Abstract

Water pollution from the release of industrial wastewater is a serious problem for almost every industry. Enzymes from portulaca, Portulaca oleracea cv., have been investigated for their ability to degrade bisphenol A (BPA), one of the well-known estrogenic pollutants. Enzymatic crude extracts from P. oleracea cv. roots were immobilized on aminopropyl-modified glass beads. They maintained BPA metabolic activity over a broad range of pH values and temperatures. The immobilized enzyme was reusable with more than 50 % of its initial activity retained after 12 batch reactions and no loss of activity after storage for 1 month at −30 °C. Thus, the immobilization of extracts from P. oleracea cv. roots is a useful method for removing BPA from industrial wastewater.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Bisphenol A [BPA, 2,2-bis(4-hydroxyphenyl)propane] is a widely used component of plastic containers for food and beverages, metal can linings, dental sealants and other applications (Chapin et al. 2008). BPA is structurally similar to estrogenic hormones, such as 17β-estradiol. Thus, BPA can cause various disorders including abnormal sexual differentiation or disrupted reproductive function in many living organisms. Hence, it is important to develop a method for removing BPA from polluted waste water.

The main methods to remove BPA from polluted waste water are based on physicochemical treatments, including adsorption to activated carbon and ozonation (Liu et al. 2009). However, these methods generally consume a lot of energy and are relatively expensive. Therefore, a low-cost and highly efficient method is still needed for sustainable water purification in aquatic environments. In this context, the plant-based cleanup of wastewater, a form of phytoremediation, is of major interest (Krämer 2005; LeDuc and Terry 2005).

Phytoremediation is cost-effective and requires relatively low energy inputs. Previously, we found that portulaca (Portulaca oleracea cv.) is superior to other plants in removing BPA; the plant almost completely removes 50 μM BPA from a hydroponic solution within 24 h (Imai et al. 2007), and the enzymes in P. oleracea cv. roots metabolize BPA (Kaneda et al. 2012). Although P. oleracea cv. is a valuable plant for removing BPA from wastewater, we cannot utilize P. oleracea cv. in all environments, such as locations unsuitable for plant growth or with limited space. Under such conditions, it is desirable to use materials to which the key enzymes have been immobilized. Moreover, to make the process more economical, crude enzymatic extracts from roots can serve as low-cost alternatives to purified enzymes for applications where enzyme purity is not essential. To date, no investigations using enzyme immobilization methods with crude enzymatic extracts from P. oleracea cv. have been used for BPA removal. The objective of this report is to evaluate the possible usage of immobilized-enzyme glass beads (IE-GB) for BPA removal.

Methods

Plant materials and culture conditions

Portulaca (P. oleracea cv.) was purchased from a local market in Osaka, Japan. The plants were sterilized with 1 % (v/v) sodium hydrochloride, followed by repeated washes with sterile water. The sterile plants were maintained by successive transfers and cultivation of shoots cut from whole plants on Murashige–Skoog medium containing vitamins, 1 % (w/v) sucrose and 0.2 % (w/v) gellan-gum in a culture bottle at 25 °C under continuous light (50–100 μmol m−2 s−1) as described previously (Imai et al. 2007). Plants cultivated for about 3 months were used for this study.

Preparation of crude protein extracts from P. oleracea roots

P. oleracea cv. roots were flash-frozen in liquid N2 and ground in a mortar with a pestle. Extraction buffer (50 mM HEPES/KOH pH 7.5, 0.33 M D-sorbitol, 1 mM MgCl2, 1 mM MnCl2, 2 μM EDTA and 1.14 mM ascorbic acid) was added at 5 ml per 1 g fresh weight of homogenized material. The obtained extract was centrifuged at 17,000×g for 10 min at 4 °C, and the supernatant was collected and centrifuged at 20,000×g for 10 min at 4 °C. This supernatant is termed ‘enzymatic extract’. The protein content in the enzymatic extracts was determined according to the Bradford dye binding method, using bovine serum albumin as a standard.

Enzyme immobilization

Glass beads, aminopropyl-CPG (particle size: 70–140 μm, pore size: 500 Å. Biosearch Technologies, Inc. Petaluma, CA), were used as enzyme carriers. They (200 mg) were suspended in 20 ml 2.5 % (w/w) glutaraldehyde and stirred at 25 °C for 2 h. After filtering the suspension, the residue was washed with ultra-pure water. The beads were added to crude protein extracts from P. oleracea cv. roots at 20 mg per 7 ml protein extract and stirred at 4 °C for 24 h. The resulting IE-GB were washed with ultra-pure water and recovered by centrifugation at 17,000×g for 2 min at 4 °C. This washing process was repeated twice.

Bisphenol A metabolic activity assay

To assay the bisphenol A (BPA) metabolic activity of IE-GB, 50 μM BPA in citrate buffer, pH 6, was added to IE-GB at 20 mg IE-GB to 3 ml BPA. BPA levels were determined by HPLC. BPA in the assay solution was separated by Inertsil ODS-3 column, (4.6 mm i.d. ×50 mm, particle size 5 μm; GL Sciences, Inc., Tokyo, Japan). The injection volume was 40 μl, and 60 % (v/v) aqueous methanol was the eluent at 1 ml min−1. The eluent was monitored at 280 nm to calculate the concentration of BPA. The relative metabolic activity was calculated with the formula,

where Vexp is initial rate of BPA decrease under the individual experimental condition, and Vbasal is initial rate of BPA decrease the basal condition. The basal conditions are provided in the figure legends.

Results and discussion

Crude enzyme immobilization

We immobilized crude P. oleracea cv. root enzymatic extracts with glutaraldehyde on aminopropyl-modified glass beads. Before immobilization, the protein content in the supernatant was 280 μg ml−1, and after immobilization, no proteins were detected in the supernatant. Thus, 9.8 mg proteins were immobilized per 1 g glass beads. This result demonstrates that almost all of the enzymatic extracts were immobilized on the beads.

Figure 1 shows the time course of BPA metabolism in the standard solution treated with IE-GB. IE-GB removed BPA effectively but beads without immobilized enzymes did not metabolize BPA. Hydroxylated and oxidized BPA derivatives, the primary BPA metabolites generated by P. oleracea cv. enzymes (Watanabe et al. 2012), were detected after treatment of BPA with IE-GB. The immobilized enzymes thus metabolized BPA but the beads alone did not absorb BPA or convert it to another metabolite. Prior to immobilization, the enzyme activity was 1.4 × 10−3 μmol min−1 g protein−1. After immobilization, the enzyme activity was 1.2 × 10−3 μmol min−1 g protein−1 and 8.7 × 10−2 μmol min−1 g beads−1. In other words, the BPA metabolic activity of IE-GB was 84 % that of the extracts containing the same amount of crude proteins. These results indicate that the enzymatic extracts of P. oleracea cv. roots immobilized to GB-maintained their BPA metabolic activity. From a previous study, polyphenol oxidase in P. oleracea cv. roots may play the main role in metabolizing BPA (Kaneda et al. 2012). This suggests that the enzymatic extracts include the polyphenol oxidases, which take on the main role in the BPA metabolic activity of IE-GB.

Many studies have used glass beads as enzyme carriers since the beads are inexpensive and renewable materials (Gόmez et al. 2006; Bhushan et al. 2008). For example, α-amylase was immobilized onto phthaloyl chloride-containing amino group functionalized glass beads (Kahraman et al. 2007). These beads were robust and could be reused many times. Stored at 4 °C, the bead lost only 20 % of the activity in 25 days, and retained 81 % activity after 25 uses. Another enzyme, nitrite reductase, was also immobilized on glass beads to serve as a biosensing device for the continuous monitoring of nitrite in groundwater, rivers and lakes (Rosa et al. 2002). The nitrile reductase beads could also be reused, and enzyme activity was retained after storage.

Enzyme immobilization can also be achieved using glutaraldehyde as the activating agent. At first, Schiff-base bonds between an aldehyde group of glutaraldehyde and an amino group of the carrier surface are formed (López-Gallego et al. 2005). Aminopropyl-modification of the glass bead surface is a promising technique to accelerate this first step. Next, the second aldehyde group of glutaraldehyde reacts with an amino group of the enzyme. In terms of stabilization, treatment with glutaraldehyde offers very good results in many cases because this molecule forms crosslinks between enzymes and carrier (López-Gallego et al. 2005). The slight reduction in the BPA metabolic activity of IE-GB compared with that of the free crude extract is likely caused by the non-specificity of glutaraldehyde. The non-specificity of glutaraldehyde generates variation in the orientation of immobilized enzymes. In such a situation, the active site of some enzymes might be blocked by the carrier and other proteins.

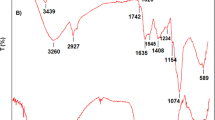

Effects of pH and temperature on BPA oxidation

Considering the practical application of IE-GB in wastewater treatment facilities, it is necessary to evaluate not only the ability to remove BPA, but also the effects of various environmental conditions on the activity of IE-GB. The optimum pH for BPA removal by IE-GB was pH 6 (Fig. 2), and optimum activity was at 25 °C; however, activity at 37 °C was almost identical to that at 25 °C (Fig. 3). The optimal conditions for BPA removal by IE-GB are consistent with those of intact plant. (Imai et al. 2007). In addition, IE-GB retained almost 50 % or more of the activity at pH 6, but the activity declined to 20 % at pH 4 (Fig. 2). Also, at 4 °C, IE-GB activity was almost 70 % of that at 25 °C (Fig. 3). These results suggest that IE-GB can be utilized at less than 38 °C and pH values from 5.8 to 8.6. The expected temperature and pH range of wastewater from industrial sources are less than 38 °C and pH 5.8–8.6. These conditions are adapted to wastewater under the strict local regulation in Japan.

Effect of pH on BPA oxidation The effect of pH was examined using 20 mM buffers (citrate buffer, pH 4–6 and HEPES buffer pH 7–9). 50 μM bisphenol A (BPA) (3 ml) was added to immobilized-enzyme glass beads (IE-GB, 20 mg) and incubated at 25 °C for 6 h. Each relative activity (%) was normalized by the basal condition; at pH 6. Data represent the mean ± SD (n = 3)

Effect of temperature on BPA oxidation 50 μM bisphenol A (BPA) (3 ml) was added to immobilized-enzyme glass beads (IE-GB, 20 mg) in citrate buffer, pH 6 and incubated at 4, 25, 37 °C for 6 h. Each relative activity (%) was normalized by the basal condition; at 25 °C. Data represent the mean ± SD (n = 3)

Reuse and storage stability of IE-GB

Removing BPA industrially will require that IE-GB are reused and are stable in storage. In comparison to using intact plants or crude enzyme extracts, the advantages of enzyme immobilization are reusability and storage stability. IE-GB retained over 50 % of the initial enzyme activity after 12 batch reactions (Fig. 4). Also, IE-GB were stored at −30, 4 and 25 °C and retested for activity after one month. IE-GB stored at −30 °C for a month retained over 100 % activity (Fig. 5) but the activity was entirely lost in the other storage conditions. Our results show that IE-GB should be a useful method for removing BPA from industrial wastewater.

Effect of multiple uses on BPA oxidation 50 μM bisphenol A (BPA) (1 ml) was added to immobilized-enzyme glass beads (IE-GB, 20 mg) and incubated at 25 °C for 24 h. Repeated batch experiments were done at 24 h cycles. Each relative activity (%) was normalized by the activity before starting batch experiment. Data represent the mean ± SD (n = 3)

Several other investigators have used immobilized enzymes as a means of removing BPA. For example, in a study in which mushroom tyrosinase was immobilized with sodium alginate (Kampmann et al. 2014). 50–500 mg mushroom powder (cell dry weight, cdw), whose BPA metabolic activity was 0.08 μmol min−1 mg mushroom powder−1, were added to 0.2 g sodium alginate. If the activity of the powder was completely retained after immobilization, the activity should be 20–200 μmol min−1 g alginate−1, however, the activity of alginate-immobilized mushroom cells was 0.44 μmol min−1 g alginate−1. In other words, the activity of enzymes decreased over 97 % after immobilization. In comparison, the activity of the crude enzyme preparation decreased about only 15 % in our study. We propose that the difference in carriers and method of enzyme immobilization are two factors responsible for this difference in retained activity. In the mushroom tyrosinase study, silica alginate matrix capsules were used to enclose the enzymes. In contrast, we used glass beads that caught enzymes on the surface.

In another study, silane-coated silica beads were used as a carrier for immobilizing laccase from the saprobic fungus, Cerrena unicolor cv. (Songulashvili et al. 2012). In addition, treatment with glutaraldehyde for immobilizing the enzyme was tested in this study in the same way as in our study. The activity of the laccases decreased about 90 % after immobilization, in contrast to our study in which the enzyme activity decreased only about 15 %. The difference between the activities of these immobilized enzymes may have been caused by an effect of enzymatic orientation. Compared to the enzymes of P. oleracea cv. roots, more active sites of C. unicolor cv. laccase might have faced the bead surface, inhibiting substance entry.

Compared to these two studies (Songulashvili et al. 2012; Kampmann et al. 2014), the activity of our immobilized enzymes in reducing the BPA content of solutions is quite low even though the immobilization was highly efficient. The reason for this low activity could be due to the lower activity of enzymatic crude extracts from P. oleracea cv. roots compared with other enzyme sources. If the activity of the IE-GB needs to be significantly improved, enzymes that metabolize BPA from P. oleracea cv. could be purified. However, the costs associated with removing BPA would be significantly lower by using immobilized enzyme extracts from P. oleracea cv. roots. The method presented in this study provides an attractive and low cost alternative to biotechnological applications of purified enzymes for phytoremediation.

References

Bhushan I, Parshad R, Qazi GN, Ingavle G, Rajan CR, Ponrathnam S, Gupta VK (2008) Lipase enzyme immobilization on synthetic beaded macroporous copolymers for kinetic resolution of chiral drugs intermediates. Process Biochem 43:321–330

Chapin RE, Adams J, Boekelheide K, Gray LE Jr, Hayward SW, Lees PS, McIntyre BS, Portier KM, Schnorr TM, Selevan SG, Vandenbergh JG, Woskie SR (2008) NTP-CERHR expert panel report on the reproductive and developmental toxicity of bisphenol A. Birth Defects Res B Dev Reprod Toxicol 83:157–395

Gόmez JL, Bόdalo A, Gόmez E, Bastida J, Hidalgo AM, Gόmez M (2006) Immobilization of peroxidases on glass beads: an improved alternative for phenol removal. Enz Microb Technol 39:1016–1022

Imai S, Shiraishi A, Gamo K, Watanabe I, Okuhata H, Miyasaka H, Ikeda K, Bamba T, Hirata K (2007) Removal of phenolic endocrine disruptors by Portulaca oleracea. J Biosci Bioeng 103:420–426

Kahraman M, Bayramoğlu G, Kayamanapohan N, Güngör A (2007) α-Amylase immobilization on functionalized glass beads by covalent attachment. Food Chem 104:1385–1392

Kampmann M, Boll S, Kossuch J, Bielecki J, Uhl S, Kleiner B, Wichmann R (2014) Efficient immobilization of mushroom tyrosinase utilizing whole cells from Agaricus bisporus and its application for degradation of bisphenol A. Water Res 57:295–303

Kaneda H, Matsui T, Tomiyasu R, Kuroda Y, Higashimoto Y, Oda T, Miyasaka H, Okuhata H, Tanaka S, Harada K, Matsuura H, Nakayama H, Kato K, Hirata K (2012) Isolation of polyphenol oxidase genes from Portulaca oleracea and evaluation of their ability to metabolize endocrine-disrupting chemicals. Plant Biotechnol 29:351–357

Krämer U (2005) Phytoremediation: novel approaches to cleaning up polluted soils. Curr Opin Biotechnol 16:133–141

LeDuc DL, Terry N (2005) Phytoremediation of toxic trace elements in soil and water. J Ind Microbiol Biotechnol 32:514–520

Liu ZH, Kanjo Y, Mizutani S (2009) Removal mechanisms for endocrine disrupting compounds (EDCs) in wastewater treatment—physical means, biodegradation, and chemical advanced oxidation: a review. Sci Total Environ 407:731–748

López-Gallego F, Betancor L, Mateo C, Hidalgo A, Alonso-Morales N, Dellamora-Ortiz G, Guisán JM, Fernández-Lafuente R (2005) Enzyme stabilization by glutaraldehyde crossliking of adsorbed proteins on aminated supports. J Biotechnol 119:70–75

Rosa CC, Cruz HJ, Vidal M, Oliva AG (2002) Optical biosensor based on nitrite reductase immobilised in controlled pore glass. Biosens Bioelectron 17:45–52

Songulashvili G, Jimenéz-Tobón GA, Jaspers C, Penninckx MJ (2012) Immobilized laccase of Cerrena unicolor for elimination of endocrine disruptor micropollutants. Fungal Biol 116:883–889

Watanabe I, Harada K, Matsui T, Miyasaka H, Okuhata H, Tanaka S, Nakayama H, Kato K, Bamba T, Hirata K (2012) Characterization of bisphenol A metabolites produced by Portulaca oleracea cv. by liquid chromatography coupled with tandem mass spectrometry. Biosci Biotechnol Biochem 76:1015–1017

Acknowledgments

This research was supported in part by a Grant-in-Aid for Challenging Exploratory Research (No. 23659064) from Japan Society for the Promotion of Science (JSPS), and a grant from the Japan Chemical Industry Association (JCIA) Long-range Research Initiative (LRI).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Matsushima, K., Kaneda, H., Harada, K. et al. Immobilization of enzymatic extracts of Portulaca oleracea cv. roots for oxidizing aqueous bisphenol A. Biotechnol Lett 37, 1037–1042 (2015). https://doi.org/10.1007/s10529-014-1761-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-014-1761-5