Abstract

Oral adsorbents have attracted increasing attention as a potential therapeutic strategy for the removal of toxic substances from the gastrointestinal tract. This review aims to provide a comprehensive overview of the structural and mechanic properties of oral adsorbents such as activated charcoal, medical clays, zeolites, silica-based adsorbents, dietary fibers (carbohydrates alginate, chitosan, pectin, carrageenan etc.), and their physicochemical properties. The review also explores the mechanisms of action of oral adsorbents, including physical adsorption, ion exchange, and specific binding interactions. Furthermore, we provide an overview of the factors that influence the adsorption capacity and selectivity of oral adsorbents. The summary of recent advances in the usage of thiolated adsorbents is discussed, which provides valuable insights into the structural and mechanistic properties of oral adsorbents and their potential as a therapeutic option for the removal of toxic substances from the gastrointestinal tract.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Oral adsorbents are substances that are used to bind to and remove toxic substances from the body, particularly from the digestive system. These substances have gained importance in recent years due to the increasing exposure of humans to various toxic substances in the environment, food, and drugs. The primary role of oral adsorbents is to prevent the absorption of toxins into the bloodstream by binding to them in the digestive system. This can be particularly important in cases of acute poisoning or drug overdose, where the rapid removal of toxins from the body can be critical for the survival of the patient [54, 113]. In addition, oral adsorbents can be useful in preventing the accumulation of toxins in the body over time, which can lead to chronic health problems. There are several reviews partially related to enterosorbents based on oxidized cellulose [106] and clays [137] that are outdated. Therefore, this review fills the gap by providing recent advances in the field of enterosorbents.

It is known that the treatment of atopic dermatitis in children often involves a combination of approaches, such as an elimination diet, antihistamine drugs, and topical medications, along with the use of enterosorbents. The most effective enterosorbents are those containing prebiotics. The use of a prebiotic drug with adsorbent action, like Lactofiltrum, has shown promising results in the complex therapy of atopic dermatitis [9]. Incorporating an enterosorbent containing pectin, inulin, and fennel extract into the standard therapy for moderate atopic dermatitis can facilitate the control of clinical symptoms during an acute allergic reaction [45].

In the review conducted by Manukhin et al., the focus is on exploring the involvement of intestinal endotoxin in the development of various obstetric and gynecological conditions. The paper also discusses the treatment outcomes of these conditions using enterosorption as a means to counteract the harmful effects of endotoxin aggression. Additionally, the review presents established techniques for evaluating anti-endotoxin immunity and provides an updated classification of enterosorbents [105]. Enterosorbents found to be effective for treatment of various diseases. During disasters like extended droughts, hurricanes, and floods, humans and animals are at risk of exposure to mixtures of chemicals from food and water. Drought stress can lead to the presence of mycotoxins such as aflatoxins B1 (AfB1) and zearalenone (ZEN) in the food supply. Additionally, toxic soil and sediments containing pesticides can contaminate water sources. To tackle this issue and mitigate toxin exposures in food, feed, and water, researchers have developed clay-based enterosorbents with broad-acting capabilities. The enterosorbents can effectively reduce the uptake of toxins when included in the diet, offering a promising solution to combat the adverse effects of chemical mixtures on both humans and animals during times of natural disasters and environmental crises. Development of enterosorbents that can be added to food and water to reduce toxin exposures during disasters [192, 193].

A suspension of enterosorbent, exposing the subject for 10–15 min. restored the free outflow of the probe’s contents. In the post-surgical intensive care unit, enterosorption was continued every 8 h (3 times a day). The combination of this intestinal therapy with antioxidant and antihypoxic therapy proved effective in preventing the progression of endogenous intoxication. It achieved this by inactivating and efficiently clearing toxic metabolites, reducing the effects of hypoxia, and significantly decreasing membrane-destabilizing effects on intestinal cell structures. This led to a substantial decrease in the expression of specific antigens of the immune system and ultimately improved clinical results [77].

The impact of Basic Therapy (BT) was investigated, and positive effects were observed. It was explored the potential benefits of adding the enterosorbents Enterosgel and Carboline to BT in COPD patients during exacerbations. The results showed that the addition of Enterosgel or Carboline to BT led to a significant reduction in serum levels of inflammatory cytokines IL-1β, TNF-α, and IL-10 in both age groups studied (40–59 years and > 60 years). The changes were more pronounced in the older age group (age group 2). This indicates that the use of these enterosorbents alongside basic therapy may provide additional benefits in reducing inflammation in COPD patients during exacerbations, particularly in older individuals [90].

1.1 Activated charcoal

Activated charcoal, also known as activated carbon, is a carbon-based material that has been treated with oxidizing agents, such as steam or chemicals, to increase its functionality, surface area and porosity. In turn, activated carbon represents carbon`s amorphous form [71].

The first medical application with activated charcoal by humanity can be traced back to the ancient time (1500 B.C), then the application had been resumed in the 18th century with the works of Scheele about discovering the adsorption properties after Lowitz had discovered the decolorization activity in different liquid aqueous solutions [153]. Since that time activated carbon components have found application in various industries, such as cosmetology (the ability to absorb fats, blemishes, and impurities adhered to the skin) [13, 155], the food industry (due to adsorption and releasing ability) [32], dairy wastewater (the synergistic effect with the chitosan as a natural coagulant) [51], heavy metals removal [85, 134], etc. Activated carbon has been widely studied for its ability to absorb harmful substances in the body, especially after the Chernobyl nuclear disaster. However, AC has some drawbacks. It’s difficult for the body to get rid of, and it can interfere with the absorption of other medications if taken together [83].

Presently, the majority of research on activated carbon synthesis is concentrated on biomass waste due to its undeniable benefits, such as waste revalorization enabling, the low-value precursors generating a low price at the output, usage of renewable resources, and the combustion of these activated carbons upon reaching the end of their useful life does not add to the accumulation of CO2 in the atmosphere since the carbon dioxide was previously assimilated during plant growth [18, 59].

The adsorption capacity of activated charcoal depends on various factors, such as its surface area, pore size distribution, chemical composition, and surface chemistry. The surface area of activated charcoal ranges from 300 to 4320 m2/g [6], which provides a large surface area for the adsorption of pollutants. The pore size distribution of activated charcoal is also an important factor that affects its adsorption capacity. Activated charcoal has a wide range of pore sizes (Fig. 1), ranging from micropores (< 2 nm), mesopores (2–50 nm), and macropores (> 50 nm), which can adsorb different sizes of molecules [11, 158].

Types of Pore Volume of activated carbon adapted with permission (according to Sushrut Chemicals [178])

The production of activated carbon involves the processes of carbonization and activation. The purpose of the carbonization process is to remove volatile substances, which helps to open up the pores on the surface of the activated carbon. The carbonation process consists of multiple stages, including the removal of water, the transformation of organic ingredients into carbon elements, and the degradation of tar, which leads to the formation of larger pores in the resulting carbon. Activated carbon can be produced using various methods, including chemical activation, physical activation, and thermal activation [93, 171, 199].

Physical activation is a widely used method for producing activated carbon, which involves the activation of carbon precursor materials by high-temperature carbonization followed by activation with oxidizing agents such as steam or carbon dioxide [25, 80]. Physical activation has several advantages over other methods, such as high yields, low production costs, and the ability to produce activated carbon with tailored pore structures and surface chemistries [119].

The properties of physically activated carbon can be influenced by several factors:

-

Carbon precursor material: Different types of precursor materials can be used, such as wood, coconut shells, peat, coal, and petroleum coke, and each has its unique properties that determine the final properties of the activated carbon. For instance, lignocellulosic materials, such as wood or coconut shells, are commonly used as carbon precursors due to their natural porosity and high carbon content. Activated carbon produced from these materials has a high surface area, pore volume, and microporosity. In contrast, non-lignocellulosic materials, such as coals are more challenging to activate physically due to their low reactivity, high ash content, and the presence of inorganic impurities [115, 175, 198].

-

Activation temperature: Higher activation temperatures can result in larger pore sizes, higher surface area, and greater porosity [139]. However, excessively high temperatures can lead to the formation of undesirable graphitic structures, which can reduce the adsorption capacity of activated carbon. The ideal activation temperature depends on the carbon precursor material and the specific application of the activated carbon [184]. For instance, wood-based activated carbon is typically activated at temperatures between 800 and 1000 °C, whereas coconut shells-based activated carbon is activated at lower temperatures, usually between 500 and 800 °C [27, 70, 95, 140]. Furthermore, activation temperature affects the chemical composition of the activated carbon, such as the degree of oxidation and the presence of functional groups on the surface. This, in turn, influences the activated carbon’s reactivity and adsorption capacity for different types of molecules [101, 22].

-

Activation time: Longer activation times generally lead to higher degrees of oxidation, which results in the creation of more oxygen-containing functional groups on the surface of the activated carbon [150]. These functional groups, such as carboxylic, lactonic, and phenolic groups, increase the surface polarity and enhance the activated carbon’s adsorption capacity for polar molecules [117, 136]. Also, it is lead to the formation of a more extensive network of micropores and mesopores, which significantly increases the surface area of the activated carbon and allows the creation of more significant pores, resulting in a higher pore volume and improved transport properties [187]. This makes the activated carbon more suitable for applications that require fast mass transfer rates, such as in adsorption or catalysis. However, excessively long activation times can lead to the formation of unwanted structures, such as tar and char, that reduce the activated carbon’s adsorption capacity. On the other hand, the rapid heating during the process of pyrolysis leads to the formation of macroporous residue [33].

-

Oxidizing agent: The oxidizing agent can affect the degree of oxidation of the activated carbon. For example, agents such as CO2 and steam produce more micropores, while agents such as HNO3, KOH, and NaOH generate the mesoporous structured activated carbon, in turn, H3PO4 and ZnCl2 create a more extensive network of mesopores with a tendency to be microporous [86]. This pore structure significantly affects the activated carbon’s surface area, pore volume, and transport properties, ultimately determining its adsorption capacity for different molecules. Introducing heteroatoms such as nitrogen and sulfur into the carbon matrix can improve the activated carbon’s selectivity for certain molecules and make it suitable for specific applications such as gas separation, catalysis, and energy storage [142, 146].

-

Impregnation: Impregnation is a process in which an activated carbon precursor material is impregnated with a chemical agent before activation. The impregnation process can occur through two primary mechanisms: pore filling and surface deposition. In the pore-filling mechanism, the impregnation agent penetrates the pores of the activated carbon, occupying the pore volume and forming a layer of the impregnation agent on the surface of the pore walls. In contrast, the surface deposition mechanism involves the adsorption of the impregnation agent onto the surface of the activated carbon. For example, impregnation with metal oxides such as TiO2, Fe2O3, and MnO2 can increase the activated carbon’s affinity for organic pollutants, while impregnation with alkali metal hydroxides such as NaOH and KOH can improve its affinity for acidic gasses. The amount and type of impregnation agent used can significantly affect the properties of the activated carbon. The degree of impregnation, impregnation agent concentration, and the impregnation time all influence the impregnation efficiency and the resulting changes in the activated carbon’s surface chemistry and pore structure [120, 149, 208, 216].

-

Particle size: Activated carbon comes in two forms: granular activated carbon (GAC) and powdered activated carbon (PAC). GAC typically ranges in particle size from 0.4 to 1.2 mm, while PAC ranges in particle size from 5 to 50 μm [55]. The findings indicated that the application of KOH solution during the carbonization of coconut shells increased both particle size and surface area of the prepared activated carbon (the particle size is 50–150 nm in diameter with more than 80% of them being less than 120 nm) [176].

Chemical activation includes four types of different agents: alkaline-based, acidic-based, neutral, and self-activating. Among all alkaline chemical agents, the greatest use is observed with KOH (potassium hydroxide) due to benefits, that encompass the capacity to inhibit the production of tar, decrease the temperature needed for the activation reaction, hasten the elimination of non-carbon elements, and improve the rate of pyrolysis reaction [112]. The impregnation process involves soaking the activated charcoal in a solution of KOH, usually at a concentration of 1:1 to 4,5:1 KOH to charcoal ratio with further stirring or agitating to ensure an even distribution of the KOH throughout the charcoal. Once the charcoal has been impregnated with KOH, it is heated to a high temperature, typically between 600 and 800 °C, in a furnace or kiln. As it was described by Zhang et al. the surface area of activated carbon reached the result of 2388 m2/g and micropores constituted 88.98% of the entire pore volume with the ratio KOH: biochar (4,5:1) with synthesis parameters (temperature 800 °C, duration 1,5 h) [211]. The results of experiments conducted by Cao et al. with obtaining activated charcoal from corn cob (at a carbonized temperature of 450 ºC and activation time at a temperature of 850 ºC for 1 h 20 min, the mass ratio of KOH to carbonized material was 4.0 the specific surface area was 2700 m2/g) [30].

The acidic-based agents are represented by phosphate esters with the active role of H3PO4 for the usage of lignocellulosic materials in the activated charcoal formation. The high polarity of H3PO4 allows for the control of physical and chemical interactions in the solution and with the substratum during the impregnation process. Therefore, the concentration of the solution is likely the primary factor in the activation process [201].

The neutral activating agent primarily forms pores through oxidation, template, and gasification mechanisms. Through reduction reactions, positive ions (such as Fe3+, Mn7+, Mg2+, Na+, and others) at their oxidation states can interact with carbon atoms, resulting in the removal of certain carbon atoms and the creation of channels in the activated material [168].

A new type of activated carbon made from refined polystyrene has been developed for treating chronic kidney disease. This material is highly porous and has a very large surface area (2125 m2/g), which allows it to effectively bind and remove harmful substances(creatinine) from the gut. It has been shown to be robust(particle strength up to 30 N) and can remove a significant amount of creatinine (up to 300 mg/g), a waste product that builds up in the blood of people with kidney disease [199].

A recent research paper focuses on creating tablets from a special type of activated carbon fiber with a nanostructure. This material is useful for medical applications. To improve the process of making these tablets, the researchers propose adjusting the compression speed and holding time under pressure. This helps to distribute the stress evenly [164]. It was established how well carbon nanofibers could remove two different types of drugs (promethazine and trimethoprim) from simulated stomach and intestinal fluids. The results illustrated that the speed of absorption was influenced by the rate at which the drugs moved into the nanofibers, and this was especially true for promethazine. The experiment also revealed that the nanofibers strongly attracted the drugs. The maximum amount of drugs that could be absorbed by the nanofibers was calculated: for trimethoprim, it was 18 mg/g in simulated stomach fluid and 41 mg/g in simulated intestinal fluid; for promethazine, it was 95 mg/g in simulated stomach fluid and 80 mg/g in simulated intestinal fluid [159].

A clinical trial involving 28 patients with cirrhosis tested a new treatment called Yaq-001, which is a type of carbon bead that absorbs harmful substances in the gut. Patients received Yaq-001 or a placebo for three months. The study found that Yaq-001 effectively removed harmful substances from the body, leading to a significant reduction in liver damage, fibrosis (scarring), high blood pressure in the veins leading to the liver, kidney problems, and death in animals with a similar condition to cirrhosis. Yaq-001 also improved gut health by reducing leakage and altering the balance of beneficial bacteria. Importantly, the treatment was found to be safe and well-tolerated by patients [104].

1.2 Clays for medical application

Clay is composed of hydrated aluminum silicate, quartz, and organic fragments, and is a fine-grained material that can be found in sedimentary rocks, soils, and other deposits [17, 116]. Clay is a common term used to describe a group of minerals that share similar properties, such as high plasticity, low permeability, and the ability to harden when heated [121]. Clay minerals are widespread and have various uses in different fields, including construction, agriculture, and medicine.

Clay minerals are classified into three categories based on the number and arrangement of tetrahedral and octahedral sheets in their structure of layer silicates (Fig. 2). In 1:1 clay minerals, each layer consists of one tetrahedral sheet and one octahedral sheet. The tetrahedral sheet is composed of silicon (Si) or aluminum (Al) ions arranged in a hexagonal lattice, while the octahedral sheet contains magnesium (Mg), aluminum (Al), or iron (Fe) ions arranged in a triangular lattice. The layers are held together by weak van der Waals forces, and examples of 1:1 clay minerals include kaolinite and serpentine.

-

2:1 Clay Minerals: 2:1 clay minerals have a layered structure composed of two tetrahedral sheets sandwiching one octahedral sheet. The tetrahedral sheets are formed by silicon (Si) or aluminum (Al) ions, and the octahedral sheet contains magnesium (Mg), aluminum (Al), or iron (Fe) ions. The layers are typically bonded together by cations and water molecules. Common examples of 2:1 clay minerals include illite, smectite (such as montmorillonite), and vermiculite.

-

2:1:1 Clay Minerals: 2:1:1 clay minerals consist of two tetrahedral sheets sandwiching two octahedral sheets. Similar to 2:1 clay minerals, the tetrahedral sheets are composed of silicon (Si) or aluminum (Al) ions, while the octahedral sheets contain magnesium (Mg), aluminum (Al), or iron (Fe) ions. The layers are held together by cations and water molecules. Chlorite is an example of a 2:1:1 clay mineral.

Clay minerals classification adapted from [121]

There are four types of clays commonly used in industrial applications. The first type is bentonites, which consist mostly of montmorillonite (the multilayered nanosheet of 10 Å thickness [36] as their primary clay mineral constituent. The second type is kaolins, which primarily contain kaolinite. The third type is made up of palygorskite and sepiolite. The fourth type is referred to as ‘common clays,’ which often contain mixed-layer minerals of illite and smectite, and are mainly used for ceramics [20].

Bentonite: A type of clay mineral that is composed mainly of montmorillonite, which is a type of layered silicate mineral. The chemical formula for montmorillonite is (Na, Ca)0.33(Al, Mg)2Si4O10(OH)2•nH2O, and the average size of natural bentonite particles was 19.96 μm. However, after subjecting bentonite to treatment at 500, 750, and 1000 °C, the particle size increased to 26.08 μm, 28.15 μm, and 30.73 μm, respectively. The adsorption capacity (Qmax) of natural bentonite was 0.60 mol/kgand after treatment at 500 °C and 750 °C, this value decreased to 0.29 mol/kgand 0.13 mol kg−1, respectively [127]. The classification of bentonites is determined by the primary types of exchangeable cations present, which includes Na-bentonite (also known as the Wyoming type), Ca-bentonite (also known as fuller’s earth), and mixed bentonites that contain both Na and Ca cations. The mineral also contains small amounts of other minerals such as feldspar, quartz, and calcite. The composition of bentonite varies depending on the location and geological environment where it is found [1, 7].

Bentonite exhibits several unique properties that make it an attractive material for use in various applications. Some of the important properties of bentonite are as follows:

-

Swelling: Bentonite can absorb water and swell up to several times its original size. This property is due to the presence of interlayer cations, which are exchanged with water molecules [92, 194, 195].

-

Cation exchange capacity (CEC): Bentonite has a high CEC, which is a measure of its ability to exchange cations. This property makes it useful for removing impurities and contaminants from water and other liquids [8, 82, 118].

-

Specific surface area: Bentonite has a high specific surface area of 20 to 130 m2/g, which is a measure of the total surface area of its particles [151, 194, 195]. This property makes it useful as an adsorbent for removing impurities and contaminants from liquids [14]. In the research of Zn2+ adsorption by thermally treated bentonite, the high surface area was raised from 147 m2/g to 310 m2/g [179].

-

Rheological properties: Bentonite exhibits thixotropic and plastic behavior, which makes it useful as a thickening agent and binder in various applications [2].

-

Thermal stability: Bentonite is stable at high temperatures, which makes it useful as a flame retardant and thermal insulation material [19].

Bentonite also exhibits good adsorption properties, which make it useful for removing impurities and contaminants from pharmaceutical products. Bentonite has several applications in the pharmaceutical industry. It is used as a binder, disintegrant, and suspending agent in tablet formulations. The modified bentonite by polyallylamine exhibited a maximum adsorption capacity of 847.5 mg/g−1 for reducing Amido black 10B dye [66]. The removal of the antibiotic Amoxicillin from pharmaceutical effluents was studied by Putra et al. using adsorbents such as bentonite and activated carbon. The pores of the bentonite were identified as mesopores, with an average pore width ranging from 20 to 80 A˚ [143]. Bentonite is also used as an excipient in the preparation of oral, topical, and injectable formulations. In addition, bentonite is used as an adsorbent in the purification of drugs and as a carrier for controlled drug release. The use of bentonite in pharmacy has increased due to its excellent biocompatibility, low toxicity, and ease of processing [76, 130, 133, 165].

Kaolinite is a 1:1 dioctahedral phyllosilicate with a layered structure, consisting of sheets of tetrahedrally coordinated silica (SiO4) and octahedrally coordinated alumina (AlO6) arranged in an alternating sequence [62]. The layers are held together by hydrogen bonds and van der Waals forces, forming a hexagonal prism-shaped crystal structure. The hydrogen atoms in the hydroxyl groups of the octahedral sheet of one-layer form bonds with the oxygen atoms in the tetrahedral sheet of the next layer [35]. The surface properties of kaolinite play an important role in its various applications. The basal planes of kaolinite crystals are negatively charged, while the edges of the crystals are positively charged. These charged surfaces can attract cations and anions from the solution, allowing kaolinite to act as an adsorbent for various substances [123]. The sorption capacity of kaolinite is influenced by the nature of its exchange complex. As a result of replacing one type of ion with another, it is possible to alter the surface properties of kaolinite. Kaolinite crystals have the morphological shape of euhedral platy crystals, laths and tubes with a size of 0.02–0.83 μm, median 0.02 μm [197].

Palygorskite (attapulgite), is a type of phyllosilicate with a rod-like morphology that is characterized by a 2:1 layered-chain structure, Frini-Srasra [58] reported that the specific surface area of palygorskite falls within the range of 60 m2/g to 279 m2 /g, while Papoulis et al. reported a maximum value of 279 m2 /g. The fibrous structure of palygorskite provides a large number of active sites for drug adsorption [132]. The combination of nanorod crystals and nanopores gives it a distinct structure that provides several benefits, including a high specific surface area (generally between 125 and 210 m2/g), cation exchange capacity (between 20 and 60 mEq/100 g), higher mechanical strength and exceptional thermal stability. Additionally, palygorskite has a high degree of biocompatibility, which is important for its potential use in biomedical applications. Palygorskite’s benefits enable the creation of different nanocomposites by utilizing rod crystals, nanopores, and surface groups and their adsorbents have found wide-ranging applications in numerous areas [129, 191].

Smectite: A group of clay minerals that have a tetrahedral-octahedral-tetrahedral (TOT) layered structure, which is also referred to as the 2:1 type layer, the chemical formula is Si8Al4O20(OH)4·nH2O [61]. The high surface area of a typical smectite (montmorillonite) is ~ 800 m2/g for < 1 μm particle sizes with the cation exchange capacity (~ 1.0 eq/kg) [102, 103]. Particles of smectite possess two distinct types of electrical charge: a fixed negative charge on the surface and a pH-dependent charge on the edges, which arises from the adsorption and desorption of protons on hydroxide groups [161]. The surface of smectite is characterized by a permanent negative charge, which arises from the substitution of lower positive charged cations (such as Si4+ and Al3+) for central ions in the tetrahedral and octahedral sheets. To balance the excess negative charge, exchangeable cations (primarily Na+ and Ca2+) are present in the interlayer spaces of the smectite [185]. Special attention is also given to clay’s capacity for adsorbing organic substances, specifically pharmaceuticals, the group of Po-Hsiang Chang et al. has described the sorption activity of clay minerals to the different groups of antibiotics [40], which expands the range of applications of these compounds in pharmacy and medicine.

Clay minerals due to their negative surface charge and affinity for water are effective at adsorbing cationic and hydrophilic contaminants. However, these dispersed materials are not as effective at adsorbing anionic and hydrophobic pollutants. Furthermore, their high cation exchange capacity (CEC) and surface area make them adept at adsorbing both inorganic and organic contaminant cations through cation exchange mechanisms [162].

According to the review of Alexander V. Bondarev et al., medical clays are widely used in the following branches of medicine [23]:

-

Corneotherapy is presented by the thermal effect of clay heated to 40 °C, which promotes the dilation of peripheral blood vessels. The resulting hyperemia enhances metabolism in superficial tissues and has an antispasmodic effect. The mechanical effect involves the pressure of the clay mass on the skin, stretching of the skin, and a peeling effect.

-

The vulnerosorption method is based on the adsorption of toxins through the wound surface. When medical clay is applied, the wound contents are purified, and the transport of toxic substances from the blood is accelerated with their subsequent sorption.

-

Gastroenterosorption is the absorption of toxic substances in the stomach and intestines by a sorbent. The sorbent is administered at a dose of 100–200 mg/kg body weight.

-

Application as excipients in pharmaceutical technology and as food additives. Due to sorption properties, in some cases, the medical clays can regulate the constants of pharmacokinetics and pharmacodynamics, thereby increasing the effectiveness of drug therapy.

The acid-processed montmorillonite clays (the total surface area was increased by 60% from 800 m2/g as in regular clays to 1300 m2/g) were shown the activity of binding aflatoxin B1, zearalenone, and glyphosate. The results of the Hydra bioassay were shown protection against aflatoxin at a 0.005% inclusion level, binding of zearalenone at an inclusion rate of 0.01%, and the ability of complete protection at the inclusion rate of 0.1% against glyphosate [192, 193].

The results suggest that the dieldrin-sorbent complex is stable and that dieldrin would not easily dissociate from the either sorbent. The topological polar surface area of one dieldrin molecule is 12.5 Å2, and the total binding area for dieldrin is equal to 2.4 × 1021Å2/g (in comparison with the available montmorillonite clays surface area of 7.8 × 1022Å2g–1). The low inclusion levels of sorbent were (0.230 g /kg for montmorillonite clays and 0.207 g/kg for acid-processed montmorillonite) [69].

In comparison to calcium bentonite clay (CB), sodium bentonite clay (SB) known as SB-E demonstrated a higher capacity for binding aflatoxin B1 (AfB1) at both acidic (pH 2) and neutral (pH 6.5) conditions. The findings of this study suggest that clays with high capacity, such as SB-E, can be utilized as efficient aflatoxin enterosorbents. Incorporating these clays into food and/or water during extended droughts and outbreaks of aflatoxicosis may prove effective in reducing short-term exposures to aflatoxin in both humans and animals. Wang, Meichen, Sara E. Hearon, and Timothy D. Phillips. “A high capacity bentonite clay for the sorption of aflatoxins.” Food Additives & Contaminants: Part A 37.2 (2020): 332–341.

NovaSil clay (NS) has demonstrated its ability to reduce aflatoxin exposure and prevent aflatoxicosis in both animal and human studies. The safety of NS and its refined version with uniform particle size has been confirmed in these studies. Research conducted on Ghanaians at high risk of aflatoxicosis has shown that NS, when administered at a dose of 0.25% w/w, effectively decreases biomarkers of aflatoxin exposure without interfering with serum levels of essential vitamins A and E, iron, or zinc [138].

A farm test was conducted to evaluate the impact of the phytobiotic enterosorbent, Zaslon-Fito, on the rumen microbiome composition, blood biochemical parameters, and productivity of dairy cows. The study involved two groups of black and white mottled Holstein cows in their 2-3rd lactation, with 15 animals in each group. The experiment spanned for 2.5 months, during which Zaslon-Fito enterosorbent was added to the cows’ diet by mixing it with their feed at a rate of 20 g per animal per day. Prior to the experiment, the ELISA method revealed that the feeds used in the study were contaminated with aflatoxins, zearalenone, and deoxynivalenol, with levels exceeding the maximum permissible concentrations. The results showed that the use of Zaslon-Fito had a significant positive effect on the milk productivity of cows, leading to a 5.5% increase in the average daily milk yield per animal, amounting to 1.8 kg [205].

The experiment aimed to study the preventive treatment for minks exposed to the combined impact of T-2 toxin and aflatoxin B1 mycotoxins. Group 1 served as the biological control. Group 2 received T-2 toxin and aflatoxin B1 in addition to their regular diet. Group 3 received T-2 toxin, aflatoxin B1, and sodium bentonite. Group 4 received T-2 toxin, aflatoxin B1, and phytosorb. One-month experiment included regular hematological and biochemical blood tests every 10 days. The toxin doses used were within the maximum permissible levels in Russia. The results showed that the combined intake of T-2 toxin and aflatoxin B1 caused significant negative changes in hematological and biochemical parameters in minks. However, the addition of sodium bentonite at a dose of 2% and phytosorb at a dose of 0.5% to the animals’ diet had a preventive effect against T-2 and aflatoxicosis, leading to the normalization of hematological, biochemical, and biological parameters [160].

The study aimed to investigate the potential of clay enterosorbent in mitigating the toxic effects of aflatoxin B1 (AFB1) from naturally contaminated moldy corn (Zea mays; containing 170 µg/kg of AFB1) on various health parameters in ducks animal model. Four dietary treatments were used: (1) low-AFB1 diets (LA) without contaminated corn; (2) LA diets supplemented with clay enterosorbent; (3) high-AFB1 diets (HA) with contaminated corn; and (4) HA diets supplemented with clay enterosorbent. The addition of 0.1% clay enterosorbent to the HA diets partially alleviated the detrimental effects of AFB1 on the hematology, serum biochemistry, and oxidative stress in ducklings. However, it was observed that the platelet count of ducklings fed the AFB1 diet decreased significantly (P < 0.05), regardless of the presence of the 0.1% clay enterosorbent. The addition of 0.1% clay enterosorbent to the diet proved to be effective in counteracting the toxic effects caused by aflatoxin B1 [96].

Four different types of adsorbents (phillipsite, chabazite, clinoptilolite, and mordenite) were tested for their ability to remove heavy metals (copper, zinc, cadmium, and lead) from the bodies of rats. All four sorbents were effective in reducing the levels of these metals in the rats. Phillipsite, chabazite, and clinoptilolite were particularly effective in reducing the levels of metals in the blood, liver, and kidneys. Mordenite was also effective in reducing metal levels in the blood and liver Cu and Zn in rat livers decreased by 1.4 folds, and Cd and Pb – by 2 folds [5].

1.3 Silica-based adsorbents

Silica-based adsorbents are a class of materials that have gained significant attention due to their unique physicochemical properties and potential applications in various fields. Silicon sorbents are typically composed of silica-based materials, such as silicon dioxide (SiO2) or silica gel, which have a high surface area of approximately 290 to 1000 m2/g [114]. According to the study of Pınar Terzioğlu et al. the silica-based aerogels made from wheat husks possess a favorable pore structure, with a pore volume of around 2.3-4.0 cm3/g and a pore size of 9–15 nm. However, despite having a surface area ranging from 513 to 587 m2/g, the aerogels still exhibit these desirable pore characteristics [183]. The surface area of the inner surface of activated carbon, which is coated with silicon oxide is around 600 m2/g − 1200 m2/g) [41]. Alternatively, mesoporous silica is a material with a pores diameter between 2 and 50 nm and a surface area in the range of 700-1500m2/g [190]. Silica materials can be classified based on their pore size as microporous (with a diameter less than 2 nm), mesoporous (with a diameter ranging between 2 and 50 nm), and macroporous (with pores larger than 50 nm) [170]. Two categories of adsorbents contain silica: natural and synthetic mineral carriers made from silicon dioxide and its chemically modified products, and organosilicon polymer sorbents [141]. White Coal, a medicinal supplement made of tiny silicon dioxide particles, is considered safe when taken in the recommended doses. These particles are clumped together and don’t break apart in the digestive system, meaning it is unlikely to be absorbed into the body. Due to its unique properties high surface area, White Coal may be helpful in treating various allergies, particularly food allergies. It can help relieve symptoms of digestive problems, reduce the body’s exposure to harmful substances, and improve overall well-being. Because of its safety profile, White Coal may also be recommended for pregnant and breastfeeding women, especially during allergy flare-ups, to help prevent allergies in babies [166].

The synthesis and functionalization of silicon sorbents can be achieved through various methods, including sol-gel, hydrothermal, and chemical vapor deposition techniques. Among these methods, sol-gel is the most widely used technique for the synthesis of silica-based materials due to its simplicity and versatility. Sol-gel involves the hydrolysis and condensation of silicon alkoxides, such as tetraethylorthosilicate (TEOS), in the presence of a catalyst and a solvent [109, 186].

Zeolites are a class of naturally occurring or synthetic minerals that are widely used in various industrial applications [207]. It is characterized by their porous crystalline structure, which provides them with unique properties, such as high surface area and ion exchange capability. Zeolites have been classified based on various criteria, including crystal structure, composition, and pore size [135].

Zeolites can be classified based on their crystal structure, which is determined by the arrangement of tetrahedral units in their structure. The International Zeolite Association (IZA) recognizes more than 250 different zeolite species based on their crystal structure [26]:

Zeolites can also be classified based on their composition, which is determined by the type and ratio of the elements in their structure, which can contain silicon, aluminum, and various other elements, such as magnesium, calcium, barium, potassium, and sodium (Zeolite | Structure, Properties, & Facts, Britannica web site). Based on their composition, zeolites can be classified as:

-

Silicate Zeolites: These zeolites contain only silicon and oxygen in their structure, with no other elements. The pore sizes of these materials, ranging from 2.0 to 10.0 nm, exceed the pore size limitation (< 2.0 nm) of microporous zeolites. Additionally, exhibiting exceptionally high surface areas (> 700 m2/g) and narrow pore size distributions [10].

-

Aluminosilicate Zeolites: These zeolites contain both aluminum and silicon in their structure, with the ratio of aluminum to silicon varying depending on the zeolite species [37]. It is possible to synthesize these materials with high surface area (> 800 m2/g) [56]. The synthesis of nanocrystalline zeolites has become a popular research area in recent years. Zeolites with a crystal size of 50 nm exhibit an external surface area greater than 100 m2 /g. In contrast, a zeolite crystal with a size of 500 nm has an external surface area of less than 10 m2 /g. The larger external surface area of nanocrystalline zeolites enables increased adsorption capacity and additional surface area for the adsorption and reaction of molecules [46].

-

Other Zeolites: These zeolites contain various other elements in their structure, such as magnesium, calcium, and sodium [84].

Finally, zeolites can be classified based on their pore size, which determines their ability to adsorb or separate molecules of different sizes [4]. Zeolites with smaller pore sizes are more suitable for adsorbing smaller molecules, while zeolites with larger pore sizes can adsorb larger molecules. Zeolites can be classified based on their pore size as [145]:

-

Small Pore Zeolites: These zeolites have a pore size of fewer than 5 angstroms and are suitable for adsorbing small molecules, such as water and carbon dioxide.

-

Medium Pore Zeolites: These zeolites have a pore size of about 5–8 angstroms and are suitable for adsorbing medium-sized molecules, such as oxygen and nitrogen.

-

Large Pore Zeolites: These zeolites have a pore size of more than 8 angstroms and are suitable for adsorbing larger molecules, such as hydrocarbons.

-

Extra-Large Pore Zeolites: These zeolites have a pore size of more than 12 angstroms and are suitable for adsorbing larger molecules, such as hydrocarbons.

Silica-based adsorbents are effective in treating a variety of medical conditions. These include:

-

gastrointestinal disorders such as diarrhea, gastroenteritis, and inflammatory bowel disease, work by adsorbing toxins and harmful substances in the digestive tract, reducing inflammation and improving overall gastrointestinal health;

-

liver disease, including acute and chronic liver failure, viral hepatitis, and liver cirrhosis, which work by adsorbing toxins in the digestive tract, preventing their absorption into the bloodstream, and reducing the workload on the liver;

-

allergies, which work by adsorbing allergens in the digestive tract, preventing their absorption into the bloodstream, and reducing the severity of allergic reactions;

-

kidney disease, including acute and chronic renal failure, nephritis, and glomerulonephritis.

The work related adsorbtion of toxins and harmful substances in the digestive tract, preventing their absorption into the bloodstream, and reducing the workload on the kidneys.

Silica-based enterosorbents include methylsilicic acid hydrogel (Enterosgel®), highly dispersed silicon dioxide or silica (Atoxil® has an average particle size between 0,12 and 0,20 mm, the specific surface area is 130 m2/g; Polisorb® particle size between 5 and 70 μm with a specific surface area of 300 m2/g), and silicic acid gel (Silicolgel®, Silicea®), are among the various oral intestinal adsorbents available [111].

The registered medicine Enterosgel® is widespread in Kazakhstan. Enterosgel is composed of a type of organosilicon compound called polymethylsiloxane polyhydrate (PMSPH), which is created through the polycondensation of methylsiloxane. It is made up of tiny globules that contain empty spaces filled with water. Enterosgel is a hydrogel formed by small microglobules that contain porous space filled with water, which connect into larger particles that are less than 250 μm in size. The gel is amorphous and cannot dissolve in water. Due to its gel-like properties, Enterosgel has a unique porous structure with a specific surface area ranging from 150 to 250 m2/g of dry weight. The gel contains pores that are smaller than 2 nm in diameter in the microporous range, while the majority of the pores are wide mesopores and small macropores ranging from 2 nm up to 100 nm in diameter. The ratio of PMSPH and water in Enterosgel is 70/30 by weight, which has been found experimentally to have the highest pore volume of approximately 1.5–1.6 cm3/g [65, 72, 204].

The maximum values of adsorption of the synthesized chitosan-fumed silica composite with a grain size ~ 50 up to 250 μm were found to be up to 97 µmol/g for taurocholic acid and 43 µmol/g for cholic acid [28].

Bentorb, a sorbent made from waste products of winemaking, has been tested for safety in animals. Studies have shown that it does not cause significant changes in the general health or survival of rats and mice. Even when given in different concentrations or stored for 2 months, Bentorb did not increase toxicity. Additionally, studies on pregnant rats showed no harmful effects on the development of fetuses. These findings suggest that Bentorb ferrocyanide-containing sorbent is safe for use [12].

Mesoporous silica nanoparticles (MSNs) with the size of 30 nm was designed and tested as adsorbents for phosphine gas. MSN, and the other was post-modified with boric acid (MSN-BA) possessed high surface areas of 1025 and 650 m2/g, respectively. These adsorbents revealed to be effective as an antidote to phosphorus poisoning, and zinc phosphide (phosphorus) powder was used as the toxic and lethal agent. the MSN-BA-treated group with a dose of 5 mg/kg was illustrated a survival rate of 60% [53].

Chrzanowska with colleagues created new materials for absorbing harmful substances in the gut by combining nano-sized silica particles (NS) with protein molecules (human serum albumin). Different methods of modifying the silica particles was tested to see how it affected the overall material. It was established that the protein coating on the silica particles created a smoother, more uniform surface. This was confirmed by using special microscopes to examine the surface details [39].

1.3.1 Dietary fibers

Enterosorption is a promising method for removing toxic substances from the body using enterosorbents, which absorb toxins in the digestive tract. Pectin is a group of intricate polysaccharides that constitute a significant proportion of plant matter. In dicotyledonous plant cells, pectin accounts for around 35% of the plant’s mass, while grasses contain between 2 and 10%, and woody tissues contain 5% [34]. Pectin is primarily composed of heterogeneous groups of glycanogalacturonans and acidic structural polysaccharides with diverse structures. The primary structure of the pectin backbone is made up of (1→4)-α-D-galacturonic acid molecules, which are connected to a limited number of rhamnose residues in the main chain. In addition, the side chains of pectin comprise arabinose, galactose, and xylose [188]. Certain carboxyl groups exist as methyl esters naturally, while others can be transformed into carboxamide groups through treatment with ammonia. These functional groups can create complexes with metal ions in a solution and convert them into metal nanoparticles, without requiring any toxic reducing or stabilizing agents [122]. Pectin is widely used in the food industry as a gelling agent, thickener, texturizer, emulsifier, and stabilizer. Also, it has been utilized as a substitute for fat or sugar in low-calorie food products during the past few years [29]. In recent years, there has been an increasing interest in the study of pectin adsorption properties. The degree of methyl-esterification primarily controls the gelation mechanism of pectin, causing the formation of gels to vary between high-methoxyl (HM) and low-methoxyl (LM) pectins. Other factors that affect the gelling process include ionic strength, pH, and molecular weight [107].

Semenov et al. reported that the polysaccharide based adsorbent, Fitosorb can be utilized as potential in preventing combined mycotoxicoses. They studied modelled combined mycotoxicoses in white rats. The rats were fed a diet containing both T-2 toxin and aflatoxin B1 (AFB1) at a dose of 0.3 mg/kg for one month. As a preventive measure, the mycotoxin adsorbent, Fitosorb, was included in the diet at a dose of either 5–10 g/kg of feed. The results revealed that the combination of T-2 toxin and AFB1 negatively affected the hematologic and biochemical parameters of the rats’ blood throughout the experiment. However, daily supplementation of the diet with the enterosorbent Fitosorb at doses ranging from 5 to 10 g/kg effectively reduced the symptoms of toxicosis and improved the overall clinical condition of the experimental animals exposed to mold fungi and their toxins [163]).

The review conducted by Ivnitsky Yu. et al. explores the potential of using pectin enterosorbents for preventing acute poisoning. Pectins have strong adhesion to the mucous membranes of the digestive tract and can non-specifically reduce the permeability of the enterohematic barrier. The preventive effect of pectin enterosorbents is expected to last for approximately 4–5 h after administration [78].

Apple pectin has been found to have a high adsorption capacity for heavy metals such as lead (303 mg/g), (250 mg/g), and nickel (100 mg/g). Another study achieved the results of capacity for adsorption of lead, cadmium, and a pH range of 2 to 8, with values of 178.57 mg/g, 112 mg/g, and 51 mg/g, respectively from the pectin of apple pomace with xanthan modification. An adsorbent derived from activated carbon using apple peels was found to possess a hexavalent chromium absorption capacity of 36.01 mg/g [63].

Citrus pectin is a type of pectin that is extracted from citrus fruits such as different types of oranges, lemons, and grapefruits [169]. It has a high degree of methylesterification (HM) compared to other pectin varieties. This high degree of methylesterification results in a large amount of methyl ester in its structure, which gives it an excellent emulsifying capacity, these properties allow it to be used in the production of emulsions [214]. In the study conducted by Tekutskaya, significant differences were observed in the values before and after pectin treatment. In contrast, patients who did not receive the enterosorbent (the comparison group) showed minimal changes in the level of organochlorine pesticides after repeated tests. It was concluded the potential mechanism of how pectins aid in the excretion of organochlorine pesticides and heavy metals from the body [182].

Pectins are also used in heavy metal poisoning treatment [110]. The clinical study investigated the efficacy of modified citrus pectin in lead poisoning (significant reduction in the levels of lead in the blood serum: P0.0016; average change of 161%, and a remarkable increase in the 24-hour urine collection: P 0.0007; average change of 132%). The heavy metal binding activity occurs due to the containing about 10% of rhamnogalacturonan II. The low degree of esterification and the presence of homogalacturonan and rhamnogalacturonan II gave modified citrus pectin a high concentration of free carboxyl groups, that makes it well-suited for binding cations like lead through chelation [213]. Also, it was found that taking MCP alone (5 g/ 3 times per day) for 12 months led to an average reduction of 73% of mercury without any side effects [52].

The biocompatibility, antioxidant, and antimicrobial properties of lignin have made it possible to effectively blend it with other polymers, such as chitosan, poly(vinyl alcohol), alginate, or cellulose, resulting in the creation of hydrogels that are ideal for promoting wound healing [148, 212].

Lignin is a complex, three-dimensional, and irregularly shaped polymer that is present in the cell walls of plants, particularly in woody tissues. It is composed of three main monolignol building blocks: p-coumaryl alcohol, coniferyl alcohol, and sinapyl alcohol (4-Hydroxy-3,5-dimethoxycinnamyl alcohol). These monolignols polymerize to form a complex network of interlinked macromolecules. The main backbone of lignin is formed by the polymerization of these monolignols, which creates a long chain of carbon-carbon and ether bonds. The polymerization of the monolignols is catalyzed by oxidative enzymes, and the resulting polymer is cross-linked through various chemical bonds, including β-aryl ether, phenylcoumaran, and resinol bonds. The chemical structure of lignin is also characterized by the presence of various functional groups, including hydroxyl, carboxyl, and methoxyl groups. These functional groups contribute to lignin’s physicochemical properties, such as its solubility and reactivity [74, 209]. Slow pyrolysis is a promising thermochemical conversion technology for transforming lignocellulosic biomass into valuable products, primarily biochar. The yield and physicochemical properties of biochar vary significantly based on numerous factors, including the type, composition, and characteristics of the biomass, as well as the pyrolysis conditions, such as temperature, heating rate, and residence time. To maximize biochar production, it is preferable to maintain a moderate pyrolysis temperature, a moderate to extended residence time, and a slower heating rate. As the pyrolysis temperature increases, the stable carbon content and aromatic content in the biochar matrix also increase, enhancing its resistance to degradation over time [115]. One of the main uses of lignin in pharmaceuticals is as an excipient. Lignin can act as a binder, disintegrant, and lubricant in the formulation of tablets, capsules, and other dosage forms. It has been shown to improve tablet hardness, reduce friability, and enhance the dissolution rate of poorly soluble drugs [49]. Lignin-based nanoparticles have been developed for targeted drug delivery, particularly for anticancer agents [57]. It has been shown to have anti-inflammatory, antioxidant, and antimicrobial properties. These properties make lignin a promising candidate for the treatment of various diseases, including cancer, cardiovascular diseases, and infections. Furthermore, lignin has been investigated for its ability to bind various microorganisms, their waste products, exogenous and endogenous toxins, allergens, xenobiotics, heavy metals, radioactive isotopes, ammonia, and divalent cations and are excreted unchanged through the intestine [180]. After 15 min of exposure of water to enterosorbent “Filtrum-STI” based on lignin hydrolised, the adsorption of low molecular weight toxins from aqueous solutions was evident for all toxins. The lead removal efficiency for the material was estimated as 19.5% [203]. There are no registered dietary fibers in the register of medicines and medical devices in the pharmaceutical market of Kazakhstan, but dietary fibers / food supplements can be produced and imported in the form of dietary supplements.

Nevertheless, there are many studies in the synthesis of porous materials for the removal of heavy metals and toxic substances, which can later be used in alternative drug development in the pharmaceutical industry. Table 1 presents some data on the sorption capacity of heavy metals of some oral adsorbents previously considered in the review.

The adsorption capacity of organic-soluble lignin enterosorbents was found to be 97.7 mg/g and 236.7 mg/g based on methylene blue and gelatin, respectively. These values were notably higher compared to the adsorption capacity of the commercial enterosorbent Polifepan, which demonstrated adsorption capacities of 44 mg/g and 115 mg/g for methylene blue and gelatin, respectively [91].

Photo of adsorbents: a pectin dry powder; b activated carbon & pectin; Electron microscopic images of the components of the composite enterosorbent; c pectin core and coal shell; d pectin; e activated carbon particle; f the proposed mechanism of binding metals by pectin metal adapted from [79]

In the study, the experimental group (n = 20) received the dietary supplement “Complex with pectin Liquid Charcoal” along with their regular treatment (1 sachet × 3 times a day, 1 h before meals). The control group received activated charcoal at a dose of 0.1 g/kg/day divided into 3 portions. Patients receiving “Complex with pectin Liquid Charcoal” experienced a 1.5-day (31.3%) shorter intoxication syndrome compared to those receiving activated charcoal (p < 0.001). Additionally, the duration of gastroenteritis syndrome in the experimental group was 0.5 days (15.4%) shorter than in the control group (p < 0.05). The “Complex with pectin Liquid Charcoal” supplement resulted in a 28% reduction in the total duration of the disease compared to the control group (3.6 ± 0.16 days vs. 5.0 ± 0.17 days) (p < 0.001). The dietary supplement showed high clinical efficacy in treating acute intestinal infections (AIIs) in adults [125].

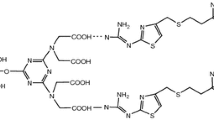

Thiolcontaining enterosorbents.

Dimercaprol, 2,3-dimercapto-1-propanol, or 1,2-dithioglycerol, is a heavy metal chelating agent belonging to organic compounds called alkylthiols forming highly stable chelates with heavy metals. It can be utilized for short-term therapy in patients with severe neurological disorders, as it can penetrate the blood–brain barrier. The most common side effects of the injection are nausea, vomiting, high blood pressure, and fast heart rate. Other possible side effects include headaches, weakness, muscle pain, watery eyes, increased saliva, burning sensations, runny nose, sweating, and restlessness. These side effects usually start soon after the injection and typically go away within 2 h. Succimer, or meso-2,3-dimercaptosuccinic acid (DMSA) is an oral chelating agent with a similar therapeutic and side effects action [88]. In order to reduce side effects of such active pharmaceutical ingredients it is needed to reduce ability to their adsorption in intestine. So, there are several approached of combination of widely used adsorbents with thiol groups. High doses of heavy metal salts (Cd, Sr, Cs, and Hg) cause significant abnormal changes in liver and kidney function in experimental animals, disrupting the regulatory function of these organs' enzymes. Administering the control drug Unithiol and an amphoteric synthetic cryogel suspension intragastrically one hour after poisoning with LD50 doses of these metals increased the animals' survival rate at 24 hours. Histopathological studies of the kidneys and liver showed significant improvement in the structure of internal organ tissues. Additionally, the biochemical blood markers of experimental animals treated with both enterosorbents, the cryogel and unithiol, improved compared to the positive control group, that was not treatmented [15].

Lingkai, Zhu, et al. studied the adsorption capacity of modified with thiol groups activated carbon fibers for Pb2+ removal and established that it is influenced by various factors, including time, pH, initial ion concentration, and adsorbent dosage. Remarkably, the maximum adsorption capacity (q max) determined was found to be 700 mg/g, indicating a high potential for efficient Pb2+ removal [100].

Julan Li et al. developed a preparation of a cost-effective one-pot synthesis method was used to create the thiolated magnetic silica composite (Fe3O4@SiO2-SH) that can be used for various toxic metal removal. The study showed that the adsorbent’s performance was influenced by pH, and the maximum gold adsorption capacity reached 15 mg/g under single saturated conditions [98]. Thiol-/thioether-functionalized porous organic polymers were employed as adsorbents, demonstrating a remarkable adsorption ability. The maximum adsorption capacity achieved for Hg(II) was 180 mg/g, while for aromatic pollutants (toluene and m-xylene as models), it ranged from 358 to 452 mg/g. Additionally, the binding kinetics for Hg(II) and aromatic pollutants were found to be acceptable and fast, respectively. These results highlight the promising potential of thiol-/thioether-functionalized porous organic polymers as effective adsorbents for the removal of Hg(II) and aromatic pollutants from various aqueous solutions [38]. It is known that functionalized with thiol groups materials displayed mucoadhesive properties, resembling the characteristics of thiol-containing polymers that have been extensively utilized in creating innovative drug formulations for transmucosal drug delivery [21]. Thiolated surface is beneficial for enterosorbents.

Velempini et al. utilized cysteamine as the ligand to complex with Hg(II), and it was grafted onto the carboxylated carboxymethyl cellulose polymer chain crosslinked with epichlorohydrin through an amide reaction. The adsorption capacity of the resulting material, thiol imprinted polymer (S-IIPs ) for Hg(II) was investigated using kinetic and isotherm models. A maximum adsorption capacity of 80 mg/g, indicating the high efficiency of S-IIPs in adsorbing Hg(II). Moreover, S-IIPs demonstrated a remarkable level of selectivity towards Hg(II) even in the presence of other metal ions such as Cu2+, Zn2+, Co2+, Pb2+, and Cd2+ [189].

Borsagli, F. G. with colleagues fabricated chitosan based cryogels that may be considered as efficient adsorbent not only for removal of heavy metals but also metal nanoparticle uptake. Some promising material based on N-acyl thiolated chitosan were utilised for rapid and efficient removal of methyl orange additionally illustrated antibacterial activity against Pseudomonas aeruginosa. Multi-functional eco-friendly 3D scaffolds has surface area of 10 m2/g and high adsorption capacity for methyl orange anionic dye pollutant of 434 ± 12.4 mg/g in water [24]. Carvalho et al. studied chitosan-based sponges produced through the freeze-dried process and functionalized with 11-mercaptoundecanoic acid (MUA) and the material was used as cationic adsorbents to remove anionic methyl orange (MO) dye from water. These sponges exhibited an impressive adsorption capacity for the MO dye, with a value of 388 mg/g. Moreover, excellent removal efficiency, achieving over 90% removal for MO solutions with concentrations ranging from 20 mg/L to 1200 mg/L was demonstrated. The results highlight the potential of these chitosan-based sponges as effective materials for the removal of MO dye from aqueous solutions [31]. Dinu, I.A. et al. obtained the cryogel based on CHI linked by glutaraldehyde, which demonstrated an impressive theoretical maximum adsorption capacity of 160.82 mg/g for the pesticide. Furthermore, these sponges were tested for their antibacterial properties against different bacterial pathogens. The material exhibited high rates of killing for Escherichia coli (around 82%), Listeria monocytogenes (100%), and Staphylococcus aureus (99%), showcasing their potential as effective antimicrobial agents [48].

World Health Organization (WHO) Guidelines for Drinking Water Quality [196] and China’s Hygienic Standard for Drinking Water for Domestic Purposes (GB5749–2022) have set the limit value of ClO4− at 0.07 mg/L. For Japan, ClO4− was determined 1–10 mg/L in tap water, meanwhile in India it can be 63–393 mg/L. A specific quaternized derivative of chitosan made of chitosan with betaine spheres (CGQS) was designed. Different factors affect the ability of a material called CGQS to remove perchlorate (a harmful chemical) from water. It was found that the amount of CGQS used, the acidity of the water, the initial amount of perchlorate, the temperature, and the presence of other chemicals all influenced how well CGQS removed perchlorate. Jin et al. in [81] investigated how the amount of perchlorate and the flow rate of water through a column of CGQS affected the removal process.

Quaternary amino-functionalized epichlorohydrin cross-linked chitosan fibers (QECFs) adsorbent preparation method were ascribed. QECFs revealed appropriate adsorption performance for diclofenac (DCF) via the pH range of 7–12. The calculated maximum adsorption capacity and the amount of adsorbed DCF per adsorption site were determined to be 987 ± 20 mg/g and 1.2 ± 0.2, respectively. Optimized design of quaternary amino-functionalized chitosan fibers for ultra-high diclofenac adsorption from aqueous solution was discussed [99].

Polymer-containing enterosorbents have been proposed for eliminating heavy metals from the body. Yasir with collaborators studied rice straw biochar (BC), chitosan-modified rice straw biochar (CT-BC), and thiol grafted chitosan-modified biochar (TH@CT-BC) in term of adsorption of ions. The maximum Cd adsorption at pH 5.5 with TH@CT-BC (261 mg/g) followed by CT-BC (103 mg/g) and BC (29 mg /g) [67].

In [126], Njuguna and Schönherr created hydrogels through the process of esterifying Xanthan gum with maleic anhydride. Subsequently, the polymeric chains were cross-linked the pendant vinyl groups using thiol-ene click chemistry with oligoethylene glycol dithiols. The hydrogel exhibited an impressive theoretical maximum adsorption capacity (qmax) of 502 mg/g (equivalent to 1.23 mmol/g) for Gentian Violet within a pH range of 8 to 9.

3-mercaptopropyltrimethoxysilane (3-MPTS) modified biochar (a type of charcoal) to remove mercury from the environment. It is already well known that adding thiol groups (containing sulfur) to biochar makes it very good at removing mercury, but this effect can be inconsistent. This study focused on understanding why this happens by looking at the chemical interactions between mercury and thiol-modified biochar.

It was discussed recently that the structure of the biochar influences how the thiol groups attach, how the thiol groups arrange themselves, and how much mercury can bind to the surface. This research provides valuable insights into designing more effective and stable biochar materials for removing mercury (Hg2+ and CH3Hg+) [75] can be considered as a potential enterosorbent.

Partially hydrolyzed polyacrylamide (PHPAm) and functionalized Fe3O4-coated magnetic nanoparticles (PHPAm/Fe3O4@SiO2-SH) have been shown to be efficient in removal of mercury and lead from aqueous solutions with maximum adsorption capacities of 256.41 and 227.27 (mg g−1) for Hg2+ and Pb2+, respectively [50].

Yang, Rui, et al. utilised a combination of oxidized cellulose nanofibers (CNF) incorporated into an electrospun polyacrylonitrile nanofibrous scaffold and then grafted with cysteine to enhance their adsorption capability for chromium (VI) and lead (II). The resulting thiol-modified cellulose nanofibers (m-CNF) exhibited high adsorption capacities for both Cr(VI) (87.5 mg/g) and Pb(II) (137.7 mg/g). This enhanced adsorption performance can be attributed to the large surface area of the nanofibers and the high concentration of thiol groups present (0.9 mmol of –SH/gram m-CNF). These findings suggest the potential of m-CNF as a promising adsorbent for the removal of Cr(VI) and Pb(II) from aqueous solutions [202].

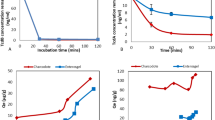

Qiu, Yue, et al. investigated Inactivated yeast-based biosorbents which can be beneficial for removing toxic contaminants. However, traditional yeast adsorbents have certain drawbacks, such as limited adsorption capacity in juice and challenges in separation. Five different chemical thiol-functionalization methods were employed to enhance the efficiency of yeast cells in adsorbing the contaminant PAT (preservative, propyl p-hydroxybenzoate) in apple juice (Fig. 4). Interestingly that glutaraldehyde cross-linked yeast significantly increase the thiol content of yeast cells to 1.26 mmol g − 1 and remarkably improved the PAT adsorption capacity of inactivated yeast in apple juice by 150 times [144].

Illustration of yeast modification with thiol groups and removal of contaminants from juice with permission from Elsielver [144]

Song, Yiheng with colleagues have developed a hyperbranched polyglycerol (HPG)-based multi-carboxylic magnetic gel (MMG) was synthesized using thiol-ene click chemistry. The resulting HPG-based MMG adsorbent possessed a porous structure and multiple carboxylic groups, enabling it to exhibit several advantageous properties. It showed a rapid adsorption rate, a high adsorption capacity, and selective adsorption towards cationic dyes, specifically methylene blue (MB) and methyl violet (MV). The adsorption capacity for MB reached as high as 458.7 mg/g, while for MV, it reached 400.0 mg/g [173].

A porous organic polymer (POP)-based adsorbent, denoted as 4AS-MBP, was synthesized using a Schiff-base reaction and thiol-ene addition between melamine, 4-allyloxy benzaldehyde, and ethanedithiol (EDT). The resulting mesoporous 4AS-MBP demonstrated an impressive maximum adsorption capacity of 312 mg/g for Hg(II). Ryu, Jihyeong, et al. revealed that the adsorption of Hg(II) onto the adsorbent occurred through monolayer chemisorption [152].

Yifan Li with colleagues developed a thiol-functionalized covalent organic framework (COF-S-SH) as an effective adsorbent for the simultaneous removal of BTEX (benzene, toluene, ethyl benzene, and xylenes) and Hg(II) ions from water. The adsorbent demonstrated excellent binding capacity, with maximum adsorption capacities (Qmax) ranging from 150 to 255 mg/g for BTEX and 588.2 mg/g for Hg(II). Moreover, it exhibited rapid adsorption kinetics, with rate constants of 0.01043 to 0.05002 g/mg/min for BTEX and 7.254 × 10 –4 g/mg/min for Hg(II) [97].

He, Yan, et al. successfully synthesized a triptycene-based porous organic polymer with abundant thiol groups (TPP-SH) through postmodification of a highly porous and robust triptycene-based porous organic polymer (TPP). The TPP-SH exhibited a high surface area and demonstrated efficient capture of cationic dyes, methylene blue (MB), and malachite green (MG). The adsorption capacities for MB and MG were found to be 1146.3 mg/g and 689.6 mg/g, respectively, surpassing the capacities of many previously reported materials. Furthermore, the adsorption rates for MB and MG were measured to be 0.0154 mg/g min and 6.69 × 10–4 mg/g min, respectively [68].

Huang, L. et al. developed synthesis of magnetic porous organic polymers (MOPs) containing plentiful thiol groups. The resulting MOP-SH demonstrated excellent thermal and chemical stability across a wide pH range (pH 2 to 13). Moreover, it exhibited remarkable adsorption capabilities for Hg(II) over a wide pH range [73].

Thiol-functionalized mesoporous silica has been successfully prepared through the synthesis of SBA-15 mesoporous silica with a high specific surface area (> 900 m2/ g). Additionally, 0.3 mmol/g of glutathione was introduced, resulting in a material capable of multi-site adsorption involving thiol and carboxylic groups. This thiol-functionalized material exhibited an impressive adsorption capacity of 1.04 mmol/g, making it a highly promising candidate for the removal of cadmium [64]. OXPESH (oxidized polyethylene functionalized with thiol groups), based on commercially used OXPE (oxidized polyethylene) for possible uses in the removal of heavy metals. Thiol-based oxidized polyethylene was successfully obtained by the esterification process was utilized as possible adsorbent for the removal of metal Ag+ > Cr3+ > Pb2+ > Al3+ > Cd2+ > Ni2+ > Cu2+ from aqueous solutions [89].

The adsorbent, prepared using the functional precursor (3-mercaptopropyltrimethoxysilane) and the cross-linking agent (tetraethoxysilane), is an organo-ceramic material. This adsorbent exhibit impressive uptake capacities for cadmium and mercury ions, with values of 222 mg/g and 1284 mg/g, respectively [94]. At the moment metal-organic framework (MOF) based materials can be expensive to be used as enteriadsorbents. Gao with colleagues investigated thiol-containing mercaptoacetic acid (MA) as the template, MOF adsorbent, Zr-MSA-MA (MSA, mercaptosuccinic acid). Unlike other carbonic acids such as acetic acid and formic acid, MA benefits to maintain high-content binding sites. Zr-MSA-MA illustrated an adsorption capacity of 715 mg g−1 for Hg2+ and rapid adsorption kinetics, compare to other MOF-based adsorbents [60].

Thiol-modified silica nanoparticles were introduced into poly(vinyl alcohol) and poly(acrylic acid) hybrid nanofibers to create an environmentally friendly adsorbent. This adsorbent demonstrated an impressive maximum adsorption capacity of 125.47 mg/g for Cu(II). The results showcase the potential of this eco-friendly adsorbent for effective removal of Cu(II) from aqueous solutions [87].

2 Conclusion and future perspectives

Oral adsorbents have emerged as a promising therapeutic option for the removal of toxic substances from the gastrointestinal tract. The properties of oral adsorbents, including their structure and mechanism of action, play a crucial role in their effectiveness and selectivity. The different types of oral adsorbents, such as activated charcoal, lignin, zeolite composites, medical clays, silica-based adsorbents, and dietary fibers, exhibit distinct physicochemical properties that influence their adsorption capacity and selectivity. The mechanisms of action of oral adsorbents involve physical adsorption, ion exchange, and specific binding interactions, which contribute to their ability to remove a wide range of toxic substances. Thio derivative adsorbents beside the excellent adsorption properties for toxic contaminants has good mucoadhasive properties, allowing slow movement via the gastrointestinal tract and therefore providing most efficient activity. However, the efficacy and safety of oral adsorbents require further investigation, particularly in clinical settings. Future research should focus on optimizing the properties of oral adsorbents, such as their selectivity, stability, and biocompatibility, to enhance their therapeutic potential. Overall, the properties of oral adsorbents make them a promising tool for the removal of toxic substances from the gastrointestinal tract, with potential applications in the treatment of various health conditions.

Data availability

Not applicable.

References

Abeyratna, S., Jayasundera, A.: Adsorption of Heavy Metals on Na-Montmorillonite: Effect of pH and Adsorbent Dosage. Proceedings of Eighth International Conference of Sabaragamuwa University of Sri Lanka (2021)

Abu-Jdayil, B., Ghannam, M.: The modification of Rheological properties of sodium bentonite-water dispersions with low viscosity CMC polymer effect. Energy Sources Part. Recover. Util. Environ. Eff. (2014). https://doi.org/10.1080/15567036.2010.551260

Abuzalat, O., Wong, D., Elsayed, M.A.: Nano-porous composites of activated carbon–metal organic frameworks (Fe-BDC@AC) for rapid removal of cr (VI): Synthesis, adsorption, mechanism, and kinetics studies. J. Inorg. Organomet. Polym. Mater. (2022). https://doi.org/10.1007/s10904-022-02237-9

Aguirre-Cruz, G., Legorreta-Garcia, F., Aguirre-Cruz, G., Stanciu, L., Aguirre-Alvarez, G.: Synthesis of hierarchical silica zeolites for heterogenous catalysis and adsorption. Microporous Mesoporous Mater. (2022). https://doi.org/10.1016/j.micromeso.2022.112274

Ahmadi, M., Kalinin, I., Tomchuk, V.: Removal of heavy metals using sorbents and biochemical indexes in rats. Ukr. J. Vet. Sci. 14(4) (2023). https://doi.org/10.31548/veterinary4.2023.09

Ahmed, A.S., Alsultan, M., Sabah, A.A., Swiegers, G.F.: Carbon dioxide adsorption by a high-surface-area activated charcoal. J. Compos. Sci. 7(5), 179 (2023). https://doi.org/10.3390/jcs7050179

Al-Hammood, A.A., Frayyeh, Q.J., Abbas, W.A.: Raw bentonite as supplementary cementitious material – a review. J. Phys. Conf. Ser. (2021). https://doi.org/10.1088/1742-6596/1795/1/012018

Alexander, J.A., Ahmad Zaini, M.A., Surajudeen, A., Aliyu, E.-N.U., Omeiza, A.U.: Surface modification of low-cost bentonite adsorbents—A review. Part. Sci. Technol. (2019). https://doi.org/10.1080/02726351.2018.1438548

Alexeeva, A.A.: Enterosorbents as a part of complex therapy of atopic dermatitis. Curr. Pediatr. 11(2), 151–154 (2012)

ALOthman, Z.A.: A Review: Fundamental Aspects of Silicate Mesoporous Materials. Materials (2012). https://doi.org/10.3390/ma5122874

Alvear-Daza, J.J., Rengifo-Herrera, J.A., Pizzio, L.R.: Performance and optimization of diclofenac and ibuprofen adsorption onto activated carbon synthesized from sunflower seed shell (Helianthus annuus) in natural groundwater samples. Adsorption 1–18 (2024)

Arakelyan, L.A., Kamentseva, P.G., Mashakova, A.D., Kolesnichenko, V.V., Karoli, I.I., Voropaev, V.V.: Preparation of a new enterosorbent bentorb and determination of its toxicological properties. Pharmacophore 15(2–2024), 105–112 (2024). https://doi.org/10.51847/d4HrIDWggY

Atmanto, D., Ambarwati, N.S.S.: Application of Activated Charcoal from Coconut Shell Waste for the Manufacture of Skin Lightening Creams and the Mechanism of the Process. The 2nd Science and Mathematics International ConferenceSMIC (2020). https://doi.org/10.1063/5.0044371

Babahoum, N., Ould Hamou, M.: Characterization and purification of Algerian natural bentonite for pharmaceutical and cosmetic applications. BMC Chem. (2021). https://doi.org/10.1186/s13065-021-00776-9

Baimenov, A.Z., Fakhradiyev, I.R., Berillo, D.A., Saliev, T., Mikhalovsky, S.V., Nurgozhin, T.S., Inglezakis, V.J.: Synthetic amphoteric cryogels as an antidote against acute heavy metal poisoning. Molecules 26(24), 7601 (2021)

Bakar, A.A.A., Razak, N.F., Akbar, N.A., Daud, N.M., Ali, K.A.M.: Removal of cr (III) from industrial wastewater using coconut shell carbon and limestone as adsorbent. Earth Environ. Sci. (2021). https://doi.org/10.1088/1755-1315/646/1/012063

Beamlaku, A., Habtemariam, T.: Soil colloids, types and their properties: A review. Open. J. Bioinforma Biostat (2021). https://doi.org/10.17352/ojbb.000010

Bedia, J., Peñas-Garzón, M., Gómez-Avilés, A., Rodriguez, J.J., Belver, C.: Review on activated carbons by chemical activation with FeCl3. C — J. Carbon Res. (2020). https://doi.org/10.3390/c6020021

Beňo, J., Vontorová, J., Matějka, V.: Evaluation of the thermal resistance of selected bentonite binders. Mater. Tehnol. 49, 465–469 (2015)

Bergaya, F., Lagaly, G.: Introduction to clay science. Developments in Clay Science. Elsevier (2013)

Bernkop-Schnürch: Andreas: Thiomers: a new generation of mucoadhesive polymers. Advanced Drug Delivery Reviews (2005). https://doi.org/10.1016/j.addr.2005.07.002

Bertran, X., Chollon, G., Dentzer, J., Gadiou, R., Fouquet, S., Dourges, M.-A., Rebillat, F.: Oxidation behavior at moderate temperature under dry and wet air of phenolic resin-derived carbon. Thermochim. Acta (2017). https://doi.org/10.1016/j.tca.2016.12.013