Abstract

Objective

To produce tagatose from fructose with a high conversion rate and to establish a high-yield purification method of tagatose from the reaction mixture.

Results

Fructose at 1 M (180 g l−1) was converted to 0.8 M (144 g l−1) tagatose by a three-step enzymatic cascade reaction, involving hexokinase, plus ATP, fructose-1,6-biphosphate aldolase, phytase, over 16 h with a productivity of 9 g l−1 h−1. No byproducts were detected. Tagatose was recrystallized from ethanol to a purity of 99.9% and a yield of 96.3%. Overall, tagatose at 99.9% purity was obtained from fructose with a yield of 77%.

Conclusion

This is the first biotechnological production of tagatose from fructose and the first application of solvent recrystallization for the purification of rare sugars.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Tagatose, a representative rare sugar, is a 4-epimer form of fructose. Although the sweetness and taste of tagatose are similar to sucrose, tagatose is a low-calorie sweetener unlike sucrose. This functional sweetener has been produced from galactose (Lim et al. 2007) and galactitol (Jagtap et al. 2014) by chemical and biological methods. However, these production methods are not economical due to the expensive substrates. Thus, tagatose production from an inexpensive substrate, such as fructose or glucose, would be beneficial.

Several chromatographic separation methods have been used for the isolation of tagatose from reaction mixtures with galactose (Adachi and Sugawara 1963; Hong et al. 2007). However, these methods result in a low purification yield to achieve tagatose with a high purity and have some disadvantages, including the formation of chemical waste and a high cost of purification. Therefore, the development of an efficient, economical, and ecofriendly purification method is needed.

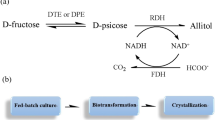

A fructose 4-epimerase, that would convert fructose to tagatose, does not exist. As an alternative route, fructose can be converted tagatose via allulose using an allulose (or psicose) 3-epimerase followed by a talitol dehydrogenase/reductase with NAD+ recycling (Izumori 2006). However, the conversion rate of fructose to allulose is less than 33%, and this two-step conversion has not been attempted. Thus, we converted fructose to tagatose with a high conversion rate by a three-step enzymatic cascade reaction, involving hexokinase, fructose-1,6-biphosphate aldolase (FbaA), and phytase, a type of phosphatase, because FbaA can convert fructose-6-phosphate (F6P) to tagatose-6-phosphate (T6P). The reaction mixture containing tagatose and fructose was then purified to a high-purity tagatose with a high yield by ethanol recrystallization.

Materials and methods

Enzyme preparation

Hexokinase from Saccharomyces cerevisiae and phytase were purchased from Sigma-Aldrich and Genofocus (Daejeon, South Korea), respectively. FbaA was prepared by gene cloning, enzyme expression, and purification in E. coli.

Cell preparation

The cloning of the fbaA and fructokinase (scrK) genes was performed based on the DNA sequences of FbaA from E. coli and ScrK from Thermus thermophilus (GenBank accession numbers, NP_417400.1 and AAS80978.1, respectively). PCR products were subcloned into the pRSF-duet-1 vector (Novagen, Madison, WI, USA), and transformed into E. coli ER2566. The gene of fructose-6-phosphate kinase (pfkA) was deleted in E. coli ER2566 using the modified P1 phage transduction method (Thomason et al. 2007). E. coli ∆pfkA mutant expressing FbaA and ScrK was used for T6P production.

Enzyme expression and purification

Recombinant E. coli was cultured in a 2 l flask containing 500 ml lysogeny broth (LB) 0.1 mM kanamycin at 37 °C and 200 rpm. When the OD600 value of the culture reached 0.6, 0.1 mM IPTG was added, and the culture was incubated at 16 °C and 150 rpm for 16 h to induce the expression of FbaA. Harvested cells were resuspended in 50 mM phosphate buffer (pH 8) containing 300 mM NaCl and 10 mM imidazole. Resuspended cells were disrupted by sonication, and the supernatant obtained by centrifugation was filtered through a 0.45 μm filter. The filtrate was applied to an immobilized metal ion affinity chromatography cartridge (Bio-Rad) equilibrated with 50 mM phosphate buffer (pH 8) containing 300 mM KCl at 4 °C. The bound protein was eluted with the same buffer supplemented with 300 mM imidazole at 1 ml min−1. Active fractions were collected and dialyzed in 50 mM Tris/HCl buffer (pH 8.5) at 4 °C for 16 h, and this solution was used as the purified enzyme.

Culture conditions

A single colony of the recombinant E. coli was inoculated into a 20 ml test tube containing 5 ml 2YT medium (16 g tryptone l−1, 10 g yeast extract l−1, and 5 g NaCl l−1) and cultured at 37 °C and 250 rpm for 12 h. This seed culture (5 ml) was transferred to a 250 ml baffled flask containing 50 ml 2YT medium and cultured at 37 °C and 200 rpm for 5 h. The pre-culture was used to inoculate a 2.5 l fermentor containing 1 l 2YT medium supplemented with 20 g fructose l−1, and then cultured at 37 °C and pH 7.0 for 28 h. Aeration was at 1 vvm, and the agitation speed was adjusted from 300 to 1200 rpm to maintain the DOT above 20%. At 10 h, 0.1 mM IPTG and 20 g fructose l−1 were added, and the agitation speed was fixed at 400 rpm.

Three-step enzymatic cascade reaction

The reactions for fructose phosphorylation, F6P 4-epimerization, and T6P dephosphorylation were performed at 35 °C and pH 8.5, 50 °C and pH 8.5, and 50 °C and pH 5.5 in 50 mM Tris/HCl buffer containing 500 U hexokinase ml−1 plus 1 M ATP, 100 U FbaA ml−1, and 1000 U phytase ml−1 for 1, 12, and 3 h, respectively. One unit (U) of hexokinase, FbaA, or phytase activity was defined as the amount of enzyme required to produce 1 µmol F6P, T6P, or tagatose per minute at 35 °C and pH 8.5, 50 °C and pH 8.5, or 50 °C and pH 5.5 using fructose, F6P, or T6P, respectively.

Purification of tagatose from the reaction mixture containing fructose

The reaction mixture containing 1 ml of fructose and tagatose (1 M) was concentrated to 0.2 ml (5 M) by drying under a vacuum at 60 °C for 3 h, and 1 ml ethanol was added to the concentrated reaction mixture. The mixture was vortexed vigorously and allowed to stand. After 1 h, the mixture showed fine precipitate, which was harvested by centrifugation. The second precipitate obtained by centrifugation after the addition of ethanol (1 ml) to the first precipitate was the purified tagatose (>99%).

Analytical methods

F6P and T6P were determined using a Bio-LC system (Dionex ICS-3000) equipped with an electrochemical detector and Carbo Pac PA1 column (Dionex), which was eluted at 30 °C at 1 ml min−1 with water/200 mM NaOH/1 M sodium acetate (35:45:20 by vol.) for 0–10 min, 35:15:50 (by vol.) for 10–15 min, and 35:45:20 (by vol.) for 15–25 min. Fructose and tagatose were analyzed by HPLC (Agilent 1260) equipped with a Shodex Sugar SP0810 column (Showa Denko, Tokyo, Japan). The column was eluted at 80 °C with water at 1 ml min−1 for 25 min.

Results and discussion

Aldol cleavage and epimerization reactions of fructose-1,6-biphosphate aldolase

Two trioses, dihydroxyacetone phosphate (DHAP) or dihydroxyacetone (DHA) and glyceraldehyde 3-phosphate (G3P) or glyceraldehyde (GA) were used as substrates for FbaA to identify its condensed products. As expected, DHAP and G3P were condensed to fructose-1,6-bisphosphate (FBP) by the enzyme. DHAP and glyceraldehyde (GA) were converted to fructose-1-bisphosphate (F1P). However, no reaction occurred for dihydroxyacetone (DHA) and GA by FbaA. When DHA and G3P were used as substrates, FbaA produced not only F6P but also T6P. Thus, we found that F6P was epimerized to T6P when only F6P was used as a substrate for FbaA (Supplementary Fig. 1). Epimerization may be due to decomposition and condensation with different orientations of DHA and G3P.

The kinetic parameters of FbaA for FBP, F6P, and T6P were determined (Table 1). The specific activity, which was expressed as k cat, of FbaA for FBP was 5.6- and 7.5-fold higher than those for F6P and T6P, respectively. The catalytic efficiency (k cat/K m) of FbaA for FBP was 22- and 200-fold higher than those for F6P and T6P, respectively, indicating that FBP aldol cleavage is more favorable to FbaA than F6P epimerization. The catalytic efficiency of FbaA for F6P was ninefold higher than that for T6P, indicating that the equilibrium shifts from F6P to T6P.

Production of tagatose from fructose by three-step enzymatic cascade reaction

The kinetic parameters of cellobiose 2-epimerase (Taguchi et al. 2008), UDP-N-acetylglucosamine 2-epimerase (Murkin et al. 2004), d-tagatose 3-epimerase (Itoh et al. 1994), d-psicose 3-epimerase (Kim et al. 2006), d-ribulose-5-phosphate 3-epimerase (Chen et al. 1999), UDP-N-acetylglucosamine 4-epimerase, UDP-glucose 4-epimerase (Creuzenet et al. 2000), and l-ribulose-5-phosphate 4-epimerase (Samuel et al. 2001) were compared with those of FbaA (Table 1). The 4-epimerization activity of FbaA was not negligible compared to those of these sugar epimerases. In particular, the k cat/K m of FbaA for F6P (2 mM−1 s−1) was 14-fold higher than that of l-arabinose isomerase from Thermotoga maritima for d-galactose (0.14 mM−1 s−1), an efficient tagatose producer (Lee et al. 2004). These results suggest that FbaA is an efficient biocatalyst for the conversion of F6P to T6P.

Maximum conversion of F6P to T6P by 4-epimerization was at pH 8.5 and 50 °C (Supplementary Fig. 2). Under these conditions, FbaA converted 1 M F6P to 0.8 M T6P over 12 h (Fig. 1). During the conversion, the peaks of the triose intermediates, DHA and G3P, were not seen in Bio-LC profiles. At all sampling times, the total concentration of F6P plus T6P was 1 M, confirming that the triose intermediates were not present during the conversion. The reactions were carried out at 50 °C in 50 mM Tris/HCl buffer (pH 7) containing 20 U FbaA ml−1 with three ratios of initial substrates, 10 mM F6P, 5 mM F6P and 5 mM T6P, and 10 mM T6P. After 24 h, the concentrations of F6P and T6P were reached to 10 and 90 mM as an equilibrium ratio.

One-pot biotransformation for the production of tagatose using 1 M fructose was performed with the following three-step enzymatic cascade reaction: Hexokinase at 500 U ml−1 completely phosphorylated 1 M fructose in the presence of 1 M ATP to 1 M F6P at pH 8.5 and 37 °C for 1 h. FbaA at 100 U ml−1 epimerized 1 M F6P to 0.8 M T6P at pH 8.5 and 50 °C for 12 h. Phytase at 1000 U ml−1 completely dephosphorylated 0.8 M T6P to 0.8 M tagatose and phosphate at pH 5.5 and 50 °C for 3 h. As a result, 0.8 M (144 g l−1) tagatose was produced from 1 M (180 g l−1) fructose over 16 h with a conversion of 80% and a productivity of 9 g l−1 h−1. This high conversion of fructose to tagatose resulted from the complete phosphorylation and dephosphorylation and the T6P-shifted equilibrium (T6P: F6P = 90:10).

Potentiality of FbaA for the production of tagatose from fructose in the three-step enzymatic cascade reaction and metabolically engineered cells

The production of tagatose from different substrates by single and multi-step enzymatic reactions is summarized in Table 2. The conversion of galactose to tagatose by l-arabinose isomerases was in the range of 30–68% (Kim et al. 2002, 2003; Lim et al. 2007). The conversion of galactitol to tagatose by galactitol dehydrogenases was in the range of 32–72% (Jagtap et al. 2014; Rollini and Manzoni 2005). The conversion of tagatose from fructose by a three-step enzymatic cascade reaction was 80%, which is higher than those of other enzymes.

Recombinant E. coli ∆pfkA expressing FbaA and ScrK was cultured for T6P production in a 2.5 l fermentor under unoptimized conditions (Fig. 2). Interestingly, the cells produced extracellularly 720 mg T6P l−1, whereas intracellularly less than 20 mg T6P l−1 (less than 1 mg cells g−1), indicating that T6P comes out through cell membrane. T6P may be transported by the sugar phosphate transporter UhpT (Amhudkar et al. 1990).

Based on the results, the strategy for the efficient and economical production of tagatose from fructose using metabolically engineered cells is established as follows: The scrK and fbaA genes are overexpressed, and the degrading genes of the precursors G3P, F6P, and T6P are deleted in the cells (Supplementary Fig. 3). Glycerol and fructose are used as a carbon source for ATP supply and a substrate for tagatose production in the cultivation, respectively. This metabolically engineered cells produce extracellularly T6P from fructose. The produced T6P is dephosphorylated to tagatose and phosphate by an extracellular immobilized phosphatase, and phosphate is recycled by the cells. The extracellular immobilized phosphatase can act on only T6P without breaking down the intracellular substrate F6P and the intracellular intermediate G6P.

Purification of tagatose from the reaction mixture containing fructose by ethanol recrystallization

For the separation of ketose epimers, Amberlite CR-1310 (Ca++-type), an ion-exchange resin, has been used (Uechi et al. 2013). A packing column containing the resin was used for the purification of tagatose from the reaction mixture containing fructose (Supplementary Fig. 4). Because of the similar chemical properties of the two ketoses, tagatose was not completely separated from fructose. As an alternative purification method of tagatose, ethanol recrystallization can be used because the solubility of fructose in ethanol (66 g l−1) is 330-fold higher than that of tagatose (0.2 g l−1). When ethanol is added to the concentrated mixture of fructose and tagatose, tagatose is precipitated while fructose remains in the supernatant. However, tagatose cannot be purified from a mixture of galactose and tagatose, which are the reaction products of l-arabinose isomerases, because the solubility of galactose in ethanol (0.63 g l−1) is similar to that of tagatose.

The reaction mixture containing 0.8 M tagatose and 0.2 M fructose obtained after the three-step enzymatic cascade reaction was concentrated for the purification of tagatose. Tagatose did not precipitate with the addition of ethanol below 3.33 M sugar, whereas the mixture was not mixed with ethanol at a concentration factor greater than 5.88 M sugar. In the sugar concentration ranging of 3.33–5.88 M, the purity of tagatose increased as the sugar concentration increased (Fig. 3). At sugar concentrations less than 4.55 M, the yield of tagatose increased as the sugar concentration increased. However, above 4.55 M, the yield remained constant and any differences in the purity were not critical. Thus, a suitable sugar concentration for the purification of tagatose ranged from 4.55 to 5.88 M. Tagatose was purified from the concentrated reaction mixture at 5 M by ethanol recrystallization with a yield of 97.4% and a purity of 98%. The resulting tagatose was dissolved to 5 M, and the solution was purified again by ethanol recrystallization to achieve a final purity of 99.9% and a yield of 96.3% (Supplementary Fig. 5). Thus, ethanol recrystallization is an efficient and economical method for the purification of tagatose. The recrystallization method has some advantage comparing with chromatographic methods, including having a lower cost and reduced time, being more environmentally friendly, and having a higher yield and purity.

Effect of the concentrated reaction mixture on the purity (filled circle) and yield of tagatose (open circle) by ethanol recrystallization. The reaction mixture contains 1 M sugar. The concentration factor was the ratio of the concentrated volume used for ethanol recrystallization to the initial volume. Data represent the means of three separate experiments and error bars represent the standard deviation

In summary, 0.8 M tagatose was produced from 1 M fructose in the presence of 1 M ATP by the cascade reaction of hexokinase, FbaA, and phytase with a conversion rate of 80%. These results suggest the possibility for the economical production of tagatose from fructose without ATP by metabolically engineered cells. The reaction mixture containing tagatose and fructose obtained from the cascade reaction was purified tagatose with a yield of 96.3% and a purity of 99.9% by ethanol recrystallization. Thus, this purified tagatose was obtained from fructose with a yield of 77% by the three-step enzymatic cascade reaction and ethanol recrystallization. To the best of our knowledge, this is the first biotechnological production of tagatose from fructose and the first application of solvent recrystallization for the purification of rare sugars. These findings may contribute to the high-yield commercial manufacturing of tagatose.

References

Adachi S, Sugawara H (1963) Separation of ketose and aldose by chromatography on an ion-exchange column. Arch Biochem Biophys 100:468–471

Amhudkar SV, Anantharamg V, Maloneyan PC (1990) UhpT, the sugar phosphate antiporter of Escherichia coli, functions as a monomer. J Biol Chem 265:12287–12292

Chen YR, Larimer FW, Serpersu EH, Hartman FC (1999) Identification of a catalytic aspartyl residue of D-ribulose 5-phosphate 3-epimerase by site-directed mutagenesis. J Biol Chem 274:2132–2136

Creuzenet C, Belanger M, Wakarchuk WW, Lam JS (2000) Expression, purification, and biochemical characterization of WbpP, a new UDP-GlcNAc C4 epimerase from Pseudomonas aeruginosa serotype O6. J Biol Chem 275:19060–19067

Hong YH, Lee DW, Lee SJ, Choe EA, Kim SB, Lee YH, Cheigh CI, Pyun YR (2007) Production of D-tagatose at high temperatures using immobilized Escherichia coli cells expressing L-arabinose isomerase from Thermotoga neapolitana. Biotechnol Lett 29:569–574

Itoh H, Okaya H, Khan A, Tajima S, Hayakawa S, Izumori K (1994) Purification and characterization of D-tagatose 3-epimerase from Pseudomonas sp. ST-24. Biosci Biotechnol Biochem 58:2168–2171

Izumori K (2006) Izumoring: a strategy for bioproduction of all hexoses. J Biotechnol 124:717–722

Jagtap SS, Singh R, Kang YC, Zhao H, Lee JK (2014) Cloning and characterization of a galactitol 2-dehydrogenase from Rhizobium legumenosarum and its application in D-tagatose production. Enzyme Microb Technol 58–59:44–51

Kim BC, Lee YH, Lee HS, Lee DW, Choe EA, Pyun YR (2002) Cloning, expression and characterization of L-arabinose isomerase from Thermotoga neapolitana: bioconversion of D-galactose to D-tagatose using the enzyme. FEMS Microbiol Lett 212:121–126

Kim HJ, Ryu SA, Kim P, Oh DK (2003) A feasible enzymatic process for D-tagatose production by an immobilized thermostable L-arabinose isomerase in a packed-bed bioreactor. Biotechnol Prog 19:400–404

Kim HJ, Hyun EK, Kim YS, Lee YJ, Oh DK (2006) Characterization of an Agrobacterium tumefaciens D-psicose 3-epimerase that converts d-fructose to D-psicose. Appl Environ Microbiol 72:981–985

Lee DW, Jang HJ, Choe EA, Kim BC, Lee SJ, Kim SB, Hong YH, Pyun YR (2004) Characterization of a thermostable L-arabinose (D-galactose) isomerase from the hyperthermophilic eubacterium Thermotoga maritima. Appl Environ Microbiol 70:1397–1404

Lim BC, Kim HJ, Oh DK (2007) High production of D-tagatose by the addition of boric acid. Biotechnol Prog 23:824–828

Murkin AS, Chou WK, Wakarchuk WW, Tanner ME (2004) Identification and mechanism of a bacterial hydrolyzing UDP-N-acetylglucosamine 2-epimerase. Biochemistry 43:14290–14298

Rollini M, Manzoni M (2005) Bioconversion of D-galactitol to tagatose and dehydrogenase activity induction in Gluconobacter oxydans. Proc Biochem 40:437–444

Samuel J, Luo Y, Morgan PM, Strynadka NCJ, Tanner ME (2001) Catalysis and binding in L-ribulose-5-phosphate 4-epimerase: a comparison with L-fuculose-1-phosphate aldolase. Biochemistry 40:14772–14780

Taguchi H, Senoura T, Hamada S, Matsui H, Kobayashi Y, Watanabe J, Wasaki J, Ito S (2008) Cloning and sequencing of the gene for cellobiose 2-epimerase from a ruminal strain of Eubacterium cellulosolvens. FEMS Microbiol Lett 287:34–40

Thomason LC, Costantino N, Court DL (2007) E. coli genome manipulation by P1 transduction. Curr Protoc Mol Biol Chapter 1:Unit 1.17

Uechi K, Takata G, Fukai Y, Yoshihara A, Morimoto K (2013) Gene cloning and characterization of L-ribulose 3-epimerase from Mesorhizobium loti and its application to rare sugar production. Biosci Biotechnol Biochem 77:511–515

Acknowledgements

This study was supported by the Ministry of Trade, Industry & Energy (MOTIE), Korea Institute for Advancement of Technology (KIAT) through the Encouragement Program for The Industries of Economic Cooperation Region.

Supporting information

Supplementary Fig. 1—Bio-LC profiles of (I) substrate and (II) product in the conversion of F6P to T6P by FbaA.

Supplementary Fig. 2—Effects of the pH and temperature of FbaA on the 4-epimerization of F6P to T6P by FbaA.

Supplementary Fig. 3—Metabolic pathway engineering for the overproduction of tagatose from glucose or fructose and glycerol in E. coli.

Supplementary Fig. 4—Purification of tagatose from the reaction mixture with fructose by ion chromatography using a column containing Amberite CR 1310 (Ca2+ form) resin.

Supplementary Fig. 5—HPLC profiles during the separation of tagatose from the reaction mixture with fructose by recrystallization from ethanol.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Lee, SH., Hong, SH., Kim, KR. et al. High-yield production of pure tagatose from fructose by a three-step enzymatic cascade reaction. Biotechnol Lett 39, 1141–1148 (2017). https://doi.org/10.1007/s10529-017-2340-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-017-2340-3