Abstract

Polyoxometalates can be tuned for specific catalytic property by substituting transition metal ions. We report the synthesis of hybrid materials of Cu2+, Co2+ and Ni2+ substituted phosphotungstates and poly(diallyldimethylammonium) chloride polymer (PDDA) for CO2 fixation. The in situ generated transition metal substituted polyoxometalates (TMS-POMs) are analyzed by FTIR, powder XRD, 31P NMR and SEM techniques. The hybrid TMS-POM materials are found to be good catalysts for converting epoxides to cyclic carbonates. Among these, PDDA-PWCo is the most efficient catalyst for cycloaddition of CO2 under solvent-free conditions at room temperature in shortest reaction time. Only 0.2 mol% of PDDA-PWCo is enough to deliver 100% conversion and selectivity to cyclic carbonates. This catalytic approach is employed for conversion of other cyclic, acyclic, and aromatic epoxides without using column purifications. Overall, the method of obtaining cyclic carbonates under green conditions using TMS-POMs-PDDA hybrid materials appears suitable for industrial applications.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The eco-friendly production of valuable chemicals is one of the best methods for CO2 fixation. In this context, capture and conversion of CO2 to valuable chemicals such as cyclic carbonates is considered as a feasible and efficient catalytic process [1,2,3,4,5]. Carbon dioxide is considered to be a thermodynamically stable molecule, and thus, higher energy supply and harsh reaction conditions are usually expected to drive CO2 conversion such as high reaction temperature and pressure, extremely reactive substrates and reagents. Thus, it is necessary to develop catalysts with higher efficiency for cost effective conversion of CO2 under mild reaction conditions. The synthesis of cyclic carbonates from epoxide and CO2 stands as atom-economic, environmentally friendly and green approach for the conversion and storage of CO2 [6,7,8]. In order to facilitate the synthesis of cyclic carbonates, various metal oxides, salen complexes, porous catalysts, organic and inorganic bases, titanosilicates, zeolites, and many metal/organic-supported complexes have been employed [8, 9]. Heterogeneous catalysts are preferred because of simple work-up procedures involved and their recyclability [10, 11]. Polyoxometalate-based hybrid materials are promising heterogeneous catalysts for CO2 conversion to valuable products and intermediates such as polycarbonates, cyclic carbonates and carboxylic acids [12,13,14].

Polyoxometalates (POMs) are metal–oxygen anionic cluster materials with varied structural characteristics and versatile functionalities useful for catalysis and photochemical reactions [15,16,17,18]. The stable Keggin-type POMs contain twelve metal-oxoctahedra assembled around a tetrahedral oxo-anion with generic formula [(Xn+M12O40]−(8−n) where M = Mo, W and X = Si, P. These clusters assemble in acidic medium (pH < 3). Lacunary polyoxometalates (L-POMs) represent an important sub-class of POMs that are synthesized by removing one or more of the MOx units from parent polyoxometalate cluster [XM12O40]n−, thus producing mono- and polylacunary POMs, respectively [14, 19,20,21,22,23,24,25,26]. The L-POMs have enhanced properties than parent POMs because of the removal of MOx octahedral moieties from the saturated Keggin anion structure. The increased anionic charge and nucleophilic oxygen enriched surface of L-POMs allow its interactions with various cations. Incorporation of transition metals into the defect sites of the L-POMs results in a whole new array of transition metal substituted polyoxometalates (TMS-POMs) with improved catalytic and other properties depending on the metal ions incorporated. The formation of these species are highly pH dependent, each possessing unique reactivity as well as stability trend [19].

However, POMs as catalysts have a few drawbacks that include difficulty in catalyst/product separation, product contamination and poor processability which are crucial factors for environmental sustainability. One of the typical methods to overcome these shortcomings is to integrate the POMs into suitable polymer matrixes having counter cationic groups that can help to exploit the intrinsic anionic character of POMs [20]. Proper combination of POMs with polymer matrices can give rise to materials for wide variety of applications [27, 28]. Polyelectrolytes are a certain group of organic polymers that can deposit on solid surfaces and colloids through electrostatic interactions [29]. Poly(diallyldimethylammonium) chloride (PDDA) is one such organic polymer that can be used as a polymer matrix to immobilize the POMs. The electrostatic interactions between the organic substrate and catalytic center of POM can enhance the stability and catalytic efficiency of the resultant hybrid material [21, 22].

POM-based materials have been employed previously for catalytic conversion of CO2 and epoxides to cyclic carbonates [14, 30]. The POM based compounds are good catalysts as these materials activate the epoxides/CO2 by interacting with the basic oxygen atoms and acidic metal sites [14, 23, 24]. Structural and functional modification of polyoxometalate clusters can lead to POM-based hybrids that are promising eco-friendly heterogeneous catalysts for the cycloaddition reaction of CO2 and epoxides. We have synthesized three PDDA-metal substituted monolacunary phosphotungstate (PDDA-TMSPOM) hybrid materials (PDDA-PWCo, PDDA-PWNi, and PDDA-PWCu) as catalysts for CO2 conversion into cyclic carbonates under solvent-free ambient reaction conditions. These POM-hybrid materials are found to be active and PDDA-PWCo is the best catalyst among them for CO2 conversion.

2 Experimental

2.1 Materials

Sodium tungstate (Na2WO4.2H2O) salt is purchased from Avra Laboratories, India. Disodium hydrogen phosphate (Na2HPO4), nitrate salts of cobalt, nickel and copper and phosphotungstic acid (H2PW12O40) were purchased from Thermo Fisher Scientific, India, and Poly(diallyldimethylammonium) chloride PDDA was supplied by Aldrich. These precursor salts are used in the preparation TMS-POMs hybrid materials.

2.2 Synthesis of PDDA-TMS-POM Hybrid Materials

The in situ synthesis of Keggin-based TMS-POM hybrid catalysts were carried out following the literature report [31]. Typically, 2.0 mmol of disodium hydrogen phosphate, 25 mmol of sodium tungstate and 3 mmol of metal nitrate (Co2+, Ni2+ and Cu2+) were dissolved in 50 ml distilled water. The pH of the solution was maintained at 4.8 using 1.0 M HNO3. The resultant solution contains the transition metal substituted Keggin ions. In the next step, the above solution is mixed with 5 ml of poly(diallyldimethylammonium) chloride (PDDA). The reaction was carried out under stirring conditions for 1 h. The resulting precipitate was washed, filtered and dried. These TMSPOM-POM hybrid materials are denoted as PDDA-PWCo, PDDA-PWNi and PDDA-PWCu respectively. The three PDDA-TMSPOM hybrid materials are soft and powdery in nature. The substituted transition metal contributes the characteristic colour to the compounds. Accordingly, the colours of the compounds, PDDA-PWCu, PDDA-PWNi and PDDA-PWCo are light blue, light green and plum color, respectively (Fig. 1).

2.3 Materials Characterization

The FTIR spectra of the samples were collected from JASCO FT/IR 4100 spectrometer adopting KBr pellet method. The UV–Visible analyses of the samples were conducted on JASCO V-660 spectrometer using BaSO4 as a reference in the range of 200–800 nm. Powder X-ray diffraction (PXRD) patterns of the hybrid materials were obtained using Bruker D8 Advance X-ray diffractometer employing Cu Kα (λ = 0.15406 nm) radiation. The microscopic studies were carried out using FEI Quanta 200F electron microscope. The samples were subjected to differential thermal analysis (DTA) and thermogravimetric analysis (TGA) in Perkin-Elmer, TGA Q500 machine in nitrogen flow. The 31P NMR analyses of the hybrid catalyst materials were done in solid state mode using Bruker-FT-NMR 400 MHz spectrometer. The X-ray photoelectron spectroscopy (XPS) measurements were recorded using an ESCA probe TPD spectrometer from Omicron Nanotechnology, with an X-ray source of 1486.6 eV from polychromatic Al Kα radiation. The catalytic conversions of CO2 to cyclic carbonates were analyzed by 1H NMR spectra recorded on Bruker-FT-NMR 500 MHz spectrometer. The reaction mixtures were dissolved in CDCl3 solvent for NMR analysis.

3 Results and Discussion

3.1 Physicochemical Characterization

Figure 2 shows the FT-IR spectra of the three PDDA-TMS-POM hybrid materials. The IR spectrum of pure phosphotungstic acid is also included in order to compare the Keggin signature peaks. The peaks at 807, 892, 988 and 1080 cm−1 correspond to the stretching frequencies of \(({\text{W}} - {\text{O}}_{{\text{e}}} - {\text{W}})\), \(({\text{W}} - {\text{O}}_{{\text{c}}} - {\text{W}})\), \(\left( {{\text{W = O}}_{{{\text{Ter}}}} } \right)\) and \(\left( {{\text{P}} - {\text{O}}} \right)\), respectively, signifying the formation of Keggin structure [25]. The intense peak at 1080 cm−1 is due to the \(\left( {{\text{P}} - {\text{O}}} \right)\) vibration of the PO4 unit in the center of parent Keggin anion. However, this peak bifurcated in the hybrids, due to the loss of symmetry of PO4 tetrahedral unit, as a result of metal substitution. This splitting of P–O band clearly indicates the formation of lacunary PW11. Thus, the FT-IR spectral signatures of Keggin ions indicate clearly that the transition metal ion is occupying the octahedral site inside the Keggin structure and not present as a counter ion [26]. The spectra show the characteristic absorption bands of asymmetrical and symmetrical stretching frequencies of –CH2 − at 3012 cm−1 and 2814 cm−1, respectively, while the significant peak at 1400 cm−1 is attributed to –CH2 − alkyl rocking vibrations present in PDDA moiety. The strong broad peaks at 3154 cm−1 and 3435 cm−1 are due to stretching of N–H and O–H, respectively [32].

The UV-Visible absorption spectra of hybrid materials are shown in Figure 3. Polyoxometalates show significant oxygen-to-metal charge transfer phenomenon in the UV region [26]. The three peaks at 210 nm, 260 nm and 310 nm correspond to the oxygen to tungsten charge transfer associated with the edge-sharing and corner-sharing oxygen of the Keggin units. The 3d metal substitution in the Keggin unit resulted in absorbance in the visible region. The green colour of PDDA-PWNi and blue colour of PDDA-PWCu containing Ni2+ and Cu2+ ions, respectively, show absorption in the region 650-800 nm and beyond. These broad bands are due to the d-d transitions of d8 (Ni2+) and d9 (Cu2+) ions. The plum colour of PDDA-PWCo indicates the substitution of Co2+ ions and show broad absorption band in the range of 470–650 nm.

The absorbance features obtained between 400 to 800 nm visible regions are attributed to the d–d transitions occurring in the 3d transition metal ions which are found to be occupying the octahedral site created in the monolacunary Keggin ion. Further, the diffuse reflectance features in the UV region are matching with the parent Keggin ion. This indicates that the electronic properties of parent Keggin structure remain unaltered in the UV region by the substitution of 3d metal ions in the octahedral moiety of monolacunary Keggin units.

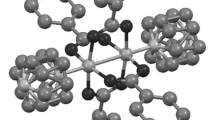

The powder XRD patterns of these hybrid materials presented in Figure 4 reveal the amorphous nature of these materials. Phosphotungstic acid (PWA) is known for its crystalline nature (Figure 4a), while the resulting hybrid materials do not show intense peaks in the higher angle region [29]. The polymeric PDDA chains interact with metal substituted Keggin units, thereby the regular spacing between them increases and crystallinity decreases. The diffraction peaks have broadened and merged into the lower region, which specify the amorphous nature of the hybrid material [29]. These hybrid materials have intense peak at around 2θ=7.5. This indicates the presence of short range order with open and layered structure and d-spacing of the layered structure is calculated to be 1.17 nm. The particle sizes of PDDA-PWCu and PDDA-PWNi samples calculated using the Scherrer equation are of found to be about 3 nm in size.

All the hybrid materials show similar stepwise decomposition pattern as seen in Figure 5. PDDA is purely organic and it shows two step decomposition in the range of 350–550 °C. The weight loss in hybrid materials till 120 °C is due to the loss of adhered water molecules. The next two-step weight loss is observed between 300-450 °C and 600–750 °C, which is due to the loss of organic moiety, PDDA present in the hybrid materials [32]. The enhanced stability of the PDDA polymeric moiety can be attributed to the strong electrostatic interaction with Keggin anions. All the hybrid materials show 15 to 20% of weight loss, which can be correlated with the interaction of each metal substituted Keggin (PW11O39M)5- with five monomeric units of PDDA. This in turn proves the formation of hybrid material of metal substituted Keggin and PDDA. Furthermore, metal substituted Keggin also shows extended thermal stability up to 750 °C, which later decomposes to its oxides.

The surface morphologies of the hybrid materials are studied by scanning electron microscopy and the images along with their respective EDAX spectra are shown in Figure 6. As explained from powder XRD patterns, these hybrid materials show amorphous morphologies. The PDDA-TMSPOM hybrid materials seem to have aggregated particles. The modification of the pure PWA by metal substitution and PDDA functionalization has resulted in the change in morphology. The PDDA-TMSPOM are composed of non-uniform particles in irregular layers. The insets in Figure 6 show closer magnification, where Figure 6a showing PDDA-PWCu has similar morphology, while Figure 6b showing PDDA-PWNi has wavy texture in its inset and Figure 6c showing PDDA-PWCo has layered morphology (inset image). Further, the EDAX data in Figure 6 shows the presence of respective substituted metal ions in the hybrids and the composition corroborates that the hybrid materials are formed by the interaction of five monomeric units of PDDA each metal substituted Keggin (PW11O39M)5-, which is also determined through TGA (Figure 5).

The 3d metal substituted Keggin ions are formed in situ during the synthesis of hybrid materials. In general, the unsubstituted Keggin, (PW12O40)3−, has a chemical shift of − 15.1 ppm [33], whereas monolacunary Keggin is deshielded to − 10 ppm [34]. The 3d metal present in the lacuna of Keggin structure shows a characteristic peak at − 13.1 ppm [26, 35]. In Fig. 7, the 31P NMR of the three hybrid materials show − 13.80, − 13.72 and − 13.83 ppm for PDDA-PWCu, PDDA-PWNi and PDDA-PWCo, respectively. This unequivocally confirms the metal substitution in the Keggin structure.

The core level XPS of the PDDA-PWCo hybrid material has been recorded to analyse the elements present in the hybrid. The full survey spectrum shown in Fig. 8a is evident of the presence of W 4f, P 2p, C 1 s, O 1 s and Co 2p. The C 1 s and O 1 s are arising from the polymeric chains of PDDA moiety. The presence of Co2+ in an octahedral site of Keggin is further evidenced from the XP spectrum, as Fig. 8b shows the peaks at 781.09 and 796.6 eV corresponding to Co2+ 2p3/2 and Co2+ 2p1/2, respectively.

3.2 Conversion of CO2 to Cyclic Carbonates Using PDDA-TMSPOM Catalysts

The hybrid materials, PDDA-TMSPOMs, are used as heterogeneous catalysts for the conversion of carbon dioxide to cyclic carbonates under mild reaction conditions. The reaction has been carried out by mixing epoxide (5 mmol), TBAB as co-catalyst (0.5 mmol) and PDDA-TMSPOM catalyst (0.2 mol%) in a round bottom flask that is fitted with a rubber stopper pierced by a balloon that contains CO2. This cycloaddition reaction is allowed to run for 4 h at room temperature. At the completion of the reaction, the work up is done by adding ethyl acetate to the reaction mixture. The catalyst is recovered by centrifugation and the organic part is collected. The collected organic part is washed with water and dried over anhydrous Na2SO4. The desired product is obtained by evaporating the ethyl acetate solvent. The final cyclic carbonate product is analyzed by NMR analysis to determine the conversion. The substrate conversion and the selectivity are based on 1H-NMR of crude reaction mixture during the optimization, substrate scope and recyclability studies. The results are summarized in Chart 1. All the reactions are carried out under solvent-free conditions for 4 h (except for entry 7 (3.5 h) and 8 (3 h) in Chart 1).

Initially, we tested the cycloaddition of CO2 to epichlorohydrin (Scheme 1). The reaction with no catalyst and co-catalyst does not give the desired product (Chart 1: entry 1). In the absence of PDDA-PWCo, TBAB gave only 35% conversion of the epoxide to the corresponding cyclic carbonate are observed whereas PDDA-PWCo gave 50% conversion in the absence of TBAB (Chart 1: entry 2 and 3). This clearly indicates that the hybrid catalysts are more efficient to carry out this cycloaddition. Interestingly, in the presence of the catalytic system comprising of PDDA-PWCo (0.2 mol%) and TBAB (0.5 mmol), the reaction resulted in 100% conversion of epichlorohydrin, producing desired cyclic carbonate (Chart 1: entry 10). The result indicates that the reaction proceeds smoothly with high selectivity without the formation of side-products. Comparatively, the combinations of PDDA-PWNi/TBAB and PDDA-PWCu/TBAB gave 60% and 50% of conversion, respectively (Chart 1: entry 11 and 12; comparative 1H NMR spectra in Figure S1). As the reaction progressed over the course of 1 and 2 h, respectively, 38% and 44% conversion was observed. Furthermore, the conversion was 55% after 3 h and 65% after 3.5 h. (comparative 1H NMR spectra in Figure S2). When the co-catalyst loading is decreased to 0.125 mmol and 0.25 mmol, the epichlorohydrin conversion is found to decrease to 60% and 40%, respectively (Chart 1: entry 4 and 5; comparative NMR spectra in Figure S3).

The screening studies show that the PDDA-PWCo in combination with TBAB has emerged as the best choice to give higher conversion of epoxide with high selectivity (Chart 1). The higher catalytic activity of PDDA-PWCo is attributed to the higher affinity of cobalt towards binding with epoxides [36]. The confined space of the layered PDDA-PWCo interlayer region may induce some restrictions in the overall structure and this may have resulted in controlling the accessibility of the catalytic active site in the interlayer region, leading to the increased catalytic activity of PDDA-PWCo. The catalytic ability of substituted Co2+ POM is shown in some reports [37, 38]. To further confirm the catalytic potential of PDDA-PWCo, recyclability studies have been carried out which revealed that this binary catalytic system gives better results even after fourth reuse under mild reaction conditions (Chart 2, for comparison 1H-NMR in Figure S4).

The reaction conditions employed herein are economically viable and most convenient to carry out. Hence these conditions are applied to reactions involving structurally diverse epoxides by using 0.2 mol% of PDDA-PWCo catalyst without any solvent at room temperature. The results are summarized in Table 1. The cycloaddition of CO2 to propylene oxide, epoxyhexane, cyclopentene oxide, epoxycyclohexane and styrene oxide proceeds efficiently giving better conversion of epoxides to the corresponding cyclic carbonates under eco-friendly reaction conditions than similar reactions reported in the literature. Interestingly, octadiene diepoxide produced efficiently corresponding cyclic dicarbonate, a result that bodes well for future uses of such fascinating compounds.

We have compared the catalytic activity of PDDA-PWCo catalyst with some of the previously disclosed POM-based catalysts used for synthesizing cyclic carbonates at room temperature with no solvent[39,40,41,42,43]. This comparative data is summarized in Table 2 for the reaction of epichlorohydrin and CO2. The reactions referred in Table 2 require higher temperatures and CO2 pressure. The PDDA-PWCo catalyst demonstrates comparatively better catalytic efficiency towards cyclic carbonates, as can be seen in Table 2. The reason for better activity of cobalt substituted hybrid seems to be the affinity of cobalt towards binding with epoxides [36]. Moreover, the surface area of PDDA-PWCo is 13 m2/g whereas PDDA-PWNi and PDDA-PWCu catalysts have surface areas of 5 m2/g and 8 m2/g, respectively. Thus, comparatively higher surface area could be another reason for better activity of PDDA-PWCo than its competitive hybrid catalysts reported here.

The plausible mechanism is shown in Scheme 2 that involves the epoxide activation by Lewis acidic hybrid material such as PDDA-PWCo. The catalyst activates the oxirane ring through the interaction with the oxygen atom to facilitate the nucleophilic attack of TBAB on the epoxide ring. The attack of bromide leads to the ring opening and at this stage, CO2 insertion in the metal alkoxide bond occurs. Finally, the intra-molecular cyclization accompanied with the removal of bromide leads to the generation of the cyclic carbonate [44, 45].

The catalytic approach developed in this study does not require any solvent and the products can be obtained in a short duration at room temperature. This clearly demonstrates that the transition metal substituted monolacunary catalytic systems are useful to synthesize cyclic carbonates under environmentally benign conditions. Finally, this catalytic process can be useful for industrial targets involving bio-based cyclic carbonate products.

4 Conclusions

In summary, we have synthesized three hybrid catalytic materials consisiting of Cu2+, Co2+, and Ni2+ ion substututed Keggin structures and PDDA polymer matrix (PDDA-TMSPOMs). The formation of transition metal substituted Keggin anions are evident from FTIR and UV–Visible spectra, and further confirmed by TGA and 31P NMR. The TGA analysis also showed the extended thermal stability of the materials upto 400 °C. The powder XRD pattern revealed the amorphous nature of all the three hybrid materials while the irregular surface morphology can be seen in SEM images. Among the POM-based bybrid catalytic materials, PDDA-PWCu, PDDA-PWNi and PDDA-PWCo, PDDA-PWCo is the most efficient heterogeneous catalyst for synthesizing cyclic carbonates under eco-friendly reaction conditions. This catalytic appraoch provides the cyclic carbonates in good yields under solvent-free conditions with 100% selectivity. Furthermore, the reported synthetic approach here requires no column purification of products, and thus, avoids tedious methods and waste generation. Considering these factors, PDDA-PWCo-catalyzed synthesis of cyclic carbonates truly stands as an environmentally friendly catalytic method towards potentially useful chemicals.

References

Truong CC, Mishra DK (2020) Environ Chem Lett 19:911–940. https://doi.org/10.1007/s10311-020-01121-7

Osman AI, Hefny M, Abdel Maksoud MIA, Elgarahy AM, Rooney DW (2020) Environ Chem Lett 19:797–849. https://doi.org/10.1007/s10311-020-01133-3

Peng J, Geng Y, Yang HJ, He W, Wei Z, Yang J, Guo C-Y (2017) Mol Catal 432:37–46. https://doi.org/10.1016/j.mcat.2017.01.019

Chen X, Liu Y, Wu J (2020) Mol Catal 483:110716. https://doi.org/10.1016/j.mcat.2019.110716

Corma A, Garcia H (2013) J Catal 308:168–175. https://doi.org/10.1016/j.jcat.2013.06.008

Zhang YY, Yang GW, Xie R, Yang L, Li B, Wu GP (2020) Angew Chem Int Ed 59:23291–23298. https://doi.org/10.1002/anie.202010651

Lang X-D, He LN (2016) Chem Rec 16:1337–1352. https://doi.org/10.1002/tcr.201500293

Zhai G, Liu Y, Lei L, Wang J, Wang Z, Zheng Z, Wang P, Cheng H, Dai Y, Huang B (2021) ACS Catal 11:1988–1994. https://doi.org/10.1021/acscatal.0c05145

Miao CX, Wang JQ, Wu Y, Du Y, He LN (2008) Chemsuschem 1:236–241. https://doi.org/10.1002/cssc.200700133

Cao JP, Xue YS, Li NF, Gong JJ, Kang RK, Xu Y (2006). J Am Chem Soc. https://doi.org/10.1201/9781420015751

Mizuno N, Kamata K, Yamaguchi K (2006) Surface and Nanomolecular Catalysis. In: Richards Ryan (ed) Liquid-phase oxidations catalysed by polyoxometalates. CRC Press Taylor and Francis, Boca Raton, pp 463–492

Chen F, Li X, Wang B, Xu T, Chen SL, Liu P, Hu C (2012) Chem Eur J 18:9870–9876. https://doi.org/10.1002/chem.201201042

Wang Y, Wu Z, Yu H, Han S, Wei Y (2020) Green Chem 22:3150–3154. https://doi.org/10.1039/d0gc00388c

Yu B, Zou B, Hu CW (2018) J CO2Util 26:314–322. https://doi.org/10.1016/j.jcou.2018.05.021

Wang SS, Yang GY (2015) Chem Rev 115:4893–4962. https://doi.org/10.1021/cr500390v

Miras HN, Yan J, Long DL, Cronin L (2012) Chem Soc Rev 41:7403. https://doi.org/10.1039/c2cs35190k

Pattnaik F, Tripathi S, Patra BR, Nanda S, Kumar V, Dalai AK, Naik S (2021) Environ Chem Lett 19:4119–4136. https://doi.org/10.1007/s10311-021-01284-x

Long DL, Tsunashima R, Cronin L (2010) Angew Chem Int Ed 49:1736–1758. https://doi.org/10.1002/anie.200902483

Nsouli NH, Ismail AH, Helgadottir IS, Dickman MH, Clemente-Juan JM, Kortz U (2009) Inorg Chem 48:5884–5890. https://doi.org/10.1021/ic900180x

Xiao Y, Chen D, Ma N, Hou Z, Hu M, Wang C, Wang W (2013) RSC Adv 3:21544. https://doi.org/10.1039/c3ra43373k

Qi W, Wu L (2009) Polym Int 58:1217–1225. https://doi.org/10.1002/pi.2654

Chen H, Wang Y, Dong S (2007) Inorg Chem 46:10587–10593. https://doi.org/10.1021/ic7009572

Ge W, Wang X, Zhang L, Du L, Zhou Y, Wang J (2016) Catal Sci Technol 6:460–467. https://doi.org/10.1039/c5cy01038a

Zhao YQ, Liu YY, Ma JF (2020) Cryst Growth Des 21:1019–1027. https://doi.org/10.1021/acs.cgd.0c01353

Shakeela K, Sinduri VL, Ranga Rao G (2017) Polyhedron 137:43–51. https://doi.org/10.1016/j.poly.2017.07.023

Shakeela K, Ranga Rao G (2018) ACS Appl Nano Mater 1:4642–4651. https://doi.org/10.1021/acsanm.8b00920

Houston JE, Patterson AR, Jayasundera AC, Schmitt W, Evans RC (2014) Chem Commun 50:5233–5235. https://doi.org/10.1039/c3cc47552b

Zhao W, Yang C, Cheng Z, Zhang Z (2016) Green Chem 18:995–998. https://doi.org/10.1039/c5gc02527c

Shakeela K, Guru S, Ranga Rao G (2020). J Chem Sci. https://doi.org/10.1007/s12039-020-01804-2

Han F, Li H, Zhuang H, Hou Q, Yang Q, Zhang B, Miao C (2021) J CO2 Util 53:101742. https://doi.org/10.1016/j.jcou.2021.101742

Simões MMQ, Conceição CMM, Gamelas JAF, Domingues PMDN, Cavaleiro AMV, Cavaleiro JAS, Ferrer-Correia AJV, Johnstone RAW (1999) J Mol Catal A Chem 144:461–468. https://doi.org/10.1016/s1381-1169(99)00025-4

Zhang Q, An Q, Luan X, Huang H, Li X, Meng Z, Tong W, Chen X, Chu PK, Zhang Y (2015) Nanoscale 7:14002–14009. https://doi.org/10.1039/c5nr03256c

Rajkumar T, Ranga Rao G (2009) J Chem Sci 120:587–594. https://doi.org/10.1007/s12039-008-0089-x

Levine DJ, Stöhr J, Falese LE, Ollesch J, Wille H, Prusiner SB, Long JR (2015) ACS Chem Biol 10:1269–1277. https://doi.org/10.1021/cb5006239

Patel K, Shringarpure P, Patel A (2010) Transit Met Chem 36:171–177. https://doi.org/10.1007/s11243-010-9450-2

Lu X-B, Wang Y (2004) Angew Chem Int Ed 43:3574–3577. https://doi.org/10.1002/anie.200453998

Singh C, Mukhopadhyay S, Das S (2018) Inorg Chem 57:6479–6490. https://doi.org/10.1021/acs.inorgchem.8b00541

Mulkapuri S, Ravi A, Das S (2022) Chem Mater 34:3624–3636. https://doi.org/10.1021/acs.chemmater.1c03917

Zalomaeva OV, Chibiryaev AM, Kovalenko KA, Kholdeeva OA, Balzhinimaev BS, Fedin VP (2013) J Catal 298:179–185. https://doi.org/10.1016/j.jcat.2012.11.029

Das SK, Chatterjee S, Bhunia S, Mondal A, Mitra P, Kumari V, Pradhan A, Bhaumik A (2017) Dalton Trans 46:13783–13792. https://doi.org/10.1039/c7dt02040f

Cheng W, Xue Y, Luo X-M, Xu Y (2018) Chem Commun 54:12808–12811. https://doi.org/10.1039/c8cc07041e

Jia J, Niu Y, Zhang P, Zhang D, Ma P, Zhang C, Niu J, Wang J (2017) Inorg Chem 56:10131–10134. https://doi.org/10.1021/acs.inorgchem.7b01231

Lu J, Ma X, Singh V, Zhang Y, Wang P, Feng J, Ma P, Niu J, Wang J (2018) Inorg Chem 57:14632–14643. https://doi.org/10.1021/acs.inorgchem.8b02321

Szczepankiewicz SH, Ippolito CM, Santora BP, Van de Ven TJ, Ippolito GA, Fronckowiak L, Wiatrowski F, Power T, Kozik M (1998) Inorg Chem 37:4344–4352. https://doi.org/10.1021/ic980162k

Khenkin AM, Efremenko I, Weiner L, Martin JML, Neumann R (2010) Chem Eur J 16:1356–1364. https://doi.org/10.1002/chem.200901673

Acknowledgements

RJ would like to express gratitude to Prof. Ranga Rao for providing research facilites to carry out this work in DSEHC-Solar Fuels Laboratory at IIT Madras. DSEHC is supported by Department of Science and Technology, Government of India through Grant No. DST/TMD/SERI/HUB/1(C). RJ, CAB, RRS and KS acknowledge BSACIST for research faciltites for a part of this work.

Author information

Authors and Affiliations

Contributions

RJ, CAB: material preparation, data collection, early draft and analysis; RRS: study conception; KS: materials design; RRS and KS: study design, monitoring, data analysis, manuscript draft preparation, editing; GRR: Funding, study design, monitoring and final editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no relevant conflicts of interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jan, R., Biji, C.A., Shakeela, K. et al. Green Synthesis of Cyclic Carbonates from Epoxides and CO2 Using Transition Metal Substituted Polyoxometalate-PDDA Hybrid Catalysts. Catal Lett 154, 1631–1641 (2024). https://doi.org/10.1007/s10562-023-04392-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-023-04392-1