Abstract

The outbreak of the COVID-19 pandemic has significantly augmented the complexity of information, adding to the challenges that firms face in effectively processing and grasping accurate information. As a result, the production uncertainty of firms has been seriously intensified during the pandemic, disrupting the normal operation of firms and their supply chains. Digital technologies serve as salient tools that help firms to process and analyse information, consequently enhancing firm resilience in the face of supply chain disruptions. This study aims to examine how digital technologies affect firm resilience in the context of COVID-19 through the lens of information processing theory and a large-scale survey conducted among Chinese manufacturers. Specifically, our study evaluates the mediating effect of supply chain integration (internal integration, customer integration and supplier integration) and the moderating effect of information complexity. The results show that supply chain integration plays a mediating role in the effect of digital technologies on firm resilience, and the mediation effect is particularly significant for customer integration. Furthermore, digital technologies have a stronger impact on firm resilience when information complexity is high. The findings advance our understanding and recognition of the resilience implications of digital technologies and provide important managerial implications for improving firm resilience in the context of COVID-19.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The outbreak of COVID-19 has seriously disrupted the normal operation of manufacturing firms worldwide, resulting in a vast imbalance between supply and demand, which has amplified the uncertainty that firms and their supply chains face (Iftikhar et al., 2021; Tarigan et al., 2021). In this situation, how to develop firm resilience to effectively manage crises as a research agenda has become a top priority in the supply chain management (SCM) literature (Golan et al., 2020; Ivanov & Dolgui, 2020; Remko, 2020; Belhadi et al., 2021). Evidence has shown that, by establishing resilience, firms are more capable of managing supply chain disruptions, ensuring business continuity and enhancing the stability of their operations (Ambulkar et al., 2015; Pettit et al., 2019).

Advanced digital technologies, such as big data, cloud computing, the Internet of Things (IoT) and analytics technologies, which are increasingly used by firms to conduct data collection, transmission, management and prediction analysis, can help them to quickly identify sources of disruptions by offering real-time information about possible disruptions (Lee & Lee, 2015; Arsovski et al., 2017; Choi et al., 2018; Ivanov et al., 2019a) and therefore resist disruptions or quickly recover from negative impacts (Belhadi et al., 2021). In particular, implementing digital technologies has been found to be an important strategy to mitigate risks caused by the ongoing COVID-19 pandemic (Belhadi et al., 2021; Burgos & Ivanov, 2021), also bringing opportunities for manufacturing firms to build resilience. However, scholars have argued that digital technologies are not always found to contribute to firm resilience. Impetuous and large-scale investment in digital technologies can be an obstacle to resilience building (Zouari et al., 2020; Faruquee et al., 2021). Hence, how and under what conditions digital technologies can help build to firm resilience still represent important research gaps.

As an attempt to bridge the above-discussed research gaps, this study posits that the impact of digital technologies on firm resilience can be realized through supply chain integration, including internal integration, customer integration and supplier integration. The literature has proved the role of digital technologies in enhancing internal functional coordination and upstream and downstream supply chain integration (de Vass et al., 2018; Novais et al., 2019; Razaghi & Shokouhyar, 2021). While internal integration realizes efficient internal process efficiency and reduces the likelihood of disruption through cross-functional cooperation, supplier and customer integration facilitates organizational responses to market changes, strengthens the transparency of the supply chain system and manages unforeseen risks by cooperating and coordinating with upstream and downstream partners (Wong et al., 2011; Vanpoucke et al., 2017; Piprani et al., 2020; Chunsheng et al., 2020). Through an empirical investigation of the automobile manufacturing industry, Balakrishnan & Ramanathan (2021) found that companies using innovative digital technologies to manage supply chain processes were more resilient and able to respond to market changes better during the pandemic. However, although existing studies have revealed the potential connection between digital technologies and supply chain management (Li et al., 2020), very few studies have investigated the role of supply chain integration in this relationship, and our study aims to shed light on this role.

This study takes information processing theory (IPT) as the theoretical foundation to develop the conceptual model (Galbraith, 1973; Premkumar et al., 2005). IPT implies that the information processing capacity of firms can be improved through the application of digital technologies (Li et al., 2020), providing strong facilitating conditions for the establishment of firm resilience. (Dubey et al., 2021). Existing research on resilience based on IPT has indicated that identifying and integrating information needs and developing information processing capabilities play inestimable roles in embedding a high degree of resilience in firm operations (Modgil et al., 2021). In addition, customer integration, supplier integration and internal integration further reduce information processing requirements and enhance information processing capabilities through information management across functional departments and beyond organizational boundaries. Finally, the matching of information processing requirements with information processing capabilities helps to achieve firm resilience (Bensaou & Venkatraman, 1995; Wang et al., 2021). Therefore, from the IPT perspective, this study explores how digital technologies can be deployed in internal integration, customer integration and supplier integration to build firm resilience.

At the same time, this study also explores how the impact of digital technologies on firm resilience changes with information complexity. IPT emphasizes that organizational information processing capacity and processing requirements should adapt to the specific operating environment (Li et al., 2020). Information complexity means that information contains many element characteristics (Li, 2016), affecting the environmental conditions of firm decision making. The impact of digital technologies on firm resilience is restricted by environmental conditions (Tukamuhabwa et al., 2015; Wamba et al., 2020; Jonsson et al., 2021). During the pandemic, incorrect and massive information, namely complex information with multielement characteristics, has spread at unprecedented rates, affecting consumers’ normal purchase behaviours (Pulido et al., 2020; Aljanabi, 2021; Bermes, 2021). Under such circumstances, it becomes more difficult for firms to make correct judgements and respond to market demand quickly, further aggravating the negative effect of the crisis on firms (Bartnik & Park, 2018). Therefore, this study also considers the information complexity of the disruptive environment and proposes that the effect of digital technologies on firm resilience is influenced by the degree of information complexity.

Based on the above discussions, this study aims to shed light on the following research questions (RQs).

RQ1: What is the direct impact of digital technologies on firm resilience?

RQ2: Does supply chain integration (internal integration, supplier integration and customer integration) play a mediating role in the digital technologies-firm resilience relationship?

RQ3: How does information complexity affect the relationship between digital technologies and firm resilience?

To answer these research questions, we develop a research framework based on the literature and empirically validate it through a survey targeting manufacturers in China. Our study contributes to the literature in several important ways. First, this study contributes to the information systems (IS) literature by making a connection between digital technologies and firm resilience, strengthening the understanding of the resilience implications of digital technologies. Second, we establish a mechanism, i.e., supply chain integration, which explains how digital technologies relate to firm resilience, thus enriching the literature from a supply chain perspective. Finally, a contextual factor, information complexity, is identified based on IPT to test the effectiveness of digital technologies on firm resilience.

The rest of this paper is organized as follows. Section 2 presents a thorough review of the literature on digital technology, supply chain integration, resilience, and IPT. Hypotheses are then developed in Sect. 3. Section 4 explains the research methods. Sections 5 and 6 present the results and corresponding discussions, respectively. Finally, Sect. 7 concludes the study and summarizes the limitations and directions for future study.

2 Literature review

2.1 Digital technologies during COVID-19

Under the influence of COVID-19, many firms have experienced supply chain disruptions due to inconvenient transportation, labour shortages, loss of supply and suppliers, and declining demand, among other causes (Ivanov & Dolgui, 2020; Jabbour et al., 2020; Wang et al., 2020b; Mahajan & Tomar, 2021). Moreover, firms feel a greater need to manage more complex information, such as excessive content (Aljanabi, 2021; Cao et al., 2021), complex sources (Laud & Schepers, 2009; Alamsyah & Zhu, 2021), and wrong and poor quality (Bermes, 2021; Fernández-Torres et al., 2021; Su, 2021; Vrdelja et al., 2021), compared to normal times. This intensified operational uncertainty has caused production decisions to become more difficult for firms with the traditional mode of operations (Nagarajan et al., 2013; Phillips-Wren & Adya, 2020). Fortunately, there is evidence that applying digital technologies can strengthen firms’ information processing capabilities and help them to identify useful and crucial information in turbulent situations (Premkumar et al., 2005; Li et al., 2020).

Currently, big data, cloud computing, the IoT and analytics are among the most discussed digital technologies in the IS and operations management literature (Ivanov et al., 2019b; Li et al., 2020). Applying these technologies helps firms to improve their information processing ability and integrate and optimize supply chain processes (Bi & Cochran, 2014; Novais et al., 2019). Among these technologies, the IoT is an intuitive, robust and scalable tool that can capture a large amount of data through its four essential layers: networking layer, sensing layer, interface layer and service layer (Xu et al., 2014; Birkel & Hartmann, 2020). Cloud computing is a large-scale and distributed computing paradigm that mainly functions in virtualization, dynamic scalability, manageable computing power, storage platforms and services through the internet (Buyya et al., 2009; Garrison et al., 2015). Big data refers to a massive dataset with heterogeneous formats and high complexity composed of structured, semistructured and unstructured data (Oussous et al., 2018). To make sense of such complex datasets, analytics are needed for firms, referring to the ability to extract valuable information from a wide range of data through the application of technical tools, such as statistics, econometrics and optimization (Wang et al., 2016).

In addition, since firm resilience is critical to maintaining normal operations during disruptions and considering that digital technologies can provide strong information processing ability, on which firm resilience depends (Li et al., 2020; Balakrishnan & Ramanathan, 2021), our study aims to explore the impact of digital technologies on firm resilience in the context of COVID-19. A thorough literature review that we conducted suggests that existing empirical studies have mostly focused on the influence of digital technologies on various dimensions of enterprise performance (Setia et al., 2013; Li et al., 2020; Moldabekova et al., 2021), with very few efforts undertaken to discuss the effects of digital technologies on firm resilience. Therefore, we aim to fill this gap.

2.2 Supply chain integration

Supply chain integration refers to the degree of strategic coordination and interconnection within and between organizations, generally including three types of integration: internal integration, supplier integration and customer integration (Flynn et al., 2010; Zhao et al., 2011). Among these integration types, supplier integration involves relevant practices regarding managing suppliers and maintaining stable long-term relationships with them (Li et al., 2006b). Customer integration refers to practices of close cooperation with crucial customers, through which firms can obtain correct insights into the market environment (Wong et al., 2011). In addition, internal integration is mainly related to practices regarding the integrating and of improving resources and information within the firm across functional boundaries (Kim, 2013). All three types of integration improve the management ability of the external and internal business functions of firms; ensure the efficient flow of information, decision making and resources; and provide value to customers to the greatest extent (Cagliano et al., 2006; Flynn et al., 2010; Schoenherr & Swink, 2012; Kang et al., 2018).

To date, researchers have explored the antecedents of supply chain integration, including servitization orientation (Shah et al., 2020), competitive conditions (Annan et al., 2016), innovativeness (Seo et al., 2014) and knowledge management (Ayoub et al., 2017). The impact of specific digital technologies on supply chain integration has also been examined. For instance, the IoT has been found to render firms more proficient in data collection and information sharing, thus enhancing their supply chain integration ability (de Vass et al., 2018). Big data analytics have also been found to positively affect the level of supply chain integration by providing greater transparency of supply chain processes, completing responsibilities for different tasks in the organization, and improving organizational relationships and working relationships (Razaghi & Shokouhyar, 2021). In summary, digital-based supply chain integration helps to realize relational integration and structural integration, which are of great significance for integrated operations management (Lee, 2021). Since firms often use multiple digital technologies simultaneously to support supply chain management (Singh et al., 2018; He et al., 2020; Koot et al., 2021), it is more sensible to discuss the collective influence of digital technologies on supply chain integration. However, this strategy remains an underresearched area into which further exploration is needed.

The existing literature has proved the positive effect of supply chain integration on innovation (Wong et al., 2013), flexibility (Khanuja & Jain, 2021), agility (Shukor et al., 2021), robustness (Zhuo et al., 2021) and responsiveness (Shukor et al., 2021), which are all conducive to improving the resilience capacity of firm operations (Ambulkar et al., 2015; Tukamuhabwa et al., 2015). Furthermore, Wijaya (2020) proposed that supplier integration and customer integration promote the consistency of business processes between firms and their supply chain partners and that internal integration promotes the coordination of functions, directly driving the development of resilience capability. An empirical study in the context of COVID-19 further showed that supply chain integration can boost firm resilience and help firms to manage unexpected changes effectively (Siagian et al., 2021). While the link between supply chain integration and resilience seems increasingly positive, other researchers have found otherwise. For instance, high-intensity supply chain integration is believed to lead to the overdependence of firms on their supply chain partners, resulting in easier dissemination and expansion of disruption risk (Świerczek, 2014). Therefore, the relationship between supply chain integration and firm resilience requires further investigation with internal and external mechanisms.

2.3 Firm resilience

Firm resilience refers to the ability of firms to feel changes in the external environment and respond quickly when facing crises and emergencies (Dormady et al., 2019; Brewton et al., 2010). The existing literature has shown that resilience is an extremely important ability to recover from supply chain disruptions and return to the normal state of operations (Ambulkar et al., 2015; Parker & Ameen, 2018; Ivanov, 2021b; Queiroz et al., 2021). It is closely related to visibility, flexibility and responsiveness (Jüttner & Maklan, 2011; Ambulkar et al., 2015; Tukamuhabwa et al., 2015). Among these factors, visualization refers to the degree of observable phenomena (Bowen, 2000), flexibility refers to the ability to change or respond with little impact on existing cost or performance (Upton, 1994), and responsiveness is the ability to respond to market changes and customer demand and in a planned manner within a short period of time (Kritchanchai & MacCarthy, 1999). The above three crucial factors have profound impacts on firm resilience. When confronted with disruptions caused by the COVID-19 pandemic, numerous supply chains have been disrupted and have had to find ways to build firm resilience (Hendricks & Singhal, 2005; Cai & Luo, 2020; Chakraborty & Biswas, 2020; Belhadi et al., 2021). As Remko (2020) pointed out, empirical studies of how to improve resilience during the current COVID-19 crisis have made both theoretical and practical contributions.

To date, researchers have studied how to manage the supply chain disruption caused by COVID-19 from the perspective of resilience. Ali et al., (2021) built a matrix tool from the dimensions of cost and time for shaping resilience to help firms to make strategic deployments during disruptions. Moosavi & Hosseini (2021) proposed that arranging additional inventory in advance is important to improving resilience. During COVID-19, firms must prioritize resource development to achieve disruption-oriented recovery strategies and fully manage scarce resources via resource reconfiguration, leading to firm resilience (Queiroz et al., 2021; Shen & Sun, 2021), through a case study, confirmed that a high level of operational flexibility and supply chain collaboration help firms to improve the level of resilience. With regard to the role of digital technologies, some have argued that they are crucial tools for firms to recover from disruptions as soon as possible in the postepidemic era (Balakrishnan & Ramanathan, 2021; Belhadi et al., 2021). However, some scholars, such as Zouari et al., (2020), have reported that digital technologies themselves do not help to achieve resilience, and the relationship between digital technologies and firm resilience remains unclear. Thus, this study intends to further explore this relationship.

2.4 Information processing theory

Information processing theory (IPT) posits that organizations are open systems (Galbraith, 1974) that are faced with external uncertainties and interferences inherent in supply chains (Cegielski et al., 2012; Wong et al., 2020). Based on IPT, interference should be managed by matching the information processing requirements and capabilities related to disruptions (Galbraith, 1973; Tushman & Nadler, 1978; Premkumar et al., 2005; Wong et al., 2020). The environmental conditions of the organization determine the degree of information processing needs, while the allocation of resources and technical tools related to information collection, processing and management affects the firm’s information processing capacity (Galbraith, 1973; Tushman & Nadler, 1978). IPT advocates that organizations have two strategies, reducing information processing needs and improving information processing capacity, which can be used to support decision making in times of uncertainty (Galbraith, 1973). IPT has been widely used in operations and supply chain management studies (Qrunfleh & Tarafdar, 2014; Fan et al., 2017), it and has the potential to explain the effect of supply chain disruption on the development of firm resilience during COVID-19 because the uncertainty of interference boosts the demand for information processing (Modgil et al., 2021; Dubey et al., 2021).

The information processing need is closely related to the uncertainty and ambiguity of the environment in which the organization is operating. Conversely, the information processing capability of the firm is related to the equivocality of information and the amount of information (Bartnik & Park, 2018). Based on IPT, the establishment of firm resilience should be based on the coordination of information processing needs and information processing ability. In this case, digital technologies play an important role in information collection and analysis, which are considered by existing research to be important ways to improve information processing ability (Li et al., 2020). For supply chain integration practices, external integration reduces the demand for information processing by obtaining more accurate information from supply chain partners (Bartnik & Park, 2018; Li et al., 2020), and it expands the information processing capacity of digital technologies in the whole chain by linking the upstream and downstream of the supply chain (Lee, 2021). Internal integration improves information processing capability through efficient and high-quality cross-functional information docking (de Vries et al., 2021; Dubey et al., 2021). Supply chain integration and digital technologies collectively help to achieve a match between information processing needs and information processing capabilities. Evidently, IPT provides an effective theoretical basis for the study of firm resilience with the potential roles played by digital technologies and supply chain integration.

3 Hypothesis development

3.1 Digital technologies and firm resilience

Improving firm resilience is an information-intensive process (Wang et al., 2021). Digital technologies, such as cloud computing, the IoT, analytics and big data, are regarded as important sources of information processing capacity for firms (Li et al., 2020). Studies based on information processing theory have shown that strong information processing capability is an important factor for firms to recover from supply chain disruptions (Dubey et al., 2021). Especially in the context of COVID-19, the dependence of operational management on information processing capability is even stronger (Schippers & Rus, 2021). Therefore, we propose that digital technologies help manufacturing firms to become more resilient through information acquisition, storage and analysis.

Visibility, flexibility and responsiveness are considered critical factors in mitigating the negative impact of disruptions on firms and are extremely important to enhancing firm resilience (Jüttner & Maklan, 2011; Ambulkar et al., 2015; Tukamuhabwa et al., 2015). In the current crisis, firms worldwide have been motivated to explore the importance of these factors to the development of resilience (Siagian et al., 2021). By introducing digital technologies into firm operations, visibility management of the whole product life cycle can be realized (Saxena & Al-Tamimi 2017; Ahmed et al., 2021). For instance, the IoT provides accurate and timely information through real-time perception of data (Al-Talib et al., 2020), supporting the development of a risk monitoring system and realizing real-time monitoring of the supply chain. As a result, data transparency and visual supervision are also enhanced. Thus, when facing disruptions, firms can make timely action decisions with the help of visualization results.

In highly uncertain competitive business environments, advanced digital technologies support firms in sharing information with supply chain members instantly and integrating the capabilities of supply chain partners to stabilize their own operations, improve efficiency and strengthen flexibility (Zhou & Wang, 2021). In the context of COVID-19, flexible exchange and utilization of information and resources among supply chain members seem to be more important than during normal times. In cloud computing-based supply chain management systems, through real-time sharing of information on the system platform and IoT-enabled integration, firms and their supply chain partners are allowed to flexibly and quickly exchange information and use IT resources (Giannakis et al., 2019), thus improving flexibility and resilience.

Embedding digital technologies into the supply chain can increase the responsiveness of firms to customer needs and ensure operational efficiency (Bejlegaard et al., 2021). For instance, due to their powerful information processing function, big data analytics, as an important digital technology, can effectively and flexibly realize the response to changing customer needs and provide support for managing supply chain uncertainties (Wang et al., 2016). By loading the collected information into the cloud database and adding the function of data analysis, firms can realize the preprocessing of data and expedite the response (Tsang et al., 2018), and in this way, firm resilience can be improved. In summary, we propose the following:

H1

Digital technologies have a positive impact on firm resilience.

3.2 The mediating role of supply chain integration

Our study argues that supply chain integration, including internal integration, supplier integration and customer integration, mediates the impact of digital technologies on firm resilience. Manufacturing firms usually develop their information processing capability and decision-making ability by investing in digital technologies between internal functional departments and the upstream and downstream of their supply chains. This powerful information processing ability constitutes the premise and foundation for customer, supplier and internal integration (Yu et al., 2021). With outstanding internal information processing capacity, on the one hand, manufacturing firms can better cooperate and exchange information with customers and suppliers, enhancing the tightness of connectivity (Lee, 2021). On the other hand, cross-functional barriers within the firm can be removed for smoother cross-functional coordination (Yu et al., 2021). Therefore, digital technologies promote the development of internal, supplier and customer integration. As shown in prior studies, manufacturing firms’ adoption of advanced digital technologies, such as big data analysis (Razaghi & Shokouhyar, 2021), cloud computing (Manuel Maqueira et al., 2019) and the IoT (de Vass et al., 2018), has shown a stronger willingness to integrate internal functions and the supply chain, and their actual level of suppliers, customers and internal integration is also higher.

In the context of COVID-19, market demand fluctuates unpreventably with consumers’ panic consumption behaviour (Islam et al., 2021), causing severe supply chain disruptions. From the perspective of IPT, technology-enabled external integration, including customer integration and supplier integration, allows firms to build an integrated supply and demand information system to obtain high-quality information that meets information processing needs (Bartnik & Park, 2018; Li et al., 2020). High-quality information, such as accurate and real-time information, guarantees supply and demand information sharing between manufacturing firms and their suppliers and customers (Gunasekaran & Ngai, 2004; Cai & Dang, 2015; Giannakis et al., 2019; Jayender & Kundu, 2021). Conversely, external integration based on digital technologies can quickly integrate and process consumer demand information and feed it back to suppliers. In other words, effective external integration means that the visual management of information exchanges among supply chain partners and the information integration between customers and suppliers can be realized (Lee, 2021). According to IPT, when firms realize the matching of requirements and capabilities of information processing related to a certain disruption, they are resilient and able to recover from negative impacts quickly (Bensaou & Venkatraman, 1995; Wang et al., 2021). Therefore, both supplier integration and customer integration have positive impacts on firm resilience.

At the same time, effective internal integration indicates a higher level of coordination among the functional departments of a firm. IPT points out that strengthening the horizontal relationship among functional departments by building cross-functional teams can improve the information processing capacity of the firm (de Vries et al., 2021; Dubey et al., 2021). The firm can thus accurately and directly integrate, transmit and share a large amount of information by centralizing decision making in cross-functional teams, reduce information distortion and ensure information quality (Sudeep & Srikanta, 2014). The efficient and high-quality information docking level within the firm demonstrates a strong information management ability, which will help the firm to better prepare for disruptions and quickly respond to risks (Feng et al., 2013; Li et al., 2006a), ultimately improving firm resilience. As found by Siagian et al., (2021) and Tarigan et al., (2021), firms implementing internal integration have shown better resilience during the COVID-19 pandemic. Therefore, we propose that internal integration has a positive effect on firm resilience.

In summary, digital technologies promote the integration of the supplier, customer and internal functions of firms with their powerful information processing capability. Customer and supplier integration based on digital technologies has a dual impact on information processing demand and information processing capacity, while internal integration based on digital technologies has potential synergistic benefits, further enhancing the ability to manage information flow. Thus, firms can quickly prevent and respond to interruptions and improve firm resilience. Accordingly, we propose the following hypotheses.

H2a

Supplier integration mediates the relationship between digital technologies and firm resilience.

H2b

Consumer integration mediates the relationship between digital technologies and firm resilience.

H2c

Internal integration mediates the relationship between digital technologies and firm resilience.

3.3 The moderating role of information complexity

Information complexity reflects a number of information features (Li, 2016), and it is an important aspect of information attribute management (Schneider, 1987; Reutskaja & Hogarth, 2009). When making strategic decisions, manufacturing firms inevitably must manage massive volumes of crowded and multielement complex information from downstream customers and upstream suppliers, as well as various departments within the firm (Wang et al., 2021). In the context of COVID-19, environmental turbulence further complicates the information that must be processed, which is then mixed with false, redundant and excessive information. Such a high degree of diversity and complexity of information seriously disrupts decision makers’ judgements of products and production (Huang, 2000; Valika et al., 2020; de Oliveira & Albuquerque, 2021). Based on IPT, firms require greater information processing ability to reduce or eliminate disruptions (Galbraith, 1973; Paul & Nazareth, 2010; Sharma et al., 2020b). Thus, firms are recommended to construct information technology infrastructures to manage the changing environment.

Manufacturing firms often improve their resilience by enhancing information transparency in their supply chains (Sarkar & Kumar, 2015). Complex information increases the difficulty for firms in obtaining and screening for accurate supply and demand information. The application of digital technologies is often listed as a crucial tool for firms to effectively process information (Li et al., 2020). The higher that the information complexity is, the greater that the incentive is for firms to adopt digital technologies to manage supply chain disruptions (Belhadi et al., 2021; Ivanov, 2021a). In this situation, firms are recommended to use digital technologies, such as big data technology, to collect and extract more valuable and accurate messages from vast amounts of information. Based on the results, they can construct strategic actions to avoid future supply chain disruptions through enhanced firm resilience. Existing studies have also reflected the importance of developing digital technologies during COVID-19, during which information complexity has been exceptionally high (Cao et al., 2021; Sheng et al., 2021), for firm resilience. Therefore, we formulate the following hypothesis:

H3

Information complexity positively moderates the relationship between digital technologies and firm resilience.

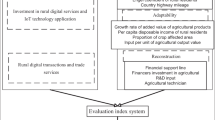

The proposed model is shown in Fig. 1.

4 Research methods

4.1 Data collection

Chinese manufacturing firms are an important part of China’s economic system and important promoters and participants of digital technologies (Lin et al., 2019). Thus, we conducted a large-scale survey among Chinese manufacturing firms to validate the proposed research model. Our sample covers different parts of China, including eastern (e.g., Shandong, Zhejiang and Jiangsu), southern (e.g., Guangxi and Guangdong), northern (e.g., Hebei, Tianjin and Beijing) and western (e.g., Sichuan and Shanxi) regions. Manufacturing firms in these regions are considered to have high willingness and levels to adopt digital technologies to improve competitiveness (Li et al., 2020). In the context of the epidemic, the Chinese government has formulated policies to encourage firms to adopt digital technologies to improve resilience, and many firms have shown good resilience in managing the impact of the epidemic (Peng et al., 2021). Therefore, we take Chinese manufacturing firms as the subjects of our investigation. We also limited the respondents to middle and senior managers of companies to ensure the reliability of the results (Gu et al., 2021b). Sample firms with corresponding contact information were identified through China Telecom Yellow Pages (Jacobs et al., 2016).

We sent online survey links to randomly selected firms by e-mail and invited experienced managers of these firms to participate in this survey. When sending the survey link, we attached a letter of introduction to inform the respondents of our research motivations and relevant ethics, as well as confidentiality information. In addition, we also offered to provide the respondents with a summary report of the research results in an attempt to motivate participation. During the survey, we sent a reminder e-mail to the respondents two weeks after our initial e-mail and made two follow-up phone calls. A total of 1263 questionnaires were distributed, and 332 valid responses were returned at the end of the survey, representing a response rate of 26.28%. The response rate was higher than that of similar studies (e.g., Gu et al., 2021a) and is considered acceptable.

Response characteristics indicate that our sample is representative, and the responses are reliable. Specifically, 80.1% of the respondents have more than 5 years of working experience in their working organizations, indicating that they have a good understanding of their firms’ overall operations situations. Respondents are in various positions in their companies, including general managers (10.2%), production managers (27.7%), purchasing managers (17.2%), product managers (15.4%), R&D managers (9.6%), marketing managers (16.6%) and others (3.3%). Moreover, the sample covers different manufacturing sectors and includes four forms of ownership. Moreover, our sample includes manufacturing firms with different numbers of employees and annual turnovers, indicating varying business scales. The demographics of the respondents are shown in Table 1.

4.2 Common method bias and nonresponse bias

In this study, procedural and statistical remedies were used to ensure that the results were not affected by common method bias (Podsakoff et al., 2003). Before conducting the survey, we carefully reviewed the content of the questionnaire to ensure that the expression of items was clear and accurate. Moreover, we applied instrumental design methods, including a mixture of listing items and anonymity, to the participants (Hanh Le, 2019). These procedural remedies ensured reliable responses (Cui et al., 2021). In terms of statistical remedies, we performed Harman’s one-factor test via EFA (exploratory factor analysis) and CFA (confirmatory factor analysis) using SPSS software, version 25, and AMOS software, version 26. First, the EFA results showed that the first extracted factor only explains 42.418% of the variance, which is less than the 50% variance threshold (Podsakoff et al., 2003; Afum et al., 2020). Next, we performed CFA linking all constructed items to separate factors. The model’s fit indices -- CFI = 0.750 IFI = 0.751, χ2/df = 5.094, NFI = 0.708, TLI = 0.727, RMSEA = 0.111 and SRMR = 0.081 -- are all unacceptable. They are significantly lower than those of the measurement model. Hence, we can fully confirm that common method bias poses no threat to the reliability of our study.

Furthermore, we also verified nonresponse bias by comparing the differences between late respondents and early respondents (Armstrong & Overton, 1977). Specifically, the differences between the late and early responses on the industry and the number of employees were compared via the t test. The results indicate no significant differences in the industry (t = 0.335, p = 0.737) or the number of employees (t=-0.745, p = 0.457), indicating that nonresponse bias is not an issue in this study.

4.3 Measures

The research instrument is developed by adaptation from established scales. Since this survey was conducted in China, we applied the back-translation methodology to achieve conceptual equivalence between the original items in English and the Chinese version (Wang & Feng, 2012; Gu et al., 2021a). To ensure face validity, several experienced operations management experts were invited to review the questionnaire and provide suggestions for revision. Based on their feedback, minor modifications were made to ensure the validity and comprehensibility of the questionnaire. Finally, a pilot test was conducted with 50 companies to further test the validity of the questionnaire. Table 2 lists the constructs with measurement items. Respondents were asked to use a 7-point Likert scale ranging from 1 (strongly disagree) to 7 (strongly agree) to rate each item based on their knowledge of their working organizations.

All of the items in this study were required to be measured in the context of COVID-19. That is, all of the measurement standards had to be based on COVID-19’s environment as follows.

The measurement items for digital technologies were adapted from established scales (Dalenogare et al., 2018; Mittal et al., 2018; Frank et al., 2019; Li et al., 2020). Specifically, respondents were asked to explain the extent to which their firms have implemented big data, cloud computing, IoT and analytics technologies in their operations during the COVID-19 pandemic. These four digital technologies are considered to be highly relevant, and their joint development can produce better aggregation benefits (Smys & Raj, 2019; Li et al., 2020).

Items for internal integration, supplier integration and customer integration came from Narasimhan & Kim (2002), Seo et al., (2014), Flynn et al., (2010) and Wong et al., (2011). The supplier integration and customer integration parts required the respondents to indicate the degree of mutual support and cooperation between customers/suppliers and their own firms based on information sharing, joint planning, strategic partnerships, product development and so on. In addition, internal integration was assessed by asking respondents to explain the degree to which they would agree with the responsiveness of all departments to other departments within their firms, integrated system application, information flow management and physical flow management.

The scale for measuring firm resilience came from the existing research of Ambulkar et al., (2015), Ali et al., (2017) and Parker & Ameen (2018). It was measured by utilizing the firm’s resilience ability to adapt to supply chain disruptions and manage the changes caused by them. In addition, the resilience ability of firms to respond to interruptions and grasp the overall situation and development trend of supply chain operations was also included. In addition, measures for information complexity were adapted from Li (2016), Huang (2000) and Tsai et al., (2008). These authors exploited a three-item scale to measure the information complexity faced by individuals, and we extended these measures to the firm level. Respondents were asked to illustrate the amount of information, the complexity of supply chain information, and the richness of information characteristics and dimensions faced by their firms in the business process.

For the covariates, we controlled firm size through annual turnover and the number of employees. Size has often been considered a control variable in the existing research on resilience (Gu et al., 2021a). Compared with smaller firms, larger firms have greater competitiveness and resource advantages and can better obtain resilience (Huo et al., 2015; Azadegan et al., 2020). In addition, we controlled for the ownership type of the firm to avoid the potential impact that could come from different ownership types on operations management (Liu et al., 2014; Amoako-Gyampah et al., 2019).

4.4 Reliability and validity

Before verifying the hypothesized relationships, we tested for construct reliability through Cronbach’s α. The Cronbach’s α value for each construct is shown in Table 3. The Cronbach’s α values for all constructs met the requirements of the measurement standard (greater than the 70% threshold), ranging from 0.788 to 0.851 (Fornell & Larcker, 1981).

In addition, we also checked the convergent validity and discriminant validity of constructs. Specifically, we carried out CFA with the maximum likelihood method, and the model fit indices were CFI = 0.961, IFI = 0.962, χ2/df = 1.671, NFI = 0.909, TLI = 0.955, RMSEA = 0.045 and SRMR = 0.0392. The results show that model fit has been achieved (Hu & Bentler, 1999). In addition, all factor loadings were found to range from 0.694 to 0.792 (greater than 0.50). The average variance extracted (AVE) values were between 0.510 and 0.561, all greater than the threshold of 0.50. Furthermore, composite reliability (CR) values ranged from 0.791 to 0.853 (greater than 0.70). Thus, convergent validity is established. The construct reliability and convergent validity results are presented in Table 3.

Finally, discriminant validity was tested. We compared the square root of the AVE values of each construct with the correlations between the construct and other constructs. The results are presented in Table 4. It can be seen that all of the constructs’ square root of AVE values are greater than their bivariate associations with other constructs. Hence, this study realized discriminant validity.

5 Analyses and results

The hypothesis verification in this study was conducted using the PROCESS macro for SPSS software (Hayes, 2017). PROCESS is a reliable and convenient tool for empirical research and is widely used in operations management research (Liu et al., 2016; Duan & Aloysius, 2019; Kalyar et al., 2020; Riquelme-Medina et al., 2021). Since the PROCESS Model 4 macro and PROCESS Model 5 macro were used to conduct multiple linear regression, we calculated the variance inflation factor (VIF) for the two models (Li et al., 2020). The VIF values in this study are lower than the threshold of 10, ranging from 1.026 to 2.627. Hence, multicollinearity was not a serious concern.

First, we utilized the PROCESS Model 4 macro to test H1, H2a, H2b and H2c. The regression results are shown in Table 5. H1 investigates the relationship between digital technologies and firm resilience. Digital technologies were found to have a significantly positive impact on firm resilience (β = 0.266, t = 5.201, p < 0.001) on the basis of the regression results after controlling for the three covariates (ownership type, the number of employees and annual turnover). Therefore, H1 was supported.

H2a, H2b and H2c represent the mediation effects of customer integration, supplier integration and internal integration on the relationship between digital technologies and firm resilience, which was tested through the bootstrapping technique (Hayes, 2017). According to the results, the effects of digital technologies on customer integration (β = 0.661, t = 18.991, p < 0.001), supplier integration (β = 0.449, t = 10.319, p < 0.001) and internal integration (β = 0.477, t = 11.126, p < 0.001) are all significant and positive, as are the paths from customer integration, supplier integration and internal integration to firm resilience (β = 0.268, t = 4.686, p < 0.001; β = 0.127, t = 2.857, p < 0.01; β = 0.163, t = 3.594, p < 0.001), while bootstrapping with 5000 resamples and a confidence interval of 95% was set to test the indirect effect (Wang et al., 2019). Table 5 reveals that the indirect effects on firm resilience from digital technologies via customer integration (β = 0.177, SE = 0.051, CI95% = [0.079, 0.280]), supplier integration (β = 0.057, SE = 0.021, CI95% = [0.016, 0.099]) and internal integration (β = 0.078, SE = 0.023, CI95% = [0.037, 0.394]) were positive and significant, indicating that customer, supplier and internal integration partially mediate the relationship between digital technologies and firm resilience. Full support was found for H2a, H2b and H2c.

Regarding Hypothesis 3, we predict that information complexity positively moderates the relationship between digital technologies and firm resilience. The PROCESS Model 5 macro was employed to test H3 with 5000 bootstrap resamples. The regression results are shown in Table 6. It is evident that the interaction term between information complexity and digital technologies (β = 0.061, t = 3.075, p < 0.01) has a significant and positive impact on firm resilience.

Table 7 shows the conditional direct effects of digital technologies on firm resilience at different levels of information complexity. It is clear that the conditional, direct impact of digital technologies on firm resilience is significant when information complexity is high (CI95% = [0.083, 0.205]), while the influence is insignificant when information complexity is low (CI95% = [-0.009, 0.108]). That is, the higher that the information complexity is, the stronger that the effect of digital technologies on firm resilience is. Thus, H3 was supported.

6 Discussion

This study provides an in-depth understanding of the relationship between digital technologies and firm resilience based on IPT in the context of COVID-19. Moreover, the mediating variables (internal integration, supplier integration and customer integration) and moderating variable (information complexity) are also considered in the main relationship. The findings of this study enrich the operations and supply chain management literature in four ways.

First, this study reveals the relationship between digital technologies and firm resilience. Specifically, digital technologies were found to positively affect firm resilience. In the context of Industry 4.0, digital technologies, such as big data, cloud computing, the IoT and analytics, are rapidly popularized and applied among firms in different industries (Smys & Raj, 2019; Li et al., 2020). Researchers have indicated that, through the configuration and integration of digital technologies, manufacturing firms can improve their capabilities, such as responsiveness (Giannakis et al., 2019), agility (Dubey et al., 2019; Troise et al., 2022), warning capability (Wang et al., 2020a), flexibility (Rialti et al., 2020), and visibility (Ben-Daya et al., 2017; Ahmed et al., 2021). However, these capabilities individually cannot reflect firm resilience (Santos Bernardes & Hanna, 2009; Srinivasan & Swink, 2018; Faruquee et al., 2021), which is considered to constitute the integration of these capabilities (Tukamuhabwa et al., 2015; Ambulkar et al., 2015). However, existing studies have not captured the collective impacts of digital technologies on resilience, especially in the context of COVID-19. During the epidemic, firms have faced more uncertainties from both the supply and demand sides, requiring digital technologies’ support to increase firm resilience to resist these disruptions of uncertainty.

Moreover, the inconsistent conclusions from existing studies of the relationship between digital technologies and firm resilience call for further explorations Some researchers have found that applying digital technologies is conducive to alleviating the impacts of interruptions and enabling firms to quickly recover from interruptions (Balakrishnan & Ramanathan, 2021; Belhadi et al., 2021; Burgos & Ivanov, 2021). Other researchers have pointed out that a large amount of investment in digital technologies could affect the trust relationship between stakeholders and the solutions to interruptions in the process of firm operation (Faruquee et al., 2021), and the application of digital technologies itself is not sufficient to develop resilience (Zouari et al., 2020). Our study emphasizes that the effect of digital technologies on firm resilience has not been fully explored, especially considering the context of COVID-19. Therefore, this study takes firm resilience as a unified construct and investigates the coherent influence of digital technologies that represent the information processing capabilities of firms in the context of COVID-19.

Second, this study confirms the mediating roles of internal integration, supplier integration and customer integration in the technology-resilience link. They offer an important mechanism through which the impacts of digital technologies on firm resilience can be realized. According to the results, the role of digital technologies in enhancing resilience can be realized through internal integration, supplier integration and customer integration. Existing studies have explored the role of supply chain integration operations management and the information systems literature. For instance, supply chain integration was found to mediate the relationship between IoT adoption and green supply chain performance (Shafique et al., 2018). Industry 4.0 technologies were found to contribute to supply chain performance (Erboz et al., 2021). However, few studies have explored how internal integration, supplier integration and customer integration mediate the impacts of advanced digital technologies on firm resilience in the context of COVID-19. This study demonstrates the mediation effect of customer integration, supplier integration and internal integration, indicating that the impact of digital technologies on firm resilience can be better realized in highly integrated supply chains. Furthermore, this study found that the mediating role of customer integration is more prominent than those of supplier integration and internal integration. Under normal circumstances, firms often face high demand uncertainty (Sharma et al., 2020a). However, during disruptions such as the pandemic, such uncertainty could be further amplified by consumer panic. In this situation, customer integration is more important because digital technologies are able to help firms to collect, sort and analyse market information and better respond to the changing market (Ardito et al., 2018; Li et al., 2018) and return to normal operations quickly. This finding is consistent with Piprani et al., (2020), who found that customer integration is more important than the other two integration types in turbulent environments.

Third, our study reveals that information complexity moderates the effect of digital technologies on firm resilience, indicating that, when the information that must be managed is more complex, manufacturing firms should take advantage of digital technologies to process internal and external information to enhance firm resilience. In situations such as the pandemic, false information is prevalent, and information becomes more complex and difficult to process (de Oliveira & Albuquerque, 2021; Valika et al., 2020). Therefore, our study suggests that, in the context of COVID-19, the information processing capability of digital technologies should be valued more to ensure firm resilience. However, to the best of our knowledge, there is a lack of empirical evidence on how information complexity can affect the influence of digital technologies on resilience. Our research thus enriches this stream of literature and contributes to an in-depth understanding of the contextual conditions that could affect the power of digital technologies.

Last, based on IPT, digital technologies are regarded as the organization’s information processing capability, while supply chain integration is considered to help improve information processing capability and reduce information processing requirements. In addition, information complexity affects the requirements of firms for information processing capability. In an environment of high information complexity, manufacturing firms must enhance their information processing ability to process information accurately. The findings of this study confirm that the matching of information processing capabilities and requirements can contribute to coping with the supply chain disruptions that support IPT (Wong et al., 2020). IPT is an effective theoretical perspective for studying firm resilience in the context of COVID-19.

Our study also offers managerial implications for manufacturing firms. Currently, global firms are facing the risk of disruptions from COVID-19 (Gu et al., 2021a). In this situation, manufacturing firms are recommended to use digital technologies, such as big data, cloud computing and the IoT, to manage disruptions to their supply chains and improve firm resilience. Firms can use these digital technologies to obtain accurate, real-time and high-quality information related to production and product demand, thus facilitating firms in returning to normal operations quickly. In particular, in natural disasters such as epidemics, during which false information is prevalent and information overload is serious (de Oliveira & Albuquerque, 2021), the value of digital technology applications is more prominent in dealing with complex information. Therefore, firms should prioritize the development of digital technologies, especially in the context of high information complexity.

In addition, according to the results, we also suggest that manufacturing firms apply digital technologies in supply chain management to integrate supplier, customer and internal resources to strengthen firm resilience to manage supply chain disruptions. Firms should pay more attention to customer integration because its moderating effect is the most obvious among all three types of supply chain integration. Firms are recommended to build close relationships with customers, acquire exact, dynamic and punctual demand information from customers and respond promptly to the changing needs of customers (Piprani et al., 2020). Under the impact of COVID-19, the significance of information management has become more prominent (Cao et al., 2021); thus, manufacturing firms are recommended to use big data and analytics technologies to determine and analyse the rapidly changing needs of consumers to service consumers efficiently. In the same way, firms can use these technologies to complete suppliers’ and internal integration, collectively enhancing firm resilience.

7 Conclusions

Firms and their supply chains are extremely vulnerable to disruptions caused by the COVID-19 pandemic. Hence, in the current global crisis, building firm resilience is an important agenda for all organizations (Sharma et al., 2020a). Based on IPT, this study tested the influence mechanism of digital technologies on firm resilience. The results show that digital technologies positively affect firm resilience due to their ability to rapidly process information within the firm and its supply chain. Internal integration, supplier integration and customer integration all mediate the technology-resilience relationship, and among them, the effect of customer integration is the most obvious. Moreover, information complexity moderates the direct impact of digital technologies on firm resilience. These findings are conducive to supporting firms in managing disruptions from COVID-19.

Our study also has several limitations. First, digital technologies in this study were measured through four factors: big data, cloud computing, the IoT and analytics. However, with continuous development, new technologies, such as artificial intelligence and blockchain, are emerging and increasingly integrated into the firm’s operations. Hence, we recommend that future studies update their scale and include all of the latest technologies. Second, similar to other theoretical studies, the measures proposed based on information processing theory in this paper might not fully cover theoretical issues related to digital technologies and firm resilience. Therefore, more possible relationships and phenomena from other theories, such as dynamic capability theory, could be further explored. Third, the survey was conducted in China, a developing country featuring rapid industrialization and technology adoption. Due to the global impact of COVID-19, relevant research in other countries during the pandemic and the postepidemic era should also be conducted.

References

Afum, E., Agyabeng-Mensah, Y., Sun, Z., Frimpong, B., Kusi, L. Y., & Acquah, I. S. K. (2020). Exploring the link between green manufacturing, operational competitiveness, firm reputation and sustainable performance dimensions: a mediated approach. Journal of Manufacturing Technology Management, 31(7), 1417–1438

Ahmed, S., Kalsoom, T., Ramzan, N., Pervez, Z., Azmat, M., Zeb, B., & Rehman, U., M (2021). Towards Supply Chain Visibility Using Internet of Things. A Dyadic Analysis Review. Sensors, 21(12), 4158

Al-Talib, M., Melhem, W. Y., Anosike, A. I., Garza Reyes, J. A., Nadeem, S. P., & kumar, A. (2020). Achieving resilience in the supply chain by applying IoT technology. Procedia CIRP, 91, 752–757

Alamsyah, N., & Zhu, Y. Q. (2021). We shall endure: Exploring the impact of government information quality and partisanship on citizens’ well-being during the COVID-19 pandemic.Government Information Quarterly,101646

Ali, M. H., Suleiman, N., Khalid, N., Tan, K. H., Tseng, M. L., & Kumar, M. (2021). Supply chain resilience reactive strategies for food SMEs in coping to COVID-19 crisis. Trends in Food Science & Technology, 109, 94–102

Ali, Z., Sun, H., & Ali, M. (2017). The Impact of Managerial and Adaptive Capabilities to Stimulate Organizational Innovation in SMEs: A Complementary PLS–SEM. Approach. Sustainability, 9(12), 2157

Aljanabi, A. R. A. (2021). The impact of economic policy uncertainty, news framing and information overload on panic buying behavior in the time of COVID-19: a conceptual exploration. International Journal of Emerging Markets. https://doi.org/10.1108/IJOEM-10-2020-1181

Ambulkar, S., Blackhurst, J., & Grawe, S. (2015). Firm’s resilience to supply chain disruptions: Scale development and empirical examination. Journal of Operations Management, 33–34(1), 111–122

Amoako-Gyampah, K., Boakye, K. G., Adaku, E., & Famiyeh, S. (2019). Supplier relationship management and firm performance in developing economies: A moderated mediation analysis of flexibility capability and ownership structure. International Journal of Production Economics, 208, 160–170

Annan, J., Boso, N., Mensah, J., & Nagbe Sulee, E. (2016). Antecedents and consequences of supply chain integration: Empirical evidence from a developing economy. International Journal of Supply Chain Management, 5(1), 10–24

Ardito, L., Petruzzelli, A. M., Panniello, U., & Garavelli, A. C. (2019). Towards Industry 4.0: Mapping digital technologies for supply chain management-marketing integration. Business Process Management Journal, 25(2), 323–346

Armstrong, J. S., & Overton, T. S. (1977). Estimating Nonresponse Bias in Mail Surveys. Journal of Marketing Research, 14(3), 396–402

Arsovski, S., Arsovski, Z., Stefanović, M., Tadić, D., & Aleksić, A. (2017). Organisational resilience in a cloud-based enterprise in a supply chain: a challenge for innovative SMEs. International Journal of Computer Integrated Manufacturing, 30(4–5), 1–11

Ayoub, H. F., Abdallah, A. B., & Suifan, T. S. (2017). The effect of supply chain integration on technical innovation in Jordan: The mediating role of knowledge management. Benchmarking: An International Journal, 24(3), 594–616

Azadegan, A., Mellat Parast, M., Lucianetti, L., Nishant, R., & Blackhurst, J. (2020). Supply Chain Disruptions and Business Continuity: An Empirical Assessment. Decision Sciences, 51(1), 38–73

Balakrishnan, A. S., & Ramanathan, U. (2021). The role of digital technologies in supply chain resilience for emerging markets’ automotive sector. Supply Chain Management: An International Journal, 26(6), 654–671

Bartnik, R., & Park, Y. (2018). Technological change, information processing and supply chain integration: A conceptual model. Benchmarking: An International Journal, 25(5), 1279–1301

Bejlegaard, M., Sarivan, I. M., & Waehrens, B. V. (2021). The influence of digital technologies on supply chain coordination strategies. Journal of Global Operations and Strategic Sourcing, 14(4), 636–658

Belhadi, A., Kamble, S., Jabbour, C. J. C., Gunasekaran, A., Ndubisi, N. O., & Venkatesh, M. (2021). Manufacturing and service supply chain resilience to the COVID-19 outbreak: Lessons learned from the automobile and airline industries. Technological Forecasting and Social Change, 163, 120447

Ben-Daya, M., Hassini, E., & Bahroun, Z. (2017). Internet of things and supply chain management: a literature review. International Journal of Production Research, 57(15–16), 4719–4742

Bensaou, M., & Venkatraman, N. (1995). Configurations of Interorganizational Relationships: A Comparison Between U.S. and Japanese Automakers. Management Science, 41(9), 1471–1492

Bermes, A. (2021). Information overload and fake news sharing: A transactional stress perspective exploring the mitigating role of consumers’ resilience during COVID-19. Journal of Retailing and Consumer Services, 61, 102555

Bi, Z., & Cochran, D. (2014). Big data analytics with applications. Journal of Management Analytics, 1(4), 249–265

Birkel, H. S., & Hartmann, E. (2020). Internet of Things – the future of managing supply chain risks. Supply Chain Management: An International Journal, 25(5), 535–548

Bowen, F. E. (2000). Environmental visibility: a trigger of green organizational response? Business Strategy and the Environment, 9(2), 92–107

Brewton, K. E., Danes, S. M., Stafford, K., & Haynes, G. W. (2010). Determinants of rural and urban family firm resilience. Journal of Family Business Strategy, 1(3), 155–166

Burgos, D., & Ivanov, D. (2021). Food retail supply chain resilience and the COVID-19 pandemic: A digital twin-based impact analysis and improvement directions. Transportation Research Part E: Logistics and Transportation Review, 152, 102412

Buyya, R., Yeo, C. S., Venugopal, S., Broberg, J., & Brandic, I. (2009). Cloud computing and emerging IT platforms: Vision, hype, and reality for delivering computing as the 5th utility. Future Generation Computer Systems, 25(6), 599–616

Cagliano, R., Caniato, F., & Spina, G. (2006). The linkage between supply chain integration and manufacturing improvement programmes. International Journal of Operations & Production Management, 26(3), 282–299

Cai, J., & Dang, X. (2015). The impact of IT implementation on quality of shared information and its effect on firm performance: evidence from China. International Journal of Internet Manufacturing and Services, 4(1), 14–36

Cai, M., & Luo, J. (2020). Influence of COVID-19 on Manufacturing Industry and Corresponding Countermeasures from Supply Chain Perspective. Journal of Shanghai Jiaotong University (Science), 25(4), 409–416

Cao, J., Liu, F., Shang, M., & Zhou, X. (2021). Toward street vending in post COVID-19 China: Social networking services information overload and switching intention. Technology in Society, 66, 101669

Cegielski, C. G., Jones-Farmer, A., Wu, L., Y., & Hazen, B. T. (2012). Adoption of cloud computing technologies in supply chains: An organizational information processing theory approach. The International Journal of Logistics Management, 23(2), 184–211

Chakraborty, S., & Biswas, M. C. (2020). Impact of COVID-19 on the textile, apparel and fashion manufacturing industry supply chain: Case study on a ready-made garment manufacturing industry. Journal of Supply Chain Management, Logistics and Procurement, 3(2), 181–199

Choi, T. M., Wallace, S. W., & Wang, Y. (2018). Big Data Analytics in Operations Management. Production and Operations Management, 27(10), 1868–1883

Chunsheng, L., Wong, C. W. Y., Yang, C. C., Shang, K. C., & Lirn, T. C. (2020). Value of supply chain resilience: roles of culture, flexibility, and integration. International Journal of Physical Distribution & Logistics Management, 50(1), 80–100

Cui, L., Wu, H., & Dai, J. (2021). Modelling flexible decisions about sustainable supplier selection in multitier sustainable supply chain management.International Journal of Production Research,1–22

Dalenogare, L. S., Benitez, G. B., Ayala, N. F., & Frank, A. G. (2018). The expected contribution of Industry 4.0 technologies for industrial performance. International Journal of Production Economics, 204, 383–394

de Oliveira, D. V. B., & Albuquerque, U. P. (2021). Cultural Evolution and Digital Media: Diffusion of Fake News About COVID-19 on Twitter. SN Computer Science, 2(6), 430

de Vass, T., Shee, H., & Miah, S. J. (2018). The effect of “Internet of Things” on supply chain integration and performance: An organisational capability perspective. Australasian Journal of Information Systems, 22, 1–19

de Vries, T. A., van der Vegt, G. S., Scholten, K., & van Donk, D. P. (2021). Heeding supply chain disruption warnings: When and how do cross-functional teams ensure firm robustness?Journal of Supply Chain Management,12262

Dormady, N., Roa-Henriquez, A., & Rose, A. (2019). Economic resilience of the firm: A production theory approach. International Journal of Production Economics, 208, 446–460

Duan, Y., & Aloysius, J. A. (2019). Supply chain transparency and willingness-to-pay for refurbished products. The International Journal of Logistics Management, 30(3), 797–820

Dubey, R., Gunasekaran, A., & Childe, S. J. (2019). Big data analytics capability in supply chain agility: The moderating effect of organizational flexibility. Management Decision, 57(8), 2092–2112

Dubey, R., Gunasekaran, A., Childe, S. J., Fosso Wamba, S., Roubaud, D., & Foropon, C. (2021). Empirical investigation of data analytics capability and organizational flexibility as complements to supply chain resilience. International Journal of Production Research, 59(1), 110–128

Erboz, G., Yumurtacı Hüseyinoğlu, I., & Szegedi, Z. (2021). The partial mediating role of supply chain integration between Industry 4.0 and supply chain performance. Supply Chain Management: An International Journal. https://doi.org/10.1108/SCM-09-2020-0485

Fan, H., Li, G., Sun, H., & Cheng, T. C. E. (2017). An information processing perspective on supply chain risk management: Antecedents, mechanism, and consequences. International Journal of Production Economics, 185, 63–75

Faruquee, M., Paulraj, A., & Irawan, C. A. (2021). Strategic supplier relationships and supply chain resilience: Is digital transformation that precludes trust beneficial? International Journal of Operations & Production Management, 41(7), 1192–1219

Feng, T., Li, T., Sun, L., & Wang, D. (2013). External involvement and operational performance: The mediating role of internal integration. Chinese Management Studies, 7(3), 488–507

Fernández-Torres, M. J., Almansa-Martínez, A., & Chamizo-Sánchez, R. (2021). Infodemic and Fake News in Spain during the COVID-19 Pandemic. International Journal of Environmental Research and Public Health, 18(4), 1781

Flynn, B. B., Huo, B., & Zhao, X. (2010). The impact of supply chain integration on performance: A contingency and configuration approach. Journal of Operations Management, 28(1), 58–71

Fornell, C., & Larcker, D. F. (1981). Evaluating Structural Equation Models with Unobservable Variables and Measurement Error. Journal of Marketing Research, 18(1), 39–50

Frank, A. G., Dalenogare, L. S., & Ayala, N. F. (2019). Industry 4.0 technologies: Implementation patterns in manufacturing companies. International Journal of Production Economics, 210, 15–26

Galbraith, J. R. (1973). Designing complex organizations. Boston: Addison-Wesley Longman Publishing Co., Inc

Galbraith, J. R. (1974). Organization Design: An Information Processing View. INFORMS Journal on Applied Analytics, 4(3), 28–36

Garrison, G., Wakefield, R. L., & Kim, S. (2015). The effects of IT capabilities and delivery model on cloud computing success and firm performance for cloud supported processes and operations. International Journal of Information Management, 35(4), 377–393

Giannakis, M., Spanaki, K., & Dubey, R. (2019). A cloud-based supply chain management system: effects on supply chain responsiveness. Journal of Enterprise Information Management, 32(4), 585–607

Golan, M. S., Jernegan, L. H., & Linkov, I. (2020). Trends and applications of resilience analytics in supply chain modeling: systematic literature review in the context of the COVID-19 pandemic. Environment Systems and Decisions, 40(2), 222–243

Gu, M., Yang, L., & Huo, B. (2021a). The impact of information technology usage on supply chain resilience and performance: An ambidexterous view. International Journal of Production Economics, 232, 107956

Gu, V. C., Zhou, B., Cao, Q., & Adams, J. (2021b). Exploring the relationship between supplier development, big data analytics capability, and firm performance. Annals of Operations Research, 302(1), 151–172

Gunasekaran, A., & Ngai, E. W. T. (2004). Information systems in supply chain integration and management. European Journal of Operational Research, 159(2), 269–295

Hanh Le, N. (2019). Knowledge sharing and knowledge acquisition of salespersons in social media environments: a social capital perspective. Business & Social Sciences Journal, 4(1), 81–103

Hayes, A. F. (2017). Introduction to mediation, moderation, and conditional process analysis: A regression-based approach. Guilford publications

He, L., Xue, M., & Gu, B. (2020). Internet-of-things enabled supply chain planning and coordination with big data services: Certain theoretic implications. Journal of Management Science and Engineering, 5(1), 1–22

Hendricks, K. B., & Singhal, V. R. (2005). Association Between Supply Chain Glitches and Operating Performance. Management Science, 51(5), 695–711

Hu, L., & Bentler, P. M. (1999). Cutoff criteria for fit indexes in covariance structure analysis: Conventional criteria versus new alternatives. Structural Equation Modeling: A Multidisciplinary Journal, 6(1), 1–55

Huang, M. H. (2000). Information load: its relationship to online exploratory and shopping behavior. International Journal of Information Management, 20(5), 337–347

Huo, B., Zhang, C., & Zhao, X. (2015). The effect of IT and relationship commitment on supply chain coordination: A contingency and configuration approach. Information & Management, 52(6), 728–740

Iftikhar, A., Purvis, L., & Giannoccaro, I. (2021). A meta-analytical review of antecedents and outcomes of firm resilience. Journal of Business Research, 135, 408–425

Islam, T., Pitafi, A. H., Arya, V., Wang, Y., Akhtar, N., Mubarik, S., & Xiaobei, L. (2021). Panic buying in the COVID-19 pandemic: A multi-country examination. Journal of Retailing and Consumer Services, 59, 102357

Ivanov, D. (2021a). Digital Supply Chain Management and Technology to Enhance Resilience by Building and Using End-to-End Visibility During the COVID-19 Pandemic.IEEE Transactions on Engineering Management,1–11

Ivanov, D. (2021b). Lean resilience: AURA (Active Usage of Resilience Assets) framework for post-COVID-19 supply chain management. The International Journal of Logistics Management. https://doi.org/10.1108/IJLM-11-2020-0448

Ivanov, D., & Dolgui, A. (2020). Viability of intertwined supply networks: extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak. International Journal of Production Research, 58(10), 2904–2915

Ivanov, D., Dolgui, A., Das, A., & Sokolov, B. (2019a). Digital Supply Chain Twins: Managing the Ripple Effect, Resilience, and Disruption Risks by Data-Driven Optimization, Simulation, and Visibility. In D. Ivanov, A. Dolgui, & B. Sokolov (Eds.), Handbook of Ripple Effects in the Supply Chain (276 vol., pp. 309–332). Cham: Springer

Ivanov, D., Dolgui, A., & Sokolov, B. (2019b). The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. International Journal of Production Research, 57(3), 829–846

Jacobs, M. A., Yu, W., & Chavez, R. (2016). The effect of internal communication and employee satisfaction on supply chain integration. International Journal of Production Economics, 171(1), 60–70

Jayender, P., & Kundu, G. K. (2021). Intelligent ERP for SCM agility and graph theory technique for adaptation in automotive industry in India. International Journal of System Assurance Engineering and Management, 1–22

Jonsson, P., Kaipia, R., & Barratt, M. (2021). Guest editorial The future of S&OP: dynamic complexity, ecosystems and resilience. International Journal of Physical Distribution & Logistics Management, 51(6), 553–565

Jabbour, A. B. L. D. S., Jabbour, C. J. C., Hingley, M., Vilalta-Perdomo, E. L., & Twigg, D. (2020). Sustainability of supply chains in the wake of the coronavirus (COVID-19/SARS-CoV-2) pandemic: lessons and trends. Modern Supply Chain Research and Applications, 2(3), 117–122

Jüttner, U., & Maklan, S. (2011). Supply chain resilience in the global financial crisis: an empirical study. Supply Chain Management: An International Journal, 16(4), 246–259

Kalyar, M. N., Shoukat, A., & Shafique, I. (2020). Enhancing firms’ environmental performance and financial performance through green supply chain management practices and institutional pressures. Sustainability Accounting, Management and Policy Journal, 11(2), 451–476

Kang, M., Yang, M. G., Park, Y., & Huo, B. (2018). Supply chain integration and its impact on sustainability. Industrial Management & Data Systems, 118(9), 1749–1765

Khanuja, A., & Jain, R. K. (2021). The mediating effect of supply chain flexibility on the relationship between supply chain integration and supply chain performance. Journal of Enterprise Information Management. https://doi.org/10.1108/JEIM-11-2020-0449

Kim, D. Y. (2013). Relationship between supply chain integration and performance. Operations Management Research, 6(1–2), 74–90

Koot, M., Mes, M. R. K., & Iacob, M. E. (2021). A systematic literature review of supply chain decision making supported by the Internet of Things and Big Data Analytics. Computers & Industrial Engineering, 154, 107076

Kritchanchai, D., & MacCarthy, B. L. (1999). Responsiveness of the order fulfilment process. International Journal of Operations & Production Management, 19(8), 812–833

Laud, R. L., & Schepers, D. H. (2009). Beyond Transparency: Information Overload and a Model for Intelligibility. Business and Society Review, 114(3), 365–391

Lee, I., & Lee, K. (2015). The Internet of Things (IoT): Applications, investments, and challenges for enterprises. Business Horizons, 58(4), 431–440

Lee, S. Y. (2021). Sustainable Supply Chain Management, Digital-Based Supply Chain Integration, and Firm Performance: A Cross-Country Empirical Comparison between South Korea. and Vietnam. Sustainability, 13(13), 7315

Li, C. Y. (2016). Why do online consumers experience information overload? An extension of communication theory. Journal of Information Science, 43(6), 835–851

Li, G., Lin, Y., Wang, S., & Yan, H. (2006a). Enhancing agility by timely sharing of supply information. Supply Chain Management: An International Journal, 11(5), 425–435

Li, L., Chi, T., Hao, T., & Yu, T. (2018). Customer demand analysis of the electronic commerce supply chain using Big Data. Annals of Operations Research, 268(1), 113–128

Li, S., Ragu-Nathan, B., Ragu-Nathan, T. S., & Subba Rao, S. (2006b). The impact of supply chain management practices on competitive advantage and organizational performance. Omega, 34(2), 107–124

Li, Y., Dai, J., & Cui, L. (2020). The impact of digital technologies on economic and environmental performance in the context of industry 4.0: A moderated mediation model. International Journal of Production Economics, 229, 107777

Lin, B., Wu, W., & Song, M. (2019). Industry 4.0: driving factors and impacts on firm’s performance: an empirical study on China’s manufacturing industry. Annals of Operations Research. https://doi.org/10.1007/s10479-019-03433-6

Liu, H., Ke, W., Wei, K. K., & Hua, Z. (2014). Moderating role of ownership type in the relationship between market orientation and supply chain integration in E-business in China. Journal of Global Information Management, 22(4), 34–53

Liu, Z., Prajogo, D., & Oke, A. (2016). Supply Chain Technologies: Linking Adoption, Utilization, and Performance. Journal of Supply Chain Management, 52(4), 22–41