Sulfur compounds are formed during the oxidation of motor oil under the influence of high temperatures, and it is quite difficult to determine the residual content of an active additive. To determine the DF-11 additive the M-10G2k oil was oxidized in a thermostat. It was established that with oxidation times of 8 and 10 hours it is only possible to determine the amount of mercaptan sulfur from the potentiometric titration curve. An algorithm and some methods of determination that make it possible to predict the wear and service life of lubricating oil are proposed for complete determination of sulfur-containing compounds in oxidized oil under working conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

As known motor oils contain a whole set of cleaning and dispersing, antioxidant, antifriction, and other additives that help to reduce the wear of engine components and affect to some degree the service life of the oil. Among the list of additives added to motor oils a special place is occupied by the DF-11 additive, which improves the antioxidant and antiwear properties of lubricating oil [1]

During the operation of an internal combustion engine practically all the additives work together, and it is quite a difficult task to determine the residual content of a specific additive [2-15]. Being oxidized, the DF-11 additive forms mercaptans, sulfides, and disulfides [1, 6]. During high-temperature oxidation of motor oil the DF-11 additive forms sulfur compounds that differ in type of interaction with AgNO3 [6].

In order to establish the possibility of determining the DF-11 additive in used oils samples of M-10G2k oil were oxidized at 90 ±2, 130±2, and 150 ± 2°C by thermal aging in a thermostat.

The table shows the concentrations of DF-11 additive and the alkali and acid numbers of M-10G2-k oil that had been submitted to thermal aging at 90, 130 and 150°C.

As shown by the results of physicochemical analysis at 90°C, for 95 h the motor oil is hardly oxidized at all.

In the case of thermal aging at 130°C there is some dissociation of the DF-11 additive into simpler chemical compounds with no reduction of its oxidizing activity. With increase of the oxidation time the alkali numbers decrease, and the acid numbers increase. The initial oxidation—reduction potential of solutions of oil in the acidic anhydrous solvent lies in the region of 245-265 mV.

At 150°C significant oxidation of the M-10G2 oil and destruction of the DF-11 additive are observed (Fig 1, table).

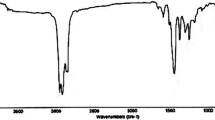

Figure 1 shows the curves for potentiometric titration of the DF-11 additive with silver nitrate in the presence of a silver-sulfide indicator electrode and a glass reference electrode in fresh unused oil that had been oxidized at 150°C for 30, 60, and 120 min.

The nature of the relationships indicates insignificant changes in the oil after oxidation for 0-120 min. After further oxidation the DF-11 additive decomposes with the formation of mercaptans. The initial oxidation—reduction potential increases from 240-260 min (in the fresh oil) to 470-500 mV.

For oxidation times of 3-4 h the potentiometric titration curves contain two potential jumps at the equivalent titration points for sulfides and mercaptans. At oxidation times of 8 and 10 h it is only possible to determine the amount of mercaptan sulfur from the titration curves, and the amount of sulfides (the amount of DF-11 additive) is evidently very small.

When the oxidation time is increased from 0.5 to 10 h the alkalinity decreases and the acidity increases (table).

Thus, when the motor oils are heated the unstable sulfur-containing DF-11 additive decomposes even at 150°C with the release of thiols and sulfides. The released sulfur compounds have high chemical activity and react with nearly all the chemical compounds and elements and also with each other. Thus, for example, free sulfur reacts with thiols with the formation of disulfides and sulfides.

The large amount of various sulfur compounds in the used oil complicates their identification considerably. It is possible to use the following algorithm to determine all the sulfur-containing compounds in the oxidized oil (Fig. 2).

As known, the sulfur compounds released from the complex of the DF-11 additive as a result of its decomposition react with ammonium molybdate in an acidic medium to form molybdenum blue (MoV and MoIV), e.g., by the reaction on which determination of the decomposition products of antioxidant additive RF-11 as a result of aging of motor fuel is based:

To determine the content of free sulfides in the oil 1 g of the oil is dissolved in 5 ml of solvent containing 30% of ethanol and 70% of toluene, and 5 ml of a nitric acid solution of (NH4)2MoO4 is added. The solution of (NH4)2MoO4 is prepared in the following way. A 1-g portion of (NH4)2Mo04, 1.5 ml of concentrated nitric acid, and 50 ml of distilled water are added to a 100-ml measuring flask, thoroughly stirred until completely dissolved, and made up to the mark with distilled water. If a precipitate separates as a result of prolonged storage the solution must be prepared anew.

The color of the molybdenum blue solution increases for 30 min. The optical density is then measured at wavelength 670 nm with cuvette thickness of 0.1 cm.

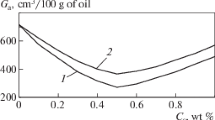

Figure 3 shows the dependence of the optical density of the solutions of M-10G2k oil on the length of oxidation at 150°C at wavelength 670 nm and solution layer thickness 0.1 cm.

When the oxidation time is increased to 8 h there is a proportionate increase in the optical density of the solutions, but as a result of the fact that the DF-11 additive has all been destroyed it does not then increase further, i.e., the concentration of the sulfur compounds does not change,.

Figure 4 shows the dependence of the optical density of the solutions on the oxidation time of the M-19G2k oil at 130°C. This relationship is linear in character (obeys the Bouguer—Lambert-Beer law), which indicates that continuous dissociation of the DF-11 into simpler chemical compounds without total destruction is observed at oxidation times of up to 85 h.

The proposed methods of measuring the residual content of DF-11 additive in motor oils make it possible to establish with some degree of reliability the state of oil operating in the engine before its replacement, to predict the wear processes that occur in the engine, and to reduce the operating, maintenance, and lubricant costs.

References

A. A. Bratkov, Theoretical Principles of Chemmotology [in Russian], Khimiya, Moscow (1985), 320 pp.

A. Gureev, Khimiya i Tekhnologii Topliv i Masel, No. 5,18-22 (1982).

O. I. Pugacheva, V. M. Pugachev, Khimiya i Tekhnologii Topliv i Masel, No. 6,52-56 (2014).

J. M. Bergthorson, M. J. Thomson, Renewable and Sustainable Energy Reviews, 42, 1393-1417 (2015).

F. C. A. Killer, Mineraloiltechnic, 5, 1-17 (1980).

V. V. Ostrikov, L. V. Kashnikova, Khimiya i Tekhnologii Topliv i Masel, No. 2,47-48 (2001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimiya i Tekhnologiya Topliv i Mosel, No. 2, pp. 17 — 19, March — April, 2019.

Rights and permissions

About this article

Cite this article

Ostrikov, V.V., Sazonov, S.N., Orobinskii, V.I. et al. Determination of Antioxidant Additive and its Decomposition Products in Working Motor Fuels. Chem Technol Fuels Oils 55, 145–150 (2019). https://doi.org/10.1007/s10553-019-01014-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10553-019-01014-8