Abstract

A series of Cellulose/poly-ethylene imine (PEI) composites were prepared by grafting hyperbranched PEI onto cellulose chains in alkali/urea aqueous solvent system through “one step” method. The SEM results showed that the Cellulose/PEI composite maintained porous structure. The Cellulose/PEI composites were tested as Cu(II) adsorbents through thermodynamics and kinetics study. The adsorption process followed pseudo-second-order kinetics equation. The adsorption isotherms could be described by both Langmuir and Freundlich isotherm models. The maximum adsorption amount was calculated to be 285.7 mg/g. The composites showed good stability so that they could be used in a wide range of pH and temperature. Besides, the Cu(II) loaded Cellulose/PEI composite could also be easily regenerated by dilute sulfuric acid and still keep a major adsorption capacity. Finally, the adsorption capacities of Celluloes/PEI composite towards other metal ions, such as Zn(II), Ni(II), Cr(III) and Pb(II), were also demonstrated. It will be a new high-performance and environmental friendly material for sewage disposal and metal pollution treatment with promising developmental potential.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, environmental pollution control has aroused great concern and become a research focus. Water pollution, especially heavy metal ions pollution, is a grave menace to public health, such as gastrointestinal, liver, kidney damage and intravascular hemolysis. How to remove the heavy metal ions from the sewage is an issue worth of studying.

Many methods were used to separate the heavy metals from waste water such as chemical separation, membrane separation, electrochemical separation, cation exchange and adsorption (Bao et al. 2015; Liu et al. 2015; Peng et al. 2014). Among such diverse sewage treatments, adsorption is the most high-efficient and economical method with relatively high adsorption capacity, selectivity, wide applicability and reusability (Demirbas et al. 2009; Feng et al. 2009;Sehaqui et al. 2014).

Natural materials such as activated carbon (Srivastava et al. 2006), chitosan (Katsutoshi et al. 1999; Dai et al. 2010; Yan et al. 2012), lignin (Adhikari et al. 2013) and cellulose (Annadurai et al. 2002; Mohammed et al. 2015; Wu et al. 2015) were used as the adsorptive materials for waste water treatment. Among these varied natural materials, cellulose (Cai et al. 2008; Chang et al. 2010) has received increasing attentions for its properties of abundance and regeneration. Cellulose materials, like hydrogel, film, microcrystal and so on, is rich in “−OH” groups which can offer some adsorption capacity. In fact, due to the low activity of “−OH” groups, the adsorption capacities of pure cellulose materials are limited. Thus some effective groups such as carbonyl group (Qiao et al. 2015; Liu et al. 2014), sulfo group (Dwivedi et al. 2014), phosphate group (Oshima et al. 2011), amino group (Xiong et al. 2010; Zhao and Mitomo 2008) were introduced in order to improve the absorption ability. PEI is a kind of water-soluble polymer and rich in amino groups (Sun et al. 2013) which can chelate Cu(II) ions very effectively. In recent years, many researchers paid attention to Cellulose-PEI composites for the removal of pollutants from water. Setyono and Valiyaveettil 2015 and Wang et al. (2014) used PEI to functionalize paper/membrane which showed excellent adsorption capacities towards heavy metal ions. Melone et al. 2015a, b did several meaningful works on cross-link of bPEI and cotton cellulose for the application of fluoride sensing and water remediation. Besides, He et al. 2014 and Tang et al. 2012 also prepared PEI-modified cellulose composite for water treatment. However, partial synthesis of these methods was still relatively complicated and the maximum adsorption capacity was still need to be improved.

In this work, we used “one-step” method to synthesize composite hydrogels in alkali/urea solution system with PEI as functional group and cellulose as skeleton. The process was simple and the reaction condition was mild. The structures and morphologies of cellulose and Cellulose/PEI composites were characterized by Solid-State NMR and Scanning electron microscopy (SEM). Through adsorption kinetic and adsorption thermodynamics, their adsorption abilities were systematically investigated. The influence factors such as temperature, pH and reusability were also investigated in this work. Furthermore, the adsorption of other heavy metal ions such as Ni(II), Zn(II), Cr(III) and Pb(II) was also investigated.

Experimental

Materials

Cellulose (Mw = 8 × 104) was supplied by Hubei Chemical Fiber Co. Ltd. Poly (ethylene imine) (PEI) (Mw = 1.0 × 104, 99 %) was purchased from Sigma Aldrich. Analytically pure Epichlorohydrin (ECH), LiOH, urea, CuSO4, Cr(NO3)3·9H2O, ZnSO4·7H2O, NiCl2·6H2O, Pb(NO3)2 and other reagents used in this work were purchased from Sinopharm Chemical Reagent Co. Ltd. and used as received in our experiments without further purification.

Preparation of Cellulose/PEI composites

A certain amount of PEI was dissolved in LiOH/urea aqueous solution (4.6/15 wt%). Then, the mixed solution was pre-cooled to −13.5 °C. Calculated amount of cellulose was then dissolved in the pre-cooled mixture solution with vigorous stirring. A certain amount of ECH as crosslinking agent was added dropwise into the Cellulose/PEI mixture solution (10 mL) and stirred at 25°C for 30 min and then placed in an oven at 60 °C for 4 h to obtain Cellulose/PEI composite hydrogels. Finally the composite hydrogels were washed with distilled water for several times with 100 mL water per time to remove the residual LiOH, urea and probably unreacted PEI until the eluate was neutral. The high concentration of LiOH/urea solution could be collected and reused. Pure cellulose hydrogel was prepared by the same method as contrast. The contents of cellulose and PEI are shown in Table 1. By changing the content of PEI from 5 to 20 wt% and cellulose from 2 to 4 wt%, four samples of Cellulose/PEI composite hydrogels were prepared and coded as CP-1, CP-2, CP-3 and CP-4 respectively.

The Cellulose/PEI composite hydrogels for 13C CP/MAS NMR, SEM and adsorption experiments were all freeze-dried samples. The proposed preparation process of the Cellulose/PEI composite hydrogel is shown in Scheme 1.

Characterization

Solid-state 13C Cross-Polarization/MAS NMR spectra were performed on Bruker 600 M Spectrometer (13C frequency = 100.18 MHz) at 25 °C. The spinning rate was 8 kHz and the Cross Polarization time was 1.0 ms. The contents of Cu(II) ions in the aqueous solutions were analyzed by UV–Vis spectrophotometry (CARY-100, Agilent), Bis(cyclohexanone) Oxalyldihydrazone (BCO) was used as complexation agent in buffer solution (pH = 9). The concentrations of Cu(II) ions were determined at 595 nm (Messori et al. 2007; Peterson and Bollier 1955; Zatta et al. 2005). The pH values of solution were controlled by METTLER TOLEDO SevenEasy pH meter. Scanning electron microscopy (FESEM, Hitachi S-4800) was used to characterize the surface morphologies and structures of the samples with an acceleration voltage of 5.0 kV.

The amount of amino groups on the Cellulose/PEI composites were determined by titration method with hydrochloric acid according to the following process: 0.05 g of dry Cellulose/PEI composites (CP-1 to CP-4) were mixed with 10 mL of 0.1 mol L−1 HCl solutions respectively. Then the mixtures were shaken for 80 h at room temperature. 2.5 mL of supernatant was diluted to 25 mL by redistilled water and 2 drops of phenolphthalein were added into the solution as the indicator. The mixture was titrated with 0.01 mol L−1 NaOH solution until the color changed from colorless to pink. The content of amino groups (α) was calculated by Eq. (1)

where C 1 and C 2 (mol L−1) are the concentrations of HCl and NaOH solutions, respectively, V 1 and V 2 (L) are the volume of HCl and NaOH solutions, respectively, and m (g) is the mass of Cellulose/PEI composite (He et al. 2014).

Adsorption of Cu(II) on Cellulose/PEI composites

To evaluate the adsorption ability, 10 mg freeze-dried Cellulose/PEI composites were placed into 10 mL Cu(II) solutions with concentration ranging from 100 to 1600 mg/L. The mixtures were shaken for 80 h at room temperature. The Cu(II) ions concentration of the supernatant solutions was measured by UV spectrophotometer. The adsorption capacity (Qe) was defined as the following Eq. (2):

where Q e is the adsorption capacity of Cu(II) (mg/g), C 0 and C e are the initial and equilibrium concentrations of Cu(II) (mg/L), V is the volume of solution (L), and m is the dry weight of the freeze-dried Cellulose/PEI composites (g).

The continuous adsorption experiments were conducted as the follows. 10 mg freeze-dried Cellulose/PEI composites were placed into 10 mL Cu(II) solutions (500 mg/L) at room temperature. The supernatant solutions would be taken out at predetermined time intervals ranging from 10 min to 78 h. The amount of adsorption (Q t ) was calculated from the Eq. (3):

where Q t is the adsorption amount of Cu(II) (mg/g) at different time, C t is the initial and equilibrium concentrations of Cu(II) (mg/L) at different time.

The effect of pH on the adsorption capacity of Cellulose/PEI composite (CP-2) towards Cu(II) was performed with an initial concentration (500 mg/L) of Cu(II) in a pH range of 1.0–6.0 at room temperature. The pH of solutions was adjusted to defined values with 0.1 mol L−1 H2SO4 or NaOH solution.

The influence of temperature on the adsorption capacity was performed with an initial concentration (500 mg/L) of Cu(II) ions at temperature ranging from 278 to 323 K.

Recycling experiments were performed to study the reusability of Cellulose/PEI composite. The Cellulose/PEI composite (CP-2) loaded Cu(II) was eluted in a 10 mL sulfuric acid with pH = 2 for 24 h at room temperature, and then washed by distilled water to remove residual acid. The Cu(II) concentration in the sulfuric acid was measured by UV spectrophotometer. Then, the regenerated Cellulose/PEI composite was put into the Cu(II) solution and used in second adsorption. The adsorption and desorption processes were repeated for five times.

Adsorption of Zn(II), Ni(II), Cr(III), Pb(II) on Cellulose/PEI composite

10 mg freeze-dried Cellulose/PEI composites (CP-2) were respectively placed into 10 mL Zn(II), Ni(II), Cr(III), Pb(II) solutions with concentration of 1000 mg/L. The mixtures were shaken for 80 h at room temperature. The pH of the mixture was set to 6 for Ni(II) and Zn(II) and to 5 for Cr(III) and Pb(II) for heavy metal ions adsorption at those pH has been widely reported (O’Connell et al. 2008; Wang et al. 2015). The initial and final concentrations of these heavy metal ions were determined by ICP-AES (IRIS Intrepid II) since UV measurement is not adapted for these heavy metal ions (Setyono and Valiyaveettil 2015). The adsorption capacities (Q e ) of Zn(II), Ni(II), Cr(III), Pb(II) were also defined as Eq. (2).

Results and discussion

Structure of Cellulose/PEI composites

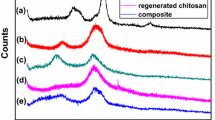

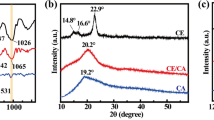

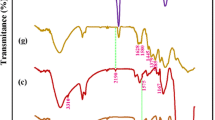

Figure 1 shows the 13C CP/MAS NMR spectra of freeze-dried Cellulose/PEI composite hydrogels samples (CP-1 to CP-4), Cellulose hydrogel and PEI. The signals of cellulose and PEI constituents can be distinguished clearly in these 13C CP/MAS NMR spectra. The signals at 107.4, 89.2, 75.2, 63.1 ppm can be assigned to the chemical shifts of cellulose (C1, C4, C2/3/5, C6) and the broad signal between 32 and 80 ppm can be attributed to PEI. All the Cellulose/PEI composite hydrogels have been washed several times by distilled water to remove alkali/urea and probably unreacted PEI. Thus the combination between cellulose and PEI could be proved by the spectra showed in Fig. 1. With the increase of the content of PEI, the integral area of the PEI peaks increased,which indicated that there were more PEI molecules grafted onto the cellulose chains. Through titration experiments, the content of amino groups were obtained as 5.10 % (CP-1), 6.22 % (CP-2), 7.14 % (CP-3) and 9.87 % (CP-4), respectively. With the increase of the content of PEI in the preparation process, the content of amino groups increased which means more adsorption sites. The results are consistent with the 13C CP/MAS NMR results.

It is well-known that higher surface-to-volume ratio leads to higher adsorption capacity in most cases. Figure 2a shows the porous structure of freeze-dried cellulose hydrogel with pore size ranging from 30 to 150 nm. After addition of PEI, the pore size of Cellulose/PEI composite decreased to 10-50 nm as shown in Fig. 2b, it is probably because that PEI molecules grafted onto the cellulose chains and partially “filled” the space among cellulose chains. The porous structure of composites could make Cu(II) ions easily diffuse into the inside of the Cellulose/PEI composites. And the large amount of amino groups of PEI could provide rich coordinate sites to effectively “capture” Cu(II) ions.

The Cellulose/PEI composite hydrogel displays better deformation resisting property and stability compared with cellulose hydrogel as shown in Fig. 3. The hyperbranched PEI molecules play the role of the reinforcement between cellulose chains to enhance the mechanical property of composite hydrogel. Because of good mechanical property, the Cellulose/PEI composite hydrogels will be very convenient to be regained from the waste-water and transported in the industrial production.

Adsorption property of Cellulose/PEI composites towards Cu(II)

Adsorption kinetics

To investigate the adsorption kinetics of Cellulose/PEI composites, the effects of adsorption time on Cellulose/PEI composites (CP-1 to CP-4) towards Cu(II) ions are depicted in Fig. 4. For all samples, the adsorption capacities of Cu(II) ions increased rapidly and reached nearly 85 % in the first period, it took 10–20 h depending on samples, then the growth trend slowed down and the adsorption capacities reached saturation after several hours later. The obviously strong adsorption ability of Cellulose/PEI composites could be attributed to the porous structure and the strong metal chelating ability of amino group (Dai et al. 2010; Setyono and Valiyaveettil 2015). When the Cellulose/PEI composites were placed into the Cu(II) solution, Cu(II) ions could easily diffuse into the composites and be chelated by amino groups of PEI. Thus the Q t increased linearly with time in the initial stage.

With the adsorption process continuing, more and more adsorption sites were occupied and steric hindrance increased. Hence the adsorption rates slowed down and reached equilibrium at last. The increased content of PEI brought more adsorption sites and a probably denser structure. Therefore, more Cu(II) ions could be adsorbed and more time was needed to reach the equilibrium. That is the reason why equilibrium time (t e ) of these composites increased with PEI content increasing. Through the same method, the adsorption capacity of pure cellulose hydrogel was measured to be 25.6 mg/g, which was much lower than that of Cellulose/PEI composites (111.7 mg/g to 184.0 mg/g).

In order to study the adsorption kinetics of Cu(II) on Cellulose/PEI composites, the adsorption data were fitted with pseudo-first-order model (Eq. 4) and pseudo-second-order model (Eq. 5) as follow (Ho and McKay 1999; Repo et al. 2010).

where Q e and Q t are the adsorption capacity (mg/g) of Cu(II) ions of Cellulose/PEI composites at equilibrium and at a given time t respectively, k 1 and k 2 are pseudo-first-order and pseudo-second-order rate constant, respectively.

The parameters of the two models are summarized in Table 2. Though both correlation coefficients R2 of the two models were greater than 0.9, while the pseudo-second-order kinetic equation provided better correlation of the adsorption process. This indicated that the adsorption process may be mainly controlled by chemisorption.

Adsorption Isotherms

Static adsorption experiments were performed in different Cu(II) initial concentration ranging from 100 to 1600 mg/L. The adsorption abilities were evaluated with Langmuir and Freundlich adsorption isotherm models (Zhou et al. 2009; Qiu et al. 2014).

The equation of the Langmuir model is described as Eq. (6):

where Q e is the amount adsorbed by Cellulose/PEI composites (mg/g) and C e is the equilibrium concentration in solution (mg/L), b (L/mg) is the Langmuir constant related to the energy of adsorption and Q m (mg/g) is the maximum adsorption capacity of the adsorbent.

The equation of the Freundlich model is described as Eq. (7):

where K F is related to the adsorption capacity, 1/n is heterogeneity factor.

The static adsorption curves are presented in Fig. 5. The parameters of the two adsorption isotherm models are listed in Table 3. With the increasing of Cu(II) initial concentration, the amount of adsorption increased. The prediction maximum adsorption capacities calculated with model were well matched with measured values.

The correlation coefficient R 2 of Langmuir isotherm model is greater than 0.98 (CP-1 to CP-4), which suggested the adsorption of Cu(II) ions on these Cellulose/PEI composites was a monolayer adsorption process on a surface with a finite number of identical sites. The Freundlich model constant (1/n) is in relation to the adsorption intensity of the material. When 1/n < 1, it suggests a favorable adsorption condition and a heterogeneous surface with an exponential distribution of energy of the adsorbent sites. In the present work, the 1/n was all around 0.3, which predicted that the Cu(II) ions could be easily adsorbed on the Cellulose/PEI composites. R 2 of both Langmuir and Freundlich models indicated significantly correlation, representing a combination of physical and chemical adsorption.

Figure 6a shows the maximum adsorption capacity of Cellulose/PEI composites with different mass ratio between PEI and cellulose (5:4 to 20:2). The CP-4 had the highest maximum adsorption capacity (285.7 mg/g), CP-3 with 236.4 mg/g, CP-2 with 201.2 mg/g and CP-1 with 165.3 mg/g. With the increasing of PEI content in the composites, the maximum adsorption capacity increased. The increase of maximum adsorption capacity is due to the increased number of adsorption sites contributed by PEI molecules. The adsorption capacities of Cellulose/PEI composites are much higher than activated carbon-based adsorption materials [25.1 mg/g (Srivastava et al. 2006), 39.5 mg/g (Diwakar and Seung 2011)]. It is also higher than some other natural adsorption materials towards Cu(II) ions that had been reported before, such as Chitosan-based Composite adsorption materials (65.8 mg/g(Yan et al. 2012),145.5 mg/g(Dai et al. 2010)).

Effect of solution Temperature

Temperature is an important factor to the adsorption ability. In this work, the temperature ranged from 278 to 323 K. As shown in Fig. 6b, there was no obvious change of the adsorption capacity to Cu(II) ions in the temperature range of experiments. It indicated that the chelation between amino groups and Cu(II) maintained stable no matter the temperature was close to freezing point (278 K) or higher than most of the environment temperature (323 K). This characteristic is very important and useful in the application of water treatment in almost any environment temperature.

Effect of solution pH

The pH is another major factor to influence the adsorption property. Cellulose/PEI composite (CP-2) was chosen as the experimental subject. The solution pH values ranged from 1.0 to 6.0 in the experiments. As shown in Fig. 6c, with the pH rising from 1.0 to 5.0, the absorption amount increased. The adsorption capacity reached the maximum value (130.8 mg/g) at pH 5.0 and reduced a little to 119.2 mg/g when pH was 6.0. It was because that the amine groups could easily be protonated at lower pH, resulting in an electrostatic repulsive force to Cu(II) ions and reducing adsorption ability. When the pH was higher than 6.0, Cu(II) ions in the solution were easily translated into Cu(OH)2 precipitation and could not be adopted. From the result, the most suitable pH range was 3.0 to 6.0. It is noticeable that when the pH is lower than 3.0, little Cu(II) ions can be adsorbed onto the Cellulose/PEI composites. This property makes the Cellulose/PEI composite can be regenerated by dilute acid solutions below pH 3.0 and reusable.

Desorption and reusability

The reusability of Cellulose/PEI composite was examined through five adsorption–desorption cycles after regenerated by dilute acid solution. Figure 7 shows that the adsorption capacity of Cellulose/PEI composite remained more than 86 % after five adsorption–desorption cycles. This result manifested that Cellulose/PEI composites were stable, reusable and would be potential candidates for environmental applications.

Adsorption property of Cellulose/PEI composite (CP-2) towards Zn(II), Ni(II), Cr(III), Pb(II)

The adsorption ability towards other heavy metal ions, such as Zn(II), Ni(II), Cr(III), Pb(II) were also investigated. As shown in Fig. 8, the adsorption values towards Zn(II), Ni(II), Cr(III) and Pb(II) were 148.4, 112.2, 30.4 and 248.2 mg/g, respectively. It’s obvious that Cellulose/PEI composite is suitable for the removal of divalent heavy metal ions because the amino groups are more inclined to chelate with divalent metal ions. Compared with other low-cost sorbents, the adsorption capacities of Cellulose/PEI composite towards Zn(II), Ni(II) and Pb(II) are definitely higher (Babel and Kurniawan 2003; Ngah and Hanafiah 2008; Sehaqui et al. 2014). The excellent adsorption property indicates that Cellulose/PEI composites have a wide application potential for removal heavy metal ions from waste water.

Conclusions

In this study, a series of Cellulose/PEI composites with different Cellulose/PEI ratio were synthesized by “one step” method. The composites maintained porous structure and showed better mechanical property. All the Cellulose/PEI composites showed excellent adsorption abilities towards Cu(II) ions. With the increasing of the content of PEI in the composites, amino groups as absorption sites increased and both the maximum adsorption capacity and equilibrium time increased. The maximum adsorption capacity towards Cu(II) reached 285.7 mg/g when PEI content achieved to 20 %. The adsorption kinetics fitting results showed that the adsorption behavior of Cellulose/PEI composites followed the pseudo-second-order model. Both the Langmuir and Freundlich models correlated with the adsorption experimental data, namely a combination of physical adsorption and chemical adsorption. The adsorption ability maintained a high level in a wide temperature range (from 278 to 323 K). Strong acid condition benefits the regeneration of the adsorbents. Even after five adsorption/desorption cycles, the adsorption capacity of regenerated samples still maintained more than 86 %. Furthermore, Cellulose/PEI composite could also adsorb some other heavy metal ions such as Zn(II), Ni (II) and Pb(II) effectively. In brief, owning to high adsorption ability, environmentally friendly components and simple preparation process, Cellulose/PEI composites may be potential materials for waste water treatment and heavy metal ions recycle applications.

References

Adhikari BB, Gurung M, Alam S, Tolnai B, Lnoue K (2013) Kraft mill lignin-a potential source of bio-adsorbents for gold recovery from acidic chloride solution. Chem Eng J 231:190–197. doi:10.1016/j.cej.2013.07.016

Annadurai G, Juang RS, Lee DJ (2002) Use of cellulose-based wastes for adsorption of dyes from aqueous solutions. J Hazard Mater 92:263–274. doi:10.1016/S0304-3894(02)00017-1

Babel S, Kurniawan TA (2003) Low-cost adsorbents for heavy metals uptake from contaminated water: a review. J Hazard Mater 97:219–243. doi:10.1016/S0304-3894(02)00263-7

Bao Y, Yan X, Du W, Xie X, Pan Z, Zhou J, Li L (2015) Application of amine-functionalized mcm-41 modified ultrafiltration membrane to remove chromium (VI) and copper (II). Chem Eng J 281:460–467. doi:10.1016/j.cej.2015.06.094

Cai J, Zhang L, Liu S, Liu Y, Xu X, Chen X, Chu B, Guo X, Xu J, Cheng H, Han C, Kuga S (2008) Dynamic self-assembly induced rapid dissolution of cellulose at low temperatures. Macromolecules 41:9345–9351. doi:10.1021/ma801110g

Chang C, Zhang L, Zhou J, Zhang L, Kennedy JF (2010) Structure and properties of hydrogels prepared from cellulose in NaOH/urea aqueous solutions. Carbohyd Polym 82:122–127. doi:10.1016/j.carbpol.2010.04.033

Dai J, Yan H, Yang H, Cheng R (2010) Simple method for preparation of chitosan/poly(acrylic acid) blending hydrogel beads and adsorption of copper(ii) from aqueous solutions. Chem Eng J 165:240–249. doi:10.1016/j.cej.2010.09.024

Demirbas E, Dizge N, Sulak MT, Kobya M (2009) Adsorption kinetics and equilibrium of copper from aqueous solutions using hazelnut shell activated carbon. Chem Eng J 148:480–487. doi:10.1016/j.cej.2008.09.027

Diwakar T, Seung M (2011) Biomass-derived materials in the remediation of heavy-metal contaminated water: removal of cadmium(II) and copper(II) from aqueous solutions. Water Environ Res 83:874–881. doi:10.2175/106143011X12928814445258

Dwivedi AD, Dubey SP, Hokkanen S, Fallah RN, Sillanpää M (2014) Recovery of gold from aqueous solutions by taurine modified cellulose: an adsorptive-reduction pathway. Chem Eng J 255:97–106. doi:10.1016/j.cej.2014.06.017

Feng N, Guo X, Sha L (2009) Adsorption study of copper (II) by chemically modified orange peel. J Hazard Mater 164:1286–1292. doi:10.1016/j.jhazmat.2008.09.096

He Z, Song H, Cui Y, Zhu W, Du K, Yao S (2014) Porous spherical cellulose carrier modified with polyethyleneimine and its adsorption for Cr(III) and Fe(III) from aqueous solutions. Chin J Chem Eng 22:984–990. doi:10.1016/j.cjche.2014.07.001

Ho YS, McKay G (1999) Pseudo-second order model for sorption processes. Process Biochemistry 34:451–465. doi:10.1016/S0032-9592(98)00112-5

Katsutoshi I, Kazuharu Y, Keisuke O (1999) Adsorptive separation of some metal ions by complexing agent types of chemically modified chitosan. Anal Chim Acta 388:209–218. doi:10.1016/S0003-2670(99)00090-2

Liu R, Tang C, Zhao J, Liu H (2014) Electrospun membranes of nanoporous structure cellulose acetate and its adsorptive behaviors using copper(II) as models. Desalin Water Treat 56:1768–1775. doi:10.1080/19443994.2014.958108

Liu Y, Xu X, Wang M, Lu T, Sun Z, Pan L (2015) Metal-organic framework-derived porous carbon polyhedra for highly efficient capacitive deionization. Chem Commun (Camb) 51:12020–12023. doi:10.1039/c5cc03999a

Melone L, Bonafede S, Tushi D, Punta C, Cametti M (2015a) Dip in colorimetric fluoride sensing by a chemically engineered polymeric cellulose/bPEI conjugate in the solid state. Rsc Advances 5:83197–83205. doi:10.1039/c5ra16764g

Melone L, Rossi B, Pastori N, Panzeri W, Mele A, Punta C (2015b) Tempo-oxidized cellulose cross-linked with branched polyethyleneimine: nanostructured adsorbent sponges for water remediation. ChemPlusChem 80:1408–1415. doi:10.1002/cplu.201500145

Messori L, Casini A, Gabbiani C, Sorace L, Muniz-Miranda M, Zatta P (2007) Unravelling the chemical nature of copper cuprizone. Dalton T 21:2112–2114. doi:10.1039/b701896g

Mohammed N, Grishkewich N, Berry RM, Tam KC (2015) Cellulose nanocrystal-alginate hydrogel beads as novel adsorbents for organic dyes in aqueous solutions. Cellulose 22:3725–3738. doi:10.1007/s10570-015-0747-3

Ngah WSW, Hanafiah MAKM (2008) Removal of heavy metal ions from wastewater by chemically modified plant wastes as adsorbents: a review. Bioresour Technol 99:3935–3948. doi:10.1016/j.biortech.2007.06.011

O’Connell DW, Birkinshaw C, O Dwyer TF (2008) Heavy metal adsorbents prepared from the modification of cellulose: a review. BioresourTechnol 99:6709–6724. doi:10.1016/j.biortech.2008.01.036

Oshima T, Taguchi S, Ohe K, Baba Y (2011) Phosphorylated bacterial cellulose for adsorption of proteins. Carbohyd Polym 83:953–958. doi:10.1016/j.carbpol.2010.09.005

Peng S, Meng H, Ouyang Y, Chang J (2014) Nanoporous magnetic cellulose–chitosan composite microspheres: preparation, characterization, and application for Cu(II) adsorption. Ind Eng Chem Res 53:2106–2113. doi:10.1021/ie402855t

Peterson RE, Bollier ME (1955) Spectrophotometric determination of serum copper with biscyclohexanoneoxalyldihydrazone. Anal Chem 27:1195–1197

Qiao H, Zhou Y, Yu F, Wang E, Min Y, Huang Q, Pang L, Ma T (2015) Effective removal of cationic dyes using carboxylate-functionalized cellulose nanocrystals. Chemosphere 141:297–303. doi:10.1016/j.chemosphere.2015.07.078

Qiu B, Guo J, Zhang X, Sun D, Gu H, Wang Q, Wang H, Wang X, Zhang X, Weeks BL, Guo Z, Wei S (2014) Polyethylenimine facilitated ethyl cellulose for hexavalent chromium removal with a wide pH range. ACS Appl Mater Inter 6:19816–19824. doi:10.1021/am505170j

Repo E, Warchol JK, Kurniawan TA, Sillanpää MET (2010) Adsorption of Co(II) and Ni(II) by EDTA- and/or DPTA-modified chitosan: kinetic and equilibrium modeling. Chem Eng J 161:73–82. doi:10.1016/j.cej.2010.04.030

Sehaqui H, Larraya UPD, Liu P, Pfenninger N, Mathew AP, Zimmermann T, Tingaut P (2014) Enhancing adsorption of heavy metal ions onto biobased nanofibers from waste pulp residues for application in wastewater treatment. Cellulose 21:2831–2844. doi:10.1007/s10570-014-0310-7

Setyono D, Valiyaveettil S (2015) Functionalized paper-a readily accessible adsorbent for removal of dissolved heavy metal salts and nanoparticles from water. J Hazard Mater. doi:10.1016/j.jhazmat.2015.09.046

Srivastava VC, Swamy MM, Mall ID, Prasad B, Mishra IM (2006) Adsorptive removal of phenol by bagasse fly ash and activated carbon: equilibrium, kinetics and thermodynamics. Colloids Surf A 272:89–104. doi:10.1016/j.colsurfa.2005.07.016

Sun X, Yang L, Xing H, Zhao J, Li X, Huang Y, Liu H (2013) Synthesis of polyethylenimine-functionalized poly(glycidyl methacrylate) magnetic microspheres and their excellent Cr(VI) ion removal properties. Chem Eng J 234:338–345. doi:10.1016/j.cej.2013.08.082

Tang Y, Ma Q, Luo Y, Zhai L, Che Y, Meng F (2012) Improved synthesis of a branched poly(ethylene imine)-modified cellulose-based adsorbent for removal and recovery of Cu(II) from aqueous solution. J Appl Polym Sci 4:1799–1805. doi:10.1002/APP.38878

Wang Q, Zhang D, Tian S, Ning P (2014) Simultaneous adsorptive removal of methylene blue and copper ions from aqueous solution by ferrocene-modified cation exchange resin. J Appl Polym Sci 21:41021–41029. doi:10.1002/APP.41029

Wang J, Lu X, Ng PF, Lee KI, Fei B, Xin JH, Wu J (2015) Polyethylenimine coated bacterial cellulose nanofiber membrane and application as adsorbent and catalyst. J Colloid Interface Sci 440:32–38. doi:10.1016/j.jcis.2014.10.035

Wu R, Tian L, Wang W (2015) Synthesis of a nanocomposite of organo-montmorillonite/cellulose-g-poly(methyl methacrylate) by atom-transfer radical polymerization and its application in removal of 2,4-dichlorophenol. Cellulose 22:3633–3643. doi:10.1007/s10570-015-0751-7

Xiong X, Duan J, Zou W, He X, Zheng W (2010) A pH-sensitive regenerated cellulose membrane. J Membr Sci 363:96–102. doi:10.1016/j.memsci.2010.07.031

Yan H, Yang L, Yang Z, Yang H, Li A, Cheng R (2012) Preparation of chitosan/poly(acrylic acid) magnetic composite microspheres and applications in the removal of copper(II) ions from aqueous solutions. J Hazard Mater 229–230:371–380. doi:10.1016/j.jhazmat.2012.06.014

Zatta P, Raso M, Zambenedetti P, Wittkowski W, Messori L, Piccioli F, Mauri PL, Beltramini M (2005) Copper and zinc dismetabolism in the mouse brain upon chronic cuprizone treatment. Cellular & Molecular Life Sciences Cmls 62:1502–1513. doi:10.1007/s00018-005-5073-8

Zhao L, Mitomo H (2008) Adsorption of heavy metal ions from aqueous solution onto chitosan entrapped CM-cellulose hydrogels synthesized by irradiation. J Appl Polym Sci 110:1388–1395. doi:10.1002/app.28718

Zhou L, Wang Y, Liu Z, Huang Q (2009) Characteristics of equilibrium, kinetics studies for adsorption of Hg(II), Cu(II), and Ni(II) ions by thiourea-modified magnetic chitosan microspheres. J Hazard Mater 161:995–1002. doi:10.1016/j.jhazmat.2008.04.078

Acknowledgments

This work is sponsored by the National Natural Science Foundation of China (51273067, 21544003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ge, H., Huang, H., Xu, M. et al. Cellulose/poly(ethylene imine) composites as efficient and reusable adsorbents for heavy metal ions. Cellulose 23, 2527–2537 (2016). https://doi.org/10.1007/s10570-016-0973-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-0973-3