Abstract

Objectives

To assess the combination of electrocoagulation and anaerobic co-digestion of olive mill wastewaters (OMWW) with other substrates, such as chicken manure, in a continuous stirred tank reactor for biogas production.

Results

Anaerobic digestion of OMWW treated by electrocoagulation allowed higher production of biogas, up to 0.74 l biogas g−1 COD introduced compared to untreated or diluted olive mill wastewaters (OMWW) (0.37 and 0.6 l biogas g−1 COD) respectively. Pretreated OMWW co-digested with chicken manure at different volumic ratios OMWW/manure in a continuous stirred tank reactor under mesophilic conditions revealed that OMWW/manure (7:3 v/v) was optimal for biogas production and process stability.

Conclusion

Anaerobic digestion could achieve promising results in depollution and valorization of OMWW under a continuous stirred tank reactor.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Large amounts of wastes, including wastewaters, are produced by the olive oil industry. Olive mill wastewater (OMWW) is a dark aqueous solution with complex composition. Such a waste causes a serious problem to the environment. Processes for treatment and reduction of toxicity of OMWW include aerobic and anaerobic treatments, physical or chemical treatments (Gunay and Karadag 2015).

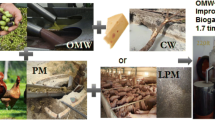

Among pretreatment techniques, electrochemical processes have shown good results in removing organic pollutants from different liquid effluents. Codigestion of OMWW with substrates rich organic nitrogen (cow manure, cheese whey, laying hen litter, slaughterhouse wastewaters) (Azbar et al. 2008) enhances biogas production by providing a balanced ratio of C/N/P to the medium.

In this study, pretreatment of OMWW was conducted using electrocoagulation to reduce the phenolic content of this effluent. In a second step, anaerobic digestion of three types of OMWW (crude, diluted and treated samples) was realized in batch mode in order to assess the effect of phenolic compounds removal on biogas production.

Codigestion of pretreated OMWW with a complementary substrate was further tested in a continuous stirred tank reactor at different volumic ratios under mesophilic conditions.

Materials and methods

Effluent and substrats collection

Olive mill wastewater (OMWW) was provided from a local industrial mill.

Solid chicken manure was obtained from a local chicken farm. Before use, manure was sieved, shredded and added to water to obtain a liquid effluent.

For reactors seeding, a digested sludge from mesophilic anaerobic reactor was used.

Electrocoagulation assay

Electrocoagulation of OMWW was conducted on 0.5 l effluent for 4 h. Current density was 4 A/dm2 using two iron electrodes placed at 4 cm from each other. No pH adjustment was needed as OMWW has an acidic pH.

Anaerobic digestion batch tests

The experimental setup for anaerobic digestion tests consisted of glass serum bottles, each one filled with crude, pretreated or diluted OMWW, and seeded with methanogenic culture according to ratio of volatile solids (inoculum/substrate) (1/1, v/v) in all batchs.

After inoculation, all the glass bottles were flushed with N2. They were capped with rubber stoppers and incubated at 37 °C.

Biogas production was monitored using a displacement method device, and pH was measured periodically.

Laboratory bench continuous stirred tank reactor (CSTR)

Co-digestion experiments of OMWW and chicken manure were carried out in a jacketed CSTR having a working volume of 1 l and operating at 37 °C.

The reactor was inoculated with digested OMWW biomass having a TS (Total Solids) content of 27.2 and 7.6% of VS (volatile solids). Chicken manure was then added at 2/1 (v/v) (manure/inoculum) of volatile solids.

The fraction of OMWW in the reactor was increased with a ramp of 10% of the total volume using a peristaltic pump and the same amount of digested effluent was withdrawn.

To control reactor activity, the following parameters were recorded: biogas volume, pH, volatile fatty acids, and alkalinity.

Analytical methods

COD, pH, NH4 +, NO3 −, NO2 −, TS, VS, total Kjeldahl nitrogen (TKN), PO 34 , volatile fatty acids and alkalinity were determined according to methods reported by (Rodier et al. 2009). Soluble phenolic compounds content was determined using the Folin–Ciocalteu procedure (Box 2016).

Results and discussion

Electrocoagulation pretreatment

Physicochemical parameters of OMWW before and after electrocoagulation process are presented in Table 1. COD content decreased to 71 g COD l−1 under electrocoagulation conditions.

The pH of OMWW increased from 4.8 to 6.8 due to OH− formation during electrocoagulation. Also, removal of phenolic compounds which most are acidic contributed to increase of pH.

Polyphenols decreased from 9 to 2 g l−1. This can be assigned to oxidation and polymerization of phenols (Kallel et al. 2009).

The quantity of suspended solids increased from 12.5 to 50 g solids l−1 after electrocoagulation. The sludge formed can be used in composting due as it is rich in Ca2+, Mg2+ and Fe3+ (Khoufi et al. 2009). Another alternative for electrocoagulation sludge is to use it as a low cost adsorbent for wastewaters decontamination (Yilmaz et al. 2011).

After 4 h of electrocoagulation, concentrations of NO3 −, NO2 − and NH4 + reached 107 ± 0.62,14 ± 0.28, and 29.6 ± 0.55 mg l−1, respectively (Table 1).

This electrocoagulation decreases the organic and inorganic content of OMWW. It also provides a biodegradable rich substrate for anaerobic digestion by reducing phenolic compounds toxicity.

Anaerobic digestion of OMWW in batch tests

Figure 1 shows variations of pH during anaerobic digestion of crude, diluted and pretreated samples of OMWW in batch mode. pH remain within the range of 6.4 to 7.4 for all samples which represent an optimal range for methanogenic bacteria (Ghanam et al. 2013).

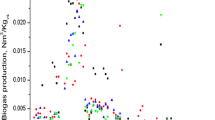

Time course production of biogas during the batch test is presented in Fig. 2. The pretreated sample shows higher yield with 0.74 l biogas g−1 of COD introduced. Diluted OMWW produced 0.6 l biogas g−1 COD while crude sample resulted in the lowest yield with only 0.37 l biogas g−1 COD.

Ruggeri et al. (2015) studied the effect of different pretreatments methods on biogas production in batch mode. Diluted OMWW produced up to 258 l biogas kg−1 VS while crude OMWW has a negligible production with only 6.67 l biogas kg−1 VS. According to our knowledge, it is the first report that associates electrocoagulation and codigestion of OMWW with other substrates, such as chicken manure in a continuous stirred tank reactor. Therefore, we looked at the effect of electrocoagulation and codigestion by determining the main factors affecting the process of biogas production under this condition.

Laboratory bench continuous stirred tank reactor (CSTR)

Physicochemical characteristics of chicken manure are presented in Table 2. In comparison with OMWW, we noted that these are differences in major physical (Table 2) and chemical characteristics; for example, the TKN content of manure (190 mg TKN l−1) is higher than OMWW (70 mg TKN l−1) and are, in fact, complementary and thus ensure an optimally accepted composition for higher yield in biogas production during anaerobic digestion.

Changes in alkalinity during anaerobic process, as reported in Fig. 3, confirm that very slight signs of perturbation or inhibition were noted as indicated by values of CaCO3 higher than 1 g l−1 that is considered the minimal limit of CaCO3 in anaerobic medium under mesophilic conditions (Kolbl et al. 2017). pH monitoring in the digester for different ratios of OMWW/manure indicated that pH remained within 6–8 along the digestion test (data not shown).

Another important factor to control during methanogenic process is the concentration of volatile fatty acids. Anaerobic digestion could be inhibited because methanogenic bacteria are very sensitive to VFA accumulation (Björnsson et al. 2000).

As depicted in Fig. 3, low amounts of VFA, compared to CaCO3 content was observed. The ratio of VFA/ALK does not exceeded 0.1 for all mixing ratios, suggesting that VFA produced are rapidly neutralized by carbonate species (Khoufi et al. 2007).

Gradual adaptation of reactor fed alternatively with 100% OMWW (v/v) or 100% of piggery effluent did not affect the balance of ratio VFA/ALK and thus no pH drop or VFA accumulation was observed as reported by (Sampaio et al. 2011).

Biogas production

Biogas production as function of the mix ratio (manure/OMWW) (Fig. 4) shows that biogas liberated in experiments with mix ratios comprised between 10 and 50% reached low values. This low biogas production can be assigned to an gradually acclimatization phase of methanogenic bacteria to changes in feed composition. From 60 to 90% biogas production increases from 110 ml to a maximum of 2210 ml for the 70/30 (v/v) OMWW/manure mix.

The same mix of 70/30 was described as optimal for biogas production as reported by (Khoufi et al. 2015) when digesting OMWW with poultry liquid manure in a jet loop reactor under mesophilic conditions; at this ratio, the medium provides a balanced C/N ratio for stable process; also inhibition by excess of free ammonia from manure is limited.

Co-digestion of effluents increases biogas recovery and reduces the effect of inhibition by VFA accumulation inside anaerobic reactors. Additionally, CSTR is well adapted to degrade effluents with high organic load such as OMWW.

Conclusion

The main results of the present study are:

-

OMWW is a potential source of pollution due to is high organic load, the presence of phenolic compounds, and its acidic pH.

-

Electrocoagulation is an effective pretreatment which aims to reduce the organic load of OMWW prior to an upcoming biological treatment which resulted in higher volume of biogas compared to crude or diluted OMWW.

-

Co digestion of OMWW with a rich nitrogen substrate like chicken manure optimizes the process of anaerobic digestion under mesophilic conditions.

References

Azbar N, Keskin T, Yuruyen A (2008) Enhancement of biogas production from olive mill effluent (OME) by co-digestion. Biomass Bioener 32(1195):1201

Björnsson L, Murto M, Mattiasson B (2000) Evaluation of parameters for monitoring an anaerobic co-digestion process. Appl Microbiol Biotechnol 54:844–849

Box J (2016) Investigation of the Folin–Ciocalteau phenol reagent for the determination of polyphenolic substances in natural waters. Appl Microbiol Biotechnol 54:844

Ghanam J, Laaboudi W, Merzouki M, Benlemlih M (2013) Response of anaerobic consortium populations to carbon/nitrogen (C/N) variation during anaerobic digestion of olive mill wastewaters. J Biotechnol Lett 4:72–78

Gunay A, Karadag D (2015) Recent developments in the anaerobic digestion of olive mill effluents. Proc Biochem 50:1893–1903

Kallel M, Chokri B, Rachdi B, Ksibia M, Montiela A, Elleuch B (2009) Olive mill wastewaters degradation by Fenton oxidation with zero-valent iron and hydrogen peroxide. J Hazard Mater 163:550–554

Khoufi S, Feki F, Sayadi S (2007) Detoxification of olive mill wastewater by electrocoagulation and sedimentation processes. J Hazard Mater 142:58–67

Khoufi S, Aloui F, Sayadi S (2009) Pilot scale hybrid process for olive mill wastewater treatment and reuse. Chem Eng Proc 48:643–650

Khoufi S, Louhichi A, Sayadi S (2015) Optimization of anaerobic co-digestion of olive mill wastewater and liquid poultry manure in batch condition and semi-continuous jet-loop reactor. Bioresour Technol 182:67–74

Kolbl S, Forte P, Stres B (2017) Potential for valorization of dehydrated paper pulp sludge for biogas production: addition of selected hydrolytic enzymes in semi- continuous anaerobic digestion assays. Energy 126:326–334

Rodier J, Legube B, Merlet N et al (2009) L’analyse de leau. Dunod, Paris

Ruggeri B, Federico B, Bernardi M, Fino D, Mancini G (2015) The selection of pretreatment options for anaerobic digestion: a case study in olive oil waste production. Chem Eng J 259:630–639

Sampaio MA, Gonçalves MR, Marques IP (2011) Anaerobic digestion challenge of raw olive mill wastewaters. Biores Technol 102:10810–10818

Yilmaz A, Boncukcuoğlu R, Kocakerim M, Karakaş IH (2011) Waste utilization: the removal of textile dye (Bomaplex Red CR-L) from aqueous solution on sludge waste from electrocoagulation as adsorbent. Desalination 277:156–163

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sounni, F., Aissam, H., Ghomari, O. et al. Electrocoagulation of olive mill wastewaters to enhance biogas production. Biotechnol Lett 40, 297–301 (2018). https://doi.org/10.1007/s10529-017-2464-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-017-2464-5