Abstract

Eco-friendly multifunctional denim products using environmentally sound technologies are still a challenge. In current study, enzymatic pretreatments of denim fabric using acid pectinases, laccases, and acid cellulases individually and in admixtures were carried out followed by post-nanocoating of bio-treated fabric samples with ZnO- and TiO2-NPs along with citric acid/sodium hypophosphite as ester-crosslinking/binding system using the pad-dry-microwave fixation technique. The impacts of enzymatic and subsequent nano-treatments on some physico-chemical, color change, anti-microbial and UV-blocking properties were assessed. Also, surface modification and nano-metal oxides immobilization were observed and confirmed using scan electron microscope and energy dispersive X-ray spectroscopy analysis. The experimental results revealed that the degree of surface modification and subsequent multifunctionalization are governed by type of enzyme or hybrid enzyme as well as kind of nano-metal oxide and its extent of fixation onto the modified/ester-crosslinked denim fabric structure. The synergistic effect and positive impacts of enzymatic treatment followed by nanofinishing especially in case of using ZnO-NPs on imparting better and durable performance and multifunctional properties without adversely affecting the coloration properties of denim fabric samples are confirmed and discussed. Mode of interactions was also suggested.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Denim is a twill woven fabric and its warp yarns are traditionally colored blue with indigo dye to fabricate blue Jeans while its weft yarns are left uncolored (Ghoranneviss et al. 2007; Paul 2015; Sumithra and Raaja 2014). Cotton fibers are extensively used for denim fabric manufacture, and can also be blended with different natural, e.g. flax, hemp, etc. or synthetic fibers such as lycra, polyester, lyocell, etc. and dyed with non-indigo dyes e.g. sulfur, vat, direct, pigment dispersions etc. to get special types of denim with new shades, looks and effects to cope with the vast popularity and continuous demand for novelties (Patra and Pattanayak 2015; Sarkar 2015).

On the other hand, application of new enzymes and/or proper enzyme formulations in denim and garment processing represent one of the key factors for minimizing the environmental foot print of denim washing and bio-finishing processes to attain fashionable, sustainable, and high quality Jeans products (Colomera and Kuilderd 2015; Hebeish and Ibrahim 2007; Pulit-Prociak et al. 2016; Shahid et al. 2016).

Moreover, special final finishes can be applied to upgrade the performance, appearance and functionality of denim fabrics and garments. Recently, intensive research and development activities have been focused on the use of nanomaterials such as metal, metal oxides, and nano-clay to add special functions and properties such as antimicrobial (Maryan et al. 2013; Montazer and Maryan 2008), UV-blocking (Becenen and Altun 2016; Rivero et al. 2015) self-decontaminating (Maryan et al. 2013; Montazer and Seifollahzadeh 2011; Vijayalakshmi et al. 2012) and others like soft handle, flame retardant (Fouda and Fahmy 2011; Kalaoglu and Paul 2015; Maryan et al. 2013) to the treated denim Jeans in order to fabricate new functionalized apparel and non-apparel denim products.

Few works have been concerned by the applications of emerging technologies, especially bio- and nanotechnology in upgrading both the performance and functional properties of denim fabrics (Maryan et al. 2013, 2015; Montazer and Seifollahzadeh 2011; Uğur and Sariişik 2015; Vijayalakshmi et al. 2012). More studies are still needed to select the proper bio-pretreatments as well as subsequent post-treatments with selected nano-metal oxides to fabricate multifunctional denim fabrics. Therefore, the goal of this study was to investigate the positive role of enzymatic pretreatments of desized denim fabric using acid cellulases, acid pectinases and laccases separately and in combinations on post-functional finishing using ZnO and TiO2-NPs.

Experimental

Martials

Indigo dyed denim fabric (100% cotton, 240 g/m2) was used in this study. Nano metal oxides namely ZnO-NPs and TiO2-NPs (10–30 nm, avg., Skyspring®, USA) were of commercial grade.

Citric acid (CA, C6H8O7), sodium hypophosphite monohydrate (SHP, NaH2PO2·H2O) and polyethylene glycol-400 (PEG-400, C16H34O9) were of analytical grade.

The following enzymes were used in bio-processing of denim fabric: Aquazym® Ultra 250 L (an alpha-amylase produced by submerged fermentation of a genetically modified Bacillus microorganism, strength 250 NAU/g), cellulase/xylanase multifunctional crude enzyme (activity: 3.31 U/ml), biosynthesized according to the method of Ibrahim et al. (2016) (Ibrahim et al. 2016), acid pectinase fungal enzyme (activity: 10.8 U/ml), biosynthesized according to Ibrahim et al. (2017a, b) (Ibrahim et al. October 23–24, 2017), and bacterial laccase crude enzyme (activity: 0.516 U/ml), biosynthesized according to Desai et al. (2011).

Enzymatic treatments

Various enzymatic treatments conditions are listed in Table 1.

Prior to individual or simultaneous applications of acid pectinase, acid cellulases and laccase enzymes, the denim fabric was desized using the nominated desizing enzyme in presence of stainless steel balls according to the given conditions in Table 1, then thoroughly washed with hot water followed by tap water to remove the hydrolyzed starch size.

After the enzymatic treatments namely bio-scouring, bio-polishing and/or bio-oxidation, the bio-processes were terminated by increasing the pH to 8 and/or by raising the temperature up to 80 °C for 10 min, then washed thoroughly with hot followed by tap water to remove any enzyme residue, hydrolyzed and/or oxidized cellulosic/non-cellulosic fragments left on the bio-treated fabric surfaces, then dried and conditioned before post-functionalization with the nominated nanometal oxides.

Post-nanocoating

Nanocaotings of biotreated fabric samples were applied using the exhaustion method. The aqueous finishing formulations were prepared with the combination of CA (20 g/L), as a fixing and ester-crosslinking agent, SHP (15 g/L), as a proper catalyzing agent, ZnO- or TiO2-NPs (10 g/L) each, as an active functionalizing agent along with PEG-400 (2 g/L), as a dispersing agent in distilled water and then sonicated for 15 min using sonicator bath at 50 kHz and 50 Watt. To functionalize the bio-processed denim fabric samples, the fabric samples were coated with the freshly prepared aqueous dispersions using IR dyeing machine cups using material to-liquor ratio 1/15 at 30 °C for 30 min, then squeezed twice with 80% wet pick up followed by microwave fixation at 386 Watt/5 min, thoroughly washed to remove the unreacted/unfixed additives, dried and conditioned before evaluation.

Surface morphology study

SEM images were observed using Model Quanta SEM 250 FEG (Field Emission Gun) attached with an energy dispersive X-ray spectroscopy (EDX) with accelerating voltage-30 kV FELCO Netherland, for determining both the surface morphology and the elemental composition of the selected fabric surface respectively.

Release of reducing sugar

Release of reducing sugar after certain enzymatic treatments was assessed in the treatment bath after bio-processing according to the method described elsewhere (Miller 1959).

Determination of metal content

The metal content of the nanometal oxides-loaded fabric samples was assessed by flame atomic absorption Spectrophotometer GBC-Avanta-Australia (Ibrahim et al. 2010a).

Determination of nitrogen content

Nitrogen content, %N, was determined according to Kjeldahl method (Vogel 1975).

Weight loss

Evaluation of the weight loss, expressed as WL%, of treated fabric samples was assessed according to ASTM (D3776-79).

Color properties

Color strength (K/S), L* (lightness), a* (redness–greenness) and b* (yellowness–blueness) color values of some treated denim fabric samples were obtained by Colour-Eye.

3100 Spectrophotometer supplied by SDL Inter. England. Color strength (K/S) values were determined using Keubelka–Munk equation: K/S = (I − R)2/2R, where K, S and R: are absorption coefficient, scattering coefficient and reflectance of denim fabric samples respectively (Judd and Wyszeck 1975).

Durability to wash

The durability to wash was evaluated after 15 laundering cycles according to AATCC test method 61(2A)-1996 (AATCC 2013).

Surface roughness

Roughness of untreated and treated fabric samples was assessed using roughness measuring instrument SE 1700, Japan, according to JIS B0601-’94 standard (JIS 1994).

UV-protection factor

UV-protection factor (UPF), of the nano-materials-loaded and unloaded denim fabric samples was determined according to the Australian/New Zealand Standard method AS/NZS 4399:1996, and remarked as follows: good protection (UPF: 15–24), very good protection (UPF: 25–39) and excellent UV-protection (UPF > 40). The higher the UPF value, the better the UV-blocking ability (AS/NZS 1996).

Antimicrobial activity

Antimicrobial activity against the following harmful microorganisms: staphylococcus aureus, Pseudomonas aeruginosa, Candida Albicans, Aspergills Niger was evaluated qualitatively as representatives of G+ve bacteria, G−ve bacteria, yeast and fungal groups, respectively, and expressed as zone of growth inhibition (Z I, mm) according to (Abdel-Aziz et al. 2015; Collins and Lyne 1985; Youssef et al. 2014).

All tests have performed in triplicate and presented as mean values and standard deviation were calculated.

Results and discussion

SEM and EDX analysis

Figure 1 shows the effect of bio-processing using different enzymes formulations on the surface morphology of treated denim fabric samples. The SEM image of sized denim (Fig. 1a) shows fibers in parallel matrix to one another coated by size ingredients with no protruding fibrils at the fabric surface because of the existence of size coat.

After desizing with α-amylase (Fig. 1b) the size material have been removed but residual size components are still exist at the fiber surface. The fibers have become more loosened and disoriented most probably due to the mechanical action and removal of the size coat during desizing process.

Post-biopolishing with acid cellulases (Fig. 1c) enhances the denim surface appearance by removing protruding fibrils and some of existed impurities. Similar effect can be observed for post-enzymatic treatment using cellulases and laccase hybrid but to lesser extent compared with acid cellulases (Fig. 1d).

Additionally, combined bioscouring and biopolishing using acid pectinase and acid cellulases mixture (Fig. 1e) showed a remarkable improve in the surface cleanness by eliminating all the surface deposits along with the existing fibrils. This synergistic effect for both enzymes makes fibers appear more polished and clean.

On the other hand, Figs. 2 and 3 represent the SEM and EDX of different enzymatic treatments followed by post-treatment with ZnO-NPs and TiO2-NPs individually. From all the SEM images and EDX spectra, deposition of the nanoparticles at the coated fabric surface can be observed. Conclusively the existence of pectinase and/or laccase in the pre-enzymatic treatment increases the add-on of the nanoparticles at the surface of the coated fabric samples regardless of the type of nano-particle most probably due to their positive impacts on enhancing the extent of adsorption, anchoring and fixation of nominated NPs. EDX spectra of nano-metal oxides loaded fabric samples confirm the presence of both TiO2-NPs and ZnO-NPs and the extent of deposition is more for TiO2-NPs than ZnO-NPs.

Enzymatic treatments of desized denim fabric

As far as the changes in the physico-chemical and coloration properties of post-treated denim fabric samples with different enzyme formulations as a function of bio-processing type, the data in Table 2 signify that bio-processing of the desized denim fabric samples using acid pectinases, acid-cellulases, laccases alone and in combination results in a reasonable loss in weight, % WL, most probably due to partial de-polymerization of non-cellulosic/hydrophobic impurities, e.g. pectins using acid pectinases (Shahid et al. 2016), partial removal of surface fibrils as in case of using acid-cellulases (Ibrahim et al. 2011, 2016), or partial oxidation and removal of indigo dye as in case of using laccase enzyme (Rodríguez-Couto 2012). Enhancing the loss in weight by using mixed enzymes reflects the synergetic effect of applying mixed enzyme formulation for bio-treatment of desized denim fabric samples. On the other hand, the loss in weight as well as the change in other evaluated properties are governed by type of enzyme or mixed enzymes, specific activity and functionality, availability and accessibility of both active and binding sites as well as mode of interaction. Moreover, bio-processing of the desized fabric samples is accompanied by a decrease in the nitrogen content, %N, as a direct consequence of partial removal of N-containing indigo dye and other N-containing hydrophobic components. The noticeable decrease in the amount of reducing sugar (RS) is attributed to dextrinization and liquefaction of most of starch size, as a film forming material, by α-amylase (Ibrahim et al. 2004; Shahid et al. 2016). It was also observed that, post treatment of desized fabric samples with the nominated enzyme formulations brings about an improvement in fabric surface softness most probably due to the removal of residual starch size, partial removal of indigo dye deposits and/or surface removal of protruding cellulosic fibrils, depending on the nature and function of enzymatic formulation, thereby minimizing the surface roughness.

On the other hand, our experimental results (Table 2) demonstrate that, post treatment of the desized denim fabric samples with the nominated enzyme formulations is accompanied by a decrease in the color strength, K/S, of the obtained products, and the degree of decolorization depends on activity and functionality of the used individual or mixed enzymes. The decrease in K/S values of bio-processed fabric samples reflects the various role of these enzyme formulations on enhancing the extent of oxidation/decolorization/degradation of indigo dye by laccase enzymes as follows (Campos et al. 2001; Shahid et al. 2016):

and the ability of acid-cellulases enzyme components namely endoglucanase (EG), cellobiohydrolases (CBH) and cellobiases to synergistically attack and hydrolyze cellulose micro fibrils at fabric surface thereby facilitating surface removal of trapped indigo dye within hairs or fuzz, which in turn positively affect both color brightness as well as surface softness (Ibrahim et al. 2016; Montazer and Maryan 2008; Shahid et al. 2016).

Moreover, enhancing the hydrophilicity and wettability of the treated denim fabric via the removal of hydrophobic contaminants thereby facilitating the removal of oxidized, decolorized, degraded as well as entrapped indigo dye could be ascribed to the positive role of acid pectinase pretreatment (İşmal 2008; Shahid et al. 2016).

Additionally, the changes in color values namely lightness (L*), redness-greenness (a*) and yellowness-blueness (b*) of the desized denim fabrics are affected by type and function of the used individual and mixed enzymes in the post-treatment steps (Table 2).

The data in Table 2 also reveal that the improvement in fabric lightness could be discussed in terms of the positive role of post-bioprocessing using the nominated enzyme formulations on enhancing the wettability of the desized denim fabric thereby facilitating the release of loose, and trapped dye molecules as well as other colored impurities from fabric structure. Additionally, the enhancement in the lightness of desized denim fabrics is also a direct consequence of attacking the chromophore component, oxidation of the dye structure and/or partial removal of the dyed protruding fibrils on fabric surface (Maryan et al. 2013). On the other hand, the given data demonstrate the color change of fabric from blue to yellow and from green to red in case of using laccases and cellulases respectively according to the obtained a* values, which confirms the change in color of the post-treated denim fabrics upon using different enzymatic formulations.

Nano-coating of bio-treated denim fabrics

The results in Table 3 reveal that nano-coating of bio-treated fabric samples using ZnO- and TiO2-NPs individually along with CA/SHP, an eco-friendly ester-crosslinking system, is accompanied by a remarkable increase in metal content of bio-treated and nano-coated fabric samples as a direct consequences of enhancing the extent of picking-up and anchoring of the nominated nano-materials during the curing step as follows (Ibrahim et al. 2017a, b):

The variation in the metal content of nano-coated bio-treated fabric samples reflects the differences among them in the extent of surface modification and functionalisation of the bio-treated samples and in their ability to pick-up and entrap the nano-materials via the –NH, –NH2 (Eq. 1) group of indigo dye or partially oxidised indigo dye by laccase enzyme along with the free -COOH groups of the ester-crosslinked denim fabric structure (Eq. 2). On the other hand, loading of the nominated nano-metal oxides onto fabrics surface results in an increase in their surface roughness. Also, post-treatment with TiO2-NPs brings about a significant increase in the lightness of biotreated fabric samples along with a remarkable decrease in their color strength, expressed as K/S values, which could be discussed in terms of the ability of loaded-TiO2-NPs to form a white color coat onto the nano-finished fabrics surface, regardless of type of enzymatic treatment, as well as partial oxidation/discoloration of indigo dye via the generated active oxygen species such as HO·, RO·, \({\text{RO}}_{2}^{ \cdot }\) onto the loaded TiO2-NPs coat surface (Ibrahim et al. 2010b; Montazer and Seifollahzadeh 2011). Moreover, the lightness and K/S values of nano-coated fabric samples follow the decresing orders: TiO2-NPs ≫ ZnO-NPs-loaded samples > None, and None > ZnO-NPs ≫ TiO2-NPs-loaded samples respectively, keeping other parameers constant.

Table 3 also illustrates the antimicrobial activity of bio-treated and post-coated fabric samples with the nominated nano-metal oxides. The obtained results signify that bio-treatments of denim fabric samples using the nominated enzyme formulations do not impart antimicrobial activity to the treated denim fabric swatches. Loading of the nominated nano-metal oxides onto the bio-treated fabric samples results in a significant improvement in their antimicrobial activities against the nominated pathogens. The extent of improvement in antimicrobial efficacy of nano-coated denim fabric swatches is generally affected by type of loaded nano-metal oxides, i.e. its chemical structure, extent of distribution/location/fixation onto fabric surface, photo-catalytic activity and abrasive effect especially in case of ZnO-NPs (Dastjerdi and Montazer 2010; Ibrahim et al. 2010b), and follows the decreasing order: ZnO-NPs > TiO2-NPs, keeping other parameters fixed. Additionally, the variation in inhibition effect, expressed as ZI value, against the nominated microorganism reflects the differences among them in cell structure as well as amenability to damage, destruct and/or to kill by the generated reactive oxygen species (ROS) due to the photocatalytic activity of loaded nano-metal oxides (Roy Choudhury 2017).

Moreover, post nano-finishing of bio-treated denim fabric swatches results in a remarkable enhancement in their UV-protection ability, expressed as UPF value. The extent of improvement in UV-protection functionality of nano-metal oxides-loaded samples is governed by the variation in surface morphology, porosity as well as smoothness, as in case of bio-polishing treatment, as well as the subsequent loading of the nominated UV-blocking agents, i.e. TiO2-and ZnO-NPs, onto the modified fabrics surface. The improvement of the imparted harmful UV-shielding capacity of the treated substrates follows the decreasing order: TiO2-NPs-loaded fabric > ZnO-NPs-loaded fabric ≫ None.

Durability to wash

The changes in antimicrobial activity, expressed as ZI, as well as in UV-blocking functionality, expressed as UPF values, of selected samples after 15 washing cycles were recorded in Table 4. The given data signify that the bio-treated-post-nano-coated denim fabric samples still had a noticeable antibacterial and UV-protection functionalities even after 15 washing cycles which confirms the durability and stability of the loaded nanoparticles, onto/within the denim fabric structure, to wash. On the other hand, washing of the selected samples has practically a slight negative impact on their color strength, expressed as K/S values.

Conclusion

In the current research and development work, fabrication of multifunctional denim fabrics with remarkable durability was successfully achieved by enzymatic pre-treatments using different enzymatic formulations followed by subsequent nano-coating using ZnO- and TiO2-NPs in the presence of CA/SHP ester-crosslinking systems and microwave fixation. The imparted antimicrobial activity and UV-blocking ability of the coated denim fabrics as well as the variation in weight, handle performance, denim color and lightness properties are governed by type of enzyme or mixed enzyme, mode of action, ability to attack, degrade and/or discolor the denim fabric surface, as well as subsequent fixation and immobilization of the nominated nano-metal oxides onto the modified surfaces along with their ability to inhibit the growth and/or to kill the nominated microorganisms as well as to shield the harmful UV-B radiation. It was observed that, the imparted functional properties of selected samples are noticeably maintained even after 15 washing cycles. Both SEM and EDX analysis of some treated denim fabrics confirm both surface modification and nano-metal oxides deposition and immobilization after the nano-coating process of bio-treated fabric samples.

References

AATCC (2013) Colorfastness to laundering, home and commercial: accelerated, AATCC TM061-TM61-TM 61, vol AATCC TM061-TM61-TM 61. American Association of Textile Chemists and Colorists, AATCC Committee RA60, USA

Abdel-Aziz MS, Abou-El-Sherbini KS, Hamzawy EMA, Amr MHA, El-Dafrawy S (2015) Green synthesis of silver nano-particles by Macrococcus bovicus and its immobilization onto montmorillonite clay for antimicrobial functionality. Appl Biochem Biotechnol 176:2225–2241

AS/NZS (1996) Sun protective clothing—evaluation and classification, vol AS/NZS 4399:1996. Council of Standards Australia and Council of Standards New Zealand Australian/New Zealand, Australian/New Zealand

Becenen N, Altun Ö (2016) Applications of TiO2, ZnO and Ag nanomaterials to denim fabric. J Nanosci Nanotechnol 16:5359–5363

Campos R, Kandelbauer A, Robra KH, Cavaco-Paulo A, Gübitz GM (2001) Indigo degradation with purified laccases from Trametes hirsuta and Sclerotium rolfsii. J Biotechnol 89:131–139

Collins CH, Lyne PM (1985) Microbiological methods, 5th edn. Butterworths, London

Colomera A, Kuilderd H (2015) Biotechnological washing of denim jeans. In: Paul R (ed) Denim. Woodhead Publishing, Cambridge, pp 357–403

Dastjerdi R, Montazer M (2010) A review on the application of inorganic nano-structured materials in the modification of textiles: focus on anti-microbial properties. Colloid Surf B 79:5–18

Desai SS, Tennali GB, Channur N, Anup AC, Deshpande G, Murtuza BPA (2011) Isolation of laccase producing fungi and partial characterization of laccase. Biotechnol Bioinform Bioeng 1:543–549

Fouda MMG, Fahmy HM (2011) Multifunctional finish and cotton cellulose fabric. Carbohydr Polym 86:625–629

Ghoranneviss M, Shahidi S, Moazzenchi B, Anvari A, Rashidi A, Hosseini H (2007) Comparison between decolorization of denim fabrics with oxygen and argon glow discharge. Surf Coat Technol 201:4926–4930

Hebeish A, Ibrahim NA (2007) The impact of frontier sciences on textile industry. Colour Annu 54:41–55

Ibrahim NA, El-Hossamy M, Morsy MS, Eid BM (2004) Development of new eco-friendly options for cotton wet processing. J Appl Polym Sci 93:1825–1836

Ibrahim NA, Eid BM, Hashem MM, Refai R, El-Hossamy M (2010a) Smart options for functional finishing of linen-containing fabrics. J Ind Text 39:233–265

Ibrahim NA, Refaie R, Ahmed AF (2010b) Novel approach for attaining cotton fabric with multi-functional properties. J Ind Text 40:65–83

Ibrahim NA, El-Badry K, Eid BM, Hassan TM (2011) A new approach for biofinishing of cellulose-containing fabrics using acid cellulases. Carbohydr Polym 83:116–121

Ibrahim NA, Abdel-Aziz MS, Eid BM, Hamdy SM, Abdallah SE (2016) Biosynthesis, optimization and potential textile application of fungal cellulases/xylanase multifunctional enzyme preparation from Penicillium sp. SAF6. Biocatal Biotransform 34:128–136. https://doi.org/10.1080/10242422.2016.1237943

Ibrahim NA, Eid BM, Abdel Aziz MS, Hamdy SM, Abd Allah SE (2017) Acid pectinase production by a newly isolated fusarium oxysporum M1-EGY strain: characterization and potential utilization in bioscouring of cotton knits. In: The first international conference of NCPAC17: chemistry for sustainable future, Cairo, Egypt, October 23–24

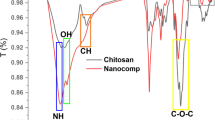

Ibrahim NA, Eid BM, El-Aziz EA, Elmaaty TMA, Ramadan SM (2017b) Loading of chitosan—nano metal oxide hybrids onto cotton/polyester fabrics to impart permanent and effective multifunctions. Int J Biol Macromol 105:769–776

İşmal ÖE (2008) Influence of wax and pectin removal on cotton absorbency. AATCC Rev 8:37–42

JIS (1994) Surface roughness, vol JIS B0601-’94. Japanese Standards Association, Japan

Judd D, Wyszeck G (1975) Color in business, science, and industry, 3rd edn. Wiley-Interscience, New York

Kalaoglu F, Paul R (2015) 14—Finishing of jeans and quality control. In: Paul R (ed) Denim. Woodhead Publishing, Cambridge, pp 425–459

Maryan AS, Montazer M, Harifi T, Rad MM (2013) Aged-look vat dyed cotton with anti-bacterial/anti-fungal properties by treatment with nano clay and enzymes. Carbohydr Polym 95:338–347

Maryan AS, Montazer M, Harifi T (2015) Synthesis of nano silver on cellulosic denim fabric producing yellow colored garment with antibacterial properties. Carbohydr Polym 115:568–574

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Montazer M, Maryan AS (2008) Application of laccases with cellulases on denim for clean effluent and repeatable. J Appl Polym Sci 110:3121–3129

Montazer M, Seifollahzadeh S (2011) Enhanced self-cleaning, antibacterial and UV protection properties of nano TiO2 treated textile through enzymatic pretreatment. Photochem Photobiol 87:877–883

Patra AK, Pattanayak AK (2015) 16—Novel varieties of denim fabrics. In: Paul R (ed) Denim. Woodhead Publishing, Cambridge, pp 483–506

Paul R (ed) (2015) Denim and jeans: an overview. In: Denim. Woodhead Publishing, Cambridge, pp 1–11

Pulit-Prociak J, Chwastowski J, Kucharski A, Banach M (2016) Functionalization of textiles with silver and zinc oxide nanoparticles. Appl Surf Sci 385:543–553

Rivero PJ, Urrutia A, Goicoechea J, Arregui FJ (2015) Nanomaterials for functional textiles and fibers. Nanoscale Res Lett 10:501

Rodríguez-Couto S (2012) Laccases for denim bleaching: an eco-friendly alternative. Open Text J 5:1–7

Roy Choudhury AK (2017) 11—Finishes for protection against microbial, insect and UV radiation. In: Principles of textile finishing. Woodhead Publishing, Cambridge, pp 319–382

Sarkar AK (2015) Dyeing technologies for denim garments A2. In: Paul R (ed) Denim. Woodhead Publishing, Cambridge, pp 271–285

Shahid M, Mohammad F, Chen G, Tang R-C, Xing T (2016) Enzymatic processing of natural fibres: white biotechnology for sustainable development. Green Chem 18:2256–2281

Sumithra M, Raaja VN (2014) Antifungal activity of herbal finish on 100% cotton denim fabric. J Fash Technol Text Eng. https://doi.org/10.4172/2329-9568.1000116

Uğur ŞS, Sariişik AM (2015) Deposition of nanoparticle multilayers to improve mechanical properties of denim fabrics. J Text Inst 106:718–724

Vijayalakshmi D, Rathinamoorthy R, Ramachandran T (2012) An experimental study on the multi-functional efficacy of nano TiO2 treated denim fabrics. J Text Appar Technol Manag 7:1–12

Vogel AI (1975) Elementary practical inorganic chemistry, 2nd edn. Longman, London

Youssef AM, Abdel-Aziz MS, El-Sayed SM (2014) Chitosan nanocomposite films based on Ag-NP and Au-NP biosynthesis by Bacillus subtilis as packaging materials. Int J Biol Macromol 69:185–191

Acknowledgments

We are gratefully acknowledge the financial support of this work from the Egyptian Academy of Scientific Research and Technology (ASRT).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Ibrahim, N.A., Eid, B.M., Abdel Aziz, M.S. et al. Green surface modification and nano-multifunctionalization of denim fabric. Cellulose 25, 6207–6220 (2018). https://doi.org/10.1007/s10570-018-1985-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-1985-y