Abstract

In this work, titanium dioxide (TiO2) nanoparticles were immobilized on the surface of cotton fabrics by in situ reduction on polydopamine (PDA) templates. Evidenced by the results of scanning electron microscopy/energy-dispersive X-ray analysis (SEM–EDX), Fourier transform infrared and X-ray photoelectron spectroscopy (XPS), PDA films were successfully formed on the surface of cotton fabrics as the templates for the in situ reduction. The morphology, chemical composition and crystal structure of the coated cotton fabrics after in situ reduction of TiO2 nanoparticles were characterized by SEM–EDX, XPS and X-ray diffraction, respectively. These results confirmed that anatase TiO2 nanoparticles were well-dispersed on the surface of cotton fabrics. The photocatalysis experiment results indicated that about 90% of methylene blue solution was degraded after UV illumination of the coated cotton fabrics. The thermogravimetric analysis results demonstrated that the TiO2 nanoparticles had little effect on the thermal stability of cotton fabrics. The results of UV protection showed that the value of the ultraviolet protection factor (UPF) of the coated cotton fabrics was 127.2. The UPF value was maintained at 108.8 after five cycles of laundering, indicating excellent durability of the coating in terms of UV protection.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cotton has been widely used in clothing for its high wettability, permeability and comfort. But its disadvantages, such as poor ultraviolet resistance and breeding bacteria, confine its application potential (Gao et al. 2017). Functionalization of cotton fabrics is thus necessary for developing protective clothing. Researcher have focused on this area, and especially TiO2 has been used to functionalize cotton fabrics with antimicrobial properties and UV protection together with antistatic, oil repellency and self-cleaning properties (Li et al. 2015; Karimi et al. 2014; Mishra and Butola 2017). Although there are several methods to immobilize TiO2, the durability of the TiO2 nanoparticles on cotton fabrics is still a big challenge.

Researchers have done extensive work to improve the durability of functional coatings on textiles by physical etching and chemical crosslinking. Sobczyk-Guzenda et al. (2013) implemented a radio frequency plasma enhanced chemical vapor deposition technique to deposit TiO2 nanoparticles on cotton fabrics for self-cleaning and wettability. Li et al. (2017a) adopted the low temperature atomic layer deposition (ALD) technology to deposit TiO2 nanoparticles on fabrics for infrared and thermal insulating properties. Bonet et al. (2015) employed acrylic resin and polycarboxylic acid as bonding agents to improve the durability of sprayed TiO2 nanoparticles on cotton fabrics. Khajavi and Berendjchi (2014) modified the surface of cotton fabrics to introduce dicarboxylic acid with different chain lengths, and then TiO2 nanoparticles were captured by the –COOH groups to generate excellent self-cleaning properties against washing. Yu et al. (2013) immobilized TiO2 nanoparticles covalently on cotton fabrics with by co-grafting polymerization of 2-hydroxyethyl acrylate under γ-ray irradiation, and the affinity between the nanoparticles and fibers were greatly improved to withstand 30 cycles of washing. Even though the affinity between nanoparticles and fibers can be improved by either physical etching or chemical crosslinking, the methods are rather complicated as special equipment is required and the treatment conditions are hard to control.

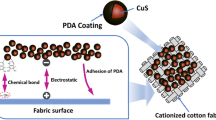

Dopamine can be polymerized on the surface of inorganic and organic materials to form a functional polydopamine (PDA) layer (Lee et al. 2007; Jiang et al. 2011). The method is simple and environmental friendly with moderated reaction conditions and a controllable reaction process. Strong affinity between deposited nanoparticles and fabrics can be achieved by applying polydopamine as a template, and this is due to the ‘bridging’ effect of PDA. Wang et al. (2012) formed a layer of silver nanoparticles on polydopamine coated polyester fibers, the resulted fibers showed excellent electrical conductivity. Xu et al. (2016) deposited silver nanoparticles on polydopamine coated PET fabrics, and the modified fabrics exhibited excellent anti-wetting and self-cleaning properties after fluorination. Sa et al. (2014) deposited silver nanoparticles on polydopamine coated aramid fibers for excellent electric conductivity with durability. Xu et al. (2013) achieved durable antimicrobial properties for cotton fabrics by the deposition of silver nanoparticles on polydopamine. Wang et al. (2015) deposited silver nanoparticles on polydopamine coated kapok fabrics, and highly-efficient antibacterial properties against staphylococcus aureus were developed. He et al. (2014) conducted dopamine polymerization to form an adhesive coating for improving the color fastness of fabrics. Liu et al. (2015) coated fabrics with polydopamine-encapsulated octadecylamine by in situ polymerization, so as to endow the fabrics with self-cleaning and self-healing abilities. According to the literature, there is no reports on the application of polydopamine as a template for deposition of TiO2 nanoparticles on cotton fabrics.

In this study, dopamine was self-polymerized to form surface-adherent polydopamine thin films on cotton fabrics, and a durable and well distributed layer of TiO2 nanoparticles was further deposited on the PDA-coated cotton fabrics by in situ reduction. The TiO2-coated cotton fabrics were characterized by SEM, XPS and XRD. Moreover, the photocatalytic activity, thermal stability together with UV protective properties of the TiO2-coated cotton fabrics were investigated.

Experimental

Materials

Cotton fabrics (plain, 135 g/m2, density: 570/10 cm for warp and 280/10 cm for weft) were purchased from Wuhan Yudahua Textile Co., Ltd, by the fabrics were cleaned by acetone and deionized water before use. 3-hydroxytyramine hydrochloride (dopamine hydrochloride) was purchased from Aldrich Chemical Co. (Milwaukee, USA). Tris(hydroxymethyl) aminomethane (Tris), ammonium fluotitanate ((NH4)2TiF6) and boric acid (H3BO3) were obtained from Aladdin Chemical Co. (Shanghai, China). All the chemicals were in analytic grade and were used without further purification.

Polymerization of dopamine on cotton fabrics

A dopamine solution with the concentration of 10 mM was dissolved in the Tris buffer solution. Then, the pH value of the solution was adjusted to 8.5 by adding HCl. Cotton fabrics were dipped into the freshly prepared dopamine solution at room temperature. After stirring for 24 h, the fabrics were washed thoroughly with deionized water followed by hanging to dry.

In situ reduction of TiO2 nanoparticles

In situ synthesis and loading of TiO2 nanoparticles on the PDA-coated cotton fabric are illustrated in Scheme 1. A PDA-coated cotton fabric was immersed into an aqueous solution containing 0.1 M (NH4)2TiF6 and 0.3 M H3BO3, and then the solution with the fabric were placed on an overhead shaker (at 40 °C) with a speed of 100 rpm for 8 h. After in situ reduction, the cotton fabrics were rinsed with deionized water and dried in a vacuum oven.

Characterizations

The surface morphology and elemental composition of cotton fabrics were observed on a scanning electron microscopy (SEM, JSM-5600LV, JEOL, Japan) with an energy dispersive X-ray spectrum (EDX, Oxford Instruments, Oxford, UK). Fourier transform infrared (FT-IR) spectra were obtained on a Nicolet 5700 instrument (Nicolet Co., US) accompanied with a wavenumber range of 4000–400 cm−1 and a resolution of 2 cm−1. The amount of TiO2 coated on cotton fabrics was measured by an inductively coupled plasma-mass spectrometry (ICP-MS, Agilent 7900, Agilent Technologies, Santa Clara, USA). XPS measurement was performed on a PHI 5000C ESCA system with a Mg Kα source at 14.0 kV and 25 mA (Perkin-Elmer, America). A transmission electron microscopy (2100F, JEOL Inc, Japan) was used to observe the TiO2 nanoparticles extracted from the coated cotton fabrics by ultrasound. The X-ray diffraction (XRD) spectra were collected on an X-ray diffractometer (D/max 2500, Rigaku, Japan) using Cu K α radiation with the diffraction angle range 2θ = 10°–80°, at 40 kV and 200 mA.

Photocatalytic activity

The photocatalytic activity of the TiO2-coated cotton fabrics was measured by degradation of MB in an aqueous solution under UV illumination by a 300 W Osram Ultra-Vitalus lamp (mixture of lights, wavelength range 365–450 nm). Photocatalysis experiments were carried out on a self-regulating UV irradiation instrument (Fig. 1). For irradiation experiments, a 100 mL of MB solution (10 mg/L) with samples immersed in were taken into the photoreactor. The degradation was monitored by sampling the solution (2 mL) at a regular interval during the irradiation. The concentration of dye in each sampling solution was measured by recording its absorbance on an UV–visible spectrophotometer (U-4100, Hitachi, Japan) at the wavelength of 664 nm.

Thermogravimetry analysis

Thermogravimetry analysis (TGA) was conducted on a Netzsch TG209 F1 thermal analyzer, with a heating rate of 10 °C/min from 30 to 700 °C under a nitrogen atmosphere at a flow rate of 60 mL/min. The instrument calibration included the balance correction and temperature correction, and the temperature was reproducible to ± 0.1 °C and the mass to ± 0.1%.

UV protective property

The UV protective property of the TiO2-coated cotton fabrics was measured using a UV-1000F ultraviolet transmission analyzer, according to the standard AS/NZS 4399:1996. The coated samples were washed in an automatic washing machine to analyze the durability of coating, in accordance with the AATCC Test Method 135-2000.

Results and discussion

Characterization of PDA-coated cotton fabrics

Dopamine was self-polymerized in an alkaline aqueous solution to coat the surface of cotton fabrics. The polymerization process was initiated by adjusting the pH value of the aqueous solution. The surface morphology of the PDA-coated cotton fabrics was obtained by SEM, as shown in Fig. 2. The photographic images of the cotton fabrics before and after treatment are depicted in Figs. 2a, b, respectively. The color of cotton fabrics turned from white to yellow/brown after the self-polymerization procedure, and this was due to the formation of melanin from the oxidization of the catechol groups of dopamine (Bernsmann et al. 2011). The SEM images of Fig. 2c, d exhibit the surface morphology of the pristine and PDA-coated cotton fabrics, respectively. The morphology of pristine cotton fabrics depicts a smooth surface with characteristic grooves. However, the grooves of cotton fibers were covered with the polydopamine film after the polymerization, resulting in a coated layer on the surface of fibers.

The PDA-coated cotton fabrics were characterized by EDX to determine the chemical elements, as shown in Fig. 3. Compared to the spectrum of the pristine cotton fabric, the spectrum of the PDA-coated cotton fabric exhibited the signal of nitrogen with a weight percentage of 6.0%. It was evident that the nitrogen was originated from dopamine, suggesting the successful polymerization of dopamine on the cotton fabrics.

The formation of dopamine on cotton fabrics has been further confirmed by FTIR spectroscopy and XPS spectrum, as shown in Fig. 4. Compared to the spectrum of the pristine cotton fabrics, the FTIR spectrum of the PDA-coated cotton fabrics contains a high intensity peak at 1614 cm−1, which is attributed to the stretch vibration of aromatic rings of dopamine (Ma et al. 2011a; Xu et al. 2016). The XPS survey spectra reveal the presence of C1s (at 286.2 eV) and O1s (at 532.7 eV) signals for the both the pristine and PDA-coated cotton fabrics. A new signal at 400 eV corresponding to N1s (7.53%) was noticed after the self-polymerization of dopamine on the cotton fabrics, and the newly detected signal was attributed to the amino groups of dopamine (Chen and Feng 2014). These results further demonstrate that the polydopamine film has been coated on the surface of cotton fabrics.

Characterization of TiO2-coated cotton fabrics

After the in situ reduction of TiO2 nanoparticles on the template of polydopamine, an evenly distributed film of nanoparticles was formed on the surface of cotton fabrics. To show the deposition of TiO2 nanoparticles on the PDA-coated cotton fabrics, the TiO2-coated cotton fabrics were characterized by SEM, as shown in Fig. 5a, b. The TiO2-coated cotton fabric was completely covered by nanoparticles, leading to the formation of a dense film of TiO2 nanoparticles on the surface of the fabric. The nanoparticles have a round shape with almost the same size (about 500 nm) as seen from the SEM images. However, the size of the extracted TiO2 nanoparticles from the coated fabric lies form 100 nm to 250 nm in the TEM image (Fig. 6). One possible reason is that the nanoparticles have aggregated to some extent during the coating process (Li et al. 2017b).

The SEM images in Fig. 5c, d show the surface morphology of the TiO2-coated cotton fabrics after five washing cycles. It can be seen that the nanoparticles are well dispersed on the fiber surface, but some free nanoparticles have been washed out from the surface of the film. This has been further confirmed by the results of ICP-MS, in which the amount of TiO2 changed from 0.284 to 0.259 mg/g after five washing cycles. As a whole, the film of nanoparticles has been well preserved after laundering, indicating the excellent durability of the coating. Since the TiO2 nanoparticles were synthesized by the hydrolysis of (NH4)2TiF6 and H3BO3 (Ou et al. 2010; Liu et al. 2017), the hydroxyl groups of polydopamine can react with the metal ion to form metal oxide nanoparticles (Li et al. 2016; Ma et al. 2011b). Owing to the chelation between TiO2 nanoparticles and polydopamine (Zheng et al. 2012), the TiO2 nanoparticles have been well dispersed on the surface of cotton fabrics with excellent affinity.

The EDX spectra of the TiO2-coated cotton fabrics before and after washing are shown in Fig. 7, and before washing there are three detected peaks in the spectrum for carbon (C), oxygen (O) and titanium (Ti) elements with the weight percentages of 8.5, 72.6 and 18.9%, respectively. After five washing cycles, the weight percentage of detected titanium has decreased slightly to 17.2%. The laundering has resulted in a loss of about 9.0% for Ti element, which is consistent with the ICP-MS results. The excellent durability is because that most of the nanoparticles have been adsorbed onto the surface of fabrics by chelation with strong binding force, and only few of the weakly adsorbed nanoparticles have been washed away.

The chemical composition of the TiO2-coated cotton fabrics was determined by XPS, as shown in Fig. 8 the XPS wide scan and Ti2p core-level spectra. The XPS wide scan spectrum contains peaks of C1s at 285.1 eV, O1s at 532.1 eV and Ti2p at 458 eV, respectively. The presence of the strong signal of Ti2p peak confirms the presence of TiO2 nanoparticles. The XPS Ti2p spectrum shows the binding energy of Ti2p3/2 at 459.1 eV and Ti2p1/2 at 464.7 eV, and the doublet separation energy between these two peaks is 5.6 eV. These results represent the typical characteristics of Ti4+ from the anatase TiO2 (Huang et al. 2017).

The crystal structure of all the coated cotton fabrics was analyzed by XRD, as presented in Fig. 9. The characteristic peaks of the crystal structure of pristine cotton fabric (Fig. 9a) can be found at 2θ = 14.7°, 16.3°, 23.1° and 34.4°, corresponding to the crystallographic plane (1–10), (110), (200) and (004), respectively (Lu and Hsieh 2010). There is no extra diffraction peak for the spectrum of PDA-coated cotton (Fig. 9b), and this is mainly due to the amorphous structure of polydopamine (Zhang et al. 2012). An extra peak appears at 25.5° as a shoulder peak for the spectrum of the TiO2-coated cotton fabric (Fig. 9c), and this peak is ascribed to the TiO2 anatase structure (Sadr and Montazer 2014; Pakdel et al. 2014).

Photocatalytic activity

The presence of the anatase crystal structure implies the potential photocatalytic ability of the TiO2-coated cotton fabrics (Luttrell et al. 2014). The photocatalytic activity of the TiO2-coated cotton fabric was evaluated by the degradation of MB under UV irradiation. The wavelength 664 nm was chosen as it is the wavelength for the main UV–Vis absorption peak of MB, and this peak can be easily monitored during the degradation (Yang et al. 2010). The photodegradation of MB solution in presence of pristine cotton fabric after UV illumination for 14 h is shown in Fig. 10a. As expected, the absorbance of residual MB solution at 664 nm changes slightly after UV irradiation, indicating that the pristine cotton fabric exhibits no photocatalytic ability. Figure 10b shows the photodegradation of MB on the TiO2-coated cotton fabrics, with the inset shows the absorbance of residual MB solution as a function of UV illumination time. The absorbance of residual MB solution at 664 nm decreases evidently with the increase of the UV illumination time, and about 90% of MB solutions have been degraded after of UV illumination for 14 h. The reason for this excellent photocatalytic activity is attributed to the presence of TiO2 nanoparticles on the coated cotton fabrics.

UV–Vis absorption spectra of photodegradation of MB solution in presence of pristine cotton fabrics after UV illumination for 14 h (a) and on TiO2-coated cotton fabrics at different UV irradiation time (b) (inset: the absorbance of residual MB solution at 664 nm as a function of UV irradiation time)

Thermal stability

The thermal degradation properties of the coated cotton fabrics were measured by thermogravimetric analysis, as shown the TG and DTG curves in Fig. 11. The onset decomposition temperature for the pristine cotton fabric is 333.7 °C and the weight residue at 700 °C is 3.1%. The DTG curve also reveals that the temperature of the maximum degradation rate is 348.5 °C. After the coating of PDA and TiO2 nanoparticles, the onset decomposition temperature decreased to 332.8 and 307.6 °C, respectively. At the same time, the temperature of the maximum degradation rate decreased to 345.1 and 332.6 °C, respectively. The decrease of these temperature values is due to the deteriorated properties of the cotton fabric by the usage of H3BO3 as the reducing agent. The weight residue at 700 °C is 4.5 and 18.5% for PDA- and TiO2-coated cotton fabrics, respectively. Thus, the weight percentage of TiO2 deposited on cotton fabric (before washing) can be calculated as 14%. It can be seen that the polydopamine coating has little effect on the thermal stability of the fabric.

UV protection property

The UV protective property of the TiO2-coated cotton fabrics was evaluated by the ultraviolet protection factor (UPF), as shown in Fig. 12. The pristine cotton fabrics show a low UPF of 6.4 due to their poor inherent UV protection property. After the coating of TiO2 nanoparticles, the UPF value increases rapidly to 127.2, indicating that coating of TiO2 nanoparticles is very effective in UV protection for cotton fabrics.

The coating showed excellent durability against washing in terms of UV protection. After five washing cycles, the UPF value decreases to 108.8 with a drop of less than 20. The calculated amount of TiO2 nanoparticles on fabrics dropped from 0.284 to 0.259 mg/g after five washing cycles, resulting in the drop of UPF value. A UPF of 40 − 50 + yielded by clothing exhibits excellent protection against UV radiation (Gorjanc et al. 2014), so that excellent UV protective property has been maintained for the TiO2-coated cotton fabrics. The durability is attributed to the PDA template on the surface of cotton fabrics that serves as an adhesion layer. These results imply that the TiO2-coated cotton fabrics exhibit excellent and durable UV protection property.

Conclusions

An innovative method was developed to immobilize TiO2 nanoparticles on cotton fabrics by in situ reduction of TiO2 nanoparticles on a polydopamine template. The polydopamine film has been coated on the surface of cotton fabrics, as confirmed by SEM–EDX, FT-IR and XPS. TiO2 nanoparticles were successfully deposited on the PDA-coated cotton fabrics as evidenced by SEM–EDX, XPS and XRD. The TG and DTG results suggested that the thermal stability of the cotton fabrics has not been affected evidently after the deposition of TiO2 nanoparticles. The TiO2-coated cotton fabrics exhibited excellent photocatalytic activity. The UPF value of the TiO2-coated cotton fabric was 127.2, and it was maintained at 108.8 even after five washing cycles. These results implied that the TiO2-coated cotton fabrics exhibited excellent photocatalytic activity and durable UV protection capacity.

References

Bernsmann F, Ball V, Addiego F et al (2011) Dopamine-melanin film deposition depends on the used oxidant and buffer solution. Langmuir 27:2819–2825. https://doi.org/10.1021/la104981s

Bonet M, Bou-Belda E, Monllor P et al (2015) A comparison between acrilic resin and butanetetracarboxylic acid used to bind TiO2 nanoparticles to cotton fabrics. Cellulose 22:1347–1354. https://doi.org/10.1007/s10570-015-0545-y

Chen S, Feng J (2014) Epoxy laminated composites reinforced with polyethyleneimine functionalized carbon fiber fabric: mechanical and thermal properties. Compos Sci Technol 101:145–151. https://doi.org/10.1016/j.compscitech.2014.07.003

Gao D, Lyu L, Lyu B et al (2017) Multifunctional cotton fabric loaded with Ce doped ZnO nanorods. Mater Res Bull 89:102–107. https://doi.org/10.1016/j.materresbull.2017.01.030

Gorjanc M, Jazbec K, Šala M et al (2014) Creating cellulose fibres with excellent UV protective properties using moist CF4 plasma and ZnO nanoparticles. Cellulose 21:3007–3021. https://doi.org/10.1007/s10570-014-0284-5

He L, So VLL, Xin JH (2014) Dopamine polymerization-induced surface colouration of various materials. RSC Adv 4:20317–20322. https://doi.org/10.1039/c4ra00098f

Huang R, Liang R, Fan H et al (2017) Enhanced photocatalytic fuel denitrification over TiO2/α-Fe2O3 nanocomposites under visible light irradiation. Sci Rep 7:7858–7867. https://doi.org/10.1038/s41598-017-08439-3

Jiang H, Yang L, Li C et al (2011) High-rate electrochemical capacitors from highly graphitic carbon-tipped manganese oxide/mesoporous carbon/manganese oxide hybrid nanowires. Energ Environ Sci 4:1813–1819. https://doi.org/10.1039/c1ee01032h

Karimi L, Yazdanshenas ME, Khajavi R et al (2014) Using graphene/TiO2 nanocomposite as a new route for preparation of electroconductive, self-cleaning, antibacterial and antifungal cotton fabric without toxicity. Cellulose 21:3813–3827. https://doi.org/10.1007/s10570-014-0385-1

Khajavi R, Berendjchi A (2014) Effect of dicarboxylic acid chain length on the self-cleaning property of nano-TiO2-coated cotton fabrics. ACS Appl Mater Inter 6:18795–18799. https://doi.org/10.1021/am504489u

Lee H, Dellatore SM, Miller WM et al (2007) Mussel-inspired surface chemistry for multifunctional coatings. Science 318:426–430. https://doi.org/10.1126/science.1147241

Li S, Huang J, Ge M et al (2015) Robust flower-like TiO2@ cotton fabrics with special wettability for effective self-cleaning and versatile oil/water separation. Adv Mater Interfaces 2:1500220. https://doi.org/10.1002/admi.201500220

Li X, Lu H, Zhang Y et al (2016) Fabrication of magnetic alginate beads with uniform dispersion of CoFe2O4 by the polydopamine surface functionalization for organic pollutants removal. Appl Surf Sci 389:567–577. https://doi.org/10.1016/j.apsusc.2016.07.162

Li L, Xu W, Wu X et al (2017a) Fabrication and characterization of infrared-insulating cotton fabrics by ALD. Cellulose 24:3981–3990. https://doi.org/10.1007/s10570-017-1380-0

Li ZR, Meng J, Wang W, Wang ZY et al (2017b) The room temperature electron reduction for the preparation of silver nanoparticles on cotton with high antimicrobial activity. Carbohyd Polym 161:270–276. https://doi.org/10.1016/j.carbpol.2017.01.020

Liu Y, Liu Z, Liu Y et al (2015) One-step modification of fabrics with bioinspired polydopamine@octadecylamine nanocapsules for robust and healable self-cleaning performance. Small 11:426–431. https://doi.org/10.1002/smll.201402383

Liu Z, Hu J, Sun Q et al (2017) Mussel-inspired multifunctional coating for enhancing the UV-resistant property of polypropylene fibers. Macromol Res 25:431–438. https://doi.org/10.1007/s13233-017-5062-4

Lu P, Hsieh YL (2010) Preparation and properties of cellulose nanocrystals: rods, spheres, and network. Carbohyd Polym 82:329–336. https://doi.org/10.1016/j.carbpol.2010.04.073

Luttrell T, Halpegamage S, Tao J et al (2014) Why is anatase a better photocatalyst than rutile? Model studies on epitaxial TiO2 films. Sci Rep 4:4043. https://doi.org/10.1038/srep04043

Ma Y, Niu H, Zhang XL, Cai Y (2011a) Colorimetric detection of copper ions in tap water during the synthesis of silver/dopamine nanoparticles. Chem Commun 47:12643–12645. https://doi.org/10.1039/c1cc15048k

Ma Y, Niu H, Zhang X, Zhang XL, Cai Y (2011b) One-step synthesis of silver/dopamine nanoparticles and visual detection of melamine in raw milk. Analyst 136:4192–4196. https://doi.org/10.1039/c1an15327g

Mishra A, Butola BS (2017) Deposition of Ag doped TiO2 on cotton fabric for wash durable UV protective and antibacterial properties at very low silver concentration. Cellulose 24:3555–3571. https://doi.org/10.1007/s10570-017-1352-4

Ou J, Wang J, Zhang D et al (2010) Fabrication and biocompatibility investigation of TiO2 films on the polymer substrates obtained via a novel and versatile route. Colloid Surf B 76:123–127. https://doi.org/10.1016/j.colsurfb.2009.10.024

Pakdel E, Daoud WA, Sun L et al (2014) Visible and UV functionality of TiO2 ternary nanocomposites on cotton. Appl Surf Sci 321:447–456. https://doi.org/10.1016/j.apsusc.2014.10.018

Sa R, Yan Y, Wei Z et al (2014) Surface modification of aramid fibers by bio-inspired poly (dopamine) and epoxy functionalized silane grafting. ACS Appl Mater Inter 6:21730–21738. https://doi.org/10.1021/am507087p

Sadr FA, Montazer M (2014) In situ sonosynthesis of nano TiO2 on cotton fabric. Ultrason Sonochem 21:681–691. https://doi.org/10.1016/j.ultsonch.2013.09.018

Sobczyk-Guzenda A, Szymanowski H, Jakubowski W et al (2013) Morphology, photocleaning and water wetting properties of cotton fabrics, modified with titanium dioxide coatings synthesized with plasma enhanced chemical vapor deposition technique. Surf Coat Technol 217:51–57. https://doi.org/10.1016/j.surfcoat.2012.11.071

Wang W, Cheng W, Tian M, Zou H, Li L, Zhang LQ (2012) Preparation of PET/Ag hybrid fibers via a biomimetic surface functionalization method. Electrochim Acta 79:37–45. https://doi.org/10.1016/j.electacta.2012.06.063

Wang R, Shin CH, Park S, Cui LZ et al (2015) Enhanced antibacterial activity of silver-coated kapok fibers through dopamine functionalization. Water Air Soil Poll 226:1–9. https://doi.org/10.1007/s11270-014-2241-1

Xu H, Shi X, Lv Y et al (2013) The preparation and antibacterial activity of polyester fabric loaded with silver nanoparticles. Text Res J 83:321–326. https://doi.org/10.1177/0040517512454187

Xu ZL, Miyazaki K, Hori T (2016) Fabrication of polydopamine-coated superhydrophobic fabrics for oil/water separation and self-cleaning. Appl Surf Sci 370:243–251. https://doi.org/10.1016/j.apsusc.2016.02.135

Yang G, Jiang Z, Shi H et al (2010) Preparation of highly visible-light active N-doped TiO2 photocatalyst. J Mater Chem 20:5301–5309. https://doi.org/10.1039/c0jm00376j

Yu M, Wang Z, Liu H et al (2013) Laundering durability of photocatalyzed self-cleaning cotton fabric with TiO2 nanoparticles covalently immobilized. ACS Appl Mater Inter 5:3697–3703. https://doi.org/10.1021/am400304s

Zhang M, Zhang X, He X et al (2012) A self-assembled polydopamine film on the surface of magnetic nanoparticles for specific capture of protein. Nanoscale 4:3141–3147. https://doi.org/10.1039/c2nr30316g

Zheng L, Qiang L, Xiong L et al (2012) Controlled preparation of titania nanofilm by a template of polydopamine film and its reversible wettability. Thin Solid Films 520:2776–2780. https://doi.org/10.1016/j.tsf.2011.12.017

Acknowledgments

This research was supported by the National Natural Science Foundation of China (51503164), the Scientific Research Fund of Hubei Provincial Department of Education (Q20171611), the Wuhan Textiles University Research Fund (142078003, ZDSYS201712) and the Collaborative Innovation Plan of Hubei Province for Key Technology of Eco-Ramie Industry (E JIAO KE HAN 2014 No. 8).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Cheng, D., He, M., Ran, J. et al. In situ reduction of TiO2 nanoparticles on cotton fabrics through polydopamine templates for photocatalysis and UV protection. Cellulose 25, 1413–1424 (2018). https://doi.org/10.1007/s10570-017-1606-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1606-1