Abstract

The oxidation of CO on Pd(111) and Pd70Au30(111) has been studied under pressures upto 100 Torr. Gold is found to decrease the surface activity by inhibiting oxygen dissociation. For a sufficient conversion time depending on the CO coverage and the surface identity, a dramatic boost of activity occurs. This is ascribed to a switch from CO-induced inhibition of O2 adsorption to a regime determined by CO adsorption. The other kinetic features are explained by oxidation of palladium and adsorption-induced restructuring of the surfaces.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Platinum group metals are very efficient oxidation and hydrogenation catalysts. In particular, palladium is among the most active metals for CO oxidation. In addition to its scientific interest, this reaction is technologically important for car-exhaust emission control, CO2 lasers, air purification, sensors and fuel cells.

Although many works concern CO oxidation over supported Pd catalysts [1–3], single-crystal surfaces [4–6] and planar supported model catalysts [7–9] under low pressure conditions (< 10−2 Torr), very few experimental studies have been performed at pressures relevant to catalysis. To our knowledge, the sole exceptions to this are the studies of Goodman and coworkers. These authors have investigated CO oxidation over Pd(110) [10], Pd(100) [11] and Pd(111) [12] and compared these surfaces to Pd/SiO2/Mo(110) model catalysts [13] at pressures ranging from 10−9 to 10 Torr. In summary, CO oxidation on palladium proceeds through a Langmuir-Hinshelwood mechanism. CO adsorbs molecularly, possibly through a weakly bonded precursor state, and O2 dissociates before the CO + O reaction occurs. At moderate temperatures, CO covers the surface and inhibits O2 dissociation. Therefore, the reaction rate is determined by CO desorption. Furthermore, the reaction is only slightly structure-sensitive.

Pd–Au catalysts have recently been found superior to pure Pd or Au catalysts for several reactions, e.g., the direct synthesis of hydrogen peroxide [14] and the ethylene acetoxylation to vinyl acetate for the VAM process [15]. In our own attempt to modify the catalytic reactivity of palladium surfaces by gold, we have investigated the hydrogenation of 1,3-butadiene [16], the oxidation of hydrogen [17] and here the oxidation of CO over single-crystal surfaces of the Pd70Au30 bulk alloy. In the case of CO oxidation and following theoretical predictions [18], gold may decrease the CO–Pd adsorption strength due to Au–Pd alloying effects (ligand and/or ensemble effects). The weaker CO–Pd interaction may favor the adsorption of O2 and promote the oxidation of CO. Thus, the reaction may start at temperatures lower than the usual ones (∼200 °C), just like on supported gold-based catalysts, which are active below room temperature [19–21].

In this Letter, we present new kinetic results concerning CO oxidation on Pd(111), under elevated pressures (upto 100 Torr) and highly oxidative conditions. Besides, we compare the catalytic properties of Pd70Au30(111) to those of Pd(111).

Experimental

We used an experimental set-up that includes facilities for sample preparation and analysis under ultrahigh vacuum (UHV), along with catalytic testing in a static reactor. This stainless-steel low-volume (120 cm3) reactor is UHV-compatible and can operate at gas pressures up to the atmospheric pressure and at temperatures between 20 and 200 °C. This apparatus has been described in details in Ref. [16].

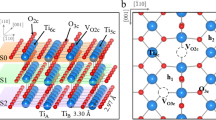

The Pd(111), Au(111) and Pd70Au30(111) samples (10 mm diameter, 1 mm thickness, 5 N purity, 0.1° miscut, 0.1 μm polishing) were cleaned by repeated cycles of Ar ion sputtering and annealing at 660, 440 and 460 °C, respectively. The surface quality was checked by Auger electron spectrometry (AES) and low energy electron diffraction (LEED). For all single-crystals, the indicators of surface cleanliness were the absence of carbon and sulfur contaminations and well-ordered LEED patterns. A fixed surface concentration (measured by the AES peak-to-peak intensity ratios: RAu/Pd = 0.4, considering the NVV transition at 73 eV for Au and the MNN transition at 332 eV for Pd) was necessary to achieve reproducible experiments over the alloy single-crystal. As reported in Ref. [16], the clean Pd70Au30(111) surface exhibits a (1 × 1) unreconstructed structure and a gold concentration of 75 ± 5 at % in the topmost atomic layer. The clean Pd(111) and Au(111) surfaces present a (1 × 1) structure and a herringbone-type (22 × √3) pattern, respectively.

After cleaning, the samples were transferred from the preparation chamber to the reactor. The pressure remained in the 10−9 Torr range during the transfers. Gas mixtures containing high-purity CO, O2 and Ar (neutral gas used for internal calibration) were introduced into the reactor. Then, the reactor content was sampled through a leak valve and analyzed with a quadrupole mass spectrometer. The stability of the catalytic surfaces was tested by performing repeated reaction cycles that included injection of the reactants, reaction, and evacuation of the reacted gases by turbomolecular pumping. After the experiments, the partial pressures of CO (pCO), O2 (pO_2) and CO2 (pCO_2) were calculated from the mass spectrometer data corrected for ion fragmentation and spectrometer sensitivity.

Results

In the investigated temperature range (T < 160 °C), the partial pressure ratios pCO/pO_2 were chosen according to Goodman and coworkers [10, 12] in order to optimize the CO2 formation rate and, therefore, obtain measurable kinetics. Au(111) is inactive whatever the temperature. In all the investigated pressure conditions, Pd and Pd–Au are inactive at room temperature; their activity increases with temperature.

Figure 1 shows the evolution of pCO and pCO_2 as a function of time during CO oxidation over Pd(111) and Pd–Au(111) at 150 °C, p 0CO = 0.1 Torr and p 0O_2 = 10 Torr (values of the partial pressures at t = 0). On both surfaces, the CO pressure decreases linearly (constant reaction rate, r1). Below a certain value of pCO, the rate suddenly increases to a constant rate r2. Pd–Au(111) is ∼4 times less active than Pd(111). Moreover, both r1 and r2 are lower for the alloy.

We performed several reaction cycles. The kinetics is roughly stable over Pd–Au (that is why only a single run is reported in figure 1). Conversely, the catalytic activity of Pd increases by a factor ∼2 from one cycle to the next but only two cycles are necessary to reach a "steady state". This boost in the CO oxidation activity concerns r1 and, to a smaller extent, r2.

Table 1 summarizes our results. We report the p thCO /p 0CO ratio (p thCO stands for the threshold CO pressure when the reaction accelerates and p 0CO is the initial CO pressure in the reactor) and the turnover frequency (TOF) of CO conversion, i.e. of CO2 formation.

On Pd(111), at 160 °C (p 0CO = 0.1 Torr and p 0O2 = 20 Torr) the reaction was so fast that we were not able to measure any rate. Under these conditions, the reaction must instantaneously reach the second kinetic regime, i.e. p thCO ≥ p 0CO . On the other hand, at 120°C (same pressure conditions) the reaction was quite slow (at least 100 min for total conversion). In this case, we observed a big boost (r2/r1 = 15) for p thCO /p 0CO = 0.4. Pd–Au(111) was inactive at 120 °C but became active at 150 °C. A slight boost (r2/r1 = 2) was observed for p thCO /p 0CO = 0.2. In all the cases, r2/r1 is lower on Pd–Au than on Pd.

Now let us analyze the effect of the total pressure for a given pCO/pO_2 ratio (Table 1). For pCO/pO2 = 0.01 (T = 150 °C) on the Pd(111) surface, the turnover frequencies, and obviously the r2/r1 ratios remain unchanged whatever the initial total pressure is. The turnover frequency is around 0.3 s−1 before the boost (TOF1) and 7–9 times greater after it (TOF2). Furthermore, p thCO /p 0CO decreases as both p 0CO and p 0O_2 increase. Conversely, on Pd–Au(111) both the TOF and the p thCO /p 0CO ratio vary with the total pressure (keeping pCO/pO_2 constant). Besides, the turnover frequency increases with p 0O_2 (at p 0CO fixed, 0.1 Torr), whereas p thCO /p 0CO decreases. At p 0O2 = 20 Torr, when p 0CO increases, the TOF and the p thCO /p 0CO ratio slightly decrease.

Figure 2 plots p thCO as a function of p 0CO (p 0O2 = 20 Torr, T = 160 °C) for Pd and Pd–Au. The threshold CO pressure increases with the initial CO pressure on both surfaces. In addition, as will be discussed below, p thCO is lower for Pd–Au(111) than for Pd(111).

CO threshold pressure p thCO (CO pressure remaining in the reactor at the time of the boost) as a function of the initial CO pressure p 0CO for CO oxidation on Pd(111) (black squares) and Pd–Au(111) (blue triangles). p 0O_2 = 20 Torr, T = 160 °C (steady state). The slope of the black line is 0.13±0.01.

We also studied the influence of the CO pressure (at a given initial oxygen pressure) on the reaction rate. In figure 3, we report the turnover frequencies as a function of the CO pressure (TOF1 as a function of p 0CO and TOF2 as a function of p thCO ). In the case of Pd(111), TOF1 is almost independent of pCO, whereas TOF2 increases with pCO. On the other hand, both TOF1 and TOF2 decrease slightly as a function of pCO in the case of Pd–Au(111).

Turnover frequency of the first reaction regime (TOF1) as a function of the CO initial pressure p 0CO (open symbols) and turnover frequency of the second reaction regime (TOF2) as a function of the CO threshold pressure p thCO (full symbols), for CO oxidation on Pd(111) (black squares) and Pd–Au(111) (blue triangles). p 0O2 = 20 Torr, T = 160 °C (steady state).

Discussion

The conversion of CO to CO2 follows the same behavior on Pd(111) and Pd70Au30(111): pCO(t) decreases (rate r1) until it reaches a threshold pressure (p thCO ); then, the reaction accelerates (rate r2). In the pressure and temperature ranges studied, CO is the most abundant species on the surface during the first kinetic regime. Thus, O2 can hardly find free sites to dissociate. However, the probability of O2 dissociation is not zero, so the initial reaction rate r1 is non-zero (see figure 1).

In addition, r1 is roughly independent of p 0CO on Pd (figure 3). This means that this first kinetic regime is intermediate between that where CO desorption is rate-limiting (negative CO order) and that where CO adsorption is rate-limiting (positive CO order) [3, 4, 12]. When the CO coverage reaches a critical value, there is a sudden reaction light-off (see Ref. [6] for the determination of such a critical coverage on Pd(110)). At this moment, the reaction switches to a second kinetic regime controlled by the supply of CO. Furthermore, provided pCO/pO_2 is constant, the absolute rates (r1 and r2) do not depend on the partial pressures in the case of Pd (Table 1). This agrees with the proposed mechanism of CO-induced blocking of oxygen adsorption. Let us notice that this activity change does not seem to be due to exothermicity-induced CO desorption, as this would lead to an exponential increase of the reaction rate.

The addition of gold decreases the activity of Pd, i.e. both reaction rates (r1 and r2) are lower on Pd–Au(111) than on Pd(111). The ratio between r2(Pd) and r2(Pd–Au) (included in the 3–5 range, see Table 1) matches the ratio between the number of surface Pd atoms on Pd(111) and the one on the alloy (the Pd coverage in the top layer of Pd70Au30(111) is 0.25 [16]). Moreover, the CO threshold pressure (p thCO ) is higher on Pd than on Pd–Au. We believe that this originates from a blocking effect of gold: the presence of Au decreases the probability of O2 dissociation. As fewer adsorption sites are available on Pd–Au than on Pd, CO desorption is rate-limiting at lower CO pressures on the former surface. Consistently, the reaction rate on Pd–Au decreases as pCO increases or as pO_2 decreases in the pressure range investigated here (figure 3 and Table 1). The same blocking effect has previously been observed for Au deposits on Pt surfaces [22, 23]. It may also explain the lower activity of Pd–Au/SiO2 catalysts in CO oxidation with respect to Pd/SiO2 [24].

We observe another important difference between Pd and Pd–Au. After reaction on the fresh surface, a second reaction run gives rise to an increase of the CO2 production rate on Pd(111), whereas it has no significant effect on Pd70Au30(111). We ascribe this activation of Pd to the formation of a palladium oxide during the second regime of the first run (i.e. after the reaction light-off, when oxygen becomes the most abundant adspecies). The elevated oxygen pressures (above 10 Torr) favor oxide formation [25]. The Pd–O surfaces with rough structures [26, 27] exhibit higher activities than Pd surfaces due to the instability of the oxide (Mars-Van Krevelen mechanism) [27, 28]. Pd–Au(111) is less sensitive to oxidation than Pd(111).

Note that under our mild temperature conditions this palladium oxide phase is more probably a two-dimensional oxide than stoichiometric bulk PdO [29]. As such a surface oxide is unstable under UHV [30] and electron beams [31], in situ analysis by suitable techniques is required to check our hypothesis.

Finally, we ascribe the increase of the threshold CO pressure (p thCO ) with the initial CO pressure (p OCO ) (Figure 2) to CO-induced restructuring during the first reaction regime (where CO almost fully covers the surface). This pressure-dependent surface modification must increase the number of active sites and/or give rise to sites of increased activity (low-coordinated sites), as has been previously observed on Au(111) under elevated CO pressures [32].

Summary

The oxidation of carbon monoxide has been studied in static mode over Pd(111), Au(111) and Pd70Au30(111) at temperatures below 160 °C, for total pressures in the 10–100 Torr range and a large O2 excess. While no activity of the gold surface has been detected, Pd–Au(111) has been found to be less active than Pd(111) for CO oxidation.

On both surfaces, a sudden acceleration of the reaction rate occurs for a CO partial pressure threshold that depends on the surface, the partial pressures and the temperature. First, CO covers most of the surface, hampering oxygen adsorption. A reaction light-off occurs when the CO coverage becomes lower than a critical value, leading to a second kinetic regime which rate is limited by CO adsorption.

An increase in the reaction rate has also been observed upon evacuation of the reacted gases and introduction of a fresh reactant mixture in the sole case of Pd(111). The different behaviors of Pd and Pd–Au surfaces are ascribed to a gold-induced inhibition of O2 adsorption and to the onset of a Mars-van Krevelen mechanism for CO oxidation upon palladium oxide formation.

References

Xu X., Goodman D.W. (1993) J. Phys. Chem. 97:7711

Ogrinc N., Kobal I., Senegacnik M. (1997) J. Phys. Chem. A 101:7236

Fuchs S., Hahn T., Lintz H.G. (1994) Chem. Eng. Processing 33:363

Engel T., Ertl G. (1978) J. Chem. Phys. 69:1267

Watanabe K., Ohnuma H., Kimpara H., Uetsuka H., Kunimori K. (1998) Surf. Sci. 402–404:100

Jones I.Z., Bennett R.A., Bowker M. (1999) Surf. Sci. 439:235

Ladas S., Poppa H., Boudart M. (1981) Surf. Sci. 102:151

Piccolo L., Becker C., Henry C.R. (2000) Appl. Surf. Sci. 164:156

Libuda J., Meusel I., Hoffmann J., Hartmann J., Piccolo L., Henry C.R., Freund H.J. (2001) J. Chem. Phys. 114:4669

Berlowitz P.J., Peden C.H.F., Goodman D.W. (1988) J. Phys. Chem. 92:5213

Szanyi J., Goodman D.W. (1994) J. Phys. Chem. 98:2972

Szanyi J., Kuhn W.K., Goodman D.W. (1994) J. Phys. Chem. 98:2978

Xu X., Szanyi J., Xu Q., Goodman D.W. (1994) Catal. Today 21:57

P. Landon, P.J. Collier, A.J. Papworth, C.J. Kiely and G.J. Hutchings, Chem. Commun. (2002) 2058.

Chen M., Kumar D., Yi C.-W., Goodman D.W. (2005) Science 310:291

Piccolo L., Piednoir A., Bertolini J.C. (2005) Surf. Sci. 592:169

Piccolo L., Piednoir A., Bertolini J.C. (2006) Surf. Sci. 600:4211

Liu P., Norskov J.K. (2001) Phys. Chem. Chem. Phys. 3:3814

Bond G.C., Thompson D.T. (2000) Gold. Bull. 33:41

Haruta M. (2004) Gold. Bull. 37:27

Azar M., Caps V., Morfin F., Rousset J.L., Piednoir A., Bertolini J.C., Piccolo L. (2006) J. Catal. 239:307

Asakura K., Lauterbach J., Rotermund H.H., Ertl G. (1997) Surf. Sci. 374:125

Skelton D.C., Tobin R.G., Lambert D.K., DiMaggio C.L., Fisher G.B. (1999) . J. Phys. Chem. B 103:964

Venezia A.M., Liotta L.F., Pantaleo G., La Parola V., Deganello G., Beck A., Koppany Z., Frey K., Horvath D., Guczi L. (2003) Appl. Catal. A251:359

Ketteler G., Ogletree F., Bluhm H., Liu H., Hebenstreit E.L.D., Salmeron M. (2005) J. Am. Chem. Soc. 127:18269

Han J., Zemlyanov D.Y., Ribeiro F.H. (2006) Surf. Sci. 600:2730

Hendriksen B.L.M., Bobaru S.C., Frenken J.W.M. (2004) Surf. Sci. 552:229

Gong X.Q., Liu Z.P., Raval R., Hu P. (2004) J. Am. Chem. Soc. 126:8

Leisenberger F.P., Koller G., Sock M., Surnev S., Ramsey M.G., Netzer F.P., Klötzer B., Hayek K. (2000) Surf. Sci. 445:380

Han J., Zemlyanov D.Y., Ribeiro F.H. (2006) Surf. Sci. 600:2752

Voogt E.H., Mens A.J.M., Gijzeman O.L.J., Geus J.W. (1997) Surf. Sci. 373:210

Piccolo L., Loffreda D., Cadete Santos Aires F.J., Deranlot C., Jugnet Y., Sautet P., Bertolini J.C. (2004) Surf. Sci. 566–568:995

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Piednoir, A., Languille, M.A., Piccolo, L. et al. Pd(111) versus Pd–Au(111) in carbon monoxide oxidation under elevated pressures. Catal Lett 114, 110–114 (2007). https://doi.org/10.1007/s10562-007-9047-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-007-9047-3