Abstract

In the field of optoelectronics, Organic Light Emitting Transistors (OLET) symbolise a new era. The OLET is a bifunctional device that combines the switching and amplification capabilities of organic field effect transistors with the electroluminescent capabilities of organic light emitting diodes in a single device. Organic semiconductor materials are important for optoelectronic devices because of their low cost, light weight, and flexible production procedures. OLETs play a vital role in the field of high mobility organic semiconductors and the fabrication of high performance organic optoelectronic devices as organic optoelectronic devices progress. The performance of OLETs with anthracene as an organic semiconductor material is discussed in detail in this research paper. The performance of OLETs is evaluated using a state-of-the-art Atlas Silvaco 2-D Simulator in terms of driving current, mobility, and current-on-off ratio. The device’s output properties are also examined, and these values are then compared to the available dataset. The parameter values are as follows: Ids of \(17\,\upmu {\mathrm{A}}\), mobility of \(12\,\times \,10^{-2}\,{\mathrm{cm}}^2/{\mathrm{Vs}}\) and on-off ratio of \(10^7\). We have also calculated power consumption value (0.54 mW). We can see that this device has much higher mobility value and lower power consumption value which makes it the better performance device.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

During the previous few decades, organic optoelectronics has grown in prominence. Organic semiconducting materials with unique electrical, optical, and magnetic properties have been developed and applied to a wide range of devices. Organic light emitting diodes (OLEDs), organic solar cells (OPVs), organic field effect transistors (OFETs), and organic light emitting transistors (OLETs) are among the devices that play a significant role [1]. OLEDs are one of the most important technological breakthroughs in recent history. OFETs are being developed in the meantime which is an another type of organic electronic component, is still in the experimental phase. They’re popular because of their versatility, light weight, and inexpensive cost. OLEDs have recently gained a lot of interest. Nonetheless, circuit complexity is one of the biggest challenges for large-area display applications [2]. A revolutionary concept is offered to merge both optical and electrical functionality in a single device to reduce complexity. An organic light-emitting transistor (OLET) is a thin-film transistor with the ability to generate light [3–5]. It is possible to fabricate electroluminescent displays with simpler driving circuitry using multicolor OLETs. There are active-matrix OLED displays on the market, which is the most advanced technology. Higher penetration conditions affects exciton charge interaction and photon losses, lowering OLED performance 30–35. The goal of OLET research is to enable new display technologies by preventing photon losses and exciton charge interactions [4–7].

An organic light-emitting transistor (OLET) is a bifunctional device made of organic material that possesses both light emission and switching capabilities. OLETs are currently potential devices that exhibit certain intriguing properties of well-known electroluminescent devices. OLETs are being considered as viable candidates in integrated circuits that process both electrical and optical signals in the future [8]. Electrically pumped organic lasers have recently received a lot of attention in the research community. These devices have the potential to make existing display systems easier to make and to accelerate advancement in new areas like photonic communications and electrically pumped organic lasers [9, 10].

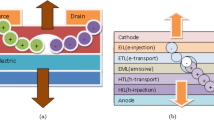

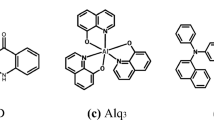

Hepp et al. developed the first organic single BGTC TFT device construction in the year 2003. Here, We’re considering of using a unipolar OLET, in which channel can conduct only one type of charge carriers either holes or electrons [11–16]. Figure 1 shows the fundamental operation of an OLET with an organic semiconductor layer of anthracene in a BC/BG (bottom contact/bottom gate) arrangement. The following are the primary components of the device: (1) There are three electrodes. Charge carriers are injected and retrieved into and out of the semiconductor via the source and drain electrodes, (2) an organic semiconductor layer, which are made of either evaporated or deposited material. It is the device’s active portion, where charge transfer and light emission take place; and (3) an organic dielectric layer that separates the gate from the source and drain electrodes [17].

2 Organic light emitting transistors: its concept, working principle and fabrication steps, and its device configurations

This section gets into the OLET working principle, fabrication steps, structural dimensions, and device configurations into detail

2.1 OLET working principle and its fabrication steps

In this device, holes are present as majority charge carriers, whereas electrons as minority charge carrier can only enter the channel by tunnelling from the drain electrode near to the drain electrode in the presence of a high electric field. In this device, light emission occurs by the excitons, which are pairs of holes and electrons in a highly excited state that develop near the drain electrode and cause radiative recombination and can emit light. As excitons are present near the drain electrode, non-radiation decay is a strong possibility. It’s caused by a charge carrier escaping into the matching metal contact, resulting in an inefficient recombination of holes and electrons. This phenomenon, also known as exciton quenching, causes a reduction in light emission [18].

To improve emission efficiency, the recombination zone should be moved to the center of the channel or distant from the electrodes. The ambipolar OLET structure, as shown in Fig. 2, is one example of this type of structure.

In case of ambipolar OLET structure, charge carriers of source and drain are interchangeable. Radiative recombination occurs in ambipolar OLET structure when opposite charges combine to form an exciton, and the exciton decimates in the form of light radiation and heat. Figure 3 shows the stages involved in fabricating BGTC-OLET.

Fabrication of OLET devices plays a vital part in the device’s performance by selecting the appropriate process stage and their materials [19]. Fabrication begins with the selection of the substrate material, which gives the device with mechanical strength. Furthermore, the gate electrode is made of PEDOT: PSS, while the dielectric layer is made of PMMA. Vacuum thermal evaporation is then used to create an organic semiconductor layer. After that, gold (Au) is used to deposit the source and drain electrodes. Table 1 depicts the structural dimensions of the device characteristics that are employed in the analysis of OLET performance.

3 OLET device configuration

Depending on the location of the device’s gate, source, and drain electrodes, different topologies of organic light emitting transistors can be generated, as shown schematically in Figs. 4 and 5. This is especially true in multilayer systems, where the use of appropriate materials and structures is possible. Because top contacts have a greater interface with the underlying semiconductor, they are good for charge injection in field effect transistors. A planar configuration for the source and drain electrodes is not the optimum design when both charges are to be injected, because one of the charges will always be limited, regardless of polarity or transistor working conditions. To maximise charge carrier injection and the in multilayer designs, the energetics of each contact with the suitable semiconductor, non-planar source and drain can be generated. Electrodes in a multi-layer arrangement with a charge transport and emissive layer have been proven to reduce contact resistance and increase electron and hole recombination efficiency, resulting in a significant increase in brightness up to around \(800\,{\mathrm{cd/m}}^2\), an ON/OFF ratio of the device greater than \(10^5\), EQE about 20 times greater than the reference sample [20–22].

4 OLETs parameters and impact of dielectrics

This section gets into the OLET parameters and importance of dielectrics into detail.

4.1 OLET parameters

The electric switching characteristic of the organic light emitting transistor (OLET) is similar to that of the organic field effect transistor (OFET). Organic light emitting diodes (OLED) electrical luminiscence characteristics [19]. Charge carrier mobility, threshold voltage, and current on-off ratio for electrical characteristics and brightness, as well as other FET and light-emitting OLED attributes [18], all have an impact on OLET parameters.

4.1.1 Mobility of the charge carrier (\(\mu\))

Charge carrier mobility is a key performance criterion for Organic semiconductors. In this experiment, an external electric field may be utilised to measure how rapidly a charge carrier can travel through a transistor channel. In highly organised materials, the range of motion is considerable \(1\,{\mathrm{cm}}^2/{\mathrm{Vs}}-10\,{\mathrm{cm}}^2/{\mathrm{Vs}}\), whereas disordered materials have lower mobilities ranging from \(10^{-3}\,{\mathrm{to}}\,10^{-5}\,{\mathrm{cm}}^2/{\mathrm{Vs}}\). The following equation can be used to estimate the carrier’s mobility

For Unipolar

For Ambipolar

where, W denotes width of the channel, L denotes length of the channel, \(\mu\) denotes mobility, \(V_{th}\) denotes threshold voltage, \(C_i\) denotes gate-dielectric capacitance, and \(V_{gs}\) denotes gate-source voltage.

4.2 On to off current ratio \(\left( \frac{I_{ON}}{I_{OFF}}\right)\)

This is one of the figure of merit which helps in better understanding of the performance of the device. The on-off ratio is the proportion of on-stage to off-stage drain currents.This means that the transistor will be able to more clearly transition between the binary states of on and off as the ratio grows. Using the equation below, the on/off current ratio is a function of the semiconductor and dielectric layer thicknesses.

where, \(\sigma\) denotes channel’s conductivity, W denotes its width, L denotes its length, and \(\mu\) denotes the carrier’s mobility. The gate to source voltage is \(V_{gs}\), the drain to source voltage is \(V_{ds}\), the threshold voltage is \(V_t\), the organic semiconducting layer thickness is \(t_{osc}\), and the gate dielectric capacitance is \(C_i\). Dielectric and semiconducting layer thicknesses are reduced which increases the current ratio by increasing \(I_{on}\) and decreasing \(I_{off}\), respectively [10].

4.3 Threshold voltage \((V_{TH})\)

At this voltage, between the source and the drain, current will flow. Maintaining power efficiency is a critical scaling factor. Voltage at the Gate Source (\(V_{gs}\)), and Voltage at the Drain Source (\(V_{ds}\)) Drain-source voltage (\(V_{DS}\)) turns on the transistor by applying a voltage to the gate-source (\(V_{GS}\)). When using transistors, low \(V_{DS}\) and levels are generally required.

5 Impact of dielectrics on OLET

A dielectrics is a materials that inhibits the transport of charges within a layer itself. The capacity of two electrodes increases when a dielectric material is introduced between them by a factor of K, a characteristic of a dielectric material known as dielectric constant. Other important parameters of a dielectric layer are the maximum electrical displacement \((D_{max})\) that the dielectric layer can sustain and breakdown field \((E_B)\) is given by [17]

and

The organic semiconductors are sandwiched between the dielectric layer of organic devices and the gate electrode. A suitable architecture and geometry can create two interfaces, one static and one dynamic, for certain dielectric materials. As a consequence of charge carrier injection into the dielectric, its threshold voltage declines with time. In the simulation, we have preffered different materials with their dielectric constant and their work function values which are given in Tables 2 and 3.

6 Simulation setup and computation of capacitance and power consumption

The simulation setup utilised to investigate the OLET device, as well as the validation of capacitance and power consumption, is described in this section.

6.1 Simulation setup

The Atlas Silvaco 2-D simulator is used to examine an organic material-based light emitting transistor. In this paper, the channel is created with a tiny molecule of p that is anthracene material. The device’s dimensions are listed in Table 1 and are used in the analysis. Poole Frenkel’s mobility model is used to investigate field-effect mobility [23–28].

where \(\mu\) denotes mobility. For p-type OSC, \(\mu _o\) represents zero-field mobility, which is field-dependent, and are defined by Activation-energy(\(\Delta\) ), and Poole Frenkel-constant(\(\beta\)). In the mobility-model, the values of \(\Delta\) and \(\beta\) are as \(1.792 \times 10^{-2}\) eV and \(7.758 \times 10^{-5}\) eV.

6.2 Calculation of capacitance

The following are the capacitance values for PMMA and PVA that are used in device simulation and analysis:

Here, \(\epsilon _{r1}\) and \(\epsilon _{r2}\) denotes the relative permittivity for PMMA and PVA materials respectively, and \(\epsilon _o\) denotes the free space permittivity, whose values are given in Table 2, and \(t_{ox}\) is oxide thickness (Table 1).

6.3 Calculation of power consumption

The International Road Map for Semiconductors (ITRS) recommends that power consumption for portable devices be kept to a bare minimum, despite the fact that this is nearly difficult due to parasitic effects. The total power consumption is given by P = VI, where \(P = 3\,\times \,17\,\times \,10^{-6} = 0.051\) mWatt is obtained by using – 3 V for \(V_{gs}\) and \(V_{ds}\).

7 Results

This section focuses into the performance of OLET device using organic semiconductor as an active layer, and simulated characteristic graphs, where its internal schematic structure is shown in Fig. 6, and its structure which corresponds to the level of doping concentration is shown in Fig. 7, the value for the same is \(21\,\times \,10^{20}/{\mathrm{cm}}^3\), and its output characteristics is shown in Fig. 8. We investigated the device behaviour with \(V_{gs}\) = –3 V and \(V_{ds}\) = –3 V, respectively, are the supply voltages. and comparing its values with the reported data [1] of tetracene as an organic semiconductor of an OLET structure. After validating simulated data, we get P = \(3\,\times \,17\,\times \,10^{-6}\)= 0.051 mWatt is the entire power consumption of an OSC-based device based on anthracene small molecules. The power consumption of an Anthracene based device is lower than that of a tetracene-based device, according to the results of the analysis. We were able to extract additional data such as mobility, drive current, and current on-off ratio using the 2-D simulation TCAD device. Table 4 has a list of all of these variables. The highest occupied molecular orbit (HOMO) and lowest unoccupied molecular orbit (LUMO) levels of organic semiconductor materials, work function of source, drain, and gate electrodes, dielectric constants of insulators and supply voltages, structural dimensions of devices, and electrical properties of OSCs used in simulation analysis all influence the extracted values of performance parameters.

8 Conclusion

The performance of an OLET device with anthracene as an organic semiconductor layer is explored in this research work, as well as the simulated values of the OLET device with anthracene as an OSC. is compared with the reported data1 of the OLET device having tetracene as an OSC. Initially, the values of drive-current, on-off ratio and mobility of OLETs are evaluated using 2-D TCAD simulator. After that output characteristics is also analysed. The generated results are then compared to the information provided. The values of performance parameters are as follows: Ids of \(17\,\upmu {\mathrm{A}}\), mobility of \(12\,\times \,10^{-2}\,{\mathrm{cm}}^2/{\mathrm{Vs}}\) and on-off ratio of \(10^7\). It is seen that anthracene based device has much higher mobility value than that of tetracene. It is also seen that power consumption in case of anthracene is lesser than that of tetracene, making it a better performance device. The work provided by this research is assessed using TCAD Silvaco simulation tool that is widely utilised in the microelectronics manufacturing industry. The performance of these devices can be modified by using high performance organic semiconductors as the active channel layer, by changing their structural specifications, their work function values, and dielectric properties.

References

Ojha, S. K., & Kumar, B. (2022). Parameter extraction of high-performance material based organic light-emitting transistors (olets). Silicon, 14(8), 3999–4007.

Liu, K., Ouyang, B., Guo, X., Guo, Y., & Liu, Y. (2022). Advances in flexible organic field-effect transistors and their applications for flexible electronics. npj Flexible Electronics, 6(1), 1–19.

Muccini, M. (2006). A bright future for organic field-effect transistors. Nature materials, 5(8), 605–613.

Liu, C.-F., Liu, X., Lai, W.-Y., & Huang, W. (2018). Organic light-emitting field-effect transistors: Device geometries and fabrication techniques. Advanced Materials, 30(52), 1802466.

Muccini, M., Koopman, W., & Toffanin, S. (2012). The photonic perspective of organic light-emitting transistors. Laser and Photonics Reviews, 6(2), 258–275.

Yamamoto, H., Oyamada, T., Sasabe, H., & Adachi, C. (2004). Amplified spontaneous emission under optical pumping from an organic semiconductor laser structure equipped with transparent carrier injection electrodes. Applied Physics Letters, 84(8), 1401–1403.

Baldo, M., Holmes, R., & Forrest, S. (2002). Prospects for electrically pumped organic lasers. Physical Review B, 66(3), 035321.

List, E., Kim, C.-H., Naik, A., Scherf, U., Leising, G., Graupner, W., & Shinar, J. (2001). Interaction of singlet excitons with polarons in wide band-gap organic semiconductors: A quantitative study. Physical Review B, 64(15), 155204.

Staudigel, J., Stößel, M., Steuber, F., & Simmerer, J. (1999). A quantitative numerical model of multilayer vapor-deposited organic light emitting diodes. Journal of Applied Physics, 86(7), 3895–3910.

Yuan, D., Awais, M. A., Sharapov, V., Liu, X., Neshchadin, A., Chen, W., & Yu, L. (2021). Synergy between photoluminescence and charge transport achieved by finely tuning polymeric backbones for efficient light-emitting transistor. Journal of the American Chemical Society, 143(13), 5239–5246.

Dong, H., Fu, X., Liu, J., Wang, Z., & Hu, W. (2013). 25th anniversary article: Key points for high-mobility organic field-effect transistors. Advanced Materials, 25(43), 6158–6183.

Wang, C., Dong, H., Hu, W., Liu, Y., & Zhu, D. (2012). Semiconducting \(\pi\)-conjugated systems in field-effect transistors: A material odyssey of organic electronics. Chemical Reviews, 112(4), 2208–2267.

Chaudhry, M. U., Muhieddine, K., Wawrzinek, R., Sobus, J., Tandy, K., Lo, S.-C., & Namdas, E. B. (2020). Organic light-emitting transistors: Advances and perspectives. Advanced Functional Materials, 30(20), 1905282.

Yuan, D., Sharapov, V., Liu, X., & Yu, L. (2019). Design of high-performance organic light-emitting transistors. ACS Omega, 5(1), 68–74.

Zaumseil, J. (2020). Recent developments and novel applications of thin film, light-emitting transistors. Advanced Functional Materials, 30(20), 1905269.

Zhang, C., Chen, P., & Hu, W. (2016). Organic light-emitting transistors: Materials, device configurations, and operations. Small, 12(10), 1252–1294.

Soldano, C. (2021). Engineering dielectric materials for high-performance organic light emitting transistors (olets). Materials, 14(13), 3756.

Kaushik, B. K., Kumar, B., Prajapati, S., & Mittal, P. (2016). Organic thin-film transistor applications: Materials to circuits. CRC Press.

Ojha, S. K., & Kumar, B. (2020) Performance analysis and parameter extraction of organic light emitting transistor (olet). In 2020 International conference on electrical and electronics engineering (ICE3) (pp. 711–716). IEEE

Sakanoue, T., Fujiwara, E., Yamada, R., & Tada, H. (2005). Preparation of organic light-emitting field-effect transistors with asymmetric electrodes. Chemistry Letters, 34(4), 494–495.

Ullah, M., Tandy, K., Yambem, S. D., Aljada, M., Burn, P. L., Meredith, P., & Namdas, E. B. (2013). Simultaneous enhancement of brightness, efficiency, and switching in rgb organic light emitting transistors. Advanced Materials, 25(43), 6213–6218.

Gao, M., Pan, S.-Y., Chen, W.-C., & Chiang, P.-C. (2018). A cross-disciplinary overview of naturally derived materials for electrochemical energy storage. Materials Today Energy, 7, 58–79.

Negi, S., Mittal, P., & Kumar, B. (2020). In-depth analysis of structures, materials, models, parameters, and applications of organic light-emitting diodes. Journal of Electronic Materials, 49(8), 4610–4636.

Negi, S., Mittal, P., Kumar, B., & Juneja, P. K. (2019). Organic led based light sensor for detection of ovarian cancer. Microelectronic Engineering, 218, 111154.

Negi, S., Mittal, P., & Kumar, B. (2019). Analytical modelling and parameters extraction of multilayered oled. IET Circuits, Devices and Systems, 13(8), 1255–1261.

Mishra, N., Mittal, P., & Kumar, B. (2019). Analytical modeling for static and dynamic response of organic pseudo all-p inverter circuits. Journal of Computational Electronics, 18(4), 1490–1500.

Negi, S., Mittal, P., & Kumar, B. (2018). Impact of different layers on performance of oled. Microsystem Technologies, 24(12), 4981–4989.

Kumar, B., Kaushik, B. K., & Negi, Y. S. (2014). Organic thin film transistors: Structures, models, materials, fabrication, and applications: A review. Polymer Reviews, 54(1), 33–111.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abbas, B., Sharma, K. Organic light emitting transistors: performance analysis and high performance device. Analog Integr Circ Sig Process 113, 383–391 (2022). https://doi.org/10.1007/s10470-022-02102-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10470-022-02102-2