Abstract

Recombinant human erythropoietin is a valuable therapeutic protein used in the treatment of several serious diseases. It exists in different isoforms and is produced by genetically modified mammalian cells such as Chinese hamster ovary or human embryonic kidney cells. As for other biopharmaceutical drugs, a key factor for its successful industrial production is to achieve a high degree of purity and to decrease the content of critical impurities to trace amounts. This goal is achieved in the separation sequence which substantial part is formed by chromatographic steps. Therefore, downstream processing forms an essential part of production costs. This review presents the overview of published separation sequences and, analyzes the use of different types of chromatographic media such as affinity, ion-exchange, reversed-phase, hydrophobic interaction, multimodal, and size-exclusion chromatography adsorbents. Their application is discussed with regard to their place in the purification stages generally denoted as capture, intermediate purification and polishing.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Erythropoietin (EPO) is a human hormone that regulates the production of red blood cells in order to meet tissue oxygen demands. Recombinant human erythropoietin (rhEPO) is a therapeutic biotechnologically produced protein which entered the market in 1989. It is used in the treatment of secondary anemia arising from the disorder of natural EPO production in patients with chronic kidney disease, AIDS or cancer.

The high market potential of rhEPO and the expiration of the patents protecting the production of original rhEPO-α and rhEPO-β are two essential factors for more than 700 similar products being currently either in the process of development or on the market (Epstein et al. 2014). This high competition naturally forces companies to reduce production costs. Cultivation-associated costs can be reduced by breeding a new cell line that can provide a higher bioreactor productivity and/or higher rhEPO concentration. Subsequent separation steps are optimized either through the development of new chromatographic adsorbents with better performance or through better design of individual steps in the separation train.

Erythropoietin purification steps utilize not only more common chromatographic adsorbent types such as ion-exchange, size-exclusion, hydrophobic, or reverse-phase but also affinity and immunoaffinity chromatography adsorbents. Affinity/immunoaffinity chromatography can reduce the number of separation steps due to the high selectivity of the adsorbents. On the other hand, the affinity adsorbents are substantially more expensive. This review article analyzes the existing knowledge that could assist in finding the relationship between the suitable purification technology and the rhEPO structure and physicochemical properties. An overview of chromatographic steps applied in the separation of rhEPO mainly on the laboratory scale is presented. These steps are discussed in regard to the state-of-the-art and future trends in the field of therapeutic protein purification.

rhEPO structure and biological production

EPO belongs to glycoproteins. Its molecule is formed by a polypeptide chain containing 165 amino acids and four carbohydrate chains bound to the polypeptide chain (Fig. 1). Glycosides represent about 40% of the total weight of EPO. A substantial part of the carbohydrate chains is formed by sialic acid. EPO is a conglomerate of isoforms differing in the structure of carbohydrate chains, which have isoelectric point in the range from 4.4 to 5.2 (Schmidt et al. 2003). The average molecular weight of EPO is 30,400 g/mol (Jelkmann 2007). The carbohydrate chains affect the glycoprotein conformation, and thus determine the intracellular transport and protein secretion, its solubility, sensitivity to proteases, in vivo activity as well as the affinity to receptors (Dordal et al. 1985; Wasley et al. 1991; Yamaguchi et al. 1991).

EPO structure. Reproduced with permission from Wang et al. (2012). Copyright by John Wiley and Sons

The road to the production of rhEPO was opened after the EPO amino acid sequence was determined (Lai et al. 1986) and gene coding rhEPO formation was successfully cloned (Jacobs et al. 1985; Lin et al. 1985). Today’s rhEPO preparations are produced exclusively using mammalian host cells. Microbial host cells cannot guarantee the required carbohydrate chain structure essential for rhEPO biological activity; yeast and fungi do not provide suitable glycosylation pattern and bacteria can be used only for the production of non-glycosylated recombinant proteins (Jelkmann 2007).

rhEPO can, in principle, be formed in any mammalian cell after the insertion of the appropriate gene; their glycan structure and therewith also in vivo activity will differ in some extent (Yuen et al. 2003). The most commonly used cell lines include Chinese hamster ovary (CHO) cells, baby hamster kidney (BHK) cells and human cell lines. CHO cells are, in general, the most important host cells for the production of biopharmaceuticals. Other mammalian cells successfully employed for rhEPO production for clinical purposes include African green monkey kidney cells (Delome et al. 1992), canine kidney cells (Kitagawa et al. 1994), murine fibroblasts (Terashima et al. 1994) or mouse mammary cells (Hayakawa et al. 1992).

These rhEPO preparations differ from the endogenous EPO mainly in the glycan structure and biophysical properties (Storring et al. 1996; Storring and Gaines Das 1992; Wide and Bengtsson 1990). The first clinically used products were epoetin-α and epoetin-β obtained using CHO epithelial cells. The term epoetin characterizes the rhEPO form with its peptide core identical to that of the endogenous EPO. The Greek letter distinguishes isoforms with different glycosylation. Epoetin-α is more homogeneous and contains less basic isoforms than epoetin-β, but it is less glycosylated overall (Storring et al. 1998). Epoetin-β exhibits higher specific in vivo activity than epoetin-α (Storring et al. 1998). Epoetin-ω is produced by BHK fibroblastoid cells (Nimtz et al. 1995; Skibeli et al. 2001). Another rhEPO is epoetin-δ which is a gene-activated product of human HT-1080 cells (Kwan and Pratt 2007). CHO cells have also been employed in the production of darbepoetin-α, which has also modifications in the intrinsic polypeptide chain (Egrie and Browne 2001).

rhEPO purification technologies

Cultivation of mammalian cells in the production of rhEPO in the pharmaceutical industry creates new challenges for its production and purification in active form. Proteins intended for therapeutic purposes must meet the high requirements declared in the European Pharmacopoeia. It is important that purified rhEPO preparation keeps high in vivo activity and does not contain substances that could endanger human health. In general, critical contaminants are viral particles, bacterial endotoxins, proteins, nucleic acids and toxic medium components. Many of these contaminants often occur in minute amounts but can cause an undesirable response of the immune system. Some host-cell proteins have similar size, charge, polarity or solubility as rhEPO. Another problem is the presence of natural proteases of the host cell that destroy the active protein form. Inactive rhEPO isoforms add another degree of difficulty to the purification procedure. The effectiveness of each phase of the purification process to remove or inactivate the contaminants has to be validated. rhEPO purification is therefore complicated and represents a significant part of the manufacturing cost.

The development of first industrial rhEPO separation processes was built on the experience from the purification of endogenous EPO from urine from patients with aplastic anemia which has a higher EPO content than urine of healthy persons. Of course, the objective of the endogenous EPO separation was not to produce a drug but to obtain a sufficiently pure EPO sample suitable for the investigation of structure and basic properties of this hormone.

Miyake et al. (1977) described a seven-step separation method with a total EPO yield of 21%, which included ion-exchange, size-exclusion, and multimodal hydroxyapatite chromatography. The isolated and purified EPO fraction had an in vitro activity of 70,400 U per mg of protein, which represented a purification factor of 740. In order to increase the EPO yield, several authors utilized the affinity interaction of EPO either with lectins (Krystal et al. 1986; Lee-Huang 1986; Yanagi et al. 1987) or with EPO antibody (Lee-Huang 1986; Miyazaki et al. 1988; Wojchowski et al. 1987; Yanagawa et al. 1984). Using an immunoaffinity adsorbent with murine hybridoma monoclonal antibody, (Yanagawa et al. 1984a; Yanagawa et al. 1984b) reduced the number of separation steps to two and achieved the yield of 63% and high EPO specific activity of 81,600 U/mg.

A key factor in the development of the rhEPO purification steps is the need to scale up the processes from laboratory to large industrial dimensions. This requirement is best reflected in the numerous patents on this subject. Among journal publications on rhEPO purification, three works have emerged presenting a technology viable at a large scale (Hu et al. 2004; Surabattula et al. 2011; Zanette et al. 2003). Industry-friendly technology must not use any hazardous organic solvents. All chromatographic media must withstand many separation and sanitation cycles. It is necessary to reduce the elution risk of biological components, such as antibodies, lectins or peptides, into the environment.

Figure 2 presents a generic scheme of the rhEPO purification steps sequence. Since rhEPO is an extracellular protein, the cultivation broth is first processed in cell-removal equipment. The filtrate is further treated by membrane processes which typically include microfiltration, ultrafiltration, and diafiltration. These steps remove microbial contaminants, larger biological macromolecules and low-molecular compounds and concentrate the protein fraction containing rhEPO. This desalted protein solution enters a sequence of chromatographic separations which can be classified as capture, intermediate purification and polishing steps. The sequence of chromatographic steps is often followed by the membrane nanofiltration process to ensure safe removal of viruses.

Chromatographic purification processes

Figure 2 shows that some types of chromatographic media are associated with several purification phases while other ones are associated only with one purification phase. For example, anion-exchange chromatography can be found in any of these phases. On the other hand, size-exclusion chromatography is applied only in the polishing phase. This limitation of size-exclusion chromatography follows from that the protein capacity factors (the equilibrium amount in the solid phase to the amount in the liquid phase) are always lower than one. Consequently, column loading is much lower than in other types of chromatography. A detailed overview of published rhEPO purification procedures is presented in Table 1. Except for some earlier works, rhEPO was produced exclusively by CHO cells. However, many patents make broader claims where the cell line source of rhEPO is concerned (Lukowsky and Painter 1972; Takeuchi et al. 1990). Some performance characteristics such as yield and available specific activity of rhEPO streams are also provided in Table 1. They are however often not disclosed in the patents, which have been the prevailing references on rhEPO purification in the recent period.

No chromatographic adsorbent provides such selectivity to purify rhEPO in a single step (Fig. 2 and Table 1). Nonetheless, Amadeo et al. (Amadeo et al. 2003) used a single step lectin affinity chromatography process optimized by the design of experiments method and achieved a product with only 72% purity albeit in a high yield of 89%. A sequence of 2–4 steps was required to provide a product with the purity of above 90%. Table 1 however documents that at least 99% purity is the declared standard. Naturally, the higher the purity, the higher the number of chromatographic steps and the lower rhEPO yield.

The highest yield reported for 99% purity was 30% and it was achieved in four steps (Carcagno et al. 2006). A similar efficiency was obtained in a five-step procedure where the yield of 25% was observed (Burg et al. 2002). On the other hand, a three-step procedure provided the required purity on the expense of higher rhEPO loss (Koh et al. 2014). The yield was only 18%. It is important that, in spite of the complexity of rhEPO separation, none of the studies examined the optimization of the separation sequence or screening of adsorbents in the individual steps.

Figure 2 classifies the chromatographic processes used in the rhEPO separation as capture, intermediate purification and polishing steps. The objective of the capture step is to concentrate rhEPO by removing easily separable proteins. Purity of the product stream in the capture step is about 50% (Burg et al. 2002; Koh et al. 2014). Most remaining proteins are removed in the intermediate steps where the purity of 99% can be achieved (Burg et al. 2002). Polishing steps thus serve either for the removal of minor impurities forming a few percent of the feed or for the elimination of some critical impurities such as host cell proteins to negligible amounts (Goletz and Stöckl 2012).

Capture steps

A typical concentration of the rhEPO feed entering the capture step is about 100 mg/L (Surabattula et al. 2011) but protein concentration is by one order of magnitude higher (Hu et al. 2004; Zanette et al. 2003). In order to achieve the rhEPO purity of 50% mentioned above, more than 90% of protein impurities had to be removed in the capture step (Burg et al. 2002; Koh et al. 2014). A highly selective adsorbent with high capacity is needed for that purpose. The chromatographic bed is loaded with a large amount of feed so that the rhEPO loss in the breakthrough during the loading phase is minimal and the captured product is not too diluted during the elution phase.

Affinity chromatography

Affinity chromatography in general and immunoaffinity chromatography in particular offer very high selectivity for rhEPO capture (Wojchowski et al. 1987; Ghanem et al. 1994; Sugaya et al. 1997). However, restrictive costs of EPO antibodies that must be cultured and purified before use prevented their testing in preparative preparations. The very high costs also explain why immunoaffinity chromatography was not included in the patented purification processes listed in Table 1. The application of lectin affinity chromatography had a similar fate (Dordal et al. 1985; Merrifield 1990; Quelle et al. 1989). Lectins are not cheap and the high cost of lectin affinity chromatography is moreover associated with the cost of elution agents such as N-acetylglucosamine and N, N-diacetylchitobiose (Merrifield 1990).

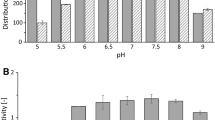

Dye-ligand chromatography, called also pseudo-affinity chromatography, is often a good compromise between the price/robustness and selectivity. Cibacron Blue is the most often used ligand in rhEPO capture (Beck and Withy 1988; Broudy et al. 1988; Burg et al. 2002; Hinderer and Arnold 2011; Merrifield 1990; Schmalz and Schmelzer 2016; Surabattula et al. 2011). This ligand binds more strongly rhEPO than other typical protein impurities such as albumins (Broudy et al. 1988; Burg et al. 2002). Since Cibacron Blue-based adsorbents tolerate low salt concentrations, a non-modified supernatant can be loaded into the adsorbent bed (Broudy et al. 1988; Surabattula et al. 2011). Less glycosylated rhEPO isoforms are usually removed already in the washing step using an acidic solution (Bavand and Blasev 2004; Surabattula et al. 2011). Elution is typically carried out using a step gradient of 1–1.5 M NaCl (Burg et al. 2002; Hinderer and Arnold 2011; Merrifield 1990; Surabattula et al. 2011).

Less common affinity ligands used in the purification of EPO are phenylboronate (Goletz and Stöckl 2012; Zanette et al. 2003) and heparin, which is a highly sulfated glycosaminoglycan with the molecular weight of 5000–30,000 (Borowski 1997; Lee et al. 2009). Phenylboronate interacts with 1,2-cis diol structures of the carbohydrate chains of glycoproteins. An advantage of phenylboronate adsorbents is that they tolerate the presence of some organic solvents. Bound molecules can be eluted either with other 1,2-cis-diol-containing compounds such as sorbitol or with Tris or citrate buffers. In heparin affinity chromatography, EPO and other glycoproteins are easily desorbed with 0.2–0.5 M NaCl (Borowski 1997; Lee et al. 2009). Nowadays, both phenylboronate and heparin affinity chromatography are also considered as a form of multimodal chromatography since these adsorbents can act as cation exchangers in certain pH range (Carvalho et al. 2014; Nascimento et al. 2018).

Finally, synthetic peptides specifically designed for rhEPO purification should be mentioned as a potential affinity ligand (Kish et al. 2018; Martínez-Ceron et al. 2011). The efficiency of adsorbents with this type of ligand has been demonstrated in the separation of rhEPO from artificial mixtures but the materials are not commercially available.

Anion-exchange chromatography

Ion-exchange chromatography is the second common type of chromatography used as the capture step. Both weak anion exchangers with a DEAE functional group (Hu et al. 2004; Lai and Strickland 1985; Quelle et al. 1989) and strong anion exchangers with a quaternary amine functional group (Alliger and Palma 2006; Bavand and Blasev 2004; Koh et al. 2014; Koticha and Chaudhari 2011) were examined for this purpose. It is noteworthy that the former type was presented only in journal articles whereas the latter one only in patents. The selectivity of these adsorbents is incomparably lower than that of the affinity ones. During the loading phase, the anion exchangers do not bind proteins with pI higher than 6–8; therefore, only a small fraction of feed proteins leaves the bed in the breakthrough stream. As most proteins including rhEPO are bound, the optimization of the eluent ionic strength is essential to achieve the separation effect (Surabattula et al. 2011). The product fraction often forms only a small part of the eluted liquid phase (Hu et al. 2004).

Intermediate purification steps

Both the specific activity and purity values in Table 1 document that purification steps following the capture step result in the reduction of impurity proteins amount to a small fraction of their initial amount in the cultivation broth, which makes rhEPO the dominant protein in the mixture. The portion of removed proteins after these purification steps can be more than 99% of the initial amount (Zanette et al. 2003). Although a single intermediate purification step has sometimes been declared as sufficient (Hu et al. 2004; Koh et al. 2014), a combination of different chromatographic steps has been reported more frequently (Alliger and Palma 2006; Bandi et al. 2017; Carcagno et al. 2006; Goletz and Stöckl 2012; Hinderer and Arnold 2011; Koticha and Chaudhari 2011; Schmalz and Schmelzer 2016). The bind-and-elute mode is typical for all these processes while the flowthrough mode is used only in rare cases (Alliger and Palma 2006; Koticha and Chaudhari 2011).

Ion-exchange chromatography

Ion-exchange chromatography has been the most frequent choice in the intermediate stage of chromatographic purification sequence or rhEPO. Table 1 documents that anion-exchange chromatography is a true workhorse of rhEPO chromatographic purification. The key impurity proteins in this step are albumins (Zanette et al. 2003). Since the overall load is about one order of magnitude lower in the intermediate steps compared to the capture step, smaller columns can be used here. On the other hand, the proportion of EPO on the total protein content is much higher.

A demand to remove a substantial part of protein impurities in the intermediate step requires a column with good separation efficiency in regard to the critical impurities. A washing step with acidic 6 M urea solution is commonly used before the elution to remove incorrectly glycosylated rhEPO forms (Bavand and Blasev 2004; Koh et al. 2014; Surabattula et al. 2011). Elution is usually carried out using a stepwise change of the NaCl concentration in the range from 150 mM (Zanette et al. 2003) to 500 mM (Carcagno et al. 2006; Hinderer and Arnold 2011). The application of linear gradient is a rare exception (Nascimento et al. 2018).

Cation-exchange chromatography has been used in the flowthrough mode to remove not sufficiently sialylated rhEPO isoforms with higher pI values (Koticha and Chaudhari 2011). In another work, the primary incentive to use cation-exchange chromatography was to remove organic solvent and rhEPO aggregates transported from the previous reversed phase chromatographic step (Hinderer and Arnold 2011). The conventional bind-and-elute mode with elution by concentrated NaCl solution was mentioned only in two patents without providing details on the separation efficiency of this step (Bandi et al. 2017; Koticha and Chaudhari 2011).

Reversed phase and hydrophobic interaction chromatography

Reversed phase and hydrophobic interaction chromatography use the principle of different surface hydrophobicity of proteins for their separation. The most typical ligand functional group in both adsorbent types is the butyl group (Bavand and Blasev 2004; Burg et al. 2002; Hinderer and Arnold 2011; Hu et al. 2004; Lai and Strickland 1985). Octyl group is the functional group in some reversed phase adsorbents used in rhEPO purification (Beck and Withy 1988; Broudy et al. 1988). Similarly, the phenyl functional group is typical for hydrophobic interaction chromatography adsorbents (Carcagno et al. 2006; Wojchowski et al. 1987).

Table 1 shows that these chromatographic adsorbents have often been applied in the intermediate purification step in spite of the use of organic eluents, associated with the reversed phase chromatography, being considered controversial. The objections include the risk of protein biological activity loss and unfavorable environmental aspects and waste disposal costs. On the other hand, declared benefits include, for example, direct binding of proteins from untreated supernatant to these adsorbents (Goletz and Stöckl 2012) or successful inactivation of potentially present viruses by the organic solvent (Hinderer and Arnold 2011). However, the major advantage of both reversed phase and hydrophobic interaction chromatography is the effective separation of different rhEPO isoforms (Alliger and Palma 2006; Hinderer and Arnold 2011).

Multimodal chromatography

Multimodal chromatography is based on adsorbents which ligands are intentionally designed to exhibit multiple interactions depending on the binding/elution conditions. Adsorbents with multimodal ligands can bind proteins by combining ionic interactions, hydrogen bridges, hydrophobic or hydrophilic forces, or affinity attraction. First modern multimodal adsorbents have been developed to find an alternative to protein A-based affinity adsorbents for the purification of monoclonal antibodies.

The use of multimodal chromatography with specially developed ligands has since been extended to many other substances, such as nucleic acids (Bischoff and McLaughlin 1984), plasmid DNA (Matos et al. 2014), viruses (Fitchmun 2017), recombinant proteins (Sejergaard et al. 2014) or oligosaccharides (Neville et al. 2009). In the area of rhEPO purification, only a few works can be found that mention the use of multimodal adsorbents (Bandi et al. 2017; Koticha and Chaudhari 2011). Both cited patents reveal almost no details about the separation conditions. One of the patents claims that the multimodal adsorbent Capto Adhere can be used instead of an anion exchanger (Koticha and Chaudhari 2011).

Hydroxyapatite chromatography exploits ligand-free adsorbents combining the affinity and ion-exchange mechanisms (Cummings et al. 2009). Binding and elution conditions depend on the acido-basic properties of bound proteins. Basic proteins are bound via the ion-exchange mechanism and are eluted using increased ionic strength. Affinity binding is characteristic for acidic proteins when their elution requires the presence of phosphates (Cummings et al. 2009). Since rhEPO belongs to the group of acidic proteins, it is advantageous to feed it into a column at relatively high salt concentrations to impede the binding of basic impurity proteins. The elution of rhEPO occurs at low phosphate concentrations when acidic impurity proteins remain bound (Bavand and Blasev 2004; Burg et al. 2002). Recovery of rhEPO from the flowthrough fraction in the binding mode has also been documented when the feed contained a low amount of phosphate (Koh et al. 2014).

Polishing steps

While the capture and intermediate purification steps substantially increase the content of rhEPO in the product streams, the objective of polishing steps is either to remove eluent components or critical impurities to a specified degree. Table 1 shows that size-exclusion chromatography and anion exchange chromatography are the most important polishing methods. In case of rhEPO polishing, the application of size-exclusion chromatography for the removal of eluent components has often been emphasized (Alliger and Palma 2006; Beck and Withy 1988; Carcagno et al. 2006; Goletz and Stöckl 2012; Hinderer and Arnold 2011; Hu et al. 2004; Lai and Strickland 1985; Zanette et al. 2003).

The size-exclusion step typically follows after reversed-phase chromatography (Alliger and Palma 2006; Beck and Withy 1988; Goletz and Stöckl 2012; Hinderer and Arnold 2011; Lai and Strickland 1985) or hydrophobic interaction chromatography (Carcagno et al. 2006; Hu et al. 2004). Organic solvents, such as ethanol, isopropanol or acetonitrile, were used as desorbents in the gradient mode in the cited reversed phase chromatography applications. The size-exclusion chromatography served then for the so-called solvent exchange which was also realized using weak anion exchangers (Burg et al. 2002; Schmalz and Schmelzer 2016). In case of hydrophobic interaction chromatography, ammonium sulfate was used to promote protein binding and rhEPO was recovered during elution carried out in the gradient of this kosmotropic salt. Size-exclusion chromatography was thus utilized here as a desalting step.

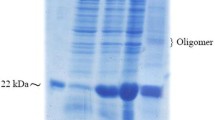

Critical impurities in the rhEPO polishing are rhEPO oligomers. Size-exclusion chromatography is a standard separation technique for the removal of inactive protein oligomers or aggregates in spite of its limited separation efficiency and the need of much longer column beds compared to other chromatography types. It has also been applied for this purpose in rhEPO polishing (Alliger and Palma 2006; Hinderer and Arnold 2011; Hu et al. 2004; Zanette et al. 2003). Table 1 includes also one case where size-exclusion chromatography was applied in the removal of viruses (Goletz and Stöckl 2012).

Strong anion exchangers with a quaternary amine have often been used in the polishing steps reported in the patent literature to remove weakly sialylated forms (Bavand and Blasev 2004; Goletz and Stöckl 2012; Koh et al. 2014; Koticha and Chaudhari 2011). Weak DEAE anion exchangers have been applied to remove N-acetylglucose amine after a lectin affinity column (Merrifield 1990). As it was shown above in the discussion of separation sequence presented in Fig. 2, nanofiltration, a non-chromatographic procedure, is often applied for virus removal as the final polishing step.

Concluding remarks

Recombinant human erythropoietin is an important biopharmaceutical product. Although it has been produced for more than two decades now, the cultivation production of its different isoforms by mammalian cells is still subject of both academic and industrial research. Industrial implementation of rhEPO production requires also good design of downstream processing steps since they form a substantial part of production costs. The results of research on rhEPO purification have been rarely reported in open literature. Recent results are mainly scattered in patents.

This review analyzes the existing work on rhEPO purification. Since the most information was extracted from patents, these research results did not get the feedback typical for work published in scientific journals. A critical analysis of patent results is often complicated by the extent of claims. Nonetheless, we made an effort to assess the chromatographic techniques that were applied in different stages of rhEPO purification from the cultivation broth to the final pure protein.

The most valuable aspect of this analysis is that it presents adsorbent material types with good selectivity in the rhEPO purification steps. When it was possible, performance data such as yield and purity were included in this review. It is however necessary to emphasize that almost all presented results were obtained in small columns with limited efficiency. On the other hand, this means that much better performance of the same chromatographic materials can be achieved when they are used in the process scale. Synthesis of the existing knowledge provided in this review can thus be a good platform for further optimization of separation sequences in the process development stage.

References

Alliger P, Palma N (2006) Chromatographic purification of recombinant human erythropoietin. US2006099674

Amadeo GI, Moreira R, Lima R, Teixeira D, Kratje R, Etcheverrigaray M (2003) Screening of lectins from South American plants used as affinity ligands to purify rhEPO. Braz J Chem Eng 20:21–26

Bandi VK, Reddy BRB, Mugthihalli SM, Iyer PK, Pasupuleti P (2017) Process for the purification of erythropoietin and darbepoetin alfa. EP3153522

Bavand M, Blasev H (2004) Process for the production and purification of erythropoietin. EP1428878

Beck AK, Withy RM (1988) Recombinant human erythropoietin. EP0267678

Bischoff R, McLaughlin LW (1984) Nucleic acid resolution by mixed-mode chromatography. J Chromatogr A 296:329–337

Borowski M (1997) Heparin chromatography of erythropoietins. WO9717366

Broudy VC, Tait JF, Powell JS (1988) Recombinant human erythropoietin: purification and analysis of carbohydrate linkage. Arch Biochem Biophys 265:329–336

Burg J, Fuerst W, Schneider W, Sellinger K-H, Wrba A (2002) Process for producing erythropoietin containing no animal proteins. US6399333

Carcagno CM, Criscuolo ME, Melo CA, Vidal JA (2006) Methods of purifying recombinant human erythropoietin from cell culture supernatants. US7012130

Carvalho RJ, Woo J, Aires-Barros MR, Cramer SM, Azevedo AM (2014) Phenylboronate chromatography selectively separates glycoproteins through the manipulation of electrostatic, charge transfer, and cis-diol interactions. Biotechnol J 9:1250–1258

Cummings LJ, Snyder MA, Brisack K (2009) Chapter 24 protein chromatography on hydroxyapatite columns. pp 1–851

Delome E, Lorenzini T, Giffin T, Martin F, Jacobsen F, Boone T, Elliot S (1992) Role of glycosylation on the secretion and biological activity of erythropoietin. Biochemistry 31:9871–9876

Dordal MS, Wang F-F, Goldwasser E (1985) The role of carbohydrate in erythropoietin action. Endocrinology 249:4202–4206

Egrie JC, Browne JK (2001) Development and characterization of novel erythropoiesis stimulating protein (NESP). Br J Cancer 84:3

Epstein MS, Ehrenpreis ED, Kulkarni PM, FDA-Related Matters Committee of the American College of Gastroenterology (2014) Biosimilars: the need, the challenge, the future: the FDA perspective. Am J Gastroenterol 109:1856–1859

Fitchmun MI (2017) Methods for purifying adenovirus vectors. WO 2017019432 A1

Ghanem AB, Winchenne JJ, Lopez C, Chrétien S, Dubarry M, Craescu CT, Le Caer JP, Casadevall N, Rouger P, Cartron JP, Lambin P (1994) Purification and biological activity of a recombinant human erythropoietin produced by lymphoblastoid cells. Prep Biochem 24:127–142

Goletz S, Stöckl L (2012) Process for the purification of glucoproteins. US2012329092

Hayakawa T, Wada M, Mizuno K, Abe S, Miyashita M, Ueda M (1992) In vivo biological activities of recombinant human erythropoietin analogues produced by CHO cells, BHK cells and C127 cells. Biologicals 20:253–257

Hinderer W, Arnold S (2011) Process for the purification of recombinant human erythropoietin (EPO, EPO thus purified and pharmaceutical compositions comprising same. WO2011035914

Hsu L-W, Chang S-C (2002) Expression system for producing recombinant human erythropoietin, method for purifying secreted human erythropoietin and uses thereof. US6376218

Hu Y, Chen S, Xu M, Zhang S (2004) An improved, inexpensive procedure for the large-scale purification of recombinant human erythropoietin. Biotechnol Appl Biochem 40:89–94

Jacobs K, Shoemaker C, Rudersdorf R, Neill SD, Kaufman RJ, Mufson A, Seehra J, Jones SS, Hewick R, Fritsch EF, Kawakita M, Shimizu T, Miyake T (1985) Isolation and characterization of genomic and cDNA clones of human erythropoietin. Nature 313:806–810

Jelkmann W (2007) Recombinant EPO production points the nephrologist should know. Nephrol Dial Transpl 22:2749–2753

Kish WS, Roach MK, Sachi H, Naik AD, Menegatti S, Carbonell RG (2018) Purification of human erythropoietin by affinity chromatography using cyclic peptide ligands. J Chromatogr B 1085:1–12

Kitagawa Y, Sano Y, Ueda M, Hiqashio K, Narita H, Okano M, Matsumoto S, Sasaki R (1994) N-glyosylation of erythropoietin is critical for apical secreation by Madin–Darby canine kidney cells. Exp Cell Res 213:449–457

Koh Y-W, Lee S-Y, Kim C-H, Lee S-H, Kim H-N, Kim S-Y, Seong J-H, Cho Y-H (2014) Methods for purifying erythropoietin analogs having lower isoelectric point. US2014243510

Koticha D, Chaudhari AB (2011) Purification of modified cytokines. WO2011063195

Krystal G, Pankratz HRC, Farber NM, Smart JE (1986) Purification of Human erythropoietin to homogeneity by a rapid five-step procedure. Blood 67:71–79

Kwan JT, Pratt RD (2007) Epoetin delta, erythropoietin produced in a human cell line, in the management of anaemia in predialysis chronic kidney disease patients. Curr Med Res Opin 23:307–311

Lai P-H, Strickland TW (1985) Erythropoietin purification. US4667016

Lai P-H, Everett R, Wang F-F, Arakawa T, Goldwasser E (1986) Structural characterization of human erythropoietin. J Biol Chem 261:3116–3121

Lee EG, Lee SH, Park KM, Baek JE, Yeon SH, Park J-K, Chang W-K, Jung J-K, Chung BH (2009) Purification and characterization of recombinant human erythropoietin from milk of transgenic pigs. J Chem Technol Biotechnol 84:643–649

Lee-Huang S (1986) Reverse immunoaffinity chromatography purification method. US4568488

Lin FK, Suggs S, Lin CH, Browne JK, Smalling R, Egrie JC, Chen KK, Fox GM, Martin F, Stabinsky Z (1985) Cloning and expression of the human erythropoietin gene. Proc Natl Acad Sci USA 82:7580–7584

Lukowsky WA, Painter RH (1972) Studies on the role of sialic acid in the physical and biological properties of erythropoietin. Can J Biochem 50:909–917

Martínez-Ceron MC, Marani MM, Taulés M, Etcheverrigaray M, Albericio F, Cascone O, Camperi SA (2011) Affinity chromatography based on a combinatorial strategy for rerythropoietin purification. ACS Comb Sci 13:251–258

Matos T, Queiroz JA, Bülow L (2014) Plasmid DNA purification using a multimodal chromatography resin. J Mol Recognit 27:184–189

Merrifield EH (1990) Purification of erythropoietin. EP0358463

Miyake T, Kung CK, Goldwasser E (1977) Purification of human erythropoietin. J Biol Chem 252:5558–5564

Miyazaki H, Kozutsumi H, Kato T, Hoshi S, Tamura S, Kubota M, Suzuki T (1988) Production of monoclonal antibodies against human erythropoietin and their use in the purification of human urinary erythropoietin. J Immunol Methods 113:261–267

Nascimento A, Pinto IF, Chu V, Aires-Barros MR, Conde JP, Azevedo AM (2018) Studies on the purification of antibody fragments. Sep Purif Technol 195:388–397

Neville DCA, Dwek RA, Butters TD (2009) Development of a single column method for the separation of lipid- and protein-derived oligosaccharides. J Proteome Res 8:681–687

Nimtz M, Wray V, Rüdiger A, Conradt HS (1995) Identification and structural characterization of a mannose-6-phosphate containing oligomannosidic N-glycan from human erythropoietin secreted by recombinant BHK-21 cells. FEBS Lett 365:203–208

Quelle FW, Caslake LF, Burkert RE, Wojchowski DM (1989) High-level expression and purification of a recombinant human erythropoietin produced using a baculovirus vector. Blood 74:652–657

Schmalz C, Schmelzer A (2016) Purification of erythropoietin. US2016333066

Schmidt CA, Codevilla CF, Fronza M, Casali RG, Dalmora SL (2003) Physico-chemical characterization and biological evaluation of recombinant human erythropoietin in pharmaceutical products. Acta Farm Bonaer 22:343–350

Sejergaard L, Karkov HS, Krarup JK, Hagel ABB, Cramer SM (2014) Model-based process development for the purification of a modified human growth hormone using multimodal chromatography. Biotechnol Prog 30:1057–1064

Skibeli V, Nissen-Lie G, Torjesen P (2001) Sugar profiling proves that human serum erythropoietin differs from recombinant human erythropoietin. Blood 98:3626–3634

Storring PL, Gaines Das RE (1992) The international standard for recombinant DNA-derived erythropoietin: collaborative study of four recombinant DNA-derived erythropoietins and two highly purified human urinary erythropoietins. J Endocrinol 134:459–484

Storring PL, Tiplady RJ, Gaines Das RE, Rafferty B, Mistry YG (1996) Lectin-binding assays for the isoforms of human erythropoietin: comparison of urinary and four recombinant erythropoietins. J Endocrinol 150:401–412

Storring PL, Tiplady RJ, Gaines DR (1998) Epoetin alpha and beta in their erythropoetin isoform compositions and biological properties. Br J Haematol 100:79–89

Sugaya S, Ohashi H, Shinozawa T (1997) Expression and purification of a recombinant human glycoprotein in mouse hybridoma SP2/0-AG14 cells. Biotechnol Lett 19:185–188

Surabattula R, Rao KS, Polavarapu R (2011) An optimized process for expression, scale-up and purification of recombinant erythropoietin produced in chinese hamster ovary cell culture. Res Biotechnol 2(3):58–74

Takeuchi M, Takasaki S, Shimada M, Kobata A (1990) Role of sugar chains in the iv vitro biological activity of human erythropoietin produced in recombinant Chinese hamster ovary cell. J Biol Chem 265:12127–12130

Terashima S, Kamihira M, Ogawa T, Ohno M, Iijima S, Kobayashi T (1994) Continuous production of human erythropoietin by immobilized recombinant L-929 cells. J Ferment Bioeng 77:52–56

Wang P, Dong S, Brailsford JA, Iyer K, Townsend SD, Zhang Q, Hendrickson RC, Shieh J, Moore MAS, Danishefsky SJ (2012) At last: erythropoietin as a single glycoform. Angew Chem Int Ed 51:11576–11584. https://doi.org/10.1002/anie.201206090

Wasley LC, Timony G, Murtha P, Stoudemire J, Dorner AJ, Caro J, Krieger M, Kaufman RJ (1991) The importance of N- and O-linked oligosaccharides for the biosynthesis and in vitro and in vivo biologic activities of erythropoietin. Blood 77:2624–2632

Wide L, Bengtsson C (1990) Molecular charge heterogeneity of human serum erythropoietin. Br J Haematol 76:121–127

Wojchowski DM, Sue JM, Sytkowski AJ (1987) Site-specific antibodies to human erythropoietin: immunoaffinity purification of urinary and recombinant hormone. Biochim Biophys Acta 913:170–178

Yamaguchi K, Akai K, Kawanishi G, Ueda M, Masuda S, Sasaki R (1991) Effects of site-directed removal of N-glycosylation sites in human erythropoietin on its production and biological properties. J Biol Chem 266:20434–20439

Yanagawa Shin-ichi, Hirade K, Ohnota H, Sasaki R, Chiba H, Ueda M, Goto M (1984a) Isolation of human erythropoietin with monoclonal antibodies. J Biol Chem 259:2707–2710

Yanagawa S, Yokoyama S, Hirade K, Sasaki R, Chiba H, Ueda M, Goto M (1984b) Hybridomas for production of monoclonal antibodies to human erythropoietin. Blood 64:357–364

Yanagi H, Soga A, Ogino S (1987) Purification of human urinary erythropoietin. J Chromatogr B 417:178–182

Yuen C-T, Storring PL, Tiplady RJ, Izquierdo M, Wait R, Gee CK, Gerson P, Lloyd P, Cremata JA (2003) Relationships between the N-glycan structures and biological activities of recombinant human erythropoietins produced using different culture conditions and purification procedures. Br J Haematol 121:511–526

Zanette D, Soffientini A, Sottani C, Sarubbi E (2003) Evaluation of phenylboronate agarose for industrial-scale purification of erythropoietin from mammalian cell cultures. J Biotechnol 101:275–287

Acknowledgements

This work was supported by grants from the Agency of the Ministry of Education, Science, Research and Sport of the Slovak Republic for the Structural Funds of EU (Grant Number: ITMS 26240220071), the Slovak Research and Development Agency (Grant Number: APVV-14-0474) and the Slovak Grant Agency for Science (Grant Number: VEGA 1/0573/17).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no financial or commercial conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Adamíková, J., Antošová, M. & Polakovič, M. Chromatographic purification of recombinant human erythropoietin. Biotechnol Lett 41, 483–493 (2019). https://doi.org/10.1007/s10529-019-02656-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-019-02656-8