sources prior to determining the suitable N source for K. intermedius; that is, a combination of YE and P (YE/P), malt extract (ME), and ammonium sulfate (AS). The effect of different N sources on the yield of BC produced by K. intermedius is shown in Fig. 1c. It was noted that P, as the sole N source, could help the bacteria to provide a higher yield of BC, compared to that of YE/P > ME > YE. Meanwhile, no formation of BC was observed during culture by using AS as the N-source.

Similar to C sources, the suitable N sources differ among the bacteria. The K. intermedius was not able to utilize AS as the inorganic N source. A similar result was observed during the culture of Acetobacter sp., where no BC formation was observed with AS as N source (Son et al. 2001). This may be related to the toxic effect and the ionic strength produced by the addition of AS (Müller et al. 2006). Still, among the highly diverse BC producing, especially the Komactobacter genus, there are other species that are able to utilize AS for BC synthesis (Ramana et al. 2000).

Response surface methodology optimization

As mentioned in the two previous subsections, fructose (Fru) and peptone (P) were selected to culture the K. intermedius. The optimum concentration of the two nutrient sources, as well as optimum culture pH, were determined by using the response surface methodology (RSM) with three sets of variables. The three variables include the concentration of Fru (X1), the concentration of P (X2), and pH (X3).

A set of the individual experiment for each variable (X1, X2, and X3) was conducted; this is to investigate their effect on the BC yield using a one-factor-at-a-time approach. Fru (X1) concentration of 0–100 g/L was used, and it was found that the Fru concentration of 20 g/L gives the highest yield of BC (Fig. 2a). Interestingly, at a Fru concentration of 0 g/L, K. intermedius is still able to produce a small amount of BC. This suggests that K. intermedius may be capable of utilizing peptone and citric acid as a carbon source for producing BC.

One-variable-at-a-time measurement: a effect of fructose concentration (0, 20, 40, 60, 80, 100 g/L) to the BC yield. b Effect of peptone concentration (0, 10, 30, 50, 70 g/L) to the BC yield. c Effect of culture medium pH (3, 4, 5, 6, 7, 8) to the yield of BC. All measurements were done in triplicate, with P < 0.05

A different concentration of P (X2 = 0–70 g/L) was used for the optimization study. As shown in Fig. 2b., the BC yield of K. intermedius is significantly increased by using a P concentration of 30 g/L. It was noted that K. intermedius was not able to produce BC in the absence of P; thus, the presence of N source is mandatory in the BC production. The importance of N source is also shown in some other studies; for instance, A. xylinum only able to generate a small amount of BC after culture in fruit juice alone (Kurosumi et al. 2009). Li and co-workers reported that the addition of ammonium citrate to culture medium made from candied jujube wastewater is necessary to boost BC yield, which results in a five-fold increase in BC production (Li et al. 2015). The optimal N source concentration found in this study is three times higher than that of HS medium; this is possibly due to the buffering effect provided by the N source.

The BC production was also observed under a wide range of pH (X3) of 3–10, in which the highest yield was obtained at a pH of 6 (Fig. 2c). There is no BC synthesis observed under a pH of 3 or over 8. This result, however, is contradictory to a previous experiment conducted on the same strain, in which the strain exhibited high tolerance and high yield under a basic environment. During the last study, HS medium was used for culture media for K. intermedius (BCRC 910677); 1.2 g/L of BC was able to synthesized at pH 8 (Lin et al. 2016). The difference between the previous and current results may be attributed to the difference in culture media, especially the use of Fru instead of Glu. When Glu is used as C source, the formation of gluconic acid (which can inhibit the formation of BC) is minimized when the pH becomes more alkaline (Pourramezan et al. 2009; Panesar et al. 2012); while this is not happening when Fru used as C source, gluconic acid formation remains minimal despite low pH. Virtually, the BC-producing bacteria also prefer low pH than alkaline pH (Bae and Shoda 2005; Rani et al. 2011; Mohite et al. 2013). A higher starting pH value helps to maintain the preferred pH level in BC synthesis, as the accumulation of gluconic acid will lower the pH of the medium (Liu et al. 2015). Membrane-bound dehydrogenase is a common feature in the AABs; besides glucose dehydrogenase, fructose dehydrogenase also exists in the membrane of some species (Adachi and Yakushi 2016). However, significantly fewer reports have addressed the effect of fructose dehydrogenase in BC production and its enzyme activity.

The RSM model was designed according to the results of the individual experiment for each variable. The data set for RSM is as summarized in Table 2, and the corresponding fitting between experimental and theoretical data are given in Table 3. The second-polynomial order model obtained for BC yield (Y, g/L) is as follows:

the R2 = 86.99% was adequately high to show the significance of the model. The optimized value for each variables as predicted by the model are X1 = 41 g/L, X2 = 38 g/L, and X3 = 5.2.

The BC yield (Y) was found to be 4.012 g/L, based on the predicted model, while from the experiment using the optimized culture medium, the BC yield of 3.906 g/L was obtained. The difference between the predicted and experimental value is only 2.64%; thus, it is noted that the obtained RSM model can well correlate the data. There are no second-degree correlations observed in the RSM experiment, suggesting indirect interactions between factors within the experiment design, as indicated by the P value of 0.081 (that is > 0.05 confidence level) and small F value of 3.72. The RSM study proves that the traditional one-variable-at-a-time method is insufficient for achieving optimal yield. The optimized medium composition (41 g/L of fructose, and 38 g/L of peptone) obtained by conducting RSM study is much higher than that of typical HS medium (20 g/L of glucose, 5 g/L of yeast extract, and 5 g/L of peptone). K. intermedius culture in optimized media results in an increase in BC yield of 382% (compare to the culture in HS medium).

The three-dimensional plots showing the interaction between every two tested variables to the BC yield (g/L) are illustrated as a contour plot (Fig. 3). The corresponding surface plots are given in Supplementary Data Figure S1. It can be observed that there is an optimal value for fructose and peptone prior to improve the BC yield. As illustrated in Fig. 3, it is shown that BC production prefers lower alkaline pH. Although pH value is often linked to BC production yield, it is not yet clear how the pH affected the BC synthesis pathway. A complete genome analysis on how enzymes affected by changes of medium pH and its correlation to BC yield is required to understand the mechanism. As we have observed that changes in the composition of the medium can affect pH preferences, this is an essential point in the following RSM study.

Comparison of BC yield with other optimization studies

As recorded in Table 4, the culture of K. intermedius in an optimized medium shows a 3.82-fold increase in BC yield, compared to the culture in HS medium. The BC yield obtained from K. intermedius is much lower than that of A. xylinum; but, it is comparable to other species (e.g., Gluconacetobacter, and G. hansenii). Moreover, in some other studies, they include the use of other additives such as agar (Bae and Shoda 2005) or ethanol (Jahan et al. 2012), which raised the production cost. This study provides a cost-effective way to increase BC production with only slight adjustments. Also, in most studies, glucose is used as the C source. One of the problems with raising glucose concentration is that it leads to a higher gluconic acid conversion rate and, ultimately, higher gluconic acid output rather than BC output. Therefore, enhancement of BC production by raising glucose concentration is inadvisable (Masaoka et al. 1993). Utilization of fructose as the primary C source may address this problem and boost BC yield, without the worry of gluconic acid formation.

Characterization of the produced BC

The characterization of fermented BC in HS and optimized media was carried out to evaluate the effects of different fermentation media on product characteristics. The surface morphology of BC produced by K. intermedius was observed by using the SEM. As shown in Fig. 4a and b, the produced BC (both using HS and optimized media) exhibit a 3D network structure constituted of nano cellulose bundles. A computer program, namely ImageJ, is used to analyze the fiber diameter of BC produced in HS and optimized media. At least 20 measurements were done to ensure the reproducible statistics of the BC fiber size distribution. BC produced from culture in optimized media have fiber diameters range of 14–70 nm, with an average diameter of 38 nm and a median of 36 nm; while BC from culture in HS media have fiber diameters range of 21–147 nm, with an average of 50 nm and a median of 40 nm (Fig S2). According to the obtained density map, the diameters of BC produced from the culture in HS medium are thicker and distributed more widely, while the one in the optimized medium is thinner with a more uniform diameter. BC produced by K. intermedius (BCRC 910677) in HS medium shows a similar density pattern to a previous study (Lin et al. 2016).

In XRD analysis (Fig. 5), the crystaillinity and crystal type were also evaluated. BC from optimized medium exhibited the similar crystallinity compared to BC from HS medium (81.9% vs. 80.3%), which is also similar to our previous study (Lin et al. 2016). Three major peaks from the <100>, <010> and <110> planes of BC were observed, suggesting that both BC samples were in the cellulose Iα form for randomly oriented crystallites (French 2014).

Therefore, BC produced by K. intermedius has the potential to replace commercial BC. BC from K. intermedius can be used in biomedical applications, such as raw material for wound dressing (Wu et al. 2018; Lin et al. 2017). It can also be applied as a substrate material for many flexible devices, such as solar cells. BC can be easily transformed into the transparent film through oxidation (Wu and Cheng 2016).

Conclusion

The response surface methodology, with a Box–Behnken design, was successfully employed to investigate the interaction of fructose concentration, peptone concentration, and pH to the BC production yield of Komactobacter intermedius (BCRC 910677). The study revealed that the optimal concentration of fructose (as carbon source) and peptone (as nitrogen source) in the culture medium is much higher than that of typical HS medium. The culture in the optimized media has an increase in BC yield up to 382%. The BC yield of the studied strain, however, is still much lower than that of commercial BC strain. Nevertheless, the results of this study provide important insights into the nutritional requirements of AAB fermentation, especially for K. intermedius. Furthermore, K. intermedius possesses high potentials for commercial BC productions and as feedstock, as it displayed good BC yield during a relatively short culturing time (6 days).

References

Adachi O, Yakushi T (2016) Membrane-bound dehydrogenases of acetic acid bacteria. In: Matsushita K, Toyama H, Tonouchi N, Okamoto-Kainuma A (eds) Acetic acid bacteria: ecology and physiology. Springer, Tokyo, pp 273–297

Bae S, Shoda M (2005) Statistical optimization of culture conditions for bacterial cellulose production using Box–Behnken design. Biotechnol Bioeng 90:20–28

Basu A, Vadanan SV, Lim S (2019) Rational design of a scalable bioprocess platform for bacterial cellulose production. Carb Polym 207:684–693

Box GEP, Hunter JS, Hunter WG (2005) Statistics for experimenters, 2nd edn. Wiley, New York

Brown AJ (1886) XLIII—on an acetic ferment which forms cellulose. J Chem Soc Faraday Trans 49:432–439

Cheng KC, Catchmark JM, Demirci A (2009) Enhanced production of bacterial cellulose by using biofilm reactor and its material property analysis. J Biol Eng 3:12

Fan X, Gao Y, He W, Hu H, Tian M, Wang K, Pan S (2016) Production of nano bacterial cellulose from beverage industrial waste of citrus peel and pomace using Komagataeibacter xylinus. Carbohydr Polym 151:1068–1072

Fernández J, Morena AG, Valenzuela SV, Pastor FIJ, Díaz P, Martínez J (2019) Microbial Cellulose from a Komagataeibacter intermedius Strain Isolated from Commercial Wine Vinegar. J Polym Environ 27:956–967

Ferreira SLC, Bruns RE, Ferreira HS, Matos GD, David JM, Brandão GC, da Silva EGP, Portugal LA, dos Reis PS, Souza AS, dos Santos WNL (2007) Box–Behnken design: an alternative for the optimization of analytical methods. Anal Chim Acta 597:179–186

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21(2):885–896

Gullo M, China SL, Petroni G, Gregorio SD, Giudici P (2019) Exploring K2G30 genome: a high bacterial cellulose producing strain in glucose and mannitol based media. Front Microbiol 10:58

Hassan E, Hassan M, Abouzeid R, Berglund L, Oksman K (2017) Use of bacterial cellulose and crosslinked cellulose nanofibers membranes for removal of oil from oil-in-water emulsions. Polymers 9:388

Hestrin S, Schramm M (1954) Synthesis of cellulose by Acetobacter xylinum: preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem J 58:345–352

Iguchi M, Yamanaka S, Budhiono A (2000) Bacterial cellulose—a masterpiece of nature’s arts. J Mater Sci 35:261–270

Irving BA, Weltman JY, Brock DW, Davis CK, Gaesser GA, Weltman A (2007) NIH ImageJ and Slice-O-Matic computed tomography imaging software to quantify soft tissue. Obesity 15:370–376

Jahan F, Kumar V, Rawat G, Saxena RK (2012) Production of microbial cellulose by a bacterium isolated from fruit. Appl Biochem Biotechnol 167:1157–1171

Johnson DT, Taconi KA (2007) The glycerin glut: options for the value-added conversion of crude glycerol resulting from biodiesel production. Environ Prog 26:338–348

Jung H-I, Jeong J-H, Lee O-M, Park G-T, Kim K-K, Park H-C, Lee S-M, Kim Y-G, Son H-J (2010) Influence of glycerol on production and structural–physical properties of cellulose from Acetobacter sp. V6 cultured in shake flasks. Bioresour Technol 101:3602–3608

Kurosumi A, Sasaki C, Yamashita Y, Nakamura Y (2009) Utilization of various fruit juices as carbon source for production of bacterial cellulose by Acetobacter xylinum NBRC 13693. Carbohydr Polym 76:333–335

Li Z, Wang L, Hua J, Jia S, Zhang J, Liu H (2015) Production of nano bacterial cellulose from waste water of candied jujube-processing industry using Acetobacter xylinum. Carbohydr Polym 120:115–119

Lin S-P, Calva LL, Catchmark JM, Liu J-R, Demirci A, Cheng K-C (2013) Biosynthesis, production and applications of bacterial cellulose. Cellulose 20:2191–2219

Lin D, Lopez-Sanchez P, Li R, Li Z (2014) Production of bacterial cellulose by Gluconacetobacter hansenii CGMCC 3917 using only waste beer yeast as nutrient source. Bioresour Technol 151:113–119

Lin S-P, Huang Y-H, Hsu K-D, Lai Y-J, Chen Y-K, Cheng K-C (2016) Isolation and identification of cellulose-producing strain Komagataeibacter intermedius from fermented fruit juice. Carbohydr Polym 151:827–833

Lin S-P, Kung H-N, Tsai Y-S, Tseng T-N, Hsu K-D, Cheng K-C (2017) Novel dextran modified bacterial cellulose hydrogel accelerating cutaneous wound healing. Cellulose 24:4927–4937

Liu M, Zhing C, Wu X-Y, Wei Y-Q, Bo T, Han P-P, Jia S-R (2015) Metabolomic profiling coupled with metabolic network reveals differences in Gluconacetobacter xylinus from static and agitated cultures. Biochem Eng J 101:85–98

Lo K-Y, Tseng T-N, Lin S-P, Liu J-M, Shih T-Y, Cheng K-C (2019) PVA/Dextran/Chitosan hydrogel with antimicrobial and biocompatible abilities in wound dressing. Cell Polym 38:15–30

López-Meza J, Araíz-Hernández D, Carrillo-Cocom LM, López-Pacheco F, Rocha-Pizaña MdR, Alvarez MM (2016) Using simple models to describe the kinetics of growth, glucose consumption, and monoclonal antibody formation in naive and infliximab producer CHO cells. Cytotechnology 68:1287–1300

Lu Z, Zhang Y, Chi Y, Xu N, Yao W, Sun B (2011) Effects of alcohols on bacterial cellulose production by Acetobacter xylinum 186. World J Microbiol Biotechnol 27:2281–2285

Mamlouk D, Gullo M (2013) Acetic acid bacteria: physiology and carbon sources oxidation. Indian J Microbiol 53:377–384

Masaoka S, Ohe T, Sakota N (1993) Production of cellulose from glucose by Acetobacter xylinum. J Biosci Bioeng 75:18–22

Mohammadkazemi F, Azin M, Ashori A (2015) Production of bacterial cellulose using different carbon sources and culture media. Carbohydr Polym 117:518–523

Mohite BV, Salunke BK, Patil SV (2013) Enhanced production of bacterial cellulose by using Gluconacetobacter hansenii NCIM 2529 strain under shaking conditions. Appl Biochem Biotechnol 169:1497–1511

Montgomery DC (1991) Design and analysis of experiments. Wiley, New York

Müller T, Walter B, Wirtz A, Burkovski A (2006) Ammonium toxicity in bacteria. Curr Microbiol 52:400–406. https://doi.org/10.1007/s00284-005-0370-x

Ohrem HL, Schornick E, Kalivoda A, Ognibene R (2013) Why is mannitol becoming more and more popular as a pharmaceutical excipient in solid dosage forms? Pharm Dev Technol 19:257–262

Panesar PS, Chavan Y, Chopra HK, Kennedy JF (2012) Production of microbial cellulose: response surface methodology approach. Carbohydr Polym 87:930–934

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3(1):1

Pourramezan GZ, Poayaei AM, Qezelbash QR (2009) Optimization of culture conditions for bacterial cellulose production by Acetobacter sp. Biotechnology 8:150–154

Ramana KV, Tomar A, Singh L (2000) Effect of various carbon and nitrogen sources on cellulose synthesis by Acetobacter xylinum. World J Microbiol Biotechnol 16:245–248

Rani MU, Rastogi NK, Appaiah KA (2011) Statistical optimization of medium composition for bacterial cellulose production by Gluconacetobacter hansenii UAC09 using coffee cherry husk extract–an agro-industry waste. J Microbiol Biotechnol 21:739–745

Ruka DR, Simon GP, Dean KM (2012) Altering the growth conditions of Gluconacetobacter xylinus to maximize the yield of bacterial cellulose. Carbohydr Polym 89:613–622

Santoso SP, Kurniawan A, Soetaredjo FE, Cheng K-C, Putro JN, Ismadji S, Ju Y-H (2019) Eco-friendly cellulose–bentonite porous composite hydrogels for adsorptive removal of azo dye and soilless culture. Cellulose 16:3339–3358

Schneider CA, Rasband WS, Eliceiri KW (2012) NIH Image to ImageJ: 25 years of image analysis. Nat Methods 9:671–675

Son H-J, Kim M-S, Kim Y-G, Lee S-J (2001) Optimization of fermentation conditions for the production of bacterial cellulose by a newly isolated Acetobacter. Biotechnol Appl Biochem 33:1–5

Toda K, Asakura T, Fukaya M, Entani E, Kawamura Y (1997) Cellulose production by acetic acid-resistant Acetobacter xylinum. J Biosci Bioeng 84:228–231

Trovatti E, Serafim LS, Freire CSR, Silvestre AJD, Neto CP (2011) Gluconacetobacter sacchari: an efficient bacterial cellulose cell-factory. Carbohydr Polym 86:1417–1420

Wu C-N, Cheng K-C (2016) Strong, thermal-stable, flexible, and transparent films by self-assembled TEMPO-oxidized bacterial cellulose nanofibers. Cellulose 24:269–283

Wu J-M, Liu R-H (2012) Thin stillage supplementation greatly enhances bacterial cellulose production by Gluconacetobacter xylinus. Carbohydr Polym 90:116–121

Wu C-N, Fuh S-C, Lin S-P, Lin Y-Y, Chen H-Y, Liu J-M, Cheng K-C (2018) TEMPO-oxidized bacterial cellulose pellicle with silver nanoparticles for wound dressing. Biomacromol 19:544–554

Yalkowsky SH, Dannenfelser RM (1992) The AQUASOL database of aqueous solubility, 5th edn. University of Arizona College of Pharmacy, Tucson

Zhong C, Zhang G-C, Liu M, Zheng X-T, Han P-P, Jia S-R (2013) Metabolic flux analysis of Gluconacetobacter xylinus for bacterial cellulose production. Appl Microbiol Biotechnol 97:6189–6199

Acknowledgments

This study was partly funded by the Ministry of Science and Technology, Taiwan, under Contract No. 106-2628-E-002-009-MY3.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Santoso, S.P., Chou, CC., Lin, SP. et al. Enhanced production of bacterial cellulose by Komactobacter intermedius using statistical modeling. Cellulose 27, 2497–2509 (2020). https://doi.org/10.1007/s10570-019-02961-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02961-5