This article gives a brief description of a procedure for designing a noise-controlled area, using a simulated plant as an example. It also analyzes the results of calculation of on-site noise pollution within the noise-controlled area from simulated and real oil refineries and their individual units.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

The research being discussed in this article was performed in accordance with the requirements of regulation SanPiN 2.2.1/2.1.1.1200–03, “Noise-Controlled Areas and Noise Classification of Factories, Installations, and Other Objects.” The methodology and assumptions that were used were substantiated earlier [1,2]. The method consists of two parts: taking an inventory of sources of noise; calculating the level of sound pressure at a chosen point in a designated test area of rectangular form.

As part of the inventory process, the territory occupied by the refinery or plant in question is subdivided into rectangles based on the locations of the thoroughfares. The coordinates of the center of each rectangle are determined in accordance with the plant’s general plan. The center is then used as a intermediate acoustic center.

The existing noise sources in each rectangle are determined along with their characteristics: sound pressure or acoustic power (based on equipment catalogs or data sheets) and the nature of the given source (single or group, the presence of barriers). In the case of group sources (pump systems, industrial furnaces, multi-section cooling towers, air condensers, etc.) the total acoustic power is calculated and the noise source itself is henceforth regarded as a single source. For barriers, we determine the material and thickness of the walls and the area of any openings in the barrier (embrasures and viewing windows in industrial furnaces, open vents and doors in pump buildings).

The equations and methods in the regulations [3,4] and the handbook [5] are used for the initial analysis of the data that is collected. Since the noise characteristics of sources are expressed in different units of measurements in equipment catalogs and data sheets (equivalent acoustic power or sound pressure in dBA, octave bands of acoustic power or sound pressure in dB), all of the citations need to be converted to the acoustic power of the source and, if necessary, expanded into octave bands.

The relationship between sound pressure and acoustic power is determined by Eqs. (11) and (12) in SNiP 23-03–03 [3] as a function of the temperature of the source: Eq. (1) for a point source and Eq. (2) for an extended source:

where L Pi is the sound-pressure level at the test point, dB; L wi is the level of the acoustic power of the source, dB; r is a distance, m (and is chosen in accordance with the corresponding GOST standard that establishes the rules for measurement of the noise generated by a specific type of equipment); Φ is the coefficient that characterizes the directionality of the noise source (Φ = 1 for uniformly radiating sources); β is the noise attenuation factor in the atmosphere (the value of this factor is found from Table 5 in [3]); Ω is the solid angle of radiation of the source, radians (the value of this angle is found from Table 3 in [3]).

If necessary, the following equation is used to take a noise characteristic that is expressed in dBA and convert it to the acoustic-power level of the source in octave bands in accordance with the method in [5]:

where L Wi is the octave acoustic power at geometric-mean frequencies from 63 to 8000 Hz, dB; L WA is the corrected level of acoustic power, dBA; ΔL Ai is a coefficient whose value depends on the indices of the band (the value of the coefficient is found from Table 16.5 in [5]).

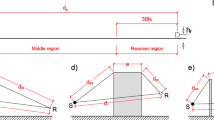

When structures that serve as a barrier to a source of noise (the lining of industrial furnaces, buildings that house pumps, noise shields, etc.) are present, a calculation is performed to determine the noise attenuation R w on the outside of the barrier. The calculation is performed using the graphical method presented in SNiP 23-103–03 [4]. As an example, Fig. 1 shows the result obtained from calculating the attenuation of noise by the brick wall of a pump room.

The effect of openings in a barrier is accounted for by means of the relation [4]:

where R WOi is the noise attenuation (in octave bands, dB) by a barrier with allowance for its openings; R Wi is the noise attenuation by the barrier (in octave bands, dB); S 0 is the area of the openings, m2; S 1 is the area of the radiating wall, m2.

Equation 16.14 in [5] is used to convert the results obtained from the initial analysis of the noise characteristics of each source into the equivalent value of acoustic power level L WA corrected in accordance with the noise characteristic A of the noise meter. The new quantity L WA is then itself converted into sound-pressure level L P at the intermediate acoustic center. The formulas used to perform these two conversions are as follows:

where Δi is the relative frequency characteristic A of the noise meter (the value of this characteristic is determined in accordance with the standard GOST 17187–81 [6]; r is the distance from the source of the noise to the intermediate acoustic center, m.

The sound pressure created at the intermediate acoustic center by road-building equipment is calculated in accordance with the data in [7]. The degree of attenuation of the noise is then calculated in accordance with the above-indicated formula from SNiP 23-03–03 [3].

The sound pressure L Aeqv created at the intermediate acoustic center by traffic flows (roads, railroad spurs) is calculated using Eq. (11) in [8] and Eq. (4) in [9]:

where N is traffic intensity (during the night or day), units/h; V is average velocity, km/h; \( \varDelta {L_{{{A_6}}}} \) is a correction that accounts for the railroad tracks (\( \varDelta {L_{{{A_6}}}} \) = +2 dBA for tracks with jointed rails on pre-stressed concrete ties, \( \varDelta {L_{{{A_6}}}} \) = 0 for tracks with jointed rails on wood ties and continuously welded rails on pre-stressed concrete ties, and \( \varDelta {L_{{{A_6}}}} \) = – 2 dBA for tracks with continuously welded rails on wood ties); \( \varDelta {L_{{{A_7}}}} \) = 101g(l av/l plan) is a correction for the actual length of the train, dBA (l av is the average train length, m; L plan = - 1200 m).

where \( \varDelta {L_{{{A_{dist }}}}} \) is the decrease in noise level in relation to the distance between the noise source and the test point (determined from the nomogram in [9]); \( \varDelta {L_{{{A_{ctg }}}}} \) is the decrease in noise level in relation to the nature of the coating, dBA [9]; \( \varDelta {L_{{{A_{air }}}}} \) is the decrease in noise level due to absorption in air, dBA (determined from the nomogram in [9]); \( \varDelta {L_{{{A_{veg }}}}} \) = 0.08l veg is the decrease in noise level due to the thickness I veg (m) of the planted vegetation, dBA; \( \varDelta {L_{{{A_{{\alpha i}}}}}} \) is the decrease in noise level in relation to the field of view α (determined in accordance with [9]).

The acoustic power of the sound created by road-building equipment and traffic flows at the intermediate acoustic center can be expanded at the center (in octave bands) by the method in [5]. In this case, the character of the noise spectrum from road-building equipment is determined from the data in [9].

Microsoft Excel is used to calculate the contribution L PPTi of each noise source at an arbitrary point of the test triangle with allowance for Eq. (4) in [10]:

where A DIV = 201gr + 11 is the attenuation of the sound due to geometric divergence; A ATM = βr/1000 is sound absorption by the atmosphere (the value of β is found from Table 2 in [10]; A PB = αr 1 is the absorption of the sound as it propagates over the grounds of the plant (the value of α is found from Table A2 in [10]; r = [(X I – X TP)2 + (Y I Y TP )2]0.5 is the distance from the intermediate acoustic center to the test point, m; r 1 = r(X PB – X I)/(X TP – X I) is the distance from the intermediate acoustic center to the plant boundary, m; X I, X TP, X PB, Y I, and Y PB, respectively, are the coordinates of the intermediate acoustic center (subscript “I”), the test point (subscript “TP”), and the plant boundary (subscript “PB”), m.

Total sound pressure at each test point is calculated from Eq. (10) in [3]:

The resulting data is used to construct isolines depicting noise pollution of the atmosphere above a given test rectangle.

The grounds of a simulated plant that was used in this study included 11 single and group sources of noise. The characteristics of these sources are shown in Table 1.

Figure 2 shows the results obtained from calculation of the acoustic field within an arbitrarily chosen test rectangle. The mesh size of the grid is 500 m along both axes.

Negative values of the logarithmic quantities have a physical meaning and indicate that the level of sound pressure is below the audibility threshold (2 · 10-5 Pa). Table 2 shows the results obtained by converting sound pressure from dBA into absolute pressure P by means of the formula L P = 20lg[P/(2 · 10-5)].

The above-described method was used to calculate the level of sound pressure at the boundary of a noise-controlled area (NCA). The calculations were performed for eight oil refineries. The results of the calculations (Table 3) have been federally approved for use in planning documents.

The method described above makes it possible to evaluate noise pollution of the atmosphere at the boundary of the NCA of oil refineries and petrochemical plants. The main types of equipment used at these facilities are accounted for in the method. The absolute error of the calculations is no greater than ±2 dB, which is acceptable for NCA evaluations.

References

V. I. Glazunov, A. B. Magid, and E. R. Akhmadieva, Khim. Tekh. Topliv. Masel, No. 2, 14-16 (2011).

V. I. Glazunov, A. B. Magid, and E. R. Akhmadieva, Ibid., No. 1, 50-52 (2013).

SNiP 23-03–03. Protection from Noise. Gosstroi RF, Moscow (2004).

SN 23-103–03. Design of the Acoustic Insulation of Sound Barriers for Residential and Public Buildings. Gosstroi RF, Moscow (2004).

G. L. Osipov, Acoustic Insulation and Sound Absorption [in Russian], AST Astrel’, Moscow (2004).

GOST 17187–81. Noise Meters. General Technical Requirements and Test Methods. Gosstandart SSSR, Moscow (1981).

N. I. Ivanov, Engineering Acoustics [in Russian], Logos, Moscow (2008), pp. 324-325.

Guide to MGSN 2.04–97. Design of Equipment to Protect Residential and Public Buildings from Traffic Noise and Vibration. Moskomarkhitektura, Moscow (1999).

G. L. Osipov, Noise Protection in Town Planning and Building. Handbook for Planners [in Russian], Stroiizdat, Moscow (1993).

GOST 31295–05, Part 2. Noise Attenuation during Local Propagation [in Russian], Rostekhregulirovanie, Moscow (2006).

Author information

Authors and Affiliations

Additional information

Translated from Khimiya i Tekhnologiya Topliv i Masel, No. 5, pp. 53 – 56, September – October, 2013.

Rights and permissions

About this article

Cite this article

Glazunov, V.I., Magid, A.B. & Akhmadieva, E.R. Procedure for Designing a Noise-Controlled Area for Petrochemical Plants. Chem Technol Fuels Oils 49, 451–457 (2013). https://doi.org/10.1007/s10553-013-0469-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10553-013-0469-x