Abstract

A cellulose filter for water disinfection was developed using a polycarboxylic acid and an aromatic amine via a simple process with water as a solvent. 1,2,3,4-Butanetetracarboxylic acid/m-phenylenediamine solution was applied to cellulose filters using a pad–dry–curing process. The surfaces of treated cellulose filters were examined by Fourier-transform infrared spectroscopy and X-ray photoelectron spectroscopy. The liquid permeabilities of treated cellulose filters were determined by capillary flow porometry, and their water disinfection efficacies were measured by non-pressure-driven filtration. Chlorinated cellulose filters disinfected Escherichia coli- and Staphylococcus aureus-containing solutions to a much higher degree than observed for nonchlorinated cellulose filters.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Public health considerations have given prominence to the significance of drinking water in several countries. In terms of water supply facilities, most metropolitan areas in advanced countries are well equipped and city dwellers are able to purchase bottled drinking water in stores without difficulty. On the other hand, people in many third-world countries and who live far from civilization are unable to do so and often rely on surface or ground water as a drinking water source. Accordingly, when surface water or ground water is contaminated, residents are exposed to waterborne diseases (Leclerc et al. 2002; Backer 2002; Hunter 2003; Ashbolt 2004; Kim et al. 2013; Uwimpuhwe et al. 2014; Kim et al. 2014). International travelers, soldiers, and those in emergency situations are also at risk of contracting waterborne diseases. To disinfect water, free halogen, ozone, or chlorine dioxide have been utilized, but these water-soluble disinfectants are unstable and can react with organic impurities to produce undesired byproducts (Worley and Williams 1988). As a result, insoluble polymeric water disinfectants have been developed; For example, Worley and coworkers focused on the development of polymeric N-halamines for water disinfection (Sun et al. 1994, 1995a, b, 1996; Panangala et al. 1997). These polymers are defined as materials that contain a covalent bond between nitrogen and a halogen, although chlorine has generally been employed. Because dehydrohalogenation, involving a halogen and an adjacent hydrogen (α-hydrogen), can be triggered by ultraviolet (UV) light or heat, a heterocyclic structure is preferred for N-halamines (Ren et al. 2009a, b; Lee et al. 2007a, b; Sun and Sun 2001; Kou et al. 2009). In fact, N-halogenated polystyrenehydantoins, such as poly[1,3-dichloro-5-methyl-5-(4-vinylphenyl)hydantoin] and poly[1,3-dibromo-5-methyl-5-(4-vinylphenyl)hydantoin], have been developed in the form of beads (Chen et al. 2003a, b; Chen et al. 2004). However, although these polymeric N-halamines showed excellent water disinfection function, they were unable to remove solid impurities.

On the other hand, development of membrane systems to remove impurities, including waterborne pathogens, is still progressing. In terms of separation, nanofiltration (NF) and reverse osmosis (RO) using membrane pore sizes of 0.5–2 nm and <0.5 nm, respectively, are capable of removing microorganisms from contaminated water (Bruggen et al. 2003; Pervov et al. 2000; Uyak et al. 2008). However, NF and RO require pressure generation for effective application. Microfiltration (MF) is defined as a filtration process based on pore sizes of 100–10,000 nm, thus bacteria are not effectively removed by some MF systems (Eisnor et al. 2001). To address these limitations of N-halamine beads, NF, RO, and MF, we proposed an N-halamine nanofibrous membrane for non-pressure-driven water disinfection (Kim et al. 2011). Although the nanofibrous membrane was determined to be capable of removing microorganisms from water, membrane production required an electrospinning process, which is specialized, comparatively expensive, and time consuming. In addition, m-aramid used to produce the nanofibrous membranes is relatively expensive.

In this study, we developed a cellulose filter for water disinfection (Fig. 1). The preparation of the cellulose filter involved the use of only water as solvent. In addition, the short drying and curing times may save energy and improve productivity. The disinfection efficacies of filters were examined by filtering bacterial solutions. In addition, the effects of curing temperature and polycarboxylic acid/aromatic amine molar ratio were examined.

Experimental

Materials

1,2,3,4-Butanetetracarboxylic acid (BTCA, 99 %), m-phenylenediamine (m-PDA, 99 %), and sodium hypophosphite (95 %) were purchased from Aldrich Chemicals and used as received. Cellulose filters (grade no. 4 filter paper) and glass microfiber filters (model number 1822-110) were purchased from Whatman (Clifton, NJ). Cellulose filters and glass microfiber filters of 11 cm diameter were used.

Preparation of BTCA/m-PDA-treated filters

A homogeneous 10 wt% BTCA/m-PDA solution was prepared by adding 7.84 g BTCA and 3.61 g m-PDA to 150 mL distilled water containing 3.54 g sodium hypophosphite (catalyst) with constant stirring at ambient temperature for 10 min. BTCA and m-PDA were dissolved at molar ratios of 1/1, 1/2, 1/3, 2/1, or 3/1 (BTCA/m-PDA), but the amount of sodium hypophosphite was fixed. Homogeneous BTCA/m-PDA solutions were applied to cellulose filter using a pad–dry–curing process. Briefly, a cellulose filter was padded through a homogeneous BTCA/m-PDA solution for 5 min to wet pickup of approximately 100 wt%, dried at 85 °C for 5 min, and cured at 180 °C for 2 min. The pressure of the pneumatic mangle (NM-450S; Daiei Kagaku Seiki, Kyoto, Japan) used for padding was 2 kgf/cm2. Cured cellulose filters were rinsed with distilled water and air-dried. Two replicates were prepared for each sample.

Chlorination

A 150-mL aliquot of commercial bleach (Yuhan-Clorox, Seoul, Korea), which contained 4 % hypochlorite, was diluted with 850 mL distilled water. The pH of the diluted solution was buffered to 7.5 with acetic acid, and the BTCA/m-PDA-treated filters were soaked in the solution at ambient temperature for 60 min. The chlorinated filters were then rinsed with a large excess of distilled water and dried at 45 °C for 2 h to remove unbound chlorine. An iodometric titration was used to determine oxidative chlorine content, as previously described (Lee et al. 2007b).

Sample [Cl+]% levels were calculated using the following equation:

where [Cl+] % is the wt % of oxidative chlorine of the sample, V is the titrant volume [sodium thiosulfate solution (mL)], N is the normality of the titrant, and W is the weight of the sample (g). The following constants were used: 35.45 is the atomic weight of Cl, 2 is the change in the oxidation state of Cl during titration, and 10 is a factor that provides % Cl values.

Fourier-transform infrared (FTIR) spectroscopy

The surfaces of treatment-naïve and BTCA/m-PDA-treated cellulose filters were investigated by FTIR (Spectrum 100; PerkinElmer Co., Waltham, MA, USA) spectroscopy in attenuated total reflectance (ATR) mode. Germanium (Ge) ATR crystals were used as the internal reflection elements. A sample was held against one side of the Ge crystal. Background spectra were obtained using a Ge crystal and nitrogen gas in the absence of a sample. FTIR spectra were obtained from 700 to 4,000 cm−1 for 64 scans at resolution of 2 cm−1 after drying samples at 105 °C for 2 h.

X-ray photoelectron spectroscopy (XPS)

XPS was used to confirm the presence of nitrogen in m-PDA. XPS measurements were obtained using a Quantera SXM (ULVAC-PHI; Ulvac, Tokyo, Japan). A monochromatic Al X-ray source was used. The beam size, beam power, electron source, and pass energy were 100 µm, 100 W, 18 kV, and 26 eV, respectively.

Capillary flow porometry

The liquid permeabilities of treatment-naïve and BTCA/m-PDA-treated filters were determined using a PMI capillary flow porometer (Porous Material Inc., Ithaca, NY). Pure water was used as the working fluid, and the measured pressure accuracy was 0.15 %.

Thermogravimetric analysis (TGA)

The thermal characters of treatment-naïve and BTCA/m-PDA-treated cellulose filters were examined by TGA (Q500; TA Instruments, New Castle, DE, USA) at scan rate of 30 °C/min from room temperature to 600 °C under a nitrogen purge.

Water disinfection test

Escherichia coli KCTC 2441 and Staphylococcus aureus KCTC 1621 were incubated under optimal medium and temperature conditions. A 1-mL aliquot of culture fluid was then diluted with 9 mL sterile distilled water, streaked onto a plate, and incubated at 37 °C for 24 h. The total bacterial counts of E. coli and S. aureus cultures were determined as 1.20 × 107 and 1.28 × 107 cfu/100 mL, respectively. Two layers of treated cellulose filter (410 µm thickness) and one layer of glass fiber filter (260 µm thick) placed between the cellulose filters were used. A porcelain Büchner funnel was placed underneath the filters, and no pressure was applied during the filtration procedure. Bacterial solution was added dropwise to the filters. After filtration, 0.5 mL of the various bacterial suspensions was quenched with 5.0 mL sterile 0.02 N sodium thiosulfate solution. The quenched bacterial suspensions were then diluted with pH 7 phosphate buffer and plated on trypticase soy agar. Plates were then incubated at 37 °C for 24 h, and the presence or absence of viable bacteria was determined.

Results and discussion

Reaction of BTCA and m-PDA with cellulose

FTIR was used to confirm the reaction between BTCA and m-PDA and cellulose. Results are shown in Fig. 2. Treatment-naïve cellulose filters revealed peaks at 3,300, 2,900, and 1,420 cm−1, which were assigned to O–H stretching, C–H stretching, and CH2 bending, respectively (Baiardo et al. 2002; Pandey 1999). On the other hand, the BTCA/m-PDA-treated filter paper showed an additional band at 1,714 cm−1, which was presumed to be due to C=O stretching. Two polycarboxyl groups in BTCA might cause ring formation due to loss of H2O caused by anhydride-mediated esterification at elevated temperatures, and subsequent reaction between the –OH of cellulose or the –NH2 of m-PDA and BTCA, as previously described (Lee et al. 2007a; Li et al. 2008). Regarding reactive sites, m-PDA may not possess any site that directly reacts with cellulose. Thus, the additional band at 1,714 cm−1 suggests that BTCA reacted with cellulose. Moreover, the BTCA/m-PDA-treated cellulose filter retained the band at 1,714 cm−1 after chlorination (Fig. 2c), indicating that BTCA bound to cellulose remained during treatment with diluted sodium hypochlorite solution. After chlorination, the band at 1,714 cm−1 shifted to 1,717 cm−1.

XPS was employed to confirm that BTCA acted as a crosslinking agent between m-PDA and cellulose; results are shown in Fig. 3. Unlike the XPS pattern of treatment-naïve cellulose filters, BTCA/m-PDA-treated cellulose filters revealed a nitrogen peak at 399 eV (Fig. 3b). m-PDA possesses amine nitrogen, whereas BTCA and cellulose possess no nitrogen. Accordingly, the distinctive nitrogen peak shown by treated cellulose filters can be assigned to m-PDA. Based on the FTIR spectra and XPS patterns of BTCA/m-PDA-treated cellulose filters, m-PDA was considered to connect to cellulose via BTCA as m-PDA does not react with cellulose.

Effect of treatment conditions

To consider the reactivity of BTCA and m-PDA with cellulose under different temperatures, the curing temperature was varied; results are shown in Fig. 4. Because the N–H site on phenyl ring of m-PDA is a potential chlorination site, measurements of chlorine content provide a means of assessing the amount of m-PDA attached to cellulose. At temperatures up to 180 °C, the oxidative chlorine (Cl+) content of treated cellulose filters increased gradually; For example, [Cl+]% values relative to the chlorinated BTCA/m-PDA filters were 0.21 and 0.75 at 140 and 180 °C, respectively. Regarding the crosslinking mechanism of BTCA, we consider that the amine group on the phenyl ring of m-PDA and the primary alcohol groups in cellulose compete for BTCA (Lee et al. 2007a). Compared with the treatment results at 180 °C, the amount of m-PDA connected to cellulose decreased at 200 and 220 °C, suggesting the amine groups on the phenyl ring in m-PDA dominate the reaction with BTCA at higher temperatures.

The amount of m-PDA connected to cellulose was measured at different molar ratios of BTCA to m-PDA; results are shown in Fig. 5. A molar ratio of BTCA to m-PDA of 1:3 resulted in higher [Cl+]% than ratios of 1:2 or 1:1. In other words, when the m-PDA contribution was increased, the amount of m-PDA connected to cellulose also increased. In terms of the number of carboxyl groups, BTCA contains four carboxyl groups. One H2O molecule might be lost during imide ring formation between two carboxylic acids at elevated temperatures. Thus, the result obtained at molar ratio of BTCA to m-PDA of 1:3 suggests that one BTCA molecule could connect to at least two m-PDA molecules. On the other hand, when the BTCA contribution was increased, the amount of m-PDA on cellulose decreased. Because the number of primary alcohols of cellulose is limited, the number of BTCA molecules that can react with cellulose is also limited. Thus, despite increasing the BTCA contribution, excess BTCA might only react with m-PDA, thus the [Cl+]% value of treated cellulose would be reduced.

Porous characteristics and thermal properties

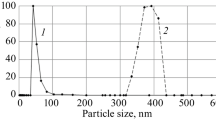

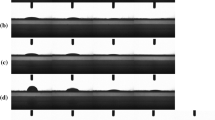

Permeabilities and pore size distributions of treated cellulose filters were measured; results are shown in Figs. 6 and 7, respectively. In terms of filter permeabilities, no significant pre/post BTCA/m-PDA treatment difference was observed (Fig. 6a, b). Chemical bonding of BTCA and m-PDA onto cellulose is believed to be responsible for these similar permeabilities. The average void diameters of the BTCA/m-PDA-treated and chlorinated filters were somewhat larger than that of the treatment-naïve filters (Fig. 7). We presume that cellulose or impurities in cellulose filters were detached during processes involving water or sodium hypochlorite solution.

The thermal properties of filter samples were also examined; results are shown in Fig. 8. The weight loss of samples observed at ~100 °C was attributed to evaporation of water. After treatment with BTCA/m-PDA, the degradation temperature (T d) decreased, but the T d of BTCA/m-PDA-treated filters was increased by chlorination; For instance, the T d values of treatment-naïve, BTCA/m-PDA-treated, and chlorinated filters were 368, 337, and 362 °C, respectively. However, the starting temperature of degradation was prominently reduced by chlorination. The chlorinated filter started to degrade at ~200 °C, whereas the treatment-naïve pure and BTCA/m-PDA-treated filters started to degrade at ~300 °C. On the other hand, residues obtained after treatment at 600 °C for the treatment-naïve, BTCA/m-PDA, and chlorinated filters were 11, 30, and 18 wt%, respectively. The greater amount of residues left by the BTCA/m-PDA-treated filters was presumably influenced by the crosslinking of cellulose chains in filters. In other words, BTCA might cause crosslinking after its reaction with cellulose to an extent that resisted thermal degradation (Han et al. 1999; Zhou et al. 2006).

Water disinfection and rechargeability

As outlined in the “Introduction,” the purpose of this study is to develop a cellulose filter for water disinfection using a simple process with water as the solvent. Chlorinated BTCA/m-PDA filters were subjected to XPS to confirm the presence of surface chlorine (Fig. 3b). After chlorination, the XPS patterns of treated filters revealed distinguishable chlorine peaks at 201 eV (Cl 2p) and 271 eV (Cl 2s), suggesting the presence of N-halamine. Undissociated hypochlorous acid (HOCl) may be considered an active chlorinating agent, and reactions under acidic conditions probably proceed via direct substitution of hydrogen atoms by Cl+ at nitrogen atoms (Sun and Sun 2004).

The water disinfection efficacy of treated filters was also measured; results are presented in Table 1. The filtrate obtained using chlorinated BTCA/m-PDA filters contained bacteria. On the other hand, although it does not have antimicrobial properties, insertion of a glass filter between two chlorinated cellulose filters inactivated all bacteria. As shown in Fig. 6, the flow rate through a glass filter was lower than that through a cellulose filter. Actual contact times, defined as the void volumes (empty bed volumes) of filters dividing by the flow rate of solutions, were measured; results are presented in Table 2. The actual contact time of water in the chlorinated BTCA/m-PDA filter was approximately 3.9 s. When a glass filter was used, the actual contact time of water was approximately 12.0 s, which is thrice as long as the contact time of the chlorinated BTCA/m-PDA filter. Thus, the chlorinated BTCA/m-PDA filters completely inactivated bacteria within 15.9 s of actual contact time. These findings indicate that the water disinfecting efficacy of the chlorinated BTCA/m-PDA filters requires a certain minimum contact time.

The rechargeability of N-halamine cellulose filters after exhaustion of oxidative chlorines (Cl+) may be a crucial factor for use in conventional applications. The chlorinated BTCA/m-PDA filters were rechlorinated after water disinfection; results are presented in Table 3. The [Cl+]% value of rechlorinated BTCA/m-PDA filters recovered approximately 93 % of the initial value.

Conclusions

m-PDA was bonded to cellulose in filter paper using BTCA as a crosslinking agent. The N-halamine cellulose filter was produced relatively simply, in a green manner, using water as the solvent. The water disinfection efficacies of gravity-fed N-halamine cellulose filters were assessed by determining optimum contact times. The N-halamine cellulose filter was found to have higher water disinfection efficacies against bacterial solutions containing E. coli or S. aureus. Although flow rates through the N-halamine cellulose filter were manipulated using the glass filter, the N-halamine cellulose filter produced is well suited to gravity-fed water disinfection applications in regions lacking a potable water supply.

References

Ashbolt NJ (2004) Microbial contamination of drinking water and disease outcomes in developing regions. Toxicology 198:229–238

Backer H (2002) Water disinfection for international and wilderness travelers. Clin Infect Dis 34:355–364

Baiardo M, Frisoni G, Scandola M, Licciardello A (2002) Surface chemical modification of natural cellulose fibers. J Appl Polym Sci 83:38–45

Bruggen BVD, Vandecasteele C, Gestel TV, Doyen W, Leysen R (2003) A review of pressure-driven membrane processes in wastewater treatment and drinking water production. Environ Prog 22:46–56

Chen Y, Worley SD, Kim J, Wei CI, Chen TY, Santiago JI, Sun G (2003a) Biocidal poly(styrenehydantoin) beads for disinfection of water. Ind Eng Chem Res 42:280–284

Chen Y, Worley SD, Kim J, Wei CI, Chen TY, Suess J, Williams JF (2003b) Biocidal polystyrenehydantoin beads. 2. Control of chlorine loading. Ind Eng Chem Res 42:5715–5720

Chen Y, Worley SD, Huang TS, Weese J, Kim J, Wei CI, Williams JF (2004) Biocidal polystyrene beads, IV. Functionalized methylated polystyrene. J Appl Polym Sci 92:368–372

Eisnor JD, O’Leary KC, Gagnon GA (2001) Evaluation of particle removal at water treatment plants in Nova Scotia. Water Qual Res J Can 36:105–119

Han SO, Lee DW, Han OH (1999) Thermal degradation of crosslinked high density polyethylene. Polym Degrad Stab 63:237–243

Hunter PR (2003) Climate change and waterborne and vector-borne disease. J Appl Microbiol 94:37S–46S

Kim SS, Jung D, Choi UH, Lee J (2011) Antimicrobial m-aramid nanofibrous membrane for nonpressure driven filtration. Ind Eng Chem Res 50:8693–8697

Kim SS, Kim M, Lee J (2013) Cellulose filter coated with m-aramid for water disinfection. J Appl Polym Sci 129:3454–3458

Kim SS, Jeong J, Lee J (2014) Antimicrobial m-aramid/cellulose blend membranes for water disinfection. Ind Eng Chem Res 53:1638–1644

Kou L, Liang J, Ren X, Kocer HB, Worley SD, Tzou YM, Huang TS (2009) Synthesis of a water-soluble siloxane copolymer and its application for antimicrobial coatings. Ind Eng Chem Res 48:6521–6526

Leclerc H, Schwartzbrod L, Dei-Cas E (2002) Microbial agents associated with waterborne diseases. Crit Rev Microbiol 28:371–409

Lee J, Broughton RM, Akdag A, Worley SD, Huang T (2007a) Antimicrobial fibers created via polycarboxylic acid durable press finishing. Text Res J 77:604–611

Lee J, Broughton RM, Worley SD, Huang TS (2007b) Antimicrobial polymeric materials; Cellulose and m-aramid composite fibers. J Eng Fibers Fabr 2:25–32

Li W, Xu X, Chen S, Zhou X, Li L, Chen D, Wang X (2008) Esterification crosslinking structures of rayon fibers with 1,2,3,4-butanetetracarboxylic acid and their water-responsive properties. Carbohyd Polym 71:574–582

Panangala VS, Liu L, Sun G, Worley SD, Mitra A (1997) Inactivation of rotavirus by new polymeric water disinfectants. J Virol Methods 66:263–268

Pandey KK (1999) A study of chemical structure of soft and hardwood and wood polymers by FTIR spectroscopy. J Appl Polym Sci 71:1969–1975

Pervov AG, Dudkin EV, Sidorenko OA, Antipov VV, Khakhanov SA, Makarov RI (2000) RO and NF membrane systems for drinking water production and their maintenance techniques. Desalination 132:315–321

Ren X, Kocer HB, Worley SD, Broughton RM, Huang TS (2009a) Rechargeable biocidal cellulose: synthesis and application of 3-(2,3-dihydroxypropyl)-5,5-dimethylimidazolidine-2,4-dione. Carbohyd Polym 75:683–687

Ren X, Kou L, Kocer HB, Worley SD, Broughton RM, Tzou YM, Huang TS (2009b) Antimicrobial modification of polyester by admicellar polymerization. J Biomed Mater Res B Appl Biomater 89B:475–480

Sun Y, Sun G (2001) Novel regenerable N-halamine polymeric biocides. I. Synthesis, characterization, and antibacterial activity of hydantoin-containing polymers. J Appl Polym Sci 80:2460–2467

Sun Y, Sun G (2004) Novel refreshable N-halamine polymeric biocides: N-chlorination of aromatic polyamides. Ind Eng Chem Res 43:5015–5020

Sun G, Wheatley WB, Worley SD (1994) A new cyclic N-halamine biocidal polymer. Ind Eng Chem Res 33:168–170

Sun G, Allen LC, Luckie EP, Wheatley WB, Worley SD (1995a) Disinfection of water by N-halamine biocidal polymers. Ind Eng Chem Res 34:4106–4109

Sun G, Chen TY, Sun W, Wheatley WB, Worley SD (1995b) Preparation of novel biocidal N-halamine polymers. J Bioact Compat Polym 10:135–144

Sun G, Chen TY, Habercom MS, Wheatley WB, Worley SD (1996) Performance of a new polymeric water disinfectant. J Am Water Res Assoc 32:793–797

Uwimpuhwe M, Reddy P, Barratt G, Bux F (2014) The impact of hygiene and localised treatment on the quality of drinking water in Masaka, Rwanda. J Environ Sci Health A 49:434–440

Uyak V, Koyuncu I, Oktem I, Cakmakci M, Toroz I (2008) Removal of trihalomethanes from drinking water by nanofiltration membranes. J Hazard Mater 152:789–794

Worley SD, Williams DE (1988) Halamine water disinfectants. Crit Rev Environ Control 18:133–175

Zhou W, Yang H, Guo X, Lu J (2006) Thermal degradation behaviors of some branched and linear polysiloxanes. Polym Degrad Stab 91:1471–1475

Acknowledgments

This work was supported by the 2014 Yeungnam University Research Grant. The authors wish to thank Kwang Ho Choi of the Department of Applied Microbiology and Biotechnology at Yeungnam University for preparing the water disinfection test. The authors are also grateful to Hyo Jung Chae and Ji Hoon Kim for their helpful discussions and for preparing the samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, S.S., Lee, J. Water disinfection activity of cellulose filters treated with polycarboxylic acid and aromatic amine. Cellulose 21, 4511–4518 (2014). https://doi.org/10.1007/s10570-014-0430-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0430-0