Abstract

Degreasing cotton showing selectivity for the bovine hemoglobin (BHb) was developed by an imprinting procedure that is based on metal coordinate interaction. The morphological structure of the as-prepared samples was characterized by Scanning Electron Microscopy, and the chemical modification steps were characterized by Fourier Transform Infrared Spectroscopy. The results of adsorption experiments show that the maximum adsorption capacity of the Cu2+-immobilized molecularly imprinted cotton (Cu2+-MIC) and Cu2+-immobilized non-imprinted cotton (Cu2+-NIC) was 140.33 mg/g and 17.78 mg/g, respectively, at the optimum pH value of 6.2. The adsorption process followed a pseudo-second-order kinetic and the adsorption equilibrium could be achieved in 30 min. The adsorption isotherm data could be well described by a Langmuir model. Moreover, satisfactory reusability is demonstrated by five adsorption–desorption cycles with no significant decrease of the adsorption capacity. The SDS-PAGE analysis demonstrated that the Cu2+-MIC could be applied successfully in separation of BHb from the bovine blood sample. This procedure presents facile, cheap and stable fabrication strategy for efficient separation of proteins.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the advent of the proteomic era, the specific recognition of proteins is of great significance in separation (Xia et al. 2013; Liu et al. 2016), biosensing (Wang et al. 2004; Mahon and Fulton 2014) and diagnostics (Hoffman 2000; Schmidt and Skerra 2007). Molecular imprinting is a promising and facile technique to prepare artificial polymers with “tailor-made” recognition sites for specific binding the target molecules (Takeuchi and Matsui 1996). Molecularly imprinted polymers (MIPs) exhibit excellent properties such as mechanical and chemical stability, specific recognition ability, low cost and ease of mass preparation, which render them favorable alternative to natural recognition materials such as antibodies (Chen et al. 2011). To date, the imprinting of small molecules has been well-established, while it still faces a great challenge to imprint macromolecules such as proteins due to the limits of large molecular size, conformational flexibility, insolubility in organic solvents, structural complexity and the poor mass transfer (Gao et al. 2016).

To settle these problems, a variety of strategies have been exploited such as bulk imprinting, epitope imprinting and surface imprinting (Wang et al. 2008; Ouyang et al. 2008; Tamahkar et al. 2015). Among these, surface imprinting is the most promising technology and has been focused by many researchers. Highly selective recognition sites are achieved via surface imprinting by locating at the surface or very close to the surface of the support material to enable facile accessibility of recognition sites addressing mass transfer limitations for template removal and rebinding (Ozcan et al. 2006). However, the interactions between template protein and many surface MIPs are mostly non-covalent way such as electrostatic interaction, hydrogen bonding and van der Waals forces (Li et al. 2017; Gao et al. 2011; Zhou et al. 2013), which leads to the affinity and selectivity of recognition sites is commonly lower especially in aqueous media (Shi et al. 2016). Some other approaches for improved the imprinting effect involves using monomers with moieties already known to interact strongly with the target molecule, for example, taking advantage of the interactions based on enzyme-inhibitor (Sellerqren 2010; Zhang et al. 2013), boronic acid-diol (Zhou et al. 2017) and metal coordination (Chen et al. 2014; An et al. 2015). Immobilized metal-affinity chromatography (IMAC) has been employed to selectively separate proteins with histidine-tagged proteins or histidine/cysteine exposed on the surface of the proteins, based on the different interactions between template protein and metal ions immobilized on matrices (Ueda et al. 2003). According to the protein separation method based on IMAC, it is well known that metal ion coordination possesses many merits such as strength, specificity, directionality and stability in aqueous media as well as simple template extraction (Tamahkar et al. 2015). That’s because chelation is a kind of special bond with high stability due to its five-member ring or six-member ring (Aguilar et al. 2010), which can strongly enhance the interaction between template protein and MIPs as well as produce more effective imprinting cavities.

Herein, we developed a facile method to fabricate a novel Cu2+-MIP fibrous material for the specific recognition of BHb combining metal coordination with surface molecular imprinting. Cu2+ was introduced to chelate with hydroxyl and amino groups on the surface of amino-modified degreasing cotton, and BHb can chelate with Cu2+ by imidazole groups in the histidine residues. The morphology and structure property of the prepared samples were characterized by the SEM and FTIR. Additionally, the prepared Cu2+-MIC was involved in a batch experiments to evaluate its adsorption selectivity, and recyclability as well as the adsorption isotherm models and kinetics.

Experiment

Materials

BHb (MW = 64.0 kDa, pI = 6.5–6.8) and lysozyme (Lyz; MW = 13.4 kDa, pI = 11.2) were supplied by Sigma-Aldrich. Bovine serum albumin (BSA; Mw = 68.0 kDa, pI = 4.9) and ovalbumin (OVA; MW = 43.0 kDa, pI = 4.7) were purchased from Guangzhou Ruite Biotechnology Company (Guangzhou, China). Phosphate buffer saline (PBS; 50 mM, pH = 6.2) was received from Xiamen Science and Technology Co., Ltd (Xiamen, China). Epichlorohydrin, diethylenetriamine (DETA), N,N-dimethylformamide (DMF), glutaraldehyde, sodium dodecyl sulfate (SDS) and copper sulfate pentahydrate (CuSO4·5H2O) were obtained from Sinopharm Chemical Reagent Corp (Shanghai, China). Degreasing cotton was supplied from Xuzhou Weicai Hygiene of Material Factory Co. LTD (Xuzhou, China).

Preparation of amino-functionalized degreasing cotton

Amino-functionalized degreasing cotton was synthesized via in situ polymerization. 0.2 g of degreasing cotton was immersed in the mixed solvent of 10 ml of N,N-dimethylformamide and 10 ml epichlorohydrin. The mixture was stirred for 1.5 h at 85 °C in thermostatic water bath and then 1 ml of diethylenetriamine was added into the mixture drop by drop and stirred for 1 h. At the end of the chemical reaction period, the sample was immersed in ethyl alcohol for 30 min without stirring, followed by thorough rinsing with distilled water and drying at 60 °C for 5 h.

Preparation of the Cu2+-immobilized imprinted polymers and reference polymers

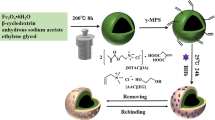

Typically, 0.1 g of amino-functionalized degreasing cotton was immersed in 100 mL of phosphate buffer (pH 6.2, 50 mM) and added CuSO4·5H2O to immobilize Cu2+ on the surface of amino-functionalized degreasing cotton with stirred vigorously for 1 h at room temperature and this solution was subsequently incubated with 50 mg of BHb for 1 h. Then, 4 ml glutaraldehyde was added by dripping slowly and the reaction continued for an additional 1 h at 30 °C. The obtained samples washed with deionized water, with EDTA-2Na+ solution (0.1 M) to desorb Cu2+, and then with SDS/acetic acid (10% w/v:10% v/v) to remove the template. Finally, the as-prepared product (denoted as Cu2+-MIC) washed with deionized water several times and dried at 60 °C for 5 h. The procedure for preparation of Cu2+-MIC is illustrated in Fig. 1. Non-imprinted Cu2+-NIC, MIC and NIC were synthesized following the similar conditions of Cu2+-MIC except without the addition of BHb, CuSO4·5H2O, both BHb and CuSO4·5H2O, respectively.

Characterization

The morphology and structure of the degreasing cotton, Cu2+-MIC and Cu2+-NIC were examined by scanning electron microscopy (SEM) using a JSM-IT300A scanning electron microscope (JEOL Ltd., Tokyo, Japan). All samples were coated with a gold film to increase their conductivity. The bonding configuration and surface functionalization of all samples were collected by Fourier transform infrared (FTIR) spectroscopy using a VERTEX 70 FTIR spectrometer in the wavenumber range from 450 to 4000 cm−1. The mass fraction of elements were measured using an Organic Elemental Analyzer (Thermo Scientific FLASH 2000 HT). The sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS-PAGE) was performed using Mini-Protean Tetra (Bio-Rad).

Binding experiments

In order to investigate the effect of Cu2+ on the adsorption ability, 0.1 g of Cu2+-MIC or Cu2+-NIC was added to CuSO4·5H2O solution with different concentrations of Cu2+ (10, 20, 30, 40, 50, 60, 70 and 80 mg/mL) for 30 min. After that, the samples washed with deionized water to remove the Cu2+ on the surface of the polymers and dried at 60 °C. Then, 0.01 g of the Cu2+-MIC or Cu2+-NIC was added with 100 ml of a 200 mg/L BHb solution at different concentrations or pH values in PBS for optimized times. The concentration of BHb in the supernatant was measured by an UV-2700 UV–visible spectrophotometer at 405 nm. The adsorption capacity (Q, expressed in units of mg/g) of the protein was calculated by the formula as follows:

where C0 and Ce (mg/L) are the initial concentration and the equilibrium concentration of template BHb, V (mL) is the volume of BHb solution, and m (mg) is the mass of the absorbent.

Additionally, the imprinting factor (IF) and selectivity coefficient (SC) were calculated to determine the selectivity properties of Cu2+-MIC and Cu2+-NIC toward template and non-template proteins. The IF and SC were calculated from the following equations:

where QMIC and QNIC (mg/g) represent the adsorption capacity of protein for Cu2+-MIC, Cu2+-NIC, MIC and NIC. IFtem and IFnon are imprinting factors of template protein and non-template protein respectively.

Results and discussion

Characterization of the samples

The morphologies of the degreasing cotton, Cu2+-MIC and Cu2+-NIC were investigated by SEM. The SEM images showed that the diameter of degreasing cotton (Fig. 2a) was about 8 um with a smooth surface. After surface modification and cross-linking, both the Cu2+-NIC (Fig. 2b) and Cu2+-MIC (Fig. 2c) became much rougher, indicating that the organic monomers were grafted on the surface of the cellulosic backbone. Moreover, it can be found that there are many cracks on the surface of the Cu2+-MIC, which may be due to the BHb removed out of the cross-linked network.

FTIR spectra of degreasing cotton, Cu2+-MIC and Cu2+-NIC are shown in Fig. 3. The spectrum displayed in Fig. 3a shows the characteristic peaks of degreasing cotton, the peak at 3338 cm−1, corresponding to the hydrogen bond O–H stretching vibration; the characteristic absorption bands at 1425 cm−1 and 1313 cm−1 were assigned to CH2 bending and CH bending, respectively; the peaks at 1161 cm−1 and 1029 cm−1 were ascribed to antisymmetric stretching vibrations of the C–O–C bridge and skeletal vibrations involving C−O stretching, respectively (Anirudhan et al. 2013). From the Cu2+-MIC and Cu2+-NIC spectra displayed in Fig. 3b, c, respectively, we can read out that the peaks at 3408 cm−1 and 1546 cm−1 exist in both spectra, certifying the insertion of amine groups into the degreasing cotton (Deng et al. 2016; Zhang et al. 2014). Compared with the degreasing cotton, the stronger intensity of the C-H stretching bonds in the peak at 2922 cm−1 confirmed the introduction of aliphatic chains from glutaraldehyde by crosslinking (Li et al. 2013). In addition, the new band at 1649 cm−1 corresponded to the imine C=N bonds, demonstrating that the amino groups were converted into C=N bonds in the crosslinking reaction process between the amino groups on the degreasing cotton and the aldehyde groups of the glutaraldehyde.

In order to study the amount of amine functionalization, the mass fraction of elements of degreasing cotton, amino-functionalized degreasing cotton, Cu2+-NIC and Cu2+-MIC were measured using an Organic Elemental Analyzer. As shown in Table 1, it can be found that the content of N element increased obviously after grafted, which demonstrates that the degreasing cotton has been successfully amino functionalized.

Batch adsorption studies

Effect of Cu2+ on adsorption properties

Considering the effect of Cu2+ on the imprinting efficiency of Cu2+-MIC, the optimal concentration of Cu2+ in the synthesis process was evaluated. Cu2+-MIC was added into CuSO4·5H2O solution with different concentrations of Cu2+ (10, 20, 30, 40, 50, 60, 70 and 80 mg/mL) to make different batches of adsorbents. As shown in Fig. 4, BHb adsorption capacity of Cu2+-MIC first increased with the increase of the concentration of Cu2+, the adsorption capacity was no obvious increase after the concentration of Cu2+ reach to 50 mg/mL. Therefore, we chose 50 mg/mL as the optimum concentration of Cu2+.

Effect of pH

The influence of solution pH ranging from 4.0 to 10.0 on the adsorption performance of Cu2+-MIC and Cu2+-NIC for BHb was shown in Fig. 5. The maximum adsorption capacity was obtained at pH 6.2, with a decrease at lower and higher pH values. This result is similar to previous literature, which was due to the proteins get strongly adsorbed onto negatively charged species near or below the isoelectric point (Demanèche et al. 2009). The maximum adsorption of protein from aqueous solutions is always reached at their isoelectric point because proteins have no net charge at the isoelectric point. The adsorption capacity gets decreased when deviating from the isoelectric point, which is due to the increase in the conformational size of the protein molecules and the lateral electrostatic repulsions between adjacent adsorbed protein molecules (Anirudhan et al. 2013). Therefore, the adsorption solution (pH = 6.2) was used for subsequent experiments.

Effect of grafting degree on adsorption properties

Functional groups were introduced onto degreasing cotton through ammonification. The grafting degree of amino-functionalized degreasing cotton was calculated according to the following equation (Li et al. 2011):

where W0 and W1 are the weights of the original and grafted degreasing cotton, respectively.

The grafting of amino groups onto the degreasing cotton increased with the quantity of DETA and could react with Cu2+ by chelation. The relationship between the grafting degree and adsorption ability of Cu2+-MIC to BHb is shown in Fig. 6. As can be seen, the adsorption capacity increased dramatically after the introduction of amino groups onto the surface of degreasing cotton. Obviously, introducing amino groups could provide more reactive sites to chelate with Cu2+, and consequently causing a higher adsorption capacity of BHb.

Adsorption kinetics

Adsorption kinetics of BHb onto Cu2+-MIC and Cu2+-NIC were evaluated to determine the rate of adsorption process, as shown in Fig. 7. It could be seen that the adsorbed capacity of Cu2+-MIC for BHb increased quickly in the first 15 min and reach the equilibrium adsorption within 30 min. At the beginning of the adsorption kinetics, many unoccupied imprinted cavities located at the surface of Cu2+-MIC, which promoted BHb to be adsorbed to them with less resistance. With the time extension, these cavities became gradually saturated and the adsorption reached equilibrium eventually. Since the Cu2+-NIC was nonspecific adsorption, thus the adsorption capacity is very low. The saturated rebinding amount of BHb onto Cu2+-MIC is about 140.33 mg/g and this is 7.89 times more than that of the Cu2+-NIC. For better understanding, a comparison of maximum adsorption capacity with other synthesized MIPs have shown in Table 2. From the comparison, we can found that the adsorption capacity of our adsorbent was greater than most MIPs below. Moreover, Cu2+-MIC is very easy to remove from solutions, which makes it more recyclable than many nanoparticle materials.

To examine the controlling mechanism of adsorption process, pseudo-first-order and pseudo-second-order kinetic models were used to fit the kinetic data:

where Qe (mg/g) and Qt (mg/g) are the adsorption capacities of BHb at equilibrium and time t (min) respectively; k1 (min−1) and k2 (g mg−1 min−1) are the pseudo-first-order rate constant and pseudo-second-order rate constant, respectively.

The pseudo-first-order model and the pseudo-second-order model fitting curves for the Cu2+-MIC are shown in Fig. 8. In contrast to the fitting of the pseudo-first-order rate law, the pseudo-second-order kinetic model exhibited the best fitted the data of the adsorption of BHb, which was revealed by the higher R2 (0.999) value of the pseudo-second-order kinetic model. Besides, the calculated Qe value estimated from the pseudo-second-order model agreed with the experimental value better. These results suggested that the binding of BHb onto Cu2+-MIC follows a pseudo-second-order reaction model thus indicating chemisorption as a rate-limiting step that controls the adsorption process.

Adsorption isotherm

Adsorption isotherm experiments were carried out at different initial concentrations of BHb to investigate the adsorption capacity of Cu2+-MIC and Cu2+-NIC, as shown in Fig. 9. The adsorption values increased with increasing initial concentration of BHb, and a saturation value is achieved at 200 mg/L. It was observed that the Cu2+-MIC displayed a significant preferential binding of BHb compared with Cu2+-NIC, suggesting an obvious imprinting effect of the Cu2+-MIC which possesses efficient imprinted cavities.

Langmuir and Freundlich models were frequently used to evaluate the saturation binding data, the two equations are expressed as follows:

where Qe (mg/g) is the amount of BHb bound to the Cu2+-MIC at equilibrium, Ce (mg/L) is the equilibrium concentration, and Qmax (mg/g) is the apparent maximum adsorption capacity. KL is the Langmuir constant, KF and 1/n are the Freundlich constants.

The linearized plots of the Langmuir and Freundlich isotherms for the adsorption of BHb onto Cu2+-MIC are shown in Fig. 10. It was determined that the R value of Langmuir isotherm model was 0.998, which is greater than that obtained with the Freundlich model. The calculated maximum adsorption capacity Qmax according to Langmuir model was close to the experimentally measured adsorption capacity Qe, indicating that BHb adsorption was better fitted with the Langmuir model and the adsorption of BHb onto Cu2+-MIC was the monolayer adsorption process.

Selectivity studies

In order to evaluate the selectivity of Cu2+-MIC and Cu2+-NIC to BHb, BSA, Lyz and OVA were chosen as references because of their wide range of isoelectric point and molecular mass. Figure 11 shows the adsorption capacities of Cu2+-MIC, Cu2+-NIC, MIC and NIC for these proteins with an initial concentration of 200 mg/L. Due to the imprinting cavities exist on the surface of Cu2+-MIC and MIC, which are complementary to the shape, size, and functional groups of template protein for BHb, Cu2+-MIC and MIC show significant binding selectivity for BHb. However, the adsorption capacity of Cu2+-MIC toward BHb was higher than MIC, indicating the presence of Cu2+ in the preparation process can improve the imprinting performance. The IF and SC of Cu2+-MIC and MIC were evaluated and listed in Table 1. Obviously, both IF and SC of Cu2+-MIC for BHb are larger than other adsorbents, demonstrating the highest binding affinity toward BHb (Table 3).

Reproducibility and reusability of Cu2+-MIC and Cu2+-NIC

The regeneration feature of the adsorbents is an important property for the application in the affinity separation. In these recycling experiments, the adsorbed Cu2+ and BHb could be eluted from the adsorbents using EDTA-2Na+ solution (0.1 M) and SDS/acetic acid (10% w/v:10% v/v) solution as the eluent. As such, the adsorption–desorption cycle was repeated five times by using the same Cu2+-MIC and Cu2+-NIC to investigate their reusability. The results are shown in Fig. 12, it can be observed that the adsorption capacity of Cu2+-MIC drops slightly after each cycle, and it decreased gradually in subsequent runs to 96% after five adsorption-regeneration cycles, indicating that the Cu2+-MIC has favorable physical robustness and mechanically durable network. The possible reason for the minor loss might be attributed to some recognition sites in the imprinted network of Cu2+-MIC deformed during the washing step and jammed after regeneration. However, the adsorption capacity of the Cu2+-NIC remained almost unchanged all the time on account of non-specific adsorption affinity. These results demonstrated the satisfactory regeneration capability of Cu2+-MIC had potential applications in practice.

Real sample adsorption experiment

In order to demonstrate the practical application of Cu2+-MIC, the mixtures of binary proteins BHb and BSA solution, 150-fold diluted bovine blood were carried out by contacting Cu2+-MIC. The results are shown in Fig. 13. The Line 0, Line 1, Line 4 present the protein molecular weight marker, the standard protein mixture of BSA and BHb and 150-fold diluted bovine blood, respectively. It can be observed that the band of BHb became faded after treatment with Cu2+-MIC (Line 2 and Line 5), whereas the BSA band is almost unchanged. After elution with SDS/acetic acid (10% w/v:10% v/v), only the bands of BHb reappeared with low content in Line 3 and Line 6. These results indicate that the Cu2+-MIC can separate BHb from real sample effectively.

SDS-PAGE analysis of to evaluate the applicability of Cu2+-MIC towards BHb. Line 0: Molecular weight marker, Line 1: 200 mg/L BHb and BSA binary solution, Line 2: remaining BHb and BSA solution after treatment with Cu2+-MIC, Line 3: the eluted BHb and BSA mixture by SDS/acetic acid (10% w/v:10% v/v), Line 4: bovine blood diluted 150-fold, Line 5: remaining bovine blood after treatment with Cu2+-MIC, Line 6: the absorbed bovine blood eluted by SDS/acetic acid (10% w/v:10% v/v)

Conclusions

In summary, we demonstrated a facile and effective approach for the preparation of specific recognition sites of BHb onto degreasing cotton surface via metal ion coordination. The resultant Cu2+-MIC exhibited a high adsorption capacity, excellent specificity towards BHb and rapid binding kinetics due to combined effect of surface imprinting onto Cu2+-MIC and specific metal ion coordination interaction. The Cu2+-MIC showed no significant decrease in its adsorption capacity after five adsorption–desorption cycles. In addition, the Cu2+-MIC has been successfully applied in the specific isolation of BHb from real bovine blood sample. Therefore, the Cu2+-MIC possesses great potential in practical applications for removing highly abundant His-rich proteins.

References

Aguilar D, Fernandez I, Cuesta L (2010) Synthesis, structure, and reactivity of N-benzoyl iminophosphoranes ortho lithiated at the benzoyl group. J Org Chem 75:6452–6462

An LJ, Pang ZY, Guo YL (2015) Synthesis of magnetic molecular imprinted silica spheres for recognition of ciprofloxacin by metal-coordinate interaction. J Sol Gel Sci Technol 76(1):36–43

Anirudhan TS, Rejeena SR, Tharun AR (2013) Investigation of the extraction of hemoglobin by adsorption onto nanocellulose-based superabsorbent composite having carboxylate functional groups from aqueous solutions: kinetic, equilibrium, and thermodynamic profiles. Ind Eng Chem Res 52:11016–11028

Chen L, Xu S, Li J (2011) Recent advances in molecular imprinting technology: current status, challenges and highlighted applications. Chem Soc Rev 40(5):2922–2942

Chen HC, Kong J, Yuan DY, Fu GQ (2014) Synthesis of surface molecularly imprinted nanoparticles for recognition of lysozyme using a metal coordination monomer. Biosens Bioelectron 53:5–11

Demanèche S, Chapel JP, Monrozier LJ, Quiquampoix H (2009) Dissimilar pH-dependent adsorption features of bovine serum albumin and α-chymotrypsin on mica probed by AFM. Colloid Surf B 70:226–231

Deng H, Ning JH, Wang XN (2016) Amino-functionalized cotton fiber for enhanced adsorption of active brilliant red X-3B from aqueous solution. Microsc Res Tech 79:1200–1207

Gao RX, Kong X, Wang X, He XW, Chen LX, Zhang YK (2011) Preparation and characterization of uniformly sized molecularly imprinted polymers functionalized with core–shell magnetic nanoparticles for the recognition and enrichment of protein. J Mater Chem 21:17863–17871

Gao RX, Mu XR, Hao Y, Zhang LL, Zhang JJ, Tang YH (2014) Combination of surface imprinting and immobilized template techniques for preparation of core–shell molecularly imprinted polymers based on directly amino-modified Fe3O4 nanoparticles for specific recognition of bovine hemoglobin. J Phys Chem B 2(12):1733–1741

Gao RX, Cui XH, Hao Y, He GY, Zhang M, Tang YH (2016) Preparation of Cu2+-mediated magnetic imprinted polymers for the selective sorption of bovine hemoglobin. Talanta 150:46–53

Hao Y, Gao R, Liu D, Zhang B, Tang Y, Guo Z (2016) Preparation of biocompatible molecularly imprinted shell on superparamagnetic iron oxide nanoparticles for selective depletion of bovine hemoglobin in biological sample. J Colloid Interface Sci 470:100–107

Hoffman AS (2000) Bioconjugates of intelligent polymers and recognition proteins for use in diagnostics and affinity separations. Clin Chem 46(9):1478–1486

Li TY, Chen SX, Li HC, Li QH, Wu L (2011) Preparation of an ion-imprinted fiber for the selective removal of Cu2+. Langmuir 27(11):6753–6758

Li Y, Qiu TB, Xu XY (2013) Preparation of lead-ion imprinted crosslinked electro-spun chitosan nanofiber mats and application in lead ions removal from aqueous solutions. Eur Polym J 49:1487–1494

Li Y, Chen Y, Huang L, Lou B, Chen G (2017) Creating BHb-imprinted magnetic nanoparticles with multiple binding sites. Analyst 142(2):302–309

Liu YJ, Wang YZ, Dai QZ, Zhou YG (2016) Magnetic deep eutectic solvents molecularly imprinted polymers for the selective recognition and separation of protein. Anal Chim Acta 936:168–178

Mahon CS, Fulton DA (2014) Mimicking nature with synthetic macromolecules capable of recognition. Nat Chem 6(8):665–672

Ouyang R, Lei J, Ju H (2008) Surface molecularly imprinted nanowire for protein specific recognition. Chem Commun 30(44):5761–5763

Ozcan AA, Say R, Denizli A, Ersoz A (2006) L-histidine imprinted synthetic receptor for biochromatography applications. Anal Chem 78(20):7253–7258

Schmidt TG, Skerra A (2007) The Strep-tag system for one-step purification and high-affinity detection or capturing of proteins. Nat Protoc 2(6):1528–1535

Sellerqren B (2010) Molecularly imprinted polymers: shaping enzyme inhibitors. Nat Chem 2(1):7–8

Shi L, Tang Y, Hao Y, He G, Gao R, Tang X (2016) Selective adsorption of protein by a high-efficiency Cu (2 +)-cooperated magnetic imprinted nanomaterial. J Sep Sci 39(14):2876–2883

Takeuchi T, Matsui J (1996) Molecular imprinting: an approach to “tailor-made” synthetic polymers with biomimetic functions. Acta Polymer 47(1112):471–480

Tamahkar E, Tulin K, Denizli A (2015) Surface imprinted bacterial cellulose nanofibers for cytochrome c purification. Process Biochem 12:2289–2297

Ueda EKM, Gout PW, Morganti L (2003) Current and prospective applications of metal ion-protein binding. J Chromatogr A 988(1):1–23

Wang J, Liu G, Jan MR (2004) Ultrasensitive electrical biosensing of proteins and DNA: carbon-nanotube derived amplification of the recognition and transduction events. J Am Chem Soc 126(10):3010–3011

Wang YT, Zhou YX, Sokolov J, Rigas B, Levon K, Rafailovich M (2008) A potentiometric protein sensor built with surface molecular imprinting method. Biosens Bioelectron 24(1):162–166

Xia ZW, Lin Z, Xiao Y, Wang L, Zheng JN, Yang HH, Chen GN (2013) Facile synthesis of polydopamine-coated molecularly imprinted silica nanoparticles for protein recognition and separation. Biosens Bioelectron 47:120–126

Zhang Z, Li L (2018) Efficient synthesis of molecularly imprinted polymers with bio-recognition sites for the selective separation of bovine hemoglobin. J Sep Sci 41(11):2479–2487

Zhang HQ, Jiang JH, Zhang HT, Zhang Y, Sun PC (2013) Efficient synthesis of molecularly imprinted polymers with enzyme inhibition potency by the controlled surface imprinting approach. ACS Macro Lett 2(6):566–570

Zhang Y, Li D, Yu M, Ma W, Guo J, Wang C (2014) Fe3O4/PVIM-Ni2+ magnetic composite microspheres for highly specific separation of histidine-rich proteins. Acs Appl Mater Interface 6(11):8836–8844

Zhou TC, Shen XT, Chaudhary S, Ye L (2013) Molecularly imprinted polymer beads prepared by pickering emulsion polymerization for steroid recognition. J Appl Polym Sci 131(1):1–15

Zhou X, Gao XX, Song FY, Wang CP, Chu FX, Wu SS (2017) A sensing approach for dopamine determination by boronic acid-functionalized molecularly imprinted graphene quantum dots composite. Appl Surf Sci 423:810–816

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, P., Yin, Y., Xu, J. et al. Facile synthesis of Cu2+-immobilized imprinted cotton for the selective adsorption of bovine hemoglobin. Cellulose 27, 867–877 (2020). https://doi.org/10.1007/s10570-019-02816-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02816-z