Abstract

The use of immobilized enzymes during saccharification of lignocelluloses enables the continuous process of enzymatic hydrolysis and repeatable use of enzyme, resulting in reduced operational cost. Novel nano-biocarriers were developed by layer-by-layer deposition of carbon nanotube (CNT) on the foam structures, and their efficiency for enzyme immobilization was demonstrated with cellulase and β-glucosidase. A three-fold enhancement was achieved in the activity of cellulase immobilized on CNT coated polyurethane foam. In addition, both cellulase and β-glucosidase immobilized on the CNT-foam showed much better storage stability and operational stability than the ones immobilized on the commercial biocarrier (Celite), which is critical for a continuous operation. CNT coated monolith was also developed as a biocarrier, offering high surface area and geometric stability. These nano-biocarriers are promising candidates for the efficient saccharification of biomass and to reduce carbon footprint and cost of the equipment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recycling of enzymes can substantially reduce the cost of enzymatic hydrolysis during saccharification of lignocelluloses (Tu et al. 2007). The presence of solid residuals (mainly lignin) and dissolution of the enzymes in the hydrolyzates make the enzymes difficult to separate. Immobilization is an effective way to retain the enzymes in the reactor. Enzyme immobilization often results in improved thermostability, activity, and resistance to shear inactivation (Dincer and Telefoncu 2007; Neumann et al. 2004). Various biocarriers have been studied for immobilization of cellulase, xylanase, and β-glucosidase, including but not limited to polyurethane foam, Celite, Eudragit, and colloidal spherical particles (Chakrabarti and Storey 1988; Dincer et al. 2005; Haupt et al. 2005; Neumann et al. 2004; Tu et al. 2006; Vasudevan et al. 2004). The immobilization of enzymes commonly involves physical entrapment, chemical adsorption or crosslinking. The immobilized enzymes enable the continuous process of enzymatic hydrolysis and repeatable use of enzyme, resulting in reduced operational cost. Immobilization can however, cause steric hindrance and reduce freedom of movement of enzyme (Taherzadeh and Karimi 2007). Another major problem in immobilization is to separate the immobilized support from the residual solid of the reactor.

New advances in nanotechnology offer great potential to increase the efficiency of a bioreactor. Nanotechnology has not been widely applied in the area of bioethanol production. Instead, the use of nanomaterials for enzyme immobilization in biosensor applications has been studied extensively, and the concept is well documented (Balasubramanian and Burghard 2006; Lu et al. 2007). A wide variety of nanomaterials have been explored for their application in biosensors due to their unique chemical, physical, and optoelectronic properties, e.g. carbon nanotubes (CNT) and fullerenes, which greatly increased biosensor sensitivity and response speed (Sherigara et al. 2003). These nanomaterials can be used as nano biocarriers for enzyme immobilization in the bioreactor for improved catalyst density.

Polyurethane foam is well studied as a biocarrier for immobilizing various types of enzymes, but lacks practical usage due to limited enzyme loading (Bakker et al. 2000). The traditional approach embedded enzymes deep into the foam macrostructure, resulting in very poor mass transfer characteristics (Vasudevan et al. 2004). In this work, novel nano-biocarriers were developed by tuning the wall structure of polyurethane foam into nanostructure, offering unique structure and high surface area, which is suitable for the application in the continuous biocatalytic conversion of lignocellulose to sugar (Lu and Okeke 2012). A commercially available microbiocarrier: Celite R635 was used for comparison. The effectiveness of nanostructured polyurethane foam for the enzyme immobilization was examined, and the storage stability and reusability of immobilized enzymes were evaluated.

Materials and methods

Materials

Celite R635 was kindly supplied by World Minerals. The polyurethane foam material used for immobilization of enzyme was supplied by EN Murray Co. The average pore size of foam materials was 0.85 mm (30 pores per inch). Foam materials were cut into cylinders (25 mm × 25 mm diam.). Novozyme 188, a commercial β-glucosidase from Aspergillus (Aldrich), and cellulase from Trichoderma reesei ATCC 26921 (Aldrich) were used for immobilization studies. Carbon nanotubes were purchased from Nanolab, which have diameters of 5–20 nm, and average length 5 μm. Poly(diallydimethylammonium chloride) (PDAC), sulfated poly(styrene) (SPS) and branched polyethyleimine (PEI) were purchased from Aldrich. Average molecular weights of PDAC, SPS and PEI were ~100,000–200,000, 70,000, and 750,000, respectively. Aqueous polyelectrolyte solutions were prepared containing either 20 mM PDAC or 10 mM SPS in 0.1 M NaCl. PEI solution was prepared containing 0.1 % (w/v) PEI in DI water. The solutions were filtered through 0.22 μm cellulose acetate membranes to remove particulates.

Preparation of SPS coated carbon nanotubes

Stable aqueous CNT suspension was prepared based on the procedure published previously (Lu et al. 2010): 0.1 g CNT was dispersed in 100 ml SPS solution by tip sonication with an output power of 23 W (Misonix Ultrasonic Liquid Processors, XL-2000 Series) for 30 min continuously, followed by stirring for 24 h. The excess SPS was removed by filtering the suspension through 0.22 μm cellulose acetate membrane followed with DI water washing for three times. The SPS coated CNT was redispersed into 100 ml DI water by mild sonication for 10–15 min.

Layer-by-layer self-assembly procedure

To prepare 3D CNT coated polyurethane foam, the foam pieces were washed with DI water three times and dried in vacuum oven. They were treated with UV ozone for 30 min which made the surface hydrophilic. The pretreated foam pieces were first immersed in PEI solution for 1 h, followed by three times of 5 min rinses in DI water. Then the foam pieces were immersed in the CNT suspension for 30 min, followed by rinsing with DI water until no CNT was coming off from the surface. The foam pieces were then immersed in the PDAC solution for 20 min. The sequence was repeated until the desired number of bilayers was formed. PEI was applied as the final layer. For comparison, polyurethane foam was also functionalized with one layer of PEI. The foam pieces were dried in a vacuum oven.

Enzyme immobilization

Cellulase was immobilized on the Celite, the PEI-coated foam (PEI-foam), and the CNT-coated foam (CNT-foam). The different biocarriers were packed in a glass column with a volume of 150 ml. The cellulase solution was circulated through the column by recycling for 24 h. The enzyme solution was collected, and the biocarriers were washed three times with DI water. β-glucosidase was also immobilized on the Celite and the CNT-foam, and the stability of immobilized and free enzymes were compared.

Enzyme activities

Cellulase activity was measured by incubating one quarter of the foam disk (diam. 2.5 cm, length 1.25 cm) with approx. wt 0.033 g with 0.5 ml carboxymethyl-cellulose solution in 50 mM sodium acetate buffer (pH 5.0) at 50 °C for 1 h, and the reducing sugars were measured with dinitrosalicylic acid method. β-Glucosidase activity was determined based on the following procedure: the reaction mixture comprised 100 μl enzyme (or one quarter of the foam disk immobilized with enzyme), and 100 μl 40 mM p-nitrophenol β-d-glucoside in 100 mM sodium acetate buffer (pH 5.0). The reaction mixture was incubated for 30 min at 50 °C. Thereafter the reaction was immediately terminated by the addition of cold 500 mM Na2CO3. Light yellow color development due to liberation of p-nitrophenol from the substrate was determined by measuring absorbance at 405 nm. Enzyme activity was expressed in units (IU), defined as μmol p-nitrophenol released per min under the assay condition. All samples were analyzed in triplicate.

The storage stability of free and immobilized cellulase was studied by storing at 50 °C and measuring the cellulase activity intermittently. The storage stability of free and immobilized β-glucosidase were studied at room temperature and 50 °C. The optimal pH of free and immobilized β-glucosidase was studied in the pH range of 2.0–8.0. The operational stability of immobilized β-glucosidase was studied by repeating the hydrolysis process, and the residual enzyme activities were measured after each hydrolysis process.

Results and discussion

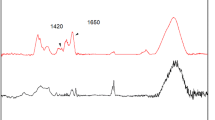

Morphology of biocarrier

Figure 1 shows the SEM images of polyurethane foam with and without the CNT coating. Polyurethane is hydrophobic; UV-ozone (UVO) treatment activated the surface which made the surface hydrophilic. A plain PU shows a water contact angle of 76°, while it decreased to 15° after UVO treatment. Layer by layer (LbL) deposition of negatively charged CNT and positively charged PDAC were achieved by electrostatic force. As shown in Fig. 1, the pristine polyurethane surface is relatively smooth (Fig. 1b). The six bilayers of PDAC/CNT completely covered the surface with improved surface roughness and surface area (Fig. 1c). Enzymes such as cellulase can be immobilized on CNT by electrostatic force. Since the final layer before enzyme immobilization was the PEI layer, which promotes a quite broad heterogeneity of protein-PEI interactions (protein orientation, and penetration of the protein in the bed), and therefore, of binding strength. As shown in Fig. 1d, although it is not possible to see enzymes under SEM, it did show that the surface of CNT had some coating. The advantage of using PEI is that it provides an appropriate environment for enzyme immobilization; more significantly, reversible immobilization of enzyme could be achieved with PEI-coated supports (Mateo et al. 2000; Pessela et al. 2005), because PEI is an ion exchanger. Many protocols for enzyme immobilization involve the irreversible covalent binding between the enzyme and a preexisting support. When the immobilized enzyme becomes inactivated during its application, both the enzyme and the support should be eliminated as wastes. Instead, with reversible immobilization, it is possible to completely desorb enzymes away from the support when the enzymes are inactivated, and the supports can be fully recovered.

For comparison, commercial Celite R635 diatomaceous earth beads were also studied. Celite is mainly composed of diatomaceous earth, which is amorphous SiO2 with minor amounts of minerals (Fe2O3, Ca(OH)2, Mg2+, Na+, Al3+). The Celite R635 is diatomaceous earth pellets with a pore size from 1 to 30 μm (mean pore size of 20 μm). It has a large surface area and high liquid absorptive capacity. As shown in Fig. 2a, the Celite has very rough surface which can effectively trap enzymes. After the immobilization of β-glucosidase, there was a visible layer of coating on Celite, as shown in Fig. 2b.

Cellulase immobilization on polyurethane foam

The data presented in Fig. 3 compare the enzyme activity of cellulase immobilized on the PEI- and the CNT-coated PU foams. The enzyme activity of cellulase immobilized on the CNT-foam is approximately three times of that on the PEI-foam, which is possibly due to the high immobilization yield of enzymes on the CNT coated foam, resulting from the high surface area of carbon nanotubes. The operational and storage stabilities of immobilized enzymes are the most important parameters to determine the economic viability of the bioprocess (Buchholz and Klein 1987). The storage stability of free cellulase and the ones immobilized on the Celite, and the PU foams were studied and compared in Fig. 4. The activity of free cellulase gradually decreased with time, and after 20 days of storage, their activity dramatically decreased. In the case of cellulase immobilized on the Celite, the maximum activity was reached after 5 days storage, and it remained almost constant for 20 days thereafter, though the activity of immobilized enzyme disappeared after 30 days of storage, following the same trend as the free cellulase. In the case of cellulase immobilized on the CNT-coated polyurethane foam, the immobilized cellulase was very stable for the initial 20 days, although there was a slight decrease thereafter. The immobilized cellulase has kept 95 % of activity after 30 days storage at 50 °C. The improved storage stability of cellulase on the PEI coated support is possibly due to the stabilization effect of PEI, as well as the strong protein-PEI interaction (Pessela et al. 2005).

Immobilization of β-glucosidase

The nano-biocarrier was further examined for the immobilization of β-glucosidase. β-Glucosidase is frequently used to supplement cellulase preparation for the hydrolysis of cellulosic and lignocellulosic substrates in order to accelerate the conversion of cellobiose to glucose. Initial study showed that ~0.62 g enzyme solution was adsorbed by each gram of Celite. The loading efficiency was 0.41 mg β-glucosidase/g of Celite. The immobilization of β-glucosidase on the CNT coated PU foam was also studied. It resulted β-glucosidase activity of ~4 IU/g foam. The storage stability of enzymes in buffer solution at room temperature and 50 °C was evaluated.

As shown in Fig. 5, both free and immobilized β-glucosidase on the Celite are stable at room temperature and 50 °C up to 30 days, but the enzyme activities dramatically decreased after that. In addition, they responded differently on temperatures. For free enzyme, it showed higher activity at room temperature than 50 °C, but the immobilized enzyme showed the opposite trend, possibly due to increased thermostability for immobilized enzyme. The β-glucosidase immobilized on the CNT-foam showed much better stability compared to free enzyme and the ones immobilized on the Celite, as shown in Fig. 5. At room temperature storage, the activity of immobilized β-glucosidase increased initially, and then slightly decreased, but the activity of enzyme after 45 days storage was still higher than the initial enzyme activity. This is possible due to inert carbon nanotube surface and stabilization effect of PEI. PEI has been reported to have positive effects on the enzyme stability via different mechanisms (Bryjak 1995). Figure 6 shows that free β-glucosidase shows an optimal pH at 4.0, and a shift in pH optima from 4.0 to 3.0 for immobilized β-glucosidase on the CNT-foam was observed, which is possibly due to the ionization of groups on the carrier; in addition, the immobilized β-glucosidase was stable in a broader pH range compared to free ones.

The reusability of immobilized β-glucosidase on the Celite and the CNT-foam was examined by repeating the hydrolysis process. Figure 7 shows that the relative activity of immobilized β-glucosidase on the Celite slightly decreased after 1st use, but kept approximately constant for the next eight uses. There was a big drop in enzyme activity between 9th and 10th uses. It retained 40 % of its initial activity after twelve repeated uses. The β-glucosidase immobilized on the CNT-foam showed much better reusability. The activity of β-glucosidase on the CNT-foam slightly increased with repeated uses up to 13 times, and then remained nearly constant. Even after 19 times repeated uses, the enzyme activity was still close to initial activities. This study confirmed that newly developed 3D CNT-foam is an effective biocarrier, and the immobilized β-glucosidase on CNT-foam showed much better storage and operational stability than the ones immobilized on the commercial biocarrier (Celite), which is critical for a continuous bioprocess.

To further increase the geometric stability of nano-structured biocarriers, honeycomb catalyst supports such as ceramic monolith can be used as alternatives to polyurethane foam. Figure 8a shows the classical honeycomb monolith, which offers several advantages, such as a high geometric external surface, structural durability, easy catalyst separation, low pressure drop, and uniform flow distribution within the matrix (de Lathouder et al. 2008). Monolith was first coated with a layer of silica, and then the same procedure for coating polyurethane foam was used for coating the monolith with multilayers of CNT, which turned into black color after 6 bilayer of CNT coating, as shown in Fig. 8b. The SEM image of monolith shows particulated structure, and the one after CNT deposition shows a hairy surface morphologies. This nano-biocarrier features high surface area and geometric stability.

Conclusions

Novel nano-biocarriers were developed which comprise high surface area-carbon nanotube-coated on the foam structures using the layer-by-layer approach. The high efficiency for enzyme immobilization exhibited by these nano-biocarriers make them attractive candidates for the continuous saccharification of lignocellulosic biomass. The loading of cellulase on the polyurethane foam coated with CNT was much higher than the one without, which can be attributed to the high surface area of CNT. In addition, both cellulase and β-glucosidase immobilized on the CNT-foam showed much better storage stability and operational stability than the ones immobilized on the commercial biocarrier (Celite), which is critical for a continuous bioprocess. CNT coated monolith was also developed as a biocarrier, which offers high surface area and geometric stability.

References

Bakker M, van de Velde F, van Ranwijk F, Sheldon RA (2000) Highly efficient immobilization of glycosylated enzymes into polyurethane foams. Biotechnol Bioeng 70(3):342–348

Balasubramanian K, Burghard M (2006) Biosensors based on carbon nanotubes. Anal Bioanal Chem 385(3):452–468

Bryjak J (1995) Storage stabilization of enzyme-activity by poly(ethyleneimine) Bioproc Eng 13(4):177–181

Buchholz K, Klein J (1987) Methods in enzymology: immobilized enzymes and cells. Academic Press. London, pp 3–30

Chakrabarti AC, Storey KB (1988) Immobilization of cellulase using polyurethane foam. Appl Biochem Biotechnol 19(2):189–207

de Lathouder KM, van Benthem DTJ, Wallin SA, Mateo C, Lafuente RF, Guisan JM, Kapteijn F, Moulijn JA (2008) Polyethyleneimine (PEI) functionalized ceramic monoliths as enzyme carriers: preparation and performance. J Mol Catal B-Enzym 50(1):20–27

Dincer A, Telefoncu A (2007) Improving the stability of cellulase by immobilization on modified polyvinyl alcohol coated chitosan beads. J Mol Catal B-Enzym 45(1–2):10–14

Dincer A, Okutucu B, Zihnioglu F, Telefoncu A (2005) Immobilization of alpha-glucosidase in chitosan coated polygalacturonic acid. Prep Biochem Biotechnol 35(2):103–111

Haupt B, Neumann T, Wittemann A, Ballauff M (2005) Activity of enzymes immobilized in colloidal spherical polyelectrolyte brushes. Biomacromolecules 6(2):948–955

Lu J, Okeke B (2012) Process for whole cell saccharification of lignocelluloses to sugars using a dual bioreactor system. US Patent 8,143,040 B2

Lu J, Drzal LT, Worden RM, Lee I (2007) Simple fabrication of a highly sensitive glucose biosensor using enzymes immobilized in exfoliated graphite nanoplatelets Nafion membrane. Chem Mater 19(25):6240–6246

Lu J, Do I, Fukushima H, Lee I, Drzal LT (2010) Stable aqueous suspension and self-assembly of graphite nanoplatelets coated with various polyelectrolytes. J Nanomater 18:64–86

Mateo C, Abian O, Fernandez-Lafuente R, Guisan JM (2000) Reversible enzyme immobilization via a very strong and nondistorting ionic adsorption on support-polyethylenimine composites. Biotechnol Bioeng 68(1):98–105

Neumann T, Haupt B, Ballauff M (2004) High activity of enzymes immobilized in colloidal nanoreactors. Macromol Biosci 4(1):13–16

Pessela BCC, Betancor L, Lopez-Gallego F, Torres R, Dellamora-Ortiz GM, Alonso-Morales N, Fuentes M, Fernandez-Lafuente R, Guisan JM, Mateo C (2005) Increasing the binding strength of proteins to PEI coated supports by immobilizing at high ionic strength. Enzym Microb Technol 37(3):295–299

Sherigara BS, Kutner W, D’Souza F (2003) Electrocatalytic properties and sensor applications of fullerenes and carbon nanotubes. Electroanalysis 15(9):753–772

Taherzadeh MJ, Karimi K (2007) Enzyme-based hydrolysis processes for ethanol from lignocellulosic materials: a review. Bioresources 2(4):707–738

Tu MB, Zhang X, Kurabi A, Gilkes N, Mabee W, Saddler J (2006) Immobilization of beta-glucosidase on Eupergit C for lignocellulose hydrolysis. Biotechnol Lett 28(3):151–156

Tu MB, Chandra RP, Saddler JN (2007) Evaluating the distribution of cellulases and the recycling of free cellulases during the hydrolysis of lignocellulosic substrates. Biotechnol Prog 23(2):398–406

Vasudevan PT, Lopez-Cortes N, Caswell H, Reyes-Duarte D, Plou FJ, Ballesteros A, Como K, Thomson T (2004) A novel hydrophilic support, CoFoam, for enzyme immobilization. Biotechnol Lett 26(6):473–477

Acknowledgments

We would like to thank the funding support from the Department of Energy Small Business Innovation and Strategies Program (DE-FG02-07ER84872), the Michigan University Research Corridor (URC), and the Michigan Initiative for Innovation and Entrepreneurship.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Lu, J., Weerasiri, R.R. & Lee, I. Carbon nanotubes tuned foam structures as novel nanostructured biocarriers for lignocellulose hydrolysis. Biotechnol Lett 35, 181–188 (2013). https://doi.org/10.1007/s10529-012-1066-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-012-1066-5