Abstract

A logistics center is the hub of a specific area, within various logistics-related activities (distribution, storage, transportation, consolidation, handling, customs clearance, imports, exports, transit processes, infrastructural services, insurance, banking, etc.) that are performed on a commercial basis. Determining the location of the logistics center is an important decision regarding cost and benefit analysis. A three-stage methodology has been applied for presenting a framework for logistics center location selection in the context of Kayseri’s logistics development plan. The first stage includes the determination of criteria through literature review and interviews with experts. The second stage includes the weighting of determined criteria using linear BWM (best–worst method). The third stage includes the ranking of locations using the evaluation based on distance from average solution (EDAS) method with different distance measures. Our proposed methodology BWM–EDAS and also EDAS with different distance measures, which are applied for the first time in the literature, provides helpful findings to rank the logistics center locations. Lastly, sensitivity analysis is conducted to validate the robustness.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Turkey is at the crossroads of Europe–Asia and is a hub on the way from Europe to the Middle East and the Turkic Republics. Neighboring countries transfer natural gas and oil via Turkey to Europe markets. This situation provides strategic importance concerning logistics. In Turkey, the presence of Europe’s largest road transport fleet and multinational logistics companies allows the local companies to access technical know-how. To strengthen the international logistics position of Turkey, the proportion of logistics cost in total cost should be reduced, and shorten the accessing time of consumer to the final products (Ministry of Development 2013).

This study was prepared due to the necessity of the logistics center in Kayseri which is the heart of Anatolia and is an important trade and production center. The logistics center to be established in Kayseri will make a significant contribution to transport the products to the market faster, more reliable and more economically. Moreover, the Kayseri logistics center will provide a competitive advantage for domestic and foreign trade development infrastructure. It will provide serious support to the economy of the surrounding provinces.

As a result of developing trade, the importance of logistics centers is increasing day by day and the logistics center has a direct impact on the efficiency of logistics management; therefore, the selection of a logistics center location also gains importance. In selection, it is also important to consider the cost–benefit analysis. With this in mind, this study has the following aims:

To determine the criteria of a logistics center’s location and present a novel framework for its selection among selected regions.

To distinguish the relative importance of the weight of each criterion for the logistics centers.

To select the most efficient area among the various set of alternative locations for Kayseri’s logistics center.

To propose administrative and helpful inferences.

To obtain the mentioned above aims, a novel hybrid methodology BWM–EDAS was applied. This study is a first application, which proposes and utilizes the integrated methodology of BWM and EDAS which were used separately in many past studies efficiently. BWM is a pairwise comparison methodology was used to weigh the criteria of Kayseri’s logistics center location selection and EDAS was used to rank the regions according to these criteria. Moreover, we consider this method with different distance measures: Euclidean, Manhattan, Lorentzian and Pearson and the rankings are also calculated by these new EDAS methods. The obtained rankings ensure decision-makers can make more consistent and meaningful decisions.

In MCDM problems, the ranking results depend on the characteristic of criteria values which are imprecise and changeable. The possible effect of the criteria weight should be considered (Triantaphyllou and Sánchez 1997). The significance of the robustness has been recognized in many areas of application hence the decision-making process should be robust against changing of criteria weight. Robustness indicates that the ability of responsiveness to these changes. To accomplish the effective robustness, sensitivity analysis is conducted by exchanging each criterion weight with another. Sensitivity analysis shows effectivity to control the decision making process results.

The paper is organized as follows. Section 2 introduces the logistics center location selection. Section 3 introduces the methodology. Section 4 applies the methodology to evaluate the alternative locations of the Kayseri’s logistics center and in Sect. 5, results and discussion, sensitivity analysis is applied to confirm the robustness. Finally, conclusions and future work are given in Sect. 6.

2 Logistics center location selection

Logistics centers are national and international areas within which all activities related with logistics such as transportation and forwarding, the distribution of goods, material handling, storage, and other related transactions (banking, insurance, etc.) are carried out by various operators on a commercial basis. A logistics center must be equipped with all public facilities to perform the above-mentioned activities. These centers are usually selected outside settled living areas and should be settled near connections to highways, railways, airports, and if possible, seaports as well as production and commercial centers. Finally, it must be managed by a single public or private body (Erkayman et al. 2011).

Logistics centers need to be provided with a specific infrastructure standard. These standards are listed below;

The existence of intermodal transport infrastructure,

Multi-functionality; carrier, agency, customs consultant, and public institutions should be in the logistics center,

Effective use of information technologies in transactions,

The availability of facilities suitable for effective management of commercial cargo,

All public and private sector organizations can be involved in these areas,

The existence of a structure that will provide cooperation between the production, trade, and service sectors,

All logistics center users should be able to fairly share the costs arising from the operation,

The presence of auxiliary services (cleaning, security, communication, social facilities, etc.).

In addition to these basic standards, logistics centers at the highest level of development have the following qualities;

Physically integrating different modes of transport (intermodal structure),

By improving the cooperation between the logistics centers, the utilization of scale economies has been ensured,

Ensuring the efficiency of international transportation by providing the trade load density in these areas,

Providing the environmental conditions that the transportation sector can develop.

One of the most important issues about logistics centers is the selection of these centers location. The selected place for a logistics center should be large enough to cover the future demands of the country, the region, and even the local market. Besides, environmental impacts should be taken into consideration during site selection. Rapid growth in transportation defaces cities with traffic congestion and environmental pollution, due to the consumption of fossil fuels. Environmental problems arising from transportation can be reduced through an efficient transportation system and well-planned logistics centers.

From this point of view, a logistics center location selection is a strategic investment decision in the logistical system. There are several studies on this subject in literature. Li et al. (2011) proposed a methodology to evaluate the logistics center location consists of two parts (Axiomatic Fuzzy Set and TOPSIS). Wang et al. (2010) employed the fuzzy AHP to solve the logistic distribution center selection. Chen et al. (2014) integrated fuzzy TOPSIS and multi-choice goal programming to obtain an appropriate logistics center from many alternative locations for the airline industry. Tomic et al. (2014) focused on a more detailed analysis of the effects on the environment to finding the most suitable location for the logistic centers in the area of the Balkan Peninsula, by using mathematical methods such as Greedy heuristic algorithm and Analytic Hierarchy Process. Erkayman et al. (2011), proposed a fuzzy TOPSIS approach to select a logistics center location in the eastern Anatolia region of Turkey. Wang and Liu (2007) establishes the indicator system of location selection of logistics center with fuzzy AHP and TOPSIS. Wang et al. (2014) proposed a fuzzy MCDM (multi-criteria decision making) model based on the credibility of decision-makers and applied this model to select the logistics center location. Żak and Węgliński (2014) presented a two-stage MCDM procedure to select the location of the logistics center: the macro-analysis of the regions and evaluation of these regions with the Electre III/IV. Rao et al. (2015) presented a fuzzy multi-attribute group decision-making technique based on a linguistic 2-tuple for the location selection of logistics centers from a sustainability perspective. Chen and Wang (2017) proposed a logistics center location selection algorithm based on the research of sixteen cities in southeastern China and neural network algorithms.

Uyanik et al. (2018) conducted a literature review on the logistics centers’ location selection problem. According to this, many of decision making techniques are applied such as: Analytic Hierarchy Process (AHP), Analytic Network Process(ANP), Technique for Order Preference by Similarity to Ideal Solution (TOPSIS), Elimination et Choice Translating Reality (ELECTRE), VlseKriterijumska Optimizacija I Kompromisno Resenjetechnique (VIKOR), The Preference Ranking Organization Method for Enrichment of Evaluations (PROMETHEE), Analytic Network Process/Benefits, Opportunities, Costs and Risks (ANP/BOCR), Axiomatic Fuzzy Set (AFS), Artificial Neural Network (ANN), DELPHI Method, Fuzzy Graph Theory, and Goal Programming. There is no EDAS or BWM among these applied techniques. EDAS–BWM methods are applied for the first time in the selection of the logistics center.

As seen in the literature review for decision criteria, the location selection problems of the logistics centers are mainly handled by using MCDM methods, and, this makes it more important to select proper decision criteria for better solutions of the proposed methodology.

Besides, logistics centers were evaluated with a maximum of 29 and an average of 14 criteria. In our proposed approach, the 9 main and 44 sub-criteria are employed to evaluate the logistics center locations. Although this study has the widest number of criteria in the literature on this topic and it has also gained new criteria for the literature. Uyanık et al. (2018) classified the criteria into 5 groups and in Fig. 1, most preferred criteria implemented in literature are summarized.

3 Methodology

In this section, we will first explain the BWM and EDAS methods that are used to assess the importance of the criteria and the ranking of the alternatives.

3.1 BWM–EDAS

The Kayseri city logistics development plan reported that a large-scale logistics village was necessary. Therefore, a novel three-stage methodology (see Fig. 2) is proposed for the Kayseri logistics center location selection problem in this study. The first stage involves the determination of criteria for the logistics center location with the exploration of alternative areas. The second stage involves calculating weights of each criterion and sub-criteria using BWM and final stage involves the ranking of alternative logistics center areas using the EDAS method to these criteria. Each of these stages is discussed below:

3.1.1 BWM

Rezaei recently developed a robust MCDM method that is called BWM (Rezaei 2015). This method obtains criteria weights by using fewer pairwise comparisons. BWM only compares other criteria with the best and the worst criteria. The original BWM is presented as a non-linear optimization problem, while there exists a linear approximation. In 2016 (Rezaei 2016), the linear model for BWM, which can achieve easier unique results with fewer pairwise comparisons, is proposed. The linear BWM method can also derive reliable results with consistency. While there exist multiplicative version and some hybrid versions with MCDM techniques. As given in Fig. 3, these are TOPSIS, VIKOR, DELPHI, PROMETHEE, ELECTRE, SAW, COPRAS, MOORA, QFD, etc. (Mi et al. 2019).

The BWM is a suitable methodology to structure highly complex systems so that decision-makers and policymakers would be able to better understand the system of interest. The method has also been extensively used in many real-world applications as given in Fig. 4: Airline industry, Energy, Investment, Location selection, Manufacturing, Performance evaluation, Supplier selection, Supply chain, Technology, Transportation, Water management, etc. (Mi et al. 2019). Besides, there are two logistics applications of BWM: the relative importance of the logistics performance index indicators is measured (Rezaei et al. 2018) and third-party logistics provider are evaluated (Pamucar et al. 2019). As far as our knowledge it is the first time the BWM is applied for logistics center location with this study.

The linear BWM method has five steps to derive the weights of decision criteria (Rezaei 2016). These are as follows:

Step 1 Determine a set of decision criteria \( \left\{ {c_{1} , c_{2} , \ldots c_{n} } \right\}. \)

Step 2 Determine the best and the worst criteria from the set of criteria.

Step 3 The other criteria are compared with the best criteria. In comparisons, a number from 1 to 9 is assigned to indicate the importance level. (Definitions of 1–9 measurement scales: 1 = equal importance, 3 = Moderately more important, 5 = Strongly more important, 7 = Very strongly more important, 9 = Extremely more important, with 2, 4, 6, and 8 = Intermediate values.)

This will result in best-to-others vector would be:

where \( a_{Bj} \) indicates the importance of the most important criterion \( B \) over criterion \( j \). Besides \( a_{BB} = 1 \).

Step 4 The other criteria are compared with the worst criteria. In comparisons, a number from 1 to 9 is assigned

This will result in Worst-to-Others vector would be:

where \( a_{jw} \) represents the importance of the criterion \( j \) over the worst criterion \( W \). Besides \( a_{ww} = 1 \).

Step 5 Find the optimal weights.

Solving the following model produces the optimal weights \( \left( {w_{1}^{*} , w_{2}^{*} , \ldots , w_{n}^{*} } \right) \) and \( \xi^{L} \).

For this model, \( \xi^{L} \) can be directly considered as an indicator of the consistency of the comparisons. Values of \( \xi^{L} \) close to zero show a high level of consistency.

3.1.2 EDAS

EDAS has been applied in the literature as a suitable method to cope with many conflicting criteria. Many researchers have proven that its results are highly consistent with other methods, such as TOPSIS, VIKOR and so on (Keshavarz Ghorabaee et al. 2015). Traditional compromise MCDM methods: the VIKOR and TOPSIS methods provide the best alternative according to the ideal and nadir solutions. In contrast to these methods, EDAS is established upon the concept of positive and negative distances from the average for appraising alternatives. Thus EDAS is a relatively easy approach since ideal and nadir solutions are not calculated (Li et al. 2019). The advantages of EDAS are:

EDAS is easy to apply

EDAS can handle both subjective and objective criteria

EDAS is rational and understandable

EDAS computation processes are straightforward.

EDAS has been applied a variety of applications; building construction, healthy and safe built environment, conveyor selection problem, automated guided vehicles selection problem, steel rope analysis and diagnostic, public infrastructure for electric vehicles, subcontractor evaluation, facility location, construction equipment evaluation, and personnel selection (Ouenniche et al. 2019). EDAS is applied to some other topics like supplier selection (Ghorabaee et al. 2017a; b), solid waste disposal site selection (Kahraman et al. 2017) and prioritization of cultural heritage structures for renovation projects (Turskis et al. 2017). To the best of our knowledge, the EDAS method is first time applied in logistics center location selection in the literature.

The EDAS method has eight steps to derive the weights of decision criteria (Keshavarz Ghorabaee et al. 2015).

Step 1 Construct a comparison matrix \( \left( X \right) \) of alternatives with different criteria.

Where \( X_{ij} \) denotes the performance value of \( i \)th alternative on \( j \)th criterion.

Step 2 Determine the average solution according to all criteria.

where

Step 3 Calculate the PDA (positive distance from average) and NDA (the negative distance from average) matrixes.

where \( {\text{PDA}}_{\text{ij}} \) and \( {\text{NDA}}_{\text{ij}} \) denote the positive and negative distance of \( i \)th alternative from average solution in terms of \( j \)th criterion, respectively.

If the \( j \)th criterion is beneficial,

If \( j \)th criterion is cost,

Step 4 Determine the weighted sum of \( PDA \) and \( NDA \) for all alternatives.

where \( {\text{w}}_{\text{j}} \) is the weight of the \( j \)th criterion.

Step 5 Normalize the values of \( SP \) and \( SN \) for all alternatives.

Step 6 Calculate the \( AS \) (appraisal score) for all alternatives,

where \( 0 \le {\text{AS}}_{\text{i}} \le 1 \).Step 7 Rank the alternatives according to the decreasing values of \( AS \).

3.1.3 EDAS method with different distance measures

In the literature, there aren’t study that apply different distance calculation formulas in EDAS technique. The different distance measures are introduced and the alternative rankings obtained by using these methods are given. It is seen that the ranking of decision alternatives doesn’t change. The obtained results can support decision-makers to make more consistent and meaningful decisions. Besides, these consistent results show that the combination of BWM and EDAS is the right choice.

The different measures: Euclidean, Manhattan, Lorentzian, and Pearson are applied while calculating the PDA/NDA and SP/SN.

Euclidean distance measure (Cha 2008)

Manhattan distance measure (Cha 2008)

Lorentzian distance measure (Cha 2008)

Pearson distance measure (Cha 2008)

The steps of EDAS with different measures are below:

Step 1 is the same as the original EDAS method.

Step 2 Calculate the normalized and weighted comparison matrix.

where

Step 3 Determine the average solution according to all criteria.

where

Step 3 Calculate the PDA (positive distance from average) and NDA (the negative distance from average) matrixes.

where \( {\text{PDA}}_{\text{ij}} \) and \( {\text{NDA}}_{\text{ij}} \) denote the positive and negative distance of \( i \)th alternative from average solution in terms of \( j \)th criterion, respectively.

If the \( j \)th criterion is beneficial,

EDAS with different distance measure | |||||

|---|---|---|---|---|---|

Euclidean | Lorentzian | Manhattan | Pearson | ||

\( {\text{PDA}}_{\text{ij}} = {\text{if X}}_{\text{ij}} < {\text{AV}}_{\text{j}} \) | 0 | 0 | 0 | 0 | (27) |

otherwise | \( ({\text{X}}_{\text{ij}} - {\text{AV}}_{\text{j}} )^{2} \) | \( \ln \left( {1 + \left| {{\text{X}}_{\text{ij}} - {\text{AV}}_{\text{j}} } \right|} \right) \) | \( \left| {{\text{X}}_{\text{ij}} - {\text{AV}}_{\text{j}} } \right| \) | \( \frac{{({\text{X}}_{\text{ij}} - {\text{AV}}_{\text{j}} )^{2} }}{{{\text{AV}}_{\text{j}} }} \) | |

\( {\text{NDA}}_{\text{ij}} = {\text{if X}}_{\text{ij}} > {\text{AV}}_{\text{j}} \) | 0 | 0 | 0 | 0 | (28) |

otherwise | \( ({\text{X}}_{\text{ij}} - {\text{AV}}_{\text{j}} )^{2} \) | \( \ln \left( {1 + \left| {{\text{X}}_{\text{ij}} - {\text{AV}}_{\text{j}} } \right|} \right) \) | \( \left| {{\text{X}}_{\text{ij}} - {\text{AV}}_{\text{j}} } \right| \) | \( \frac{{({\text{X}}_{\text{ij}} - {\text{AV}}_{\text{j}} )^{2} }}{{{\text{AV}}_{\text{j}} }} \) | |

If \( j \) th criterion is cost,

EDAS with different distance measure | |||||

|---|---|---|---|---|---|

Euclidean | Lorentzian | Manhattan | Pearson | ||

\( {\text{PDA}}_{\text{ij}} = {\text{if X}}_{\text{ij}} > {\text{AV}}_{\text{j}} \) | 0 | 0 | 0 | 0 | (29) |

otherwise | \( ({\text{X}}_{\text{ij}} - {\text{AV}}_{\text{j}} )^{2} \) | \( \ln \left( {1 + \left| {{\text{X}}_{\text{ij}} - {\text{AV}}_{\text{j}} } \right|} \right) \) | \( \left| {{\text{X}}_{\text{ij}} - {\text{AV}}_{\text{j}} } \right| \) | \( \frac{{({\text{X}}_{\text{ij}} - {\text{AV}}_{\text{j}} )^{2} }}{{{\text{AV}}_{\text{j}} }} \) | |

\( {\text{NDA}}_{\text{ij}} = {\text{if X}}_{\text{ij}} < {\text{AV}}_{\text{j}} \) | 0 | 0 | 0 | 0 | (30) |

otherwise | \( ({\text{X}}_{\text{ij}} - {\text{AV}}_{\text{j}} )^{2} \) | \( \ln \left( {1 + \left| {{\text{X}}_{\text{ij}} - {\text{AV}}_{\text{j}} } \right|} \right) \) | \( \left| {{\text{X}}_{\text{ij}} - {\text{AV}}_{\text{j}} } \right| \) | \( \frac{{({\text{X}}_{\text{ij}} - {\text{AV}}_{\text{j}} )^{2} }}{{{\text{AV}}_{\text{j}} }} \) | |

Step 4 Determine the \( SP \) and \( SN \) for all alternatives.

EDAS with different distance measure | ||||

|---|---|---|---|---|

Euclidean | Lorentzian | Manhattan | Pearson | |

\( {\text{SP}}_{\text{i}} = \sqrt {\mathop \sum \limits_{j = 1}^{n} {\text{PDA}}_{\text{ij}} } \) | \( \mathop \sum \limits_{j = 1}^{n} {\text{PDA}}_{\text{ij}} \) | \( \mathop \sum \limits_{j = 1}^{n} {\text{PDA}}_{\text{ij}} \) | \( \mathop \sum \limits_{j = 1}^{n} {\text{PDA}}_{\text{ij}} \) | (31) |

\( {\text{SN}}_{\text{i}} = \sqrt {\mathop \sum \limits_{j = 1}^{n} {\text{NDA}}_{\text{ij}} } \) | \( \mathop \sum \limits_{j = 1}^{n} {\text{NDA}}_{\text{ij}} \) | \( \mathop \sum \limits_{j = 1}^{n} {\text{NDA}}_{\text{ij}} \) | \( \mathop \sum \limits_{j = 1}^{n} {\text{NDA}}_{\text{ij}} \) | (32) |

Step 5 Normalize the values of \( SP \) and \( SN \) for all alternatives.

Step 6 Calculate the \( AS \) (appraisal score) for all alternatives,

where \( 0 \le {\text{AS}}_{\text{i}} \le 1 \).

Step 7 Rank the alternatives according to the decreasing values of \( AS \).

4 Selection of the logistics center: the case of Kayseri

Located in the center of Turkey, in Kayseri, which has over 6000 years of history and one of the oldest settlements. This location has maintained its importance in every era and has continued its trade tradition of trade, which started in Kültepe, which is regarded as the first organized trade center of the world. Currently, there are 3 industrial zones (The Kayseri, Mimarsinan, and İncesu industrial zones), 16 small industrial sites, a regional, and a technology development zone. There are 44,074,000 m2 in a total space for the industrial areas.

In the Kayseri industrial zone (the biggest one in Turkey), approximately 65,000 people are employed in 1199 firms. In the Mimarsinan Industrial Zone, about 5000 people are employed in 201 firms. In the İncesu Organized Industrial Zone, 28 companies are in actual production and employ 1.1001 people. The Kayseri Free Zone was established on an area of 6905,000 m2. A total of 4046 people are employed in 102 firms located in the region (http://www.kayseri.gov.tr/sanayi-gelisimi).

4.1 The determination of the alternative Kayseri logistics center location regions

In determining the alternative regions, many criteria are considered such as proximity to organized industrial zones, railway, and highway; the suitability of land structure, size; the scope of the city development plan, etc. In this context, regional surveys were conducted, and 6 alternative regions were identified. The regional locations of the alternative logistics centers are shown in Fig. 5.

Although each alternative region can be a logistics village, some of them are more advantageous in this regard. The representatives of the sector in Kayseri and academicians who are experts in this field were informed about the selected alternatives and the alternative regions were examined with this group. The positive and negative aspects of each region are evaluated.

Alternative Region 1 is next to Kayseri Industrial Zone, which is the most important production center of Kayseri, and Kayseri Free Zone. This region has a very advantageous position in terms of accessibility to both the market and production centers. Furthermore, D300 highway is in the distance of 3 km to the west of Alternative Region -1 also stands out due to the location of the railway parallel to the highway. This highway connects Kayseri to Mersin Port, which is used extensively for export and import transportation. Unfortunately, the size of the Alternative Region 1 does not meet the demand for the future logistics center. As well as the risk of land subsidence brings additional costs for the construction.

Alternative Region 2 is considered almost close to both Kayseri and İncesu Industrial Zones. Besides, its’ location near to both the railway station and the D300 highway. The development plan and infrastructure projects (electricity, natural gas, water, communication) belonging to the region are not completed. If the decision to establish a logistics center is made because the entire infrastructure is located around 10 km of the land. Because the ground structure of the land is a solid rock and the average slope is 1%, it is very suitable for building construction. The size of the land is large enough to meet long-term demand for the logistics center.

The expansion region of the İncesu Industrial Zone was identified as the Alternative Region 3. Although the size of the region is insufficient for the logistics center, it is possible to complete it with expropriation. Alternative Region 3 is adjacent to the Incesu Industrial and also close to the Kayseri Industrial Zone, D300 highway and railway. Moreover, the advantage of this alternative is that the city is far away. Besides, İncesu Industrial Zone has Turkey’s cheapest energy. The ground structure of the land is a solid rock and the average slope is 2%, making it very suitable for building construction.

Alternative Region 4 Located just west of the Çöl lake and close to Sultan Reeds. For this reason, a detailed investigation is needed in terms of emission gases that can be created by the logistics center in order not to adversely affect the birds in the region. The land is suitable for building construction due to the substructure and 1.6% slope. Also, the size of the land is large enough to meet the present and future demands of the Kayseri logistics center. According to the position of the region, it is close to the Incesu Industrial Zone than other Industrial Zones but farther away from the other ones than the other alternative regions. However, the region is located close to the railway and D300 highway, and far away from the city center.

Alternative region 5 is in the west of the new campus of Abdullah Gül University, and the southwest of Mimarsinan Industrial Zone. The disadvantages of the Alternative region 5 are: not being ready for infrastructure facilities (natural gas, electricity, water, etc.) and is far away to Kayseri and Incesu Industrial Zone, Kayseri Free Zone, D300 highway.

The D300 highway is passing through the south of the Alternative Region 6 and the highway is an important and advantageous position in terms of transportation. Construction costs are greatly increased by the fact that the land slope. Boğazköprü Station Directorate is still in the region and logistics activities are still being carried out. Therefore, technical infrastructure facilities (electricity, water, sewerage, etc.) are available and utilized.

4.2 Determination of the criteria for logistics center location selection

An extensive literature review was done to identify the criteria affecting the selection of the logistics center location (Li et al. 2011; Żak and Węgliński 2014; Kayikci 2010; Hong and Xiaohua 2011; Kuo 2011; Chen 2001; Awasthi et al. 2011; Bamyacı 2008). In addition to criteria identified through literature review, experts were consulted to add some other criteria not included in previous studies. These criteria are B5. Proximity to Middle Eastern markets, C4. Employment contribution, F1. Operational competence, G3. Port fees and I2. Risk of accident. A total of 9 main criteria and 44 sub-criteria were determined by experts and literature review. The main criteria, sub-criteria, and options developed in the aim of determining the optimal logistics center location are shown by the hierarchical structure shown in Fig. 6.

The explanations of the criteria are given below:

The A. LAND is an important criterion and it is examined in 5 sub-criteria. Due to rapid urbanization, it is getting harder and harder to find land with sufficient A1. Size and shape of the land at the optimal distance of the city (Li et al. 2011; Elgün 2011). Long-term thinking is essential when choosing land for such large infrastructure investments. With the increase of trade volume, extra capacity will be needed every day. A2. Ownership and tenure condition of the land refers that whether it is in the public domain is preferred in terms of faster implementation (Hong and Xiaohua 2011; Elgün 2011). Apart from this, the condition of being suitable for construction should also be examined. It is preferable to use the land, which is advantageous in terms of A3. Land infrastructure factors such as energy, water, road, telecommunication, etc. Besides the A4. Land expansion potential should meet growing demand (Żak and Węgliński 2014). A5. Physical conditions of the land such as slope, topography and geological structure of the land, and suitability for natural disasters are important (Li et al. 2011). Besides, the weather, the shape of the ground, and the risk of earthquakes must be taken into consideration. It is preferred that the zone for logistics activities be located on smooth and firm grounds.

Sub-criteria of the B. MARKET: B1. Proximity to free zone, B2. Accessibility is the accessibility to public and private modes of transport. (Tram etc.), B3. International consumption market, B4. International production market and B5. Proximity to Middle Eastern markets (Kayikci 2010).

C. SOCIAL main criterion consists of 4 sub-criteria. The clustering of the logistics sector will also contribute the C1. Urban traffic impact in a similar way to its impact on the environment. Urban transport happens with smaller tonnage transport vehicles, preventing heavy tonnage trucks from damaging roads in the city. Logistics centers have a key role in ensuring that logistics can be met efficiently and effectively in the event of a disaster. The organized logistics zones should consider C2. Impact on disaster logistics. Since they are specially secured and protected areas, the logistics center’s warehouses and facilities can be used for the various needs of the city, urban residents and helpers at any disaster. It shows that C3. Social attraction and the level of difficulty in each region and defined based on two main components: the unemployment rate and career development opportunities (Żak and Węgliński 2014). Employee participation in employment in the region is the C4. Employment contribution.

The most important factor “D. TRANSPORTATION” is that logistics are a unit that performs the optimization of transportation according to the function of the village. This criterion can be detailed as the proximity to the other places where the logistics center is related. D1. Proximity to the city: A logistics sector clustering outside the city center will reduce environmental problems originating from the logistics sector. For this reason, the center should be located at a certain distance away from the settlement areas, close to the industrial sites and in places that will not prevent the necessary enlargement in later dates (Elgün 2011). D2. Proximity to production centers: Organized industrial zone etc. production centers are places where logistics demand is high. Logistics center helps to ensure accurate forecasting of material supply time and absence of deviations. D3. Proximity to consumption centers, such as proximity to production centers, is also important. This is because both the production and consumption centers need to be at optimal distances be able to meet the urban demand with the minimum cost of goods transport. D4. Proximity to the airport is important both for easier transportation of the customers and for freight transport. Although the amounts transported by air are less in comparison to land and sea, this is a characteristic that must be taken into account when choosing a location (Awasthi et al. 2011). D5. Proximity to the railway: European Union policies are to increase rail freight transport. Logistics centers tend to be built on railway lines (Awasthi et al. 2011). Railway crossing from within or near the logistics center will ensure both the transport costs of the employees are minimized and the traffic of the city is reduced relatively. The role of national and international freight road transport in Turkey is great. Therefore, D6. Proximity to the highway is as important as railway and proximity to ports (sea) (Awasthi et al. 2011). Most of import and export shipments in Turkey are carried by sea. D7. Proximity to port (sea) is also an important criterion since there are huge quantities in question. When the amount handled is taken into consideration, it is seen that the proximity criteria to the ports are also important (Elgün 2011). D8. Connectivity to other transport methods: such as roads, railways, ports, airports, etc.

E. ENVIRONMENTAL EFFECTS has 3 sub-criteria. E1. Environment-friendly assesses whether the alternative zone is environmentally friendly in terms of noise level, image and environmental pollution level and emission gases (Żak and Węgliński 2014). E2. Energy use (Kayikci 2010) and E3. Waste disposal. The alternative site should be suitable for the disposal of solid, liquid and hazardous waste materials.

Sub-criteria of the F. INTERMODAL OPERATION AND MANAGEMENT: F1. Operational competence is the adequacy of resources in the Alternative Region (raw material, human resources), Import/Export volume, transportation line density and service quality. F2. Information technology infrastructure, F3. Service availability, F4. Coordination, F5. Quality, F6. Connection and F7. Interoperability (Kayikci 2010).

G. COSTS is one of the important main criteria and there are many cost items. G1. Basic construction/structure/building investment is the purchase of land, warehouse construction, regional development, construction materials, standard equipment, and labor costs (Li et al. 2011). G2. Cost for users refers to the operational costs that will be faced by the enterprises that will be in the organizational logistics zone, and it is a cost that varies according to its location. It also includes labor costs and transportation costs (Kuo 2011). G3. Port fees are towage, water supply, etc. and terminal operating fees (due to port, warehouse and transportation service, arc fees). G4. Transportation cost (Kayikci 2010) and G5. Contribution to economic development (Żak and Węgliński 2014) should be considered in selecting the logistics center place to create an economic revival in and around the place where it is established.

Sub-criteria of the H. NATIONAL STABILITY: H1. Customs, H2. European corridors, H3. Political stability, H4. Economic stability and H5. Social stability (Kayikci 2010).

I. RISK AND SAFETY refer to both road and industrial safety. Traffic accidents (fatal injuries), industrial accidents, the number of crimes and crimes (theft, robbery, vandalism). It has two sub-criteria: I1. Safety, security, and I2. Risk of the accident (Kayikci 2010).

4.3 Calculation of criteria weights using BWM

After the selection of criteria by the decision-makers (i.e., experts in logistics, academicians and logistics firms), next step is to calculate the main criteria weights and then the sub-criteria weights with newly proposed BWM method (Rezaei 2015). Firstly, the best and worst criteria are selected among the compared criteria group. The preferences of best/worst criteria over all other criteria on a scale of 1–9 represented in Tables 1, 2, 3, 4, 5, 6, 7, 8, 9, 10 below. Besides, in the last column of Table 1, there are consistency values of pairwise comparison. All of them less than 0.10 and they show consistency.

The next step, after comparison of all criteria with the best/worst criteria, is to obtain the criteria weights. The weights of the criteria were obtained using the model described in Sect. 3. The criteria weights are given in Table 11.

Table 11 shows the main criteria as well as the weight and rank of the sub-criteria. The total weight of the sub-criteria was obtained by multiplying each sub-criterion with its main criterion.

Amongst nine main criteria, “A. LAND” obtains the first rank. This criterion has further five sub-criteria under it, they are ranked according to their total weights as follows A3 > A2 > A1 > A4 > A5. Besides, “A3. Land infrastructure” is ranked first among all sub-criteria.

Other sub-criteria in the top 5 are: “B2. Accessibility”, “A2. Ownership and tenure condition of the land”, “G4. Transportation cost” and “A1. Size and shape of the land”.

5 Results and discussion

After obtaining the weights of the criteria with BWM, the rankings calculated with the EDAS method and its’ extension with different distance measures: Euclidean, Lorentzian, Manhattan, and Pearson. The decision matrix shows that corresponding values of 6 alternatives for comparison are shown in Table 12. Scoring system used to evaluate alternative logistics centers was defined by decision-makers assigning a number between 1 and 10 to each criterion where 1 would mean “least important” and 10 would mean “most important”.

The obtained ranking results are presented in Table 13. The results indicate that Alternative Region 2 is top location among all the six alternatives. Alternative Region 2 come into prominence from other alternatives because it is close to Industrial Zones and its’ location near to both the railway station and the port connection highway. Besides, the land structure is suitable for construction and no negative impact on urban traffic due to being far from the city center. The results are consistent with the Kayseri logistics development plan. Thus, the proposed hybrid method is closer to real-life preferences, have successfully applicability in logistics center selection problem

The AS values calculated with the methods are given in the following chart in Fig. 7. When the results that are obtained by all methods are examined, it is observed that there aren’t significant differences in the AS values and rank ordering of all methods are same. Thus, the BWM and extensions of the EDAS method has successful applicability in countries for logistics center location evaluation and important scientific assessment for decision making.

5.1 Sensitivity analysis

In decision-making, weights given to decision criteria try to show the genuine importance of the criteria. When the criteria cannot be expressed in quantitative terms (cost, weight, volume, etc.), it is difficult to accurately demonstrate the importance of these criteria. In many cases, the decision-making process determines the critical criteria and then evaluates the criteria weights. The intuitive belief is that the criterion with the highest weight is the most critical. This may not always be true and in some cases, the criterion with lower weight may be more critical. In other words, how sensitive the current order of alternatives is to changes in the current weights of decision criteria (Triantaphyllou 2000). Therefore, we deemed it appropriate to support our study with the reliability analysis.

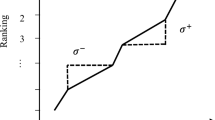

This section introduces a sensitivity analysis on the weights of the criteria to specify the influence of criteria weights on ranking, obtain various scenarios where the priorities of the alternatives change according to the criteria weight and examine the robustness of the results.

To analyze the impact of weights on the selection of location. Sensitivity analysis was performed to exchange each criterion weight with another so that we performed 946 experiments. The results of the experiments are given in Fig. 8 and Table 14.

In Table 14, it is summarized that how many times each alternative takes place in the first, second, third, fourth, fifth and last rank in all experiments. Besides, the average of the ranks obtained from the 946 experiments is given. Alternative Region 2, which is suggested as the most suitable logistics center located in the proposed method, has the highest score in 900 experiments. Mostly the experiments have parallel results with ranks obtained with the proposed method.

Figure 8 represents how the change of criterion weight affects the ranking of alternatives. Each color shows different rank. For example, red rectangles indicate 6th rank, while green rectangles represent the 1st rank. In principle, the length of the horizontal bar represents the changing ranks of each alternative according to the weight changes. When we look at the column of the Alternative Region 3 which is the most recommended by the proposed method, we can see that there is not too much color, in other words, rank change. The overall results of the experiment do not show any color change. According to the experimental results it can be inferenced that our decision-making methodology is robust and rarely sensitive to the criteria weights.

This study develops a novel and robust framework for logistics center location selection. Managers may gain experience in logistics centers and can lead to benefits derived from collaboration with this study. Managers are working in companies and associations such as und, LOJDER (logistics association), UND (“INTERNATIONAL SHIPPER ASSOCIATION”), also conducting graduate studies in the field of logistics. This three-stage methodology enumerates the various criteria about this research area and it considered nine main criteria forty-four sub-criteria for Kayseri logistics center location selection All the past studies have given different criteria for and this study differs from those past studies in terms of various criteria being used. Consequently, the results are discussed with the logistics sector and it has agreed on the idea that there are meaningful considering the sensitivity analysis.

6 Conclusion

Many logistics companies require that a well-conceived and implemented logistics system like logistics center to increase the competition. To provide proximity between locations and to allocate long term relationships is critical for the success of the logistics center establish. For this reason, the selection of the logistics center location becomes an important issue for the implementation of a successful logistics center.

In this paper, Kayseri logistics center location selection case with six alternative locations and nine main criteria were studied. The locations of the logistics center were determined by taking into consideration modern city planning and logistics principles. Each alternative logistics center location is advantageous in terms of some criteria and disadvantageous for others. They are evaluated with BWM–EDAS and its’ extensions. The sensitivity analysis is carried out to confirm the robustness. Numerical results and sensitivity analysis show that the proposed hybrid model is effective in determining logistics center location. Besides, the ranking results are shared with the logistic managers and received positive feedbacks.

Limitation of the study is the economic, environmental, and political powers have to be considered while determining the logistics center location options. As a direction for future research, robust MCDM techniques can be performed to obtain robust results and the proposed hybrid method BWM and EDAS with different distance measures may also be useful for various MCDM problems such as logistics strategy selection, logistics service development, and logistics activities planning. It could be interesting to integrate the proposed EDAS’ extensions method with other MCDM methods such as AHP, SWARA, etc. Moreover, another clue for future research is applying the EDAS with different distance measures in the stochastic or fuzzy environment.

References

Awasthi A, Chauhan SS, Goyal SK (2011) A multi-criteria decision making approach for location planning for urban distribution centers under uncertainty. Math Comput Modell 53(1):98–109

Bamyacı M (2008) Modern Lojistik Yönetimi: Organize Lojistik Bölgeleri için Bir Yer Seçimi Modeli. İstanbul Üniversitesi Fen Bilimleri Enstitüsü, Doktora Tezi

Cha SH (2008) Taxonomy of nominal type histogram distance measures. City 1(2):1

Chen CT (2001) A fuzzy approach to select the location of the distribution center. Fuzzy Sets Syst 118(1):65–73

Chen B, Wang B (2017) Location selection of logistics center in e-commerce network environments. Am J Neural Netw Appl 3(4):40

Chen KH, Liao CN, Wu LC (2014) A selection model to logistic centers based on TOPSIS and MCGP methods: the case of airline industry. J Appl Math 2014:1–10

Elgün MN (2011) Ulusal Ve Uluslararasi Taşima Ve Ticarette Lojistik Köylerin Yapilanma Esaslari Ve Uygun Kuruluş Yeri Seçimi. Afyon Kocatepe Üniversitesi İktisadi ve İdari Bilimler Fakültesi Dergisi 13(2):203–226

Erkayman B, Gundogar E, Akkaya G, Ipek M (2011) A fuzzy TOPSIS approach for logistics center location selection. J Bus Case Stud 7(3):49

Ghorabaee MK, Amiri M, Zavadskas EK, Turskis Z (2017a) Multi-criteria group decision-making using an extended EDAS method with interval type-2 fuzzy sets. E + M Ekon Manag 20(1):48

Ghorabaee MK, Amiri M, Zavadskas EK, Turskis Z, Antucheviciene J (2017b) A new multi-criteria model based on interval type-2 fuzzy sets and EDAS method for supplier evaluation and order allocation with environmental considerations. Comput Ind Eng 112:156–174

Hong L, Xiaohua Z (2011) Study on location selection of multi-objective emergency logistics center based on AHP. Proced Eng 15:2128–2132

Kahraman C, Keshavarz Ghorabaee M, Zavadskas EK, Cevik Onar S, Yazdani M, Oztaysi B (2017) Intuitionistic fuzzy EDAS method: an application to solid waste disposal site selection. J Environ Eng Landsc Manag 25(1):1–12

Kayikci Y (2010) A conceptual model for intermodal freight logistics centre location decisions. Proced Soc Behav Sci 2(3):6297–6311

Keshavarz Ghorabaee M, Zavadskas EK, Olfat L, Turskis Z (2015a) Multi-criteria inventory classification using a new method of evaluation based on distance from average solution (EDAS). Informatica 26(3):435–451

Keshavarz Ghorabaee M, Zavadskas EK, Olfat L, Turskis Z (2015b) Multi-criteria inventory classification using a new method of evaluation based on distance from average solution (EDAS). Informatica 26(3):435–451

Kuo MS (2011) Optimal location selection for an international distribution center by using a new hybrid method. Expert Syst Appl 38(6):7208–7221

Li Y, Liu X, Chen Y (2011) Selection of logistics center location using Axiomatic Fuzzy Set and TOPSIS methodology in logistics management. Expert Syst Appl 38(6):7901–7908

Li YY, Wang JQ, Wang TL (2019) A linguistic neutrosophic multi-criteria group decision-making approach with EDAS method. Arab J Sci Eng 44(3):2737–2749

Mi X, Tang M, Liao H, Shen W, Lev B (2019) The state-of-the-art survey on integrations and applications of the best worst method in decision making: why, what, what for and what’s next? Omega 87:205–225

Ministry of Development (2013) Tenth development plan (2014–2023). http://www.kalkinma.gov.tr/Pages/KalkinmaPlanlari.aspx

Ouenniche J, Uvalle Perez OJ, Ettouhami A (2019) A new EDAS-based in-sample-out-of-sample classifier for risk-class prediction. Manag Decis 57(2):314–323

Pamucar D, Chatterjee K, Zavadskas EK (2019) Assessment of third-party logistics provider using multi-criteria decision-making approach based on interval rough numbers. Comput Ind Eng 127:383–407

Rao C, Goh M, Zhao Y, Zheng J (2015) Location selection of city logistics centers under sustainability. Transp Res Part D Transp Environ 36:29–44

Rezaei J (2015) Best-worst multi-criteria decision-making method. Omega 53:49–57

Rezaei J (2016) Best-worst multi-criteria decision-making method: some properties and a linear model. Omega 64:126–130

Rezaei J, van Roekel WS, Tavasszy L (2018) Measuring the relative importance of the logistics performance index indicators using best worst method. Transp Policy 68:158–169

Tomić V, Marinković D, Marković D (2014) The selection of logistic centers location using multi-criteria comparison: case study of the Balkan Peninsula. Acta Polytech Hung 11(10):97–111

Triantaphyllou, E. (2000). A sensitivity analysis approach for MCDM methods. In: Multi-criteria decision making methods: a comparative study, Springer, Boston, MA, pp 131–175

Triantaphyllou E, Sánchez A (1997) A sensitivity analysis approach for some deterministic multi-criteria decision-making methods. Decis Sci 28(1):151–194

Turskis Z, Morkunaite Z, Kutut V (2017) A hybrid multiple criteria evaluation method of ranking of cultural heritage structures for renovation projects. Int J Strateg Prop Manag 21(3):318–329

Uyanik C, Tuzkaya G, Oğuztimur S (2018) A literature survey on logistics centers’ location selection problem. Sigma J Eng Natl Sci/Mühendislik ve Fen Bilimleri Dergisi 36(1):141–160

Wang S, Liu P (2007).The evaluation study on location selection of logistics center based on fuzzy AHP and TOPSIS. In: 2007 International conference on wireless communications, networking and mobile computing, pp 3779–3782. IEEE

Wang MH, Lee HS, Chu CW (2010) Evaluation of logistic distribution center selection using the fuzzy MCDM approach. Int J Innov Comput Inf Control 6(12):5785–5796

Wang B, Xiong H, Jiang, C. (2014). A multicriteria decision making approach based on fuzzy theory and credibility mechanism for logistics center location selection. Sci World J

Żak J, Węgliński S (2014) The selection of the logistics center location based on MCDM/A methodology. Transp Res Proced 3:555–564

Acknowledgements

Authors would like to thank the Ministry of Development, Central Anatolia Development Agency (Republic of Turkey; Project No: TR72/14/DFD/0028) for their contributions to the study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Özmen, M., Aydoğan, E.K. Robust multi-criteria decision making methodology for real life logistics center location problem. Artif Intell Rev 53, 725–751 (2020). https://doi.org/10.1007/s10462-019-09763-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10462-019-09763-y