Abstract

The thermostablility and enzymatic activity of 1,3-1,4-β-glucanase (BglA) from Bacillus amyloliquefaciens was improved by modifying five (out of 12) ε-amino groups in lysine residues with nitrous acid. The optimal modification condition for BglA was determined as 30 mM nitrous acid at, 40 °C for 30 min. The optimally-modified BglA had higher specific activity and T 50 value, which were 3,370 U/mg and 70 °C, respectively. Its half-life values at 50 and 60 °C were extended and reached 58.5 and 49.5 min, respectively. Circular dichroism analysis showed that the secondary structures in modified BglA were almost the same with that of wild-type BglA. Thus, modification of lysine residues can simultaneously improve the activity and thermostability of β-glucanase which are ideal targets for further protein engineering.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

1,3-1,4-β-Glucanase hydrolyzes 1,3-1,4-β-glucans into oligosaccharides and has been applied in some industries. In the brewing industry, β-glucanase is often added in the mashing process to decompose barley β-glucan thereby increasing yields of extracts and filtration rate of wort. However, the low thermostability of many β-glucanases often limit their applications. The temperature in malt mashing is elevated from 48 to 78 °C, while the optimal temperatures of Bacillus β-glucanases vary from 45 to 65 °C (Planas 2000). Therefore, the thermostability of these enzymes need to be improved to meet the requirement of industrial application.

Protein functionality and thermostability is a balance of flexibility and rigidity of its structure. Engineering surface amino acid residues to strengthen their interactions while keeping the flexibility of catalytic core is a common strategy for improving protein thermostability (Fields 2001). Lysine residues located at the protein surface often have the highest average solvent accessibility, which decreases protein thermostability. Lysine residues also occupy a low proportion in thermophilic enzymes, especially in exposed or fully-exposed states (Pack and Yoo 2004). They have high root-mean-square-fluctuation values due to their long side chains (Khajeh et al. 2001). In 1,3-1,4-β-glucanase (BglA) from Bacillus amyloliquefaciens BS5582 (Li et al. 2009), all 12 lysine residues are located at the protein surface and might be potential targets for thermostability engineering.

Chemical modification is a common method for analyzing the function of specific residues in the maintenance of protein conformation. Lysine residues are frequently modified by amine-reactive reagents (Khajeh et al. 2001) due to their active ε-amino groups. Nitrous acid can rapidly modify the α-amino group of protein into hydroxyl group within 5 min, then gradually transform the ε-amino groups of lysine residues to hydroxyl groups when reaction time extends (Garrett and Grisham 1999). Chemical modification has been proved to be efficient in enzyme activity engineering (Khajeh et al. 2001). Therefore, in this study, lysine residues were subject to chemical modification to evaluate their effect on catalytic activity and thermostability of β-glucanase from B. amyloliquefaciens BS5582.

Materials and methods

Strains and culture condition

Escherichia coli BL21 (DE3) and its derivative strains were cultured in LB medium, which was supplemented with ampicillin (100 μg/ml) or kanamycin (50 μg/ml) when necessary. The fermentation medium for heterogonous production of recombinant BglA (rBglA) was the optimized TB medium (20 g yeast extract/l; 12.5 g tryptone/l; 14.1 ml glycerol/l; 2.17 g KH2PO4/l and 2.74 g K2HPO4/l).

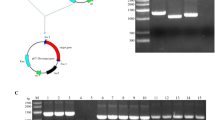

Construction of recombinant plasmids

The bglA gene from Bacillus amyloliquefacens BS5582 was amplified using the pair of primers (rBglA-F: TCACGCGGATCCATGAAACGAGTGTTGCTAATTCTT and rBglA-R: TGCACGCTCGAGGTATTTTTTTGTATAGCGCACCCA, the underlined bases represented restriction enzyme sites and the terminator codon was mutated to tyrosine), which was designed based on the previous reported sequence (GenBank Accession No. M15674) (Hofemeister et al. 1986). After ligation into vector, pET28a(+), the resulting plasmids pET28a-bglA were transformed into E. coli JM109. The positive clones were selected and verified by sequencing analysis.

Expression and purification of recombinant 1,3-1,4-β-glucanase

The recombinant plasmid pET28a-bglA, was transformed into E.coli BL21(DE3) cells and the bacteria was grown at 37 °C in TB medium. When OD600 reached 1, 0.06 mM IPTG and 8 mM α-lactose were added. The culture was then incubated at 24 °C for 6 h. The cells were harvested by centrifugation at 8,000×g for 10 min and then resuspended by 20 mM PBS Buffer (pH 6.5). After repeated rounds of sonication, the solution was centrifugated at 12,000×g for 10 min at 4 °C and the sediments were discarded. The supernatant of culture and the clear cytoplasm solution after sonication were separately loaded onto a Ni–NTA affinity column (Qiagen) for purification, respectively. GE PD-10 desalting column was then used for desalting. Subsequently, the desalted solutions were concentrated using a Pellicon Cassette concentrator (Millipore) with a 10 kDa cutoff membrane. The purity of the obtained recombinant enzyme was analyzed by SDS-PAGE. The protein concentration was determined using Bradford method with bovine serum albumin as standard. The enzymatic activities of rBglA in cytoplasm and extracellular medium after indication by IPTG and lactose were determined according to the previous reported method (Cornelis et al. 1982).

Enzymatic activity assay

Activity of 1,3-1,4-β-glucanase was determined using an improved AZO method with 1 % AZO blue barley β-glucan (Megazyme) as substrate (Wang et al. 2014). The content of reduced sugar was measured using the 3,5-dinitrosalicylic acid method. The reaction volume was incubated at 40 °C for 10 min. Termination solution (32.5 g sodium acetate/l, 4 g ZnSO4/l and 80 % (v/v) methoxy ethanol) was added and A590 was measured. One unit of enzymatic activity was defined as the amount of enzyme that releasing 1 μmol reduced sugar from the substrate per min at pH 6.5. Each measurement was repeated in triplicate.

Modeling analysis of primary and 3-D strucuture of 1,3-1,4-β-glucanase

The 3D structure modelling was executed in SWISSMODEL online server using automated mode. β-Glucanase (Hahn et al. 1995) from B.licheniformis (PDB code: 1GBG) was used as template. The identity between amino acid sequence of BglA and the sequence of template was 90.19 %. The accessible molecular surface of rBglA was calculated in the WHAT IF web server (Vriend 1990). The atomic packing of rBglA was calculated using the Voronoia method (Rother et al. 2009).

Chemical modification of 1,3-1,4-β-glucanase

The chemical modification was conducted in 20 mM phosphate buffer at pH 6.5. Nitrous acid was freshly prepared by mixing 0.2 M NaNO2 with 0.2 M HCl gently in opaque tube for each experiment. After modification, the modified 1,3-1,4-β-glucanases were purified by dialysis and concentrated using Pellicon Cassette concentrator.

Determination of modification degree

The number of amino groups modified was determined using trinitrobenzenesulphonic acid (TNBS) method: 25 μl TNBS (3.4 mM) was added to 1 ml purified rBglA sample solution in 20 mM phosphate buffer (pH 6.5) and incubated at 25 °C for 1 h. The final A420 was measured.

Thermal and pH stability of 1,3-1,4-β-glucanase

The optimal pH and temperature for both wide-type and modified 1,3-1,4-β-glucanases were determined by assaying the enzymatic activity at a range of the parameters while keeping the other conditions constant. The pH stability and thermostability analysis were carried out according to a method previous reported (Wang et al. 2014). The midpoint temperature (T 50) was defined as the temperature when the enzyme lost 50 % activity after treatment at 25–75 °C for 10 min (The enzyme was added to preheated solution). The half-life value of β-glucanase, designated as t(1/2, X °C), was defined as the time that the activity of β-glucanase declined to the half.

Far-UV circular dichroism(CD) analysis

The far-UV CD spectrums of 1,3-1,4-β-glucanases were measured from 190 nm to 250 nm by MOS-45 AF circular dichroism spectrometer (Bio-logic). The secondary structures (α-helix, β-sheet, β-turns, and random coil) were analyzed using Dichroweb online software (Whitmore and Wallace 2008).

Results and discussion

Evaluating potential effect of lysine on thermostability of 1,3-1,4-β-glucanase

Sequence alignment of several representative Bacillus β-glucanases and a thermophilic β-glucanase from Clostridium thermocellum (Schimming et al. 1991) showed that most of the Bacillus β-glucanases shared the same lysine sites except Lys214 (Supplementary Fig. 1). Alkalophilic β-glucanases from B. brevis and Bacillus strain N137 have relatively higher thermostabilities and contain fewer homologous lysine sites. As for the thermophilic β-glucanases from C. thermocellum, the homologous sites of lysine residues are even less. It is interesting that lysine residues are highly conserved in most β-glucanases from mesophilic Bacillus spp. while thermostable β-glucanases tend to contained fewer lysine residues in their protein sequences. The rBglA from B. amyloliquefaciens with 12 lysine residues was chosen as a model to analyze the effect of lysine residues on its thermostability. In the rBglA, all 12 lysines were solvent-accessible and had the highest value of solvent accessibility among all the amino acids (Supplementary Table 1). The accessibility value of side chains accounted for 65–100 % in total accessibility values of corresponding lysine residues. Due to highly activity of exposed ε-amino group, lysine residues in the rBglA were predicted to be highly sensitive to heat treatment and were subject to chemically modified by nitrous acid.

Optimizing the condition of chemical modification of 1,3-1,4-β-glucanase

Up to 97 % of enzymatic activity was detected in the medium supernatant (Supplementary Table 2) when rBglA was expressed in E. coli, which indicated that rBglA was secreted into the medium after induction. The extracellular rBglA was purified by the Ni–NTA affinity column and its purity was verified by SDS-PAGE analysis (Supplementary Fig. 2). The purified rBglA was then subjected to chemical modification using nitrous acid.

The effect of pH on the stability of rBglA was analyzed. The activity of rBglA decreased by 0.9, 1.5, 2.7 and 35.6 % after incubation for 1 h at 40 °C in PBS buffer at pH 6.0, 6.5, 7.0 and 7.5, respectively. The results indicated that rBglA had good stability from pH 6 to 7 Taking the optimal pH of rBglA into consideration, the optimal pH for the modification reaction was selected pH 6.5.

To improve the modification effect on rBglA, nitrous acid concentration, modification temperature and modification time were optimized (Supplementary Fig. 3). For nitrous acid concentration, rBglA (50 μg/ml) was stable in 10–30 mM nitrous acid. After modification, the highest activity of rBglA was detected when nitrous acid was at 30 mM but above exceeded 40 mM, the activity of rBglA declined greatly.

The optimal reaction was at 40 °C. The modification time of nitrous acid could affect the modification degree of amino groups. When rBglA was modified for 5 min (mrBglA5), its activity was almost unchanged. This indicated that the α-amino group modification did not affect the enzymatic activity. When reaction time was extended, ε-amino groups in lysine residues were thought to be modified gradually. The highest activity of modified rBglA was measured after 30 min of (mrBglA30). The modification degree of amino groups was then determined. The number of amino group modified in mrBglA5 was determined at 1 which indicated that only one α-amino group of glutamine was modified. As for mrBglA30, 5 out of 12 lysine residues were determined to be modified by nitrous acid.

Increasing catalytic properties of rBglA by chemical modification

The catalytic dynamic properties, such as special activity, K m and K cat, of mrBglA5 were almost unchanged compared with those of wild-type enzyme, (Table 1). However, these catalytic dynamic properties of mrBglA30 were significantly changed. The specific activity of mrBglA30 reached 3,370 ± 60.5 U/mg, which was 24 % higher than that of rBglA. The K m value for mrBglA30 was slightly lower than that of wild-type enzyme. Besides, the V max, K cat and K cat/K m values of mrBglA30 had a significant enhancement compared with those of rBglA. These results indicated that these improved catalytic dynamic properties of rBglA30 might result from the modification on lysine residues.

Increasing pH stability of 1,3-1,4-β-glucanase by chemical modification

rBglA, mrBglA5 and mrBglA30 displayed the same optimal pH at pH 6.5 (Fig. 1). As for pH stability, mrBglA5 was similar to rBglA in all pH condition. However, mrBglA30 performed better stability in lower pH than rBglA. The optimal pH for stability of mrBglA30 was pH 5.5 to pH 6.5, while for wild-type rBglA it was between pH 6 and pH 7. Moreover, mrBglA30 retained a higher proportion of residual activity than BglA in all tested pH condition except pH 7.0. These results indicated that mrBglA30 had a better tolerance to pH stress. The better performance of mrBglA30 in an acidic environment might result from the decreased positive charge of protein surface caused by the replacement of ε-amino groups by hydroxy groups. It is interesting that β-glucanase with reduced electrostatic repulsion can help to maintain a stable conformation and increase its stability in the acidic wort environment (Quintanilla-Guerrero et al. 2008). Therefore, the modification of lysine residues in rBglA30 can increase its pH stability, especially in lower pH conditions. This will improve its performance in brewing industry since malt is a weakly-acidic condition (pH 5–5.5).

The optimal pH and pH stability assays of rBglA, mrBglA5 and mrBglA30. a The optimal pH of β-glucanases were determined by measuring the enzymatic activity at the pH range of 4.0–8.0 at 40 °C using 20 mM buffer (pH 4.0–5.5, acid-sodium acetate buffer; pH 6.0–8.0, phosphate buffer). b pH stability was evaluated by relative activity, which was calculated by dividing the residue activities of enzyme after 1 h treatment in different pH buffers by the initial activities. The data plotted were averages of triplicate experiments. 100 % activities of rBglA, mrBglA5 and mrBglA30 were 1,100, 1,600 and 1,820 U/ml respectively

Enhancing thermostability of 1,3-1,4-β-glucanase by chemical modification

rBglA, mrBglA5 and mrBglA30 shared the same optimal temperature at 55 °C (Fig. 2). The irreversible thermal denaturation experiment showed that the changes of enzymatic activity at different temperatures were similar to each other for rBglA and mrBglA5. Both of them retained almost full activity up to 60 °C. The residual activity started to decline quickly above 60 °C (Fig. 3). In contrast, mrBglA30 kept its full activity up to 65 °C. The T 50 value of mrBglA30 was determined at 70 °C, which was 2.5 °C higher than that of rBglA.

Optimal enzymatic temperature of rBglA, mrBglA5 and mrBglA30. Activities were measured in 20 mM phosphate buffer, pH 6.5. The maximum activity measured for each enzyme was counted as 100 % relative activity. Data represented the means of three separate experiments. 100 % activities of rBglA, mrBglA5 and mrBglA30 were 1,830, 2,660 and 2,090 U/ml, respectively

mrBglA30 also had higher half-life values than rBglA and mrBglA5 at 50 °C and 60 °C (Fig. 4). Activities of both rBglA and mrBglA5 declined after 10 min and almost disappeared after 70 min at 50 °C. In contrast, mrBglA30 retained 100 % activity after 50 min and still had ~30 % activity after 70 min. At 60 °C, the inactivation curves of rBglA and mrBglA5 declined quickly while that of mrBglA30 declined more slowly (Fig. 4b). The half-life values, t(1/2, 50 °C), of rBglA, mrBglA5 and mrBglA30 were 37.5, 38 and 58.5 min, respectively, and their t(1/2, 60 °C) values were 28, 28 and 49.5 min, respectively. Compared with those of rBglA, the half-life values of mrBglA30 was increased by 56 % at 50 °C and 77 % at 60 °C.

Inactivation curves of rBglA, mrBglA5 and mrBglA30 at 50 °C (a) and 60 °C (b). Half-life values were determined by incubating the enzymes at 50 and 60 °C and the activities of enzymes were measured as time extended. The activities of enzymes which were untreated were counted as 100 % relative activity. The data shown was average of triplicate measurements. 100 % activities of rBglA, mrBglA5 and mrBglA30 were 1,830, 2,660 and 2,090 U/ml, respectively

These above results indicate that thermostability of β-glucanase was significantly enhanced by nitrous acid modification. Since little change in enzymatic properties were observed upon α-amino modification (mrBglA5), the enhancement of thermostability should be derived from the modification of lysine residues. The modification of lysine residues results in transformation of the ε-amino group into a hydroxyl group, which gives more hydrophilic groups and a greater neutral protein surface. Such a modification could reduce the exposure of enzyme core in aqueous solution, thus increasing protein thermostability. The hydroxyl groups in modified lysine residue could both donate or receive hydrogen bonds while amino groups only donate hydrogen bonds (Sterpone et al. 2010). Also they are more hydrophilic than amino groups (Etter 1990). This may provide new opportunities for the occurrence of hydrogen bonds formation between modified lysine residues and surrounding residues or water molecules. The bond energy may also be higher (Greenwood and Earnshaw 1997). So we hypothesized that this may prevent the unfolding or denaturation of the protein. Therefore, the lysine modification altered the microstructures of rBglA to increase its thermostability.

Analyzing the secondary structure of the chemically-modified 1,3-1,4-β-glucanase

The secondary structure of purified rBglA, mrBglA5 and mrBglA30 was analyzed by CD. The enzymes displayed similar patterns of CD spectra. As shown in Fig. 5, a positive band was detected at around 200 nm and a negative band was detected at near 220 nm in all three spectra. Thus rBglA is probably composed of mainly β-strands and β-turns. Small percentage of α-helix was also observed. Table 2 shows that no changes in second structure were observed among the three enzyme forms. These results indicated that modification of lysine residues did not significantly affect the second structure of rBglA although its enzymatic activity, pH stability and thermostability were obviously improved.

Conclusion

The enzymatic properties of 1,3-1,4-β-glucanase, including thermostability, pH stability and enzymatic activity, were enhanced by chemical modification using nitrous acid. The enhancement mainly resulted from the modification on 5 out of 12 lysine residues, which caused transformation of active active ε-amino group into hydroxyl group. Therefore, some lysine residues had a negative influence on the catalytic activity and thermostability of β-glucanase as we expected. Site-directed mutagenesis and other techniques could be adopted in the future to improve the properties of β-glucanase for industrial application.

References

Cornelis P, Digneffe C, Willemot K (1982) Cloning and expression of a Bacillus coagulans amylase gene in Escherichia coli. Mol Gen Genet 186:507–511

Etter M (1990) Encoding and decoding hydrogen-bond patterns of organic compounds. Acc Chem Res 23:120–126

Fields PA (2001) Review: protein function at thermal extremes: balancing stability and flexibility. Comp Biochem Physiol A 129:417–431

Garrett GH, Grisham CM (1999) Biochemistry, 2nd edn. Saunders College Publishing, Fort Worth

Greenwood N, Earnshaw A (1997) Chemistry of the elements, 2nd edn. Elsevier Butterworth-Heinemann Publishing, Oxford

Hahn M, Pons J, Planas A, Querol E, Heinemann U (1995) Crystal structure of Bacillus licheniformis 1,3-1,4-beta-D-glucan 4-glucanohydrolase at 1.8 A resolution. FEBS Lett 374:221–224

Hofemeister J, Kurtz A, Borriss R, Knowles J (1986) The beta-glucanase gene from Bacillus amyloliquefaciens shows extensive homology with that of Bacillus subtilis. Gene 49:177–187

Khajeh K, Naderi-Manesh H, Ranjbar B, Moosavi-Movahedi A, Nemat-Gorgani M (2001) Chemical modification of lysine residues in Bacillus alpha-amylases: effect on activity and stability. Enz Microb Technol 28:543–549

Li Y, Xie Y, Zhu L, Zhang Y, Gu G, Li Q (2009) Optimization of cloning and expression of beta-glucanase gene from Bacillus amyloliquefaciens. Chin J Biotech 25:542–548

Pack SP, Yoo YJ (2004) Protein thermostability: structure-based difference of amino acid between thermophilic and mesophilic proteins. J Biotechnol 111:269–277

Planas A (2000) Bacterial 1,3-1,4-beta-glucanases: structure, function and protein engineering. Biochim Biophys Acta 1543:361–382

Quintanilla-Guerrero F, Duarte-Vazquez MA, Tinoco R, Gomez-Suarez M, Garcia-Almendarez BE, Vazquez-Duhalt R, Regalado C (2008) Chemical modification of turnip peroxidase with methoxypolyethylene glycol enhances activity and stability for phenol removal using the immobilized enzyme. J Agric Food Chem 56:8058–8065

Rother K, Hildebrand PW, Goede A, Gruening B, Preissner R (2009) Voronoia: analyzing packing in protein structures. Nucleic Acids Res 37:393–395

Schimming S, Schwarz WH, Staudenbauer WL (1991) Properties of a thermoactive beta-1,3-1,4-glucanase (lichenase) from Clostridium thermocellum expressed in Escherichia coli. Biochem Biophys Res Commun 177:447–452

Sterpone F, Stirnemann G, Hynes J, Laage D (2010) Water hydrogen-bond dynamics around amino acids: the key role of hydrophilic hydrogen-bond acceptor groups. J Phys Chem 114:2083–2089

Vriend G (1990) WHAT IF: a molecular modeling and drug design program. J Mol Graph 8:52–56

Wang J, Niu C, Liu X, Chen X, Li Q (2014) Characterization of a new 1,3-1,4-beta-glucanase gene from Bacillus tequilensis CGX5-1. Appl Biochem Biotechnol. doi:10.1007/s12010-014-0900-8

Whitmore L, Wallace BA (2008) Protein secondary structure analyses from circular dichroism spectroscopy: methods and reference databases. Biopolymers 89:392–400

Acknowledgments

This study was financially supported by the program for National Science Foundation (No. 31271919), New Century Excellent Talents in University of China (No. NCET-10-0453), National Basic Research Program of China (973 Program, No. 2010CB735706), the National High Technology Research and Development Program 863 (No. 2012AA021303), the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD), Self-determined Research Program of Jiangnan University (JUSRP11218) and Program of Introducing Talents of Discipline to Universities (No. 111-2-06).

Author information

Authors and Affiliations

Corresponding author

Additional information

Chengtuo Niu and Linjiang Zhu contributed equally to this work.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Niu, C., Zhu, L., Wang, J. et al. Simultaneous enhanced catalytic activity and thermostability of a 1,3-1,4-β-glucanase from Bacillus amyloliqueformis by chemical modification of lysine residues. Biotechnol Lett 36, 2453–2460 (2014). https://doi.org/10.1007/s10529-014-1616-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-014-1616-0