Abstract

This review addresses the structure, properties, applications and future scope of lemongrass, which constitutes an abundant source of plant material around the world. As a source of cellulose, it has been successfully used for the adsorption of metal ions and dyes and for manufacturing paper and pulp. Recently, it has shown promise in the production of composites and bio energy, as well as obtaining silica and other metal oxides. However, previous research studies have mostly concentrated on utilizing the biological activities of the constituents in therapeutic uses, food preservation, cosmetics and agriculture. Therefore, this review covers literature on all areas of current studies on lemongrass and identifies its multidimensional potential. Furthermore, this review describes the intended application of lemongrass as a source of cellulosic matter, more specifically in the materials science field.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lemongrass is a popular plant and an abundant source of lignocellulose material composed of around 39.5% cellulose, 22.6% hemicellulose and 28.5% lignin (Bekele et al. 2017). The Cymbopogon genus widely grows in tropical and subtropical lands of the Indian subcontinent, South America, North America, Africa, Australia and Europe (Skaria et al. 2006). This grass is so named for its distinctive citrus aroma of the green leaves when they are crushed (Ravinder et al. 2010). It is also known as “Squinant” or “Citronella” in English, as well as other informal names around the world (Kumar et al. 2009; Ravinder et al. 2010; Adhikari et al. 2013; Ranade and Thiagarajan 2015).

Lemongrass is cultivated over an area of 16,000 ha throughout the world which generates around 1000 t of essential oil per year. The grounds on which it is cultivated are mostly infertile and wastelands (Joy et al. 2006). In addition, cultivation of this grass offers a profitable source of earning for low income cultivators, as each hectare of land produces a net profit of approximately 300 USD per annum to the growers (Singh and Jha 2008).

The plant generally grows up to 1.8 m high and 1.2 m in width. It has a small rhizome, and the leaves appear from the soil directly without any stem. The leaves are 1.3–2.5 cm in width and around 1 m in length (Shah et al. 2011). The Cymbopogon genus is comprised of more than 55 species in different countries all over the world possessing various material and chemical properties (Abdulazeez et al. 2016). However, Cymbopogon flexuosus and Cymbopogon citratus (also known as West Indian and East Indian lemongrass, respectively) represent the two major species vastly cultivated in different regions of the world for the high citral content (70–80%) in their essential oils (Robbins 1983).

The pleasant lemon fragrance of this grass has long been used in perfumery and related cosmetics, as well as food industries (Ranade and Thiagarajan 2015). Initially, lemongrass was used to flavour foods in Thai and Vietnamese cooking. It has a beneficial use in African and South American regions for flavouring tea. It is also popular in alcoholic and non-alcoholic drinks (Abdulazeez et al. 2016). Additionally, it has conventional uses in Ayurveda as a tranquilizer, diuretic, antipyretic and anti-inflammatory medicine (Carlini et al. 1986; Negrelle and Gomes 2007). There are numerous examples of the application of lemongrass for health remedies by different ethnic groups (Ravinder et al. 2010). For instance, tea made from lemon grass leaves is predominantly used as an antispasmodic, analgesic, antipyretic, sedative, diuretic and anti-inflammatory compound in Brazil (Leite et al. 1986; Souza et al. 1986). It is used for lowering blood pressure and treating catarrh and rheumatism in Cuba, as well as used to cure the sore throat and empacho in Argentina (Carbajal et al. 1989; Filipoy 1994). In addition, a number of biological properties of lemongrass are reported over the years, including but not limited to antibacterial, antifungal, antiprotozoal, anti-inflammatory, antioxidant, antitussive, antiseptic, anti-carcinogenic, cardio-protective and anti-rheumatic activities (Ekpenyong et al. 2015).

Such a broad variety of activities of lemongrass has made it a preferred choice for research and applications, especially in recent years. Figure 1 represents the number of titles published during 2000–2017 on lemongrass in the Web of Science and Scopus database, which reflects a significant increase in lemongrass research in recent years.

However, the applications of lemongrass are mostly reported on the basis of its biological and correlated activities with its developments in medical science, food science, and cosmetics, as well as agriculture. Reports are also present on the successful use of lemongrass in materials science as a raw matter in pulp and paper production (Kamoga et al. 2015), producing energy (Alfa et al. 2014), as an adsorbent (Hassan 2016), a basic constituent of composites (Bekele et al. 2017) and in the production of silica (Firdaus et al. 2015). Figure 2 describes both aspects of research applications in current years with lemongrass.

The purpose of this review is to comprehensively evaluate the properties and applications of lemongrass and to explore the future applications. Although there are several reviews available on lemongrass reporting only its phytochemical and medicinal prospective, this review aims to cover all of the current application fields of lemongrass together with its structure and properties.

Composition, properties and activities of lemongrass

Lemongrass has three basic components: cellulose, hemicellulose and lignin (Kaur and Dutt 2013; Bekele et al. 2017). The chemical constituents of the lemongrass plant are listed in Table 1. Structurally, lemongrass is the hydrocarbon mainly composed of carbon and oxygen. The elemental composition (without ash) of lemongrass is also tabulated in Table 1.

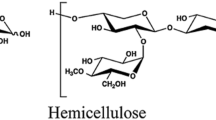

Cellulose is a three-dimensional linear molecule structure, which includes both crystalline and amorphous regions, whereas hemicellulose consists of a mainly amorphous region with several crystalline regions. Another basic difference between cellulose and hemicellulose is the degree of polymerization, which can be 100–10,000 for cellulose and less than 200 for hemicellulose (Yang 2008). Lignin is an amorphous heterogeneous three-dimensional nonlinear polymer which binds cellulosic components together (Bajpai 2016). Cellulose is made up of 1,4 β-glucopyranose units, hemicellulose comprises xylose, galactose, arabinose and mannose sub units and lignin consists mainly guaiacyl, syringyl and p-hydroxyphenyl units (Pierson et al. 2013). The structures of cellulose, hemicellulose and lignin are shown in Fig. 3.

Furthermore, there is a variety of oil content found in lemongrass depending upon the genetics, area of growth, culture and agronomic treatment. Generally, essential oil (EO) is collected around 1–2% of the total dry weight (Carlson et al. 2001). However, the method of drying can influence the composition. Oven drying of leaves can produce a greater amount of EO than sun-drying or shade-drying methods, although the oil collected from shade drying has a higher citral content on which the quality of oil is judged (Hanaa et al. 2012).

Citral is comprised of mainly two stereo-isomeric mono-terpene aldehydes: geranial and neral, trans-citral and cis-citral (Sarer et al. 1983; Rauber et al. 2005). In general, lemongrass oil contains greater than 45% of citral, but the amount can vary widely among species. The East Indian lemongrass (C. citratus) commonly possesses around 30–94% of citral (Negrelle and Gomes 2007; Moore-Neibel et al. 2012). Different hydrocarbons such as terpenes, alcohols, ketones and esters, are also reportedly found in the composition of EO (Abegaz et al. 1983; Evans 2009). The phytochemical composition of C. citratus also includes tannins, saponins, anthraquinones, phenols, flavonoids and alkaloids. In addition, myrcene, geraniol, borneol, citronellol, limonene, α-terpineol, elemicin, nerol, catechol, luteolin, apigenin, quercetin, kaempferol, glycosides, chlorogenic acid, caffeic acid, geranyl acetate as well as methylheptenone, isovaleric aldehyde, fumesol, l-linalool, furfurol, isopulegol, n-decyclic aldehyde, p-coumaric acid, terpinene are also evident in trace amount in several studies (Faruq 1994; Miean and Mohamed 2001; Negrelle and Gomes 2007; Akhila 2010). There are also reports on the presence of isoscoparin, swertiajaponin, orientin and other phytochemicals in lemongrass (Cheel et al. 2005; Bharti et al. 2013b). The amount of major constituents of lemongrass EO found in studies of Saleem et al. are represented in Fig. 4, which shows a greater presence of trans-citral (geranial) and cis-citral (neral) along with more reduced amounts of nerol, geraniol, citronellol, terpinolene, geranyl acetate, myrcene, α-terpineol and other components (Saleem et al. 2003a, b). The chemical structures of the key constituents of lemongrass EO are shown in Fig. 5. Different minerals are also present including potassium (54.02%), calcium (25.87%), silica (9.02%), phosphorus (1.57%) (Firdaus et al. 2015). It also possesses vitamins A, C, and E and folate, niacin, pyridoxine, riboflavin, as well as protein, carbohydrates and fat (Aftab et al. 2011).

Scientific studies have revealed that lemongrass is effective as an antifungal, antibacterial and antiprotozoal agent (Kishore et al. 1993; Mishra and Dubey 1994; Wannissorn et al. 1996; Vinitketkumnuen and Lertprasertsuk 1997; Tchoumbougnang et al. 2005; Pedroso et al. 2007; Bassolé et al. 2011; Revathi et al. 2012; Azeredo and Soares 2013; Tadtong et al. 2014; Gilling et al. 2014; Karbach et al. 2015; Trindade et al. 2015) which have opened a diverse area of application of this grass. The anti-nociceptive and anti-inflammatory characteristics of lemongrass also confirmed by several studies (Viana et al. 2000; Wannissorn et al. 2005; Boukhatem et al. 2014).

Some studies were conducted to find out the specific biological activities of different constituents in the EO of lemongrass. It was reported that citral and geraniol are responsible for fungicidal behavior, while the presence of myrcene enhances that antifungal activity further (Onawunmi et al. 1984; Moleyar and Narasimham 1992; Pattnaik et al. 1997). Cinnamic aldehydes, linalool, alkaloids and phenols were responsible for the antibacterial activity of lemongrass (Onawunmi et al. 1984; Moleyar and Narasimham 1992; Pattnaik et al. 1997; Hindumathy 2011). It is more probable that the antibiotic activity of lemongrass is a result of the combined actions of its components rather than a single constituent (Ekpenyong et al. 2015). Table 2 shows the biological activities of lemongrass as well as the constituents for those activities reported by the researchers over the years.

Lemongrass has shown a number of other important properties including but not limited to anti-tumor, anti-carcinogenic (Zheng et al. 1993; Suaeyun et al. 1997), anti-mutagenic (Vinitketkumnuen et al. 1994), anti-amoebic (Blasi et al. 1990), anti-diarrhoeal (Tangpu and Yadav 2006), anti-filarial (Suresh and Raj 1990), larvicidal and ascaricidal (Chungsamarnvart and Jiwajinda 1992). However, its potential in materials science applications, as an abundant source of cellulose, has sparked scientific interest in recent years. These are discussed in the next sections.

Fields of application

Application of lemongrass as a cellulosic material

Adsorption of metal ions and dyes

As cellulosic materials exhibit good adsorption properties, lemongrass has been used as a bio-absorbent material for different metal ions and dyes. Cymbopogon citratus has been reported to adsorb Cu2+, Ni2+, Pb2+, Cd2+ and Zn2+ (Zuo et al. 2012; Lee et al. 2014; Sobh et al. 2014; Hassan 2016) whereas the West Indian lemongrass, Cymbopogon flexuosus, was also found quite effective for removal of As3+ and Cr4+ from aqueous solution (Jha and Kumar 2017). For absorbing metal ions, lemongrass has been dried and crushed into powder in most cases for use as the absorbent material (Lee et al. 2014; Sobh et al. 2014). In addition, there are examples of considering the whole plant in the adsorption process (Jha and Kumar 2017). Formation of the smaller particle resulted in greater adsorption capacity, compared with 93% ion removal using the powder form of the lemongrass plant (Sobh et al. 2014).

For the dye adsorption processes, more intensive thermal treatment (500 °C) at muffle furnace (as illustrated in Fig. 6) has been reported to produce lemongrass ash for use as the absorbent. The results showed that more than 90% dyes were adsorbed onto lemongrass by 0.4–0.6 mg/100 ml adsorbent dose, indicating the true potential of this material (Singh 2014). More importantly, the isotherm models of adsorption suggest the mechanism as a chemisorption process which is stronger than physical adsorption processes (Lee et al. 2014). However, it should also be noted the removal of dye and metal ions were found highly dependent on process parameters like pH, the concentration of the ion or dye, and time duration (Singh 2014). In all cases, the solution pH was reported as a significant control point for the adsorption (Lee et al. 2014; Singh 2014). Moreover, it was observed that the initial rate of adsorption was high rather than the later period that is likely due to the significant numbers of free sorption sites at the beginning stage of adsorption. More significant concentrations of the metal ion showed better adsorption too, as the higher number of ions were present initially to become adsorbed (Lee et al. 2014). When most of the sorption sites were saturated, the adsorption rate slowed down. However, for metal ion adsorption, the most effective adsorption was reported at 1 g/L bio absorbent concentration over which no significant increase in adsorption obtained (Lee et al. 2014).

(Drawn from the concept of Singh 2014)

Preparation process flow of ashes from lemongrass for dye adsorption.

In a study of dye adsorption, waste lemon grass was collected from the lemongrass oil distillation subunit and reformed to ash to examine its adsorption capacity to methylene blue dye (Singh 2014). Almost half of the dyes from the solution were adsorbed to the lemongrass ash in the first 90 min where around 40% was adsorbed in the first 40 min. Adsorption of dyes increased with the increase of the lemongrass adsorbent dose, pH and contact time. Similar to the adsorption behavior of metal ions, a higher initial concentration of dyes also resulted in better adsorption due to the availability of absorbent sites. Figure 7 shows variation in dye removal with respect to each of contact time, adsorbent dose, pH and initial dye concentration when the other parameters were kept constant (Singh 2014).

(Redrawn from Singh 2014)

Effect of individual parameters a dye concentration, b dose of adsorbent, c time and d pH on dye removal % by lemongrass ash when all other parameters were constant.

Production of paper pulp

Several species of grasses have already been examined for pulping and papermaking (Madakadze et al. 1999, 2010; Pahkala et al. 1999; Dutt et al. 2012). Lemongrass that is rich in cellulose has shown its potential to become a raw material for paper industries (Kaur and Dutt 2013; Kamoga et al. 2015). Figure 8 illustrates a manufacturing process of pulp and paper from lemongrass. Like other pulp making raw materials, lemongrass is cut into chips (15–25 mm) before delignification. The cooking of the chips of lemongrass was reportedly performed at 130–170°C for 1–3 h in presence of alkali and anthraquinone. The cooked material was washed, screened through a vibratory flat screen (0.15 mm pore size) and taken to beating operation before the sheet forming process through rollers (Kaur and Dutt 2013).

(Drawn from the concept of Kaur and Dutt 2013)

Flow diagram for manufacturing pulp and paper from lemongrass.

Lemongrass and Sofia grass have been used for the production of chemical grade pulp where lemongrass (Cymbopogon Flexuosus) showed better mechanical strength properties than Sofia grass, which is also a Cymbopogon species (Cymbopogon Martinii) renowned as the source of Palmarosa oil (Kaur and Dutt 2013). Moreover, the freeness of pulps, which is a measure of how fast the water can drain from samples, was low in case of lemongrass pulp compared to conventional wood pulps (Kamoga et al. 2015). This is probably because of more open spaces in fibrils than wood pulps due to the presence of short and broken fibres enhancing the surface area and resulting in higher absorption capability. Canadian Standard Freeness (CSF) is a measurement of freeness that is directly related to the energy requirement of paper industries. Figure 9 shows CSF values of Cymbopogon nardus pulps prepared through two different methods. The soda-anthraquinone pulping was done by different alkali concentrations (10–25%) at temperature ranges from 100 to 160 °C for 1 h with 0.1% of anthraquinone concentration. Kraft pulping, the second pulping method was performed in 10–25% sulphidity with the same temperature range with same time duration. The CSF values were observed around 200 ml only after 500 and 1000 beating revolution whereas in general, 5000–6000 beating revolutions are required in industries to acquire 200 ml Canadian Standard Freeness (CSF) from wood pulps (Kamoga et al. 2015). This indicates the tremendous potential of lemongrass in this field in the future by consuming less energy and cost at an industrial scale.

(Produced by data from Kamoga et al. 2015)

Canadian standard freeness of Cymbopogon nardus pulps after beating revolutions.

Application as a composite material

The most recent application of lemongrass has been reported in the composite field, where lemongrass has been used as a reinforcing material for thermoplastic composite. Bekele et al. introduced lemongrass composite prepared from lemongrass flour (150–850 μm in particle size) in a combination of high density polyethylene (HDPE) with the presence of maleic anhydride grafted polypropylene (MA-g-PP) as a coupling agent (Bekele et al. 2017). The HDPE was used as matrix material where composites were prepared using varied lemongrass content from 10 to 50%. Figure 10 shows the process of producing a composite in that experiment where both modified (immersed in 0.5% Ca (OH)2 for 6 h) and unmodified flour were used. Lemongrass flour was blended with HDPE and MA-g-PP in a counter rotating twine hot-press mixer at 175 °C. Finally, the blend was cast between two stainless steel plates to prepare the composite and it was found that reinforcing lemongrass significantly increased the mechanical properties of composites especially when modified one was used. The tensile strength of the composites (22.0 MPa for modified and 20.0 MPa for unmodified lemongrass) was observed higher than the control HDPE (19.4 MPa) when 10% fibre was added (Bekele et al. 2017). However, with further increase of fibre content, tensile strength decreased (around 13–15 MPa for 50% fibre content) due to weak interaction between fibre and matrix interface (Bekele et al. 2017).

(Drawn from the methodology of Bekele et al. 2017)

Process flow of manufacturing composite from lemongrass and high density polyethylene in presence of maleic anhydride grafted polypropylene.

Lemongrass EO has also been used to produce bio-composite films in combination with chitosan and starch through the sol–gel mixture. That method also involved mixing and casting followed by an ageing process. The SEM images of the produced bio-film discovered the homogeneous surface structure. Since the tensile strength of that film was not reported (Pandharipande and Katekhaye 2017), there is no indication of the suitability of the process used in that study.

Production of bio energy

There are a few investigations into the production of bioenergy from lemongrass. Figure 11 illustrates the flow diagrams of manufacturing bio oil and bio gas from lemongrass described in separate reports (Alfa et al. 2014; Madhu et al. 2017). In case of bio oil production, Cymbopogon flexuosus was dried and crushed then passed through the pyrolysis chamber in a fluidized bed reactor under the nitrogen atmosphere (Madhu et al. 2017). At best, 50.6 wt% bio-oil was achieved at 450 °C where the oil consists of a 22% water and around 40% of oxygen. The heating value of the produced bio oil (19.4 MJ/Kg) was reportedly higher than that of cotton shell, palm shell and garlic stem in that study. However, further research is required on this bio oil to compete with the industrial grade oils, as the current industrial oils have more than double heating value compared to the produced bio oil (Madhu et al. 2017).

The other thermal processing methods of producing bio energy like grate combustion and gasification have not been reported with lemongrass yet. Anaerobic digestion, the biochemical process of producing energy has been reported where a smaller amount of bio gas was obtained from lemongrass compared to other two natural elements: cow dung and poultry dropping (Alfa et al. 2014). Moreover, there was a big difference in the pre-fermentation periods of the materials (40 days for lemongrass, 15 days for other two), as the plant material did not pass through any digestive systems like the cow dung and poultry dropping. However, the quality of bio gas obtained from lemongrass was reportedly better. For instance, the bio gas from lemongrass had left the smaller amount of total solids (TS), volatile solids (VS), volatile fatty acid (VFA), total ammonium Nitrogen (TAN), chemical oxygen demand (COD), orthophosphates, E. coli and Enterobacteriaceae counts in its solid and liquid residues (Alfa et al. 2014).

Production of silica

The current manufacturing process of silica throughout the world is expensive and energy consuming where furnace temperature ranges from 1300 to 1500 °C (Srivastava et al. 2013). Alongside the applications stated above, two different methods of obtaining silica from lemongrass have been reported (Firdaus et al. 2015, 2016). Figure 12 shows the process flow of the described methods, where one involves an acid leaching treatment while the other illustrates silica production directly by calcination. In both cases, the considered lemongrass was cultivated in heavy clay soil that had a high content of silica. The collected plant was washed, dried and ground and passed through a 20-mesh screen before doing any other treatments.

In their first method, hydrochloric acid leaching was performed on lemongrass particle at different temperatures (33–110 °C) followed by a thermal combustion at 600 °C in muffle furnace, which resulted in several metal oxides (CaO, MgO, P2O5, Fe2O3, K2O) along with SiO2 (Firdaus et al. 2015). Among the different acid leaching temperatures, though the crystallinity of lemongrass ash (which was 55% before acid leaching) decreased to 31% at 37 °C, it significantly increased to around 73% at 110 °C. In the other report, direct calcination of ground lemongrass was done without any acid pre-treatment. The calcination temperatures ranged from 400 to 700 °C with a combustion at 525 °C (Firdaus et al. 2016). The crystallinity of lemongrass ash increased from 36% (without calcination) to at best 63% (calcination at 700 °C) in that investigation. In both processes, siloxane (Si–O–Si) and silanol (Si–OH) groups were evident in lemongrass ash in all ranges of application temperatures that rely on lemongrass for silica production. Nevertheless, of the two methods, the acid leaching could be highly effective in terms of silica production, than the combustion method due to its high percentages of silica content in the end product. For example, acid leaching at 110 °C followed by thermal combustion at 600 °C produced more than 98% of silica and a very small amount of other metal oxides. But in direct combustion method, among all the metal oxides, the highest amount of silica was reported as only 24% at 400 °C.

Applications of lemongrass on basis of biological activities

Therapeutic uses

Lemongrass is widely used to heal many medical conditions due to its ability for producing secondary metabolites (Kumari et al. 2009; Oloyede 2009; Garg et al. 2012; Mirghani et al. 2012). Up to now, lemongrass has been used for numerous medical purposes such as preventing platelet aggregations (Tognolini et al. 2006), treating diabetes (Mansour et al. 2002), dyslipidemia and gastrointestinal troubles (Carlini et al. 1986; Negrelle and Gomes 2007), fever, flu and pneumonia (Negrelle and Gomes 2007) and anxiety (Xaio 1983). This plant is also used in Nigeria as an antipyretic and anti-protozoan agent for treating Malaria and related symptoms (Olaniyi et al. 1975; Tchoumbougnang et al. 2005). There are extensive reports that confirmed the influential character of constituents of lemongrass on pain sensitivity, behavior, hormone releases and neurotransmitter signaling (Seth et al. 1976; Koo et al. 2003; Gasser et al. 2006; Blanco et al. 2009). Moreover, it has also been reported that lemongrass extracts possess anticonvulsant and anxiolytic effects (Blanco et al. 2009; Sforcin et al. 2009). This grass is also proven effective for weight loss without interfering with the activity of liver enzymes (Batubara et al. 2015).

Lemongrass also has hypolipidemic, hypoglycemic and hypocholesteremic properties which are very much connected with heart conditions (de Melo Junior et al. 2002; Adeneye and Agbaje 2007; Agbafor and Akubugwo 2007). Low-density lipoproteins (LDL) and very low-density lipoproteins (VLDL) are also known as bad cholesterol because these enhance fatty build-ups and narrow the arteries resulting affecting the heart condition. In contrast, high density lipoproteins (HDL) are the good cholesterols that carry the LDLs from arteries to the liver and lower the risk of heart diseases. The ability of lemongrass to raise the HDL and limit LDL and VLDL (Fig. 13) is hence a very significant finding, reported by Adeneye and Agbaje (2007).

(Drawn by data from Adeneye and Agbaje 2007)

Effect of lemongrass leaf extract doses for 42 days on Triglycerides, High density lipoprotein (HDL), Low density lipoprotein (LDL), Very low density lipoprotein (VLDL) and total cholesterol.

Numerous applications of lemongrass and its EO are evident all over the world. Lemongrass tea and extracts are reported to be taken as an antipyretic, antispasmodic, sedative, diuretic, anti-inflammatory and analgesic compound (Leite et al. 1986; Souza et al. 1986), also to treat sore throats and empacho (Filipoy 1994), to increase the menstrual flow in the Philippines (Quisumbing 1951; Burkhill 1966), to heal wounds and bone fractures (Spring 1989), to treat diabetes (Mueller-Oerlinghausen et al. 1971), for lowering blood pressure, treating catarrh and rheumatism (Carbajal et al. 1989), to get relief from fever and severe headache (Rao and Jamir 1982) and to treat gastric troubles and cholera (John 1984), This leaf extract along with the extract from stems are also used as a diuretic and renal antispasmodic (Locksley et al. 1982). There are substantial reviews available on different medicinal applications of lemongrass and their scientific basis (Ravinder et al. 2010; Shah et al. 2011; Ranade and Thiagarajan 2015).

Application in food preservation

The antimicrobial activities of EO of lemongrass against microbes are well reported. Notably, the activity of lemongrass EO was found more beneficial than other EOs against 12 important bacterial species (de Silveira et al. 2012). The probable antibacterial mechanism of lemongrass EO on the cytoplasmic cell is illustrated in Fig. 14 that shows the EO induces cytoplasmic coagulation which includes spheroplast formation as well as preventing septum formation. It flows out the intra-cellular hydrogen ions resulting in immobility and mortality of bacterial cell (Ekpenyong and Akpan 2017).

(Redrawn from the concept of Ekpenyong and Akpan 2017)

Probable antibacterial mechanism of lemongrass essential oil for food preservation.

Moreover, the real advantage of lemongrass EO is its action against both gram positive and gram negative bacteria (Naik et al. 2010). Lemongrass was found effective against fungi (Mishra and Dubey 1994; Paranagama et al. 2003) and several bacteria including E. coli and Salmonella Enteritidis (Raybaudi-Massilia et al. 2006; Moore-Neibel et al. 2012). This EO has reportedly inhibited the germination of several key postharvest pathogens like Colletotrichum coccodes, Botrytis cinerea, Cladosporium herbarum and Rhizopus stolonifer that are significant for food preservations (Tzortzakis and Economakis 2007). It has been reported that lemongrass increases the life of different fruits like guava (Murmu and Mishra 2018) and cucumber (Omoba and Onyekwere 2016) as well as fruit juice (Tyagi et al. 2014). It was also found effective in preserving processed foods like yoghurt (Abd-El Fattah et al. 2010), cheese (Belewu et al. 2012), other dairy products (Abd-El Fattah et al. 2010) as well as bread, cake and bakery products (Guynot et al. 2003; Suhr and Nielsen 2003). Although lemongrass has potential features to become a bio preservative for food storage, as lemongrass is a natural flavour complex (NFC), it has the potential to become toxic, especially at high level of exposure to the gustatory or olfactory systems (Smith et al. 2005). These have been reviewed comprehensively by Ekpenyong et al. in different articles (Ekpenyong et al. 2015; Ekpenyong and Akpan 2017).

Application in cosmetics

The biological activities of lemongrass constituents are not only the key for applications in medicines and food science but also important for cosmetics applications. Citral, the main component of lemongrass oil is considered for producing β-ionone which provides rose aroma with low concentrations and thus significant for application perfumery industries. The EO of cymbopogon genus has commercial usages in palmarosa oil, perfume material and soap aroma (Davis et al. 1983). There are a number of lemongrass products available in the cosmetic field with patented formulas in combination with lemon balm oil and glycerol (Yongtian et al. 2015). In a particular patent, bacteria that arises from the pod of lemongrass generates pleasing and refreshing smell and therefore become a source of perfume (Yuhua et al. 2014). The antibacterial activity of lemongrass has the potential to be used as disinfectants or liquid antibacterial soaps depending on the activities of gram positive and negative bacteria (Mosquera 2016). Actions of the lemongrass EO on the pathogen and bacteria suggests its likelihood to treat human skin problems like acne (Lertsatitthanakorn et al. 2006; Melo et al. 2015). It has been shown that the EO of lemongrass has the ability to repel insects, which opens the opportunity to be used as a repellent lotion (Lima et al. 2009). The antioxidant property of this oil is very significant for cosmetic industries as this activity can be used to prevent several dermal diseases that are resulted from oxidative stress (Pereira et al. 2009). Moreover, as the oxidative stress is related to chronic degenerative diseases that cause early ageing, this material can be used as anti-ageing cream as well (Saraí et al. 2006). The bioactivities of lemongrass that are correlated with its potential cosmetic activities have been also comprehensively reviewed in the recent year (Mosquera 2016).

Agriculture and farming

Although the application of lemongrass in agriculture and farming is associated with its biological activities, this is a relatively new area of research and only a few studies have been reported. The roots of lemongrass have been used for reinforcement of a landslide-affected soil in India. It was found that the shear strength and unconfined compressive strength of natural soil was approximately doubled by only 4% of lemongrass roots (Gobinath et al. 2015). It was found also very effective with 50–50% combinations with cotton waste in the cultivation of the mushroom (Mumtaz et al. 2016). In a different study, lemongrass EO was found prospective not only in governing isariopsis spot in grape leaves and mildew but also increasing productivity grape cultivation (Maia et al. 2014). In addition, the ethanolic extract from lemongrass in combination with parthenium was reportedly an effective in citrus scab (Elsinoë fawcettii) management (Rehman et al. 2016). Lemongrass extract has shown improvement in germination of rice seed and seedlings, as well as their vigour index, and it was effective for regulating seed-borne rice fungi (Rahman et al. 2014). Furthermore, the EO of lemongrass was tested as poultry feed by including it in broiler feed in Nepal. The results suggested that inclusion of EO in broiler chicken can increase weight gain, while reducing mortality and the broiler harvesting period (Tiwari et al. 2017).

Implications and future study

Lemongrass is an abundant source of natural cellulose that possesses an enormous potential to be utilized as a prospective raw material for materials science. While there has been comprehensive research on lemongrass over the decades, there is much scope for future research on this material in different dimensions.

The research on adsorption behaviour of lemongrass is still in the embryonic stages and further investigations are required to assimilate the findings. Though there are a few reports on lemongrass and its potential adsorption properties (Lee et al. 2014; Singh 2014), identifying adsorbent characteristics towards common textile based dyes has not been investigated yet. Our current research on preparing membranes from lemongrass (unpublished results) showed well distributed pores (Fig. 15) throughout the surface of lemongrass. This is highly noteworthy as the porosity of the surface has led into better adsorption properties (unpublished results) and thus enhancing the suitability of the material for the membrane, which might be a future area of research.

The results from the initial research on paper pulp fabrication are very promising, and this fabrication provides an energy saving processing route for the paper industry (Kamoga et al. 2015). However, more detailed and systematic research is required for the bulk production. In composites, the mechanical properties of lemongrass-HDPE composites were found higher than the HDPE material which is a remarkable finding (Bekele et al. 2017). However, further research is warranted to understand the reasons behind the mechanical properties, the potential and impact of this material in composites. While production of bioenergy is a highly interesting research area and more works are emerging with natural lignocellulose biomass, not much research was reported on lemongrass in this regard. Although lemongrass has a considerable amount of fibrous content and there are reports of successful dissolution of lignocellulose materials (e.g. wheat straw and bagasse) in different solvents (Chen et al. 2014; Domínguez de María 2014; Li et al. 2015), no attempt was made to regenerate the lemongrass fibre through a spinning process.

Additionally, regeneration of packaging film from lemongrass can be a great direction of research as this material has antibacterial properties that can lead to a new way for the bio-preservation of food materials. Therefore, investigating lemongrass potential from material aspect might be the next generation precursor for biodegradable film, fibres, membranes and an antibacterial food packaging.

In contrast, research on the biological activities of lemongrass is already extensive. Nevertheless, until now most of the research concerning lemongrass in medical aspects has been conducted with animal subjects. Therefore, there is much to be proved from the standpoint of human cases. The probability of toxicity of lemongrass EO in food preservation might be another concern to look for in future research.

Conclusion

Lemongrass constitutes an abundant source of cellulose, hemicellulose and lignin and has an enormous potential as a raw matter for novel materials fabrication. However, the research in materials engineering applications is still in its infant stage. Until now the studies on lemongrass have mostly focused on its biological activities. However, there are a few encouraging research works conducted in recent years, which revealed its potential as the cellulosic material. It had been successfully used as the adsorbent for metal ions, dye and as a raw material for producing pulp and paper. It has also been introduced as a reinforced material in composites and has been used to produce bioenergy and silica. It is thus significant to find the engineering application for lemongrass to ensure the quality of commercial demands. Using lemongrass in diverse research areas suggests its enormous potential to become a new generation of raw material in the near future. Hence, collective effort from material researchers is required to consider lemongrass as the “spectacular biopolymer”.

References

Abd-El Fattah SM, Yahia Hassan A, Bayoum HM, Eissa HA (2010) The use of lemongrass extracts as antimicrobial and food additive potential in yoghurt. J Am Sci 6:582–594

Abdulazeez MA, Abdullahi AS, James BD (2016) Lemongrass (Cymbopogon spp.). In: Preedy VR (ed) Essential oils in food preservation, flavor and safety. Elsevier, Amsterdam, pp 509–516

Abegaz B, Yohannes PG, Dieter RK (1983) Constituents of the essential oil of Ethiopian Cymbopogon citratus Stapf. J Nat Prod 46:424–426. https://doi.org/10.1021/np50027a022

Adeneye AA, Agbaje EO (2007) Hypoglycemic and hypolipidemic effects of fresh leaf aqueous extract of Cymbopogon citratus Stapf. in rats. J Ethnopharmacol 112:440–444. https://doi.org/10.1016/j.jep.2007.03.034

Adhikari S, Bandopadhyay TK, Ghosh PD (2013) Assessment of genetic diversity of certain Indian elite clones of Cymbopogon species through RAPD analysis. http://nopr.niscair.res.in/handle/123456789/16529. Accessed on 22 Feb 2018

Aftab K, Ali MD, Aijaz P et al (2011) Determination of different trace and essential element in lemon grass samples by x-ray fluorescence spectroscopy technique. Int food Res J 18:265–270

Agbafor KN, Akubugwo EI (2007) Hypocholesterolaemic effect of ethanolic extract of fresh leaves of Cymbopogon citratus (lemongrass). Afr J Biotechnol 6:596

Akhila A (2010) Essential oil bearing plants: the genus Cymbopogon. CRC Press, Boca Raton

Alfa IM, Dahunsi SO, Iorhemen OT et al (2014) Comparative evaluation of biogas production from poultry droppings, cow dung and lemon grass. Bioresour Technol 157:270–277. https://doi.org/10.1016/j.biortech.2014.01.108

Azeredo CMO, Soares MJ (2013) Combination of the essential oil constituents citral, eugenol and thymol enhance their inhibitory effect on Crithidia fasciculata and Trypanosoma cruzi growth. Rev Bras Farmacogn 23:762–768. https://doi.org/10.1590/S0102-695X2013000500007

Bajpai P (2016) Pretreatment of lignocellulosic biomass. Springer, Singapore, pp 17–70

Bankole SA, Joda AO, Ashidi JS (2005) The use of powder and essential oil of Cymbopogon citratus against mould deterioration and aflatoxin contamination of “egusi” melon seeds. J Basic Microbiol 45:20–30. https://doi.org/10.1002/jobm.200410435

Bassolé IHN, Lamien-Meda A, Bayala B et al (2011) Chemical composition and antimicrobial activity of Cymbopogon citratus and Cymbopogon giganteus essential oils alone and in combination. Phytomedicine 18:1070–1074. https://doi.org/10.1016/j.phymed.2011.05.009

Batubara I, Suparto IH, Sa’diah S et al (2015) Effects of inhaled citronella oil and related compounds on rat body weight and brown adipose tissue sympathetic nerve. Nutrients 7:1859–1870. https://doi.org/10.3390/nu7031859

Bekele LD, Zhang W, Liu Y et al (2017) Preparation and characterization of lemongrass fiber (Cymbopogon species) for reinforcing application in thermoplastic composites. BioResources 12:5664–5681

Belewu MA, El-Imam AMA, Adeyemi KD, Oladunjoye SA (2012) Eucalyptus oil and lemon grass oil: effect on chemical composition and shelf-life of soft cheese. Environ Nat Resour Res 2:114. https://doi.org/10.5539/enrr.v2n1p114

Bharti SK, Krishnan S, Kumar A et al (2013a) Antidiabetic activity and molecular docking of fructooligosaccharides produced by Aureobasidium pullulans in poloxamer-407-induced T2DM rats. Food Chem 136:813–821. https://doi.org/10.1016/j.foodchem.2012.08.083

Bharti SK, Kumar A, Prakash O et al (2013b) Essential oil of Cymbopogon citratus against diabetes: validation by in vivo experiments and computational studies. J Bioanal Biomed 5:194–203. https://doi.org/10.4172/1948-593X.1000098

Blanco MM, Costa C, Freire AO et al (2009) Neurobehavioral effect of essential oil of Cymbopogon citratus in mice. Phytomedicine 16:265–270. https://doi.org/10.1016/j.phymed.2007.04.007

Blasi DV, Debrot S, Menound PA et al (1990) Amoebicidal effect of essential oils in vitro. J Toxicol Clin Expert 10:361–373

Bone K, Mills S (2013) Principles and practice of phytotherapy-e-book: modern herbal medicine. Elsevier Health Sciences, Amsterdam

Boukhatem MN, Ferhat MA, Kameli A et al (2014) Lemon grass (Cymbopogon citratus) essential oil as a potent anti-inflammatory and antifungal drugs. Libyan J Med 9:25431. https://doi.org/10.3402/ljm.v9.25431

Buchbauer G, Jirovetz L (1994) Aromatherapy—use of fragrances and essential oils as medicaments. Flavour Fragr J 9:217–222. https://doi.org/10.1002/ffj.2730090503

Burkhill IH (1966) Dictionary of the economic products of the Malay Peninsula. Ministry of Agriculture and Cooperatives, Kuala Lumpur

Carbajal D, Casaco A, Arruzazabala L et al (1989) Pharmacological study of Cymbopogon citratus leaves. J Ethnopharmacol 25:103–107. https://doi.org/10.1016/0378-8741(89)90049-4

Carlini EA, Contar JDDP, Silva-Filho AR et al (1986) Pharmacology of lemongrass (Cymbopogon citratus Stapf). I. Effects of teas prepared from the leaves on laboratory animals. J Ethnopharmacol 17:37–64. https://doi.org/10.1016/0378-8741(86)90072-3

Carlson LHC, Machado RAF, Spricigo CB et al (2001) Extraction of lemongrass essential oil with dense carbon dioxide. J Supercrit Fluids 21:33–39. https://doi.org/10.1016/S0896-8446(01)00085-7

Cheel J, Theoduloz C, Rodríguez J, Schmeda-Hirschmann G (2005) Free radical scavengers and antioxidants from Lemongrass (Cymbopogon citratus (DC.) Stapf.). J Agric Food Chem 53:2511–2517. https://doi.org/10.1021/jf0479766

Chen M, Zhang X, Liu C et al (2014) Approach to renewable lignocellulosic biomass film directly from bagasse. ACS Sustain Chem Eng 2:1164–1168

Chungsamarnvart N, Jiwajinda S (1992) A caricidal activity of volatile oil from lemon and citronella grasses on tropical cattle ticks. Kasetsart J Nat Sci 26:46–51

da Rauber CS, Guterres SS, Schapoval EES (2005) LC determination of citral in Cymbopogon citratus volatile oil. J Pharm Biomed Anal 37:597–601. https://doi.org/10.1016/j.jpba.2004.10.042

Davis JB, Kay DE, Clark V et al (1983) Plants tolerant of arid, or semi-arid, conditions with non-food constituents of potential use. Tropical Products Institute, London

de Melo Junior EJM, Raposo MJ, Neto JAL et al (2002) Medicinal plants in the healing of dry socket in rats: microbiological and microscopic analysis. Phytomedicine 9:109–116. https://doi.org/10.1078/0944-7113-00087

de Silveira SM, Júnior AC, Scheuermann GN et al (2012) Chemical composition and antimicrobial activity of essential oils from selected herbs cultivated in the South of Brazil against food spoilage and foodborne pathogen. Ciênc Rural St Maria 42:1300–1306. https://doi.org/10.1590/S0103-84782012000700026

Domínguez de María P (2014) Recent trends in (ligno) cellulose dissolution using neoteric solvents: switchable, distillable and bio-based ionic liquids. J Chem Technol Biotechnol 89:11–18

Dutt D, Sharma AK, Agnihotri S, Gautam A (2012) Characterization of dogs tooth grass and its delignification by soda pulping process. J Sci Technol 1:434–447

Ekpenyong CE, Akpan EE (2017) Use of Cymbopogon citratus essential oil in food preservation: recent advances and future perspectives. Crit Rev Food Sci Nutr 57:2541–2559

Ekpenyong CE, Akpan E, Nyoh A (2015) Ethnopharmacology, phytochemistry, and biological activities of Cymbopogon citratus (DC.) Stapf extracts. Chin J Nat Med 13:321–337. https://doi.org/10.1016/S1875-5364(15)30023-6

Elangovan V, Sekar N, Govindasamy S (1994) Chemopreventive potential of dietary bioflavonoids against 20-methylcholanthrene-induced tumorigenesis. Cancer Lett 87:107–113. https://doi.org/10.1016/0304-3835(94)90416-2

Evans WC (2009) Trease and Evans Pharmacognosy. 16th edn. Elsevier, New York

Faruq MO (1994) TLC technique in the component characterization and quality determination of Bangladeshi lemongrass oil (Cymbopogon citratus (DC) Stapf.). Bangladesh J Sci Ind Res 29:27–38

Filipoy A (1994) Medicinal plants of the pilaga of central Chaco. J Ethnopharmacol 44:181–193. https://doi.org/10.1016/0378-8741(94)01185-0

Firdaus MYN, Osman H, Metselaar HSC, Rozyanty AR (2015) A simple method for the production of pure crystalline silica from lemon grass. BioResources 11:1270–1279

Firdaus MYN, Osman H, Metselaar HSC, Rozyanty AR (2016) Preparation and characterization of active SiO2 from Cymbopogon citratus ash calcined at different temperature. BioResources 11:2839–2849. https://doi.org/10.15376/biores.11.1.2839-2849

Garg D, Muley A, Khare N, Marar T (2012) Comparative analysis of phytochemical profile and antioxidant activity of some Indian culinary herbs. Res J Pharm Biol Chem Sci 3:845–854

Gasser PJ, Lowry CA, Orchinik M (2006) Corticosterone-sensitive monoamine transport in the rat dorsomedial hypothalamus: potential role for organic cation transporter 3 in stress-induced modulation of monoaminergic neurotransmission. J Neurosci 26:8758–8766. https://doi.org/10.1523/JNEUROSCI.0570-06.2006

Gilling DH, Kitajima M, Torrey JR, Bright KR (2014) Mechanisms of antiviral action of plant antimicrobials against murine norovirus. Appl Environ Microbiol 80:4898–4910. https://doi.org/10.1128/AEM.00402-14

Gobinath R, Ganapathy GP, Akinwumi II (2015) Evaluating the use of lemon grass roots for the reinforcement of a landslideaffected soil from Nilgris district, Tamil Nadu, India. J Mater Environ Sci 6:2681–2687

Guynot ME, Ramos AJ, Seto L et al (2003) Antifungal activity of volatile compounds generated by essential oils against fungi commonly causing deterioration of bakery products. J Appl Microbiol 94:893–899. https://doi.org/10.1046/j.1365-2672.2003.01927.x

Hanaa ARM, Sallam YI, El-Leithy AS, Aly SE (2012) Lemongrass (Cymbopogon citratus) essential oil as affected by drying methods. Ann Agric Sci 57:113–116. https://doi.org/10.1016/j.aoas.2012.08.004

Hassan E (2016) Comparative study on the biosorption of Pb(II), Cd (II) and Zn (II) using Lemon grass (Cymbopogon citratus): kinetics, isotherms and thermodynamics. Chem Int 2:89–102

Hindumathy CK (2011) In vitro antibacterial activity of lemongrass. ISSRI 5:164–168

Inouye S, Yamaguchi H, Takizawa T (2001) Screening of the antibacterial effects of a variety of essential oils on respiratory tract pathogens, using a modified dilution assay method. J Infect Chemother 7:251–254. https://doi.org/10.1007/s101560170022

Jha AK, Kumar U (2017) Studies on removal of heavy metals by cymbopogon flexuosus. Int J Agric Environ Biotechnol 10:89. https://doi.org/10.5958/2230-732X.2017.00017.1

John D (1984) One hundred useful raw drugs of the Kani tribes of Trivandrum forest division, Kerala, India. Int J Crude Drug Res 22:17–39. https://doi.org/10.3109/13880208409070646

Joy PP, Skaria BP, Mathew S et al (2006) Lemongrass. Aromatic and medicinal plants research station, Odakkali

Kamoga OLM, Kirabira JB, Byaruhanga JK (2015) The potential of Cymbopogon nardus in the production of pulp for paper industry. In: International conference on computing, mechanical and electronics engineering, Singapore, pp 9–10

Karbach J, Ebenezer S, Warnke PH et al (2015) Antimicrobial effect of Australian antibacterial essential oils as alternative to common antiseptic solutions against clinically relevant oral pathogens. Clin Lab 61:61–68

Kaur H, Dutt D (2013) Anatomical, morphological and chemical characterization of lignocellulose by-products of lemon and sofia grasses obtained after recuperation of essential oils by steam distillation. Cellul Chem Technol 47:83–94

Kishore N, Mishra AK, Chansouria JPN (1993) Fungitoxicity of essential oils against dermatophytes. Mycoses 36:211–215. https://doi.org/10.1111/j.1439-0507.1993.tb00753.x

Koo B-S, Park K-S, Ha J-H et al (2003) Inhibitory effects of the fragrance inhalation of essential oil from Acorus gramineus on central nervous system. Biol Pharm Bull 26:978–982. https://doi.org/10.1248/bpb.26.978

Kumar J, Verma V, Goyal A et al (2009) Genetic diversity analysis in Cymbopogon species using DNA markers. Plant Omics 2:20

Kumari R, Agrawal SB, Sarkar A (2009) Evaluation of changes in oil cells and composition of essential oil in lemongrass (Cymbopogon citratus (DC) Stapf.) due to supplemental ultraviolet-B irradiation. Curr Sci 97:1137–1142

Lee LY, Lee XJ, Chia PC et al (2014) Utilisation of Cymbopogon citratus (lemon grass) as biosorbent for the sequestration of nickel ions from aqueous solution: equilibrium, kinetic, thermodynamics and mechanism studies. J Taiwan Inst Chem Eng 45:1764–1772. https://doi.org/10.1016/j.jtice.2014.02.002

Leite J, Maria De Lourdes VS, Maluf E et al (1986) Pharmacology of lemongrass (Cymbopogon citratus Stapf). III. Assessment of eventual toxic, hypnotic and anxiolytic effects on humans. J Ethnopharmacol 17:75–83. https://doi.org/10.1016/0378-8741(86)90074-7

Lertsatitthanakorn P, Taweechaisupapong S, Aromdee C, Khunkitti W (2006) In vitro bioactivities of essential oils used for acne control. Int J Aromather 16:43–49. https://doi.org/10.1016/j.ijat.2006.01.006

Li X, Ye J, Chen J et al (2015) Dissolution of wheat straw with aqueous NaOH/Urea solution. Fibers Polym 16:2368

Lima R, das Cardoso GM, Moraes J et al (2009) Composição dos óleos essenciais de Anis-estrelado Illicium verum L. e de Capim-limão Cymbopogon citratus (DC.) Stapf: Avaliação do efeito repelente sobre Brevicoryne brassicae (L.)(Hemiptera: Aphididae). BioAssay. https://doi.org/10.14295/BA.v3.0.56

Liu Y, Liu Y, Dai Y et al (2003) Enteric disposition and recycling of flavonoids and ginkgo flavonoids. J Altern Complement Med 9:631–640. https://doi.org/10.1089/107555303322524481

Locksley HD, Fayez MBE, Radwan AS et al (1982) Constituents of local plants. Planta Med 45:20–22

Lorenzetti BB, Souza GEP, Sarti SJ et al (1991) Myrcene mimics the peripheral analgesic activity of lemongrass tea. J Ethnopharmacol 34:43–48. https://doi.org/10.1016/0378-8741(91)90187-I

Madakadze IC, Radiotis T, Li J et al (1999) Kraft pulping characteristics and pulp properties of warm season grasses. Bioresour Technol 69:75–85. https://doi.org/10.1016/S0960-8524(98)00131-X

Madakadze IC, Masamvu TM, Radiotis T et al (2010) Evaluation of pulp and paper making characteristics of elephant grass (Pennisetum purpureum Schum) and switchgrass (Panicum virgatum L.). Afr J Environ Sci Technol 4:465–470

Madhu P, Livingston TS, Kanagasabapathy H (2017) Flash pyrolysis of lemon grass (Cymbopogon flexuosus) for bio-oil production in an electrically heated fluidized bed reactor. Waste Biomass Valorization. https://doi.org/10.1007/s12649-017-9872-6

Maia AJ, Oliveira JSB, Schwan-Estrada KRF et al (2014) The control of isariopsis leaf spot and downy mildew in grapevine cv. Isabel with the essential oil of lemon grass and the activity of defensive enzymes in response to the essential oil. Crop Prot 63:57–67. https://doi.org/10.1016/j.cropro.2014.05.005

Mansour HA, Newairy A-SA, Yousef MI, Sheweita SA (2002) Biochemical study on the effects of some Egyptian herbs in alloxan-induced diabetic rats. Toxicology 170:221–228. https://doi.org/10.1016/S0300-483X(01)00555-8

Melo GEM, López KF, Méndez GL (2015) Microencapsulación de aceite esencial de tomillo (Thymus vulgaris) en matrices poliméricas de almidón de ñame (Dioscorea rotundata) modificado. Rev Colomb Ciencias Químico Farm 44:189. https://doi.org/10.15446/rcciquifa.v44n2.56293

Miean KH, Mohamed S (2001) Flavonoid (myricetin, quercetin, kaempferol, luteolin, and apigenin) content of edible tropical plants. J Agric Food Chem 49:3106–3112. https://doi.org/10.1021/jf000892m

Mirghani MES, Liyana Y, Parveen J (2012) Bioactivity analysis of lemongrass (Cymbopogan citratus) essential oil. Int Food Res J 19:569–575

Mishra AK, Dubey NK (1994) Evaluation of some essential oils for their toxicity against fungi causing deterioration of stored food commodities. Appl Environ Microbiol 60:1101–1105

Moleyar V, Narasimham P (1992) Antibacterial activity of essential oil components. Int J Food Microbiol 16:337–342. https://doi.org/10.1016/0168-1605(92)90035-2

Moore-Neibel K, Gerber C, Patel J et al (2012) Antimicrobial activity of lemongrass oil against Salmonella enterica on organic leafy greens. J Appl Microbiol 112:485–492. https://doi.org/10.1111/j.1365-2672.2011.05222.x

Mosquera T (2016) Biological activity of Cymbopogon citratus (DC) Stapf and its potential cosmetic activities. Int J Phytocosmetics Nat Ingred. https://doi.org/10.15171/ijpni.2016.07

Mueller-Oerlinghausen B, Ngamwathana W, Kanchanapee P (1971) Investigation into Thai medicinal plants said to cure diabetes. J Med Assoc Thail Chotmaihet Thangphaet 54:105

Mumtaz MS, Khan NA, Rehman A, Jabbar A (2016) Production of oyster mushroom (Pleurotus pulmonarius) on different agriculture wastes combination with lemon grass (Cymbopogon citratus). Pak J Phytopathol 28:71–74

Murmu SB, Mishra HN (2018) The effect of edible coating based on Arabic gum, sodium caseinate and essential oil of cinnamon and lemon grass on guava. Food Chem 245:820–828. https://doi.org/10.1016/j.foodchem.2017.11.104

Naik MI, Fomda BA, Jaykumar E, Bhat JA (2010) Antibacterial activity of lemongrass (Cymbopogon citratus) oil against some selected pathogenic bacterias. Asian Pac J Trop Med 3:535–538. https://doi.org/10.1016/S1995-7645(10)60129-0

Negrelle RRB, Gomes EC (2007) Cymbopogon citratus (DC.) Stapf: chemical composition and biological activities. Rev Bras Pl Med 9:80–92

Oakenfull D, Sidhu GS (1990) Could saponins be a useful treatment for hypercholesterolaemia? Eur J Clin Nutr 44:79–88

Olaniyi AA, Sofowora EA, Oguntimehin BO (1975) Phytochemical investigation of some nigerian plants used against fevers. II. Cymbopogon citratus. Planta Med 28:186–189. https://doi.org/10.1055/s-0028-1097851

Oloyede OI (2009) Chemical profile and antimicrobial activity of Cymbopogon citratus leaves. J Nat Prod 2:98–103

Omoba OS, Onyekwere U (2016) Postharvest physicochemical properties of cucumber fruits (Cucumber sativus L) treated with chitosan-lemon grass extracts under different storage durations. Afr J Biotechnol 15:2758–2766

Onawunmi GO, Yisak W-A, Ogunlana EO (1984) Antibacterial constituents in the essential oil of Cymbopogon citratus (DC.) Stapf. J Ethnopharmacol 12:279–286. https://doi.org/10.1016/0378-8741(84)90057-6

Pahkala K, Paavilainen L, Mela T (1999) Grass species as raw material for pulp and paper [electronic publication]. In: Buchanan-Smith JG, Bailey LD, McCaughey P (eds) Proceedings of the XVIII international grassland congress, 8–17 June 1997, Winnipeg and Saskatoon, Canada [CD-ROM]. Volume III-invited papers and opening and closing sessions

Pandharipande SL, Katekhaye S (2017) Synthesis and characterization of biocomposite films using chitosan, CMC, starch and essential oils. Int J Innov Res Sci Eng Technol 6:12557–12566

Paranagama PA, Abeysekera KHT, Abeywickrama K, Nugaliyadde L (2003) Fungicidal and anti-aflatoxigenic effects of the essential oil of Cymbopogon citratus (DC.) Stapf. (lemongrass) against Aspergillus flavus Link. isolated from stored rice. Lett Appl Microbiol 37:86–90. https://doi.org/10.1046/j.1472-765X.2003.01351.x

Pattnaik S, Subramanyam VR, Bapaji M, Kole CR (1997) Antibacterial and antifungal activity of aromatic constituents of essential oils. Microbios 89:39–46

Pedroso RB, Ueda-Nakamura T, Filho BPD et al (2007) Biological activities of essential oil obtained from Cymbopogon citratus on Crithidia deanei. Acta Protozool 45:231

Pereira RP, Fachinetto R, de Souza PA et al (2009) Antioxidant effects of different extracts from Melissa officinalis, Matricaria recutita and Cymbopogon citratus. Neurochem Res 34:973–983. https://doi.org/10.1007/s11064-008-9861-z

Pierson Y, Bobbink F, Yan N (2013) Alcohol mediated liquefaction of lignocellulosic materials: a mini review. Chem Eng Process Tech 1:1014

Quisumbing E (1951) Medicinal plants of the Philippines. Department of Agriculture and Commerce, Philippine Islands Technical Bulletin

Rahman MZ, Ali MA, Hossain MS et al (2014) Effect of lemon grass (Cymbopogen citratus) extract on seed health of rice. Bangladesh Rice J 17:105–108. https://doi.org/10.3329/brj.v17i1-2.20904

Ranade SS, Thiagarajan P (2015) Lemon Grass. Int J Pharm Sci Rev Res 35:162–167

Rao RR, Jamir NS (1982) Ethnobotanical studies in Nagaland. I. Medicinal plants. Econ Bot 36:176–181

Ravinder K, Pawan K, Gaurav S et al (2010) Pharmacognostical investigation of Cymbopogon citratus (DC) Stapf. Der Pharm Lett 2:181–189

Raybaudi-Massilia RM, Mosqueda-Melgar J, Martin-Belloso O (2006) Antimicrobial activity of essential oils on Salmonella enteritidis, Escherichia coli, and Listeria innocua in fruit juices. J Food Prot 69:1579–1586. https://doi.org/10.4315/0362-028X-69.7.1579

Rehman A, Muqbool R, Alam MW, Mehboob S (2016) Exploration of ethanolic extracts of parthenium and lemon grass for management of citrus scab (Elsinoe fawcettii). Pak J Phytopathol 28:101–106

Revathi K, Kumar CK, Thamizhavahan K (2012) Combined antimicrobial activity of lemon grass oil and Tulasi oil. Int J Preclin Pharm Res 3:79–81

Robbins SRJ (1983) Selected markets for the essential oils of lemongrass, citronella and eucalyptus. Tropical Products Institute, London

Saleem M, Afza N, Anwar MA et al (2003a) Chemistry and biological significance of essential oils of Cymbopogon citratus from Pakistan. Nat Prod Res 17:159–163

Saleem M, Afza N, Anwar MA et al (2003b) A comparative study of essential oils of Cymbopogon citratus and some members of the genus Citrus. Nat Prod Res 17:369–373

Saraí B-PA, Martha S-R, Mirna R-R et al (2006) ¿ Es el estrés oxidativo la causa del envejecimiento? Bioquimia 31:113

Sarer E, Scheffer JJ, Baerheim SA (1983) Composition of the essential oil of Cymbopogon citratus (DC.) Stapf cultivated in Turkey. Sci Pharm 51:58–63

Seth G, Kokate CK, Varma KC (1976) Effect of essential oil of Cymbopogon citratus Stapf. on central nervous system. Indian J Exp Biol 14(3):370–371

Sforcin JM, Amaral JT, Fernandes A Jr et al (2009) Lemongrass effects on IL-1β and IL-6 production by macrophages. Nat Prod Res 23:1151–1159. https://doi.org/10.1080/14786410902800681

Shah G, Shri R, Panchal V et al (2011) Scientific basis for the therapeutic use of Cymbopogon citratus, stapf (Lemon grass). J Adv Pharm Technol Res 2:3. https://doi.org/10.4103/2231-4040.79796

Singh H (2014) Removal of methylene blue using lemon grass ash as an adsorbent. Carbon Lett 15:105–112. https://doi.org/10.5714/CL.2014.15.2.105

Singh K, Jha A (2008) Medicinal and aromatic plants cultivation in Bihar, India: economic potential and condition for adoption (April 8, 2008). SSRN Elect J. https://doi.org/10.2139/ssrn.2213308

Skaria BP, Joy PP, Mathew S, Mathew G (2006) Lemongrass. In: Peter KV (ed) Handbook of herbs and spices, 3rd edn. Woodhead Publishing Limited, Cambridge, pp 400–419

Smith RL, Cohen SM, Doull J et al (2005) GRAS flavoring substances 22. Food Technol 59:24–62

Sobh M, Moussawi M-A, Rammal W et al (2014) Removal of lead (II) ions from waste water by using Lebanese Cymbopogon citratus (Lemon Grass) Stem as adsorbent. Am J Phytomed Clin Ther 2:1070–1080

Souza FML, Lodder HM, Gianotti FO et al (1986) Pharmacology of lemongrass (Cymbopogon citratus Stapf). II. Effects of daily two month administration in male and female rats and in offspring exposed “in utero”. J Ethnopharmacol 17:65–74. https://doi.org/10.1016/0378-8741(86)90073-5

Souza MC, Siani AC, Ramos MFS et al (2003) Evaluation of anti-inflammatory activity of essential oils from two Asteraceae species. Die Pharm Int J Pharm Sci 58:582–586

Spring MA (1989) Ethnopharmacologic analysis of medicinal plants used by Laotian Hmong refugees in Minnesota. J Ethnopharmacol 26:65–91. https://doi.org/10.1016/0378-8741(89)90114-1

Srivastava K, Shringi N, Devra V, Rani A (2013) Pure silica extraction from perlite: its characterization and affecting factors. Int J Innov Res Sci Eng Technol 2:2936–2942

Suaeyun R, Kinouchi T, Arimochi H et al (1997) Inhibitory effects of lemon grass (Cymbopogon citratus Stapf) on formation of azoxymethane-induced DNA adducts and aberrant crypt foci in the rat colon. Carcinogenesis 18:949–955. https://doi.org/10.1093/carcin/18.5.949

Suhr KI, Nielsen PV (2003) Antifungal activity of essential oils evaluated by two different application techniques against rye bread spoilage fungi. J Appl Microbiol 94:665–674. https://doi.org/10.1046/j.1365-2672.2003.01896.x

Suresh M, Raj RK (1990) Cardol: the antifilarial principle from Anacardium occidentale. Curr Sci 59:477–479

Tadtong S, Watthanachaiyingcharoen R, Kamkaen N (2014) Antimicrobial constituents and synergism effect of the essential oils from Cymbopogon citratus and Alpinia galanga. Nat Prod Commun 9:277–280

Tangpu V, Yadav AK (2006) Antidiarrhoeal activity of Cymbopogon citratus and its main constituent, citral. Pharmacologyonline 2:290–298

Tayeboon GS, Tavakoli F, Hassani S et al (2013) Effects of Cymbopogon citratus and Ferula assa-foetida extracts on glutamate-induced neurotoxicity. Vitr Cell Dev Biol 49:706–715. https://doi.org/10.1007/s11626-013-9656-7

Tchoumbougnang F, Zollo PHA, Dagne E, Mekonnen Y (2005) In vivo antimalarial activity of essential oils from Cymbopogon citratus and Ocimum gratissimum on mice infected with Plasmodium berghei. Planta Med 71:20–23

Tiwari MR, Shah B, Jha AK, Sah MP (2017) Lemon grass oil feeding in relation to growth and carcass characteristics of broiler chicken. Nepal J Agric Sci 15:67

Tognolini M, Barocelli E, Ballabeni V et al (2006) Comparative screening of plant essential oils: phenylpropanoid moiety as basic core for antiplatelet activity. Life Sci 78:1419–1432. https://doi.org/10.1016/j.lfs.2005.07.020

Trindade LA, de Araújo OJ, de Castro RD, de Oliveira LE (2015) Inhibition of adherence of C. albicans to dental implants and cover screws by Cymbopogon nardus essential oil and citronellal. Clin Oral Investig 19:2223–2231. https://doi.org/10.1007/s00784-015-1450-3

Tyagi AK, Gottardi D, Malik A, Guerzoni ME (2014) Chemical composition, in vitro anti-yeast activity and fruit juice preservation potential of lemon grass oil. LWT-Food Sci Technol 57:731–737. https://doi.org/10.1016/j.lwt.2014.02.004

Tzortzakis NG, Economakis CD (2007) Antifungal activity of lemongrass (Cympopogon citratus L.) essential oil against key postharvest pathogens. Innov Food Sci Emerg Technol 8:253–258. https://doi.org/10.1016/j.ifset.2007.01.002

Viana GSB, Vale TG, Pinho RSN, Matos FJA (2000) Antinociceptive effect of the essential oil from Cymbopogon citratus in mice. J Ethnopharmacol 70:323–327. https://doi.org/10.1016/S0378-8741(99)00168-3

Vinitketkumnuen U, Lertprasertsuk N (1997) P XVII B. 29-P XVII B. 29 Inductive and suppressive effects of crude lemongrass on phase II xenobiotic-metabolizing enzymes. Mutat Res Mol Mech Mutagen 379:S179

Vinitketkumnuen U, Puatanachokchai R, Kongtawelert P et al (1994) Antimutagenicity of lemon grass (Cymbopogon citratus Stapf) to various known mutagens in salmonella mutation assay. Mutat Res Toxicol 341:71–75. https://doi.org/10.1016/0165-1218(94)90025-6

Wannissorn B, Jarikasem S, Soontorntanasart T (1996) Antifungal activity of lemon grass oil and lemon grass oil cream. Phyther Res 10:551–554. https://doi.org/10.1002/(SICI)1099-1573(199611)10:7%3c551:AID-PTR1908%3e3.0.CO;2-Q

Wannissorn B, Jarikasem S, Siriwangchai T, Thubthimthed S (2005) Antibacterial properties of essential oils from Thai medicinal plants. Fitoterapia 76:233–236. https://doi.org/10.1016/j.fitote.2004.12.009

Xaio P (1983) Recent developments on medicinal plants in China. J Ethnopharmacol 7:95–109. https://doi.org/10.1016/0378-8741(83)90083-1

Yang S (2008) Plant fiber chemistry. China Light Industry Press, Beijing

Yaskawa K, Takido M, Takeuchi M et al (1990) Inhibitory effects of flavonol glycoside on 12-O-Tetradecanoylphorbol-13-acetate-Induced tumor promotion. Chem Pharm Bull 38:774–776. https://doi.org/10.1248/cpb.38.774

Yongtian C, Mengyu C, Xiangyu C (2015) Preparation method of cymbopogon citratus handmade soap. China Patent No. CN104862130A (30 May 2015). https://patents.google.com/patent/CN104862130A/en

Yuhua Z, Xuanming L, Hongdong L et al (2014) Cymbopogon citratus fragrance-producing endophytic bacterium. China Patent No. CN104195063A (20 Jun 2014). https://patents.google.com/patent/CN104195063A/en

Zheng GQ, Kenney PM, Lam LKT (1993) Potential anticarcinogenic natural products isolated from lemongrass oil and galanga root oil. J Agric Food Chem 41:153–156. https://doi.org/10.1021/jf00026a001

Zuo X, Balasubramanian R, Fu D, Li H (2012) Biosorption of copper, zinc and cadmium using sodium hydroxide immersed Cymbopogon schoenanthus L. Spreng (lemon grass). Ecol Eng 49:186–189. https://doi.org/10.1016/j.ecoleng.2012.08.027

Acknowledgments

We acknowledge the Ph.D. scholarship support from Deakin University for the first author of this paper. Thanks to Dr. Jane Allardyce (Deakin University) for proofreading the draft.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Haque, A.N.M.A., Remadevi, R. & Naebe, M. Lemongrass (Cymbopogon): a review on its structure, properties, applications and recent developments. Cellulose 25, 5455–5477 (2018). https://doi.org/10.1007/s10570-018-1965-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-1965-2