Abstract

Chromatographic separation of prebiotic oligosaccharides, galacto-oligosaccharides from a typical post-reaction mixture containing unreacted substrate lactose and by-products glucose and galactose was investigated. A commercial cation-exchange resin Dowex 50WX4 was chosen as a prospective preparative-scale adsorbent and separation performance of its four ionic forms, H+, Na+, K+ and Ca2+, was tested. Since adsorption equilibrium isotherms were linear within the entire investigated range of concentrations, they were determined by pulse experiments for all saccharides present in a typical post reaction mixture including tri- and tetragalacto-oligosaccharides. From the four counter ions listed above, hydrogen offered the best selectivity and column performance. The selected H+-form of the cation exchanger was further investigated by means of frontal analysis where high ionic strength and elevated viscosity appear and can play a substantial role. Breakthrough curves were measured for monosaccharides, lactose, glucose–lactose mixture and a multicomponent commercial mixture of galacto-oligosaccharides, Vivinal® GOS. The breakthrough curves were successfully described by the dispersive plug flow model with linear driving force approximation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Galacto-oligosaccharides (GOS), also referred as TOS—trans-galactooligosaccharides, are a class of oligomeric saccharides built of galactose. Galactosyl units are linked by β-type glycosidic bonds with glucose (in most cases) at the reducing end where the degree of polymerization (DP) ranges from 2 to 8 (Hernández et al. 2009; Coulier et al. 2009). GOS are claimed to have prebiotic effect; moreover, they are non-cariogenic and low caloric what makes them a versatile functional food additive.

Galacto-oligosaccharides are one of the most commonly manufactured prebiotic oligosaccharides in the world (Cho and Finocchiaro 2009). According to a Global Industry Analysts market report, prebiotics market will reach value of $1.17 billion in EU in 2015. Therefore, the demand for a pure added-value product is high. Due to the nature of the transgalactosylation enzymatic reaction of GOS synthesis, the post-reaction mixture contains a significant amount of unreacted lactose and by-products glucose and galactose. The composition of this mixture is strongly dependent on several factors such as the source of enzyme and reaction conditions, especially temperature and concentration of lactose. Tri- and tetra-oligosaccharides are the most abundant GOS in these mixtures, while higher oligomer account only for a small percentage (Vera et al. 2012).

Several approaches to oligosaccharide separation can be found in literature. The use of zeolites, activated charcoals and membrane ultrafiltration techniques belong to the most frequently mentioned ones. Nonetheless, it was proven in the last 30 years that ion exchange resins based on poly (styrene–divinylbenzene) supports offer the greatest potential for separation of carbohydrates. The polymeric matrices of these resins exhibit resistance to various influences (Tiihonen et al. 2005). A counter-ion associated by functional groups with the resin play a substantial role and its proper choice can significantly improve the separation of saccharides (Goulding 1975). The influence of adsorbent ionic form on the adsorption behaviour of oligosaccharides was investigated by some authors (Moravčík et al. 2012; Rabelo et al. 2012; Pedruzzi et al. 2008). The most often exploited ions are Na+, Ca2+, K+, Pb2+, H+, Ag+, Li+ but some of them, due to their toxic nature, are for analytical purposes only (Martinsson and Samuelson 1970; Nobre et al. 2009; Antošová et al. 1999). Although the adsorbents used in GOS separations are cation exchangers, the underlying interaction mechanism is not typical ion-exchange. In fact, size-exclusion is the separation-governing phenomenon for the saccharides of different chain length. Separation of carbohydrates of the same chain length such as glucose and galactose is of much more complex nature. Adsorption behaviour is influenced by ion-exchange, electrostatic repulsion or attraction, hydrophobic interactions, steric hindrance and van der Waals forces among others (Brereton and Green 2012). This complex mechanism between a natural carbohydrate and ions electrostatically immobilized on a resin is sometimes called ligand exchange chromatography (Stefansson and Westerlund 1996).

Last decades showed that the simulated moving bed (SMB) technology has a great potential not only in petrochemical industry but also in demanding separations in the pharmaceutical and biotechnological fields. When well designed and implemented, it can outperform classic chromatography process in terms of productivity, purity and product dilution (Rajendran et al. 2009). To design SMB separation of GOS from remaining non-prebiotic carbohydrates present in the mixture, the choice of resin ionic form and accurate determination of adsorption equilibrium isotherms is of great importance. Therefore, they became the main focus of the present work.

Adsorption equilibrium isotherms of many saccharides on polystyrene resins crosslinked with divinylbenzene were measured (Laatikainen et al. 2011; Vaňková et al. 2010a; Pedruzzi et al. 2008), but none of them included individual galacto-oligosaccharides—galactotriose and galactotetraose. The comprehensive work presented here shows the influence of counter ion on the adsorption of five saccharides: glucose, lactose, galactose, galactotriose, and galactotetraose. Knowing that saccharides exhibit a linear shape of isotherms till high concentrations, a sample-saving and relatively quick, preparative pulse method was chosen to determine the sorption behaviour (Chilamkurthi et al. 2012; Rabelo et al. 2012).

Selectivity and capacity are two key parameters for the assessment of the suitability of a resin. Having adsorption data collected, we chose the selectivity between galactotriose and lactose to be the decisive parameter. The hydrogen form of the ion exchanger was selected for further investigations. Breakthrough curves measurement is a common method to provide experimental data for modelling of chromatographic processes (Vente et al. 2005). A study of adsorption by frontal analysis for the selected hydrogen form of the ion exchanger encompassed three single-component solutions (galactose, glucose, lactose), one binary (glucose–lactose) and one multicomponent mixture containing GOS as well as non-prebiotic saccharides. The dispersive plug flow model was used to describe adsorption kinetics in the liquid phase, while mass transfer kinetics in solid was represented by the well-known linear driving force (LDF) approximation. This approach proved its suitability for the description of adsorption experimental data obtained for saccharides on PS-DVB resins (Otero et al. 2005; Luz et al. 2008). Equilibrium concentrations as well as mass transfer coefficients were determined and incorporated into the model in order to predict the separation performance.

2 Experimental

2.1 Chemicals

Glucose (monohydrate), lactose (monohydrate) and galactose were obtained from Sigma-Aldrich (Germany); α1-3, β1-4 galactotriose (GOS3) and α1-3, β1-4, α1-3 galactotetraose (GOS4) were purchased from Dextra (United Kingdom). A standard of galactopentaose (GOS5) was not available. It was identified on the basis of retention time and molar refractivity derived from its values for the lower GOS oligomers. Vivinal® GOS syrup was kindly provided by FrieslandCampina (Netherlands). It contained 75 % of dry matter. The amount of saccharides in the dry matter was assayed by the AOAC 2001.02 method which provided the following values: total galacto-oligosaccharides—60 %, lactose anhydrous—19 %, glucose anhydrous—21 %, and galactose 1.4 %. Water used throughout entire work, also as mobile phase during preparative experiments, was ultrapure (18.2 MΩ cm), filtered through GHP 0.45 filter and degassed. Bed voidage was measured by pulse injections of Blue Dextran solution (Sigma-Aldrich, Germany) with the concentration of 2 g/L and injection volume of 100 μL.

2.2 Materials

Preparative jacketed glass columns Superformance, ID 26 mm, (Goetec, Germany) were used and maintained at 25 °C using a thermostatic water bath. The columns were equipped with dispersion filters Superformance Merck (model F). The outlet solution from the preparative and an analytical column was monitored by a refractive index detector Gilson 131 (France).

To analyze binary and multicomponent solutions, an analytical column Transgenomic ICSep ION-300 (7.8 × 300 mm, H+ form) was used. 0.04 M solution H2SO4 was used as a mobile phase. The HPLC analytical column was placed into a JetStream II Plus oven (WO Industrial Electronics, Austria) to control the temperature at 70 °C. A Smartline Pump 1000 (Knauer, Germany) was employed when the volumetric flow rate of mobile phase was 4.97 ± 0.02 mL/min for the preparative column, and—0.40 mL/min for the analytical column.

Dowex 50WX4-400 is a strong cation exchange resin (copolymer of styrene and divinylbenzene) with 4 % cross-linking and particle diameter ranging from 0.037 to 0.075 mm. Ionic forms of the resin were changed according to the procedure described in Ref. (Rabelo et al. 2012). Resin particles were packed into a preparative column according to the well-known slurry-packing procedure. Bed lengths of H+, Na+, K+ and Ca2+-forms were 11.0, 8.9, 9.4, 11.7 cm, respectively. Basic characteristics of each bed (in terms of bed voidage and solid to liquid phase ratio) for respective ionic form can be found in Table 3 in Sect. 4.1.

2.3 Pulse experiments

During determination of single component adsorption equilibrium isotherms by preparative pulse experiments the injection volume was 100 μL. Injections were made at least in duplicate. The concentration range of particular saccharide was set to reflect its typical content in the post-reaction mixture. The feed concentration ranges were as follows:

-

galactose (Gal): 5–30 g/L,

-

glucose (Glc): 20–100 g/L,

-

lactose (Lac): 20–200 g/L,

-

α1-3, β1-4 galactotriose (GOS3): 10–50 g/L,

-

α1-3, β1-4, α1-3 galactotetraose (GOS4): 7.5–25 g/L.

The first statistical moments were used to obtain retention times, tR, for each pulse experiment [Eq. (1)].

The obtained retention times of all saccharides were independent of feed concentration. Therefore adsorption equilibrium constants (distribution coefficients), K i , of linear isotherm were proportional to the retention times and calculated from the following equation:

where \( \varepsilon \) is the bed voidage, \( K_{i} \) is the distribution coefficient of the component i, \( V_{C} \) is the bed volume and Q is the volumetric flow rate.

2.4 Fixed bed experiments

In the case of single-component breakthrough curves, applied feed concentrations ranges were as follows:

-

glucose: 30, 70, and 100 g/L,

-

lactose: 40, 120, and 200 g/L,

-

galactose: 2, 4, and 6 g/L.

The galactose concentration at the column outlet was measured online by the RI detector, whereas, for other saccharides, column outlet samples were collected at fixed time intervals. They were diluted with water and were analyzed in the analytical column. For breakthrough experiments with the binary glucose–lactose mixture, the concentrations of these saccharides in the consecutive steps were increased in the same way as in the single-component breakthrough experiments. Therefore, the total saccharide concentration in the final step reached a high value—300 g/L.

The GOS syrup, was diluted to the total saccharide concentration of 201.7 g/L for the use in breakthrough experiments. The chosen concentration guaranteed that the concentrations of all saccharides contained were within the range investigated previously for the single- and bi-component mixtures. At this concentration, the density and viscosity were elevated, which simulated well industrial separation conditions. For glucose and lactose solutions at concentration of 200 g/L density and dynamic viscosity equal 1.074 g/L and 0.00162 Pa.s, respectively. Similar values might be expected for discussed GOS mixture.

3 Mathematical model

A dispersive plug flow model has been used to fit the experimental elution profiles and breakthrough curves of individual saccharides. Several assumptions included in this model are: isothermal adsorption, axial dispersion flow, constant flow rate, constant bed voidage in the axial direction and no radial gradients within the bed. The mass balance equation can be cast as:

where \( C_{i} \) and \( \bar{q}_{i} \) are the liquid-phase and average adsorbed solid-phase concentrations of the ith species, respectively; \( u_{int} \) is the interstitial velocity, D a is the axial dispersion coefficient; the variables t and z refer to the time and axial coordinates, respectively.

The boundary conditions were defined as follows:

And initial conditions:

Solid-phase mass transfer was described by the LDF approximation which can be written as:

where \( k_{h,i} \) is the mass-transfer coefficient for a homogeneous particle and \( q_{i}^{*} \) is the equilibrium solid phase concentration of the component i derived from the linear adsorption isotherm:

where K i is the adsorption constant (distribution coefficient) of the i-th saccharide.

The LDF approximation presented above assumes spherical homogeneous particles and for most gel-type resins, this assumption is valid. The mass transfer coefficient \( k_{h,i} \) was calculated according to Glueckauf equation (Glueckauf and Coates 1947):

where D m is here the molecular diffusivity and R p is the average radius of resin particles (0.056 mm); \( \varepsilon_{p} \)is the particle porosity; \( \tau \) is the tortuosity factor. The ratio \( \frac{{\varepsilon_{p} }}{\tau } \) for cation exchange gel type resin was taken from literature (Vaňková et al. 2010b).

The values of D m for galactose, glucose and lactose were taken from literature (Lee et al. 2004; Bensley 1946; Dembczynski and Jankowski 2000). Since these data for GOS were unavailable, they were estimated on the basis of the extrapolation of the dependence between the known values of diffusion coefficients and molecular weights of glucose and lactose. The calculated values of the transport parameters are presented in Table 1.

The axial dispersion coefficient was calculated from the equation:

where \( u_{int} \) is the interstitial velocity and Pe is the Peclet number calculated as follows:

In Eq. (12), t 0 and \( \sigma^{2} \) are the retention time and variance [Eq. (13)] of an unretained tracer (Blue Dextran).

The Peclet number obtained in this way for the flow rate of 5 mL/min was equal to 250.

The model equations were solved numerically using the gPROMS-general Process Modelling System version: 3.5.3. The mathematical model involves a system of partial and algebraic equations. The axial domain was discretized using third order orthogonal collocation in finite elements method, using twenty finite elements with two collocation points in each element. The system of ordinary differential and algebraic equations was integrated over time using the DASOLV integrator implementation in gPROMS.

4 Results and discussion

4.1 Selection of adsorbent ionic form

Preparative pulse experiments provided comprehensive data about adsorption of five investigated carbohydrates at 25 °C. Dowex 50WX4-400 is a resin of a very fine mesh size therefore elevated back pressure could be expected at the working flow rate of 5 mL/min. It however ranged only from about 1 bar up to 2 bars, for the potassium form. Taking into account the contribution of the tubing and fittings to the overall backpressure, it can be concluded that this resin, despite of its very small particle size, seems to be suitable for preparative, high throughput purposes.

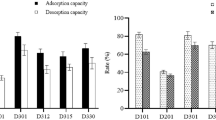

Distribution coefficients K i were calculated from Eq. (2) for three–four different feed concentrations. Their values for each saccharide did not change with the concentration what confirmed the linearity of adsorption isotherms. Table 2 presents the values of these adsorption equilibrium constants and their corresponding standard errors. Linearity of adsorption isotherm of monosaccharides and disaccharides could be expected for this kind of adsorbent and conditions. This work extended the existing knowledge by that higher saccharides, such as galactose oligomers, galactotriose and galactotetraose, are also linearly adsorbed.

The order of elution of investigated carbohydrates, Gal < Glc < Lac < GOS3 < GOS4, is linked with their molecular weight. With the increasing value of molar mass, the distribution coefficient decreased regardless of the adsorbent ionic form. As other researchers reported, the size-exclusion plays here a governing role since the pore size is close to the sizes of separated molecules (Vaňková et al. 2010b; Rabelo et al. 2012). More attention deserves the comparison of elution of glucose and galactose—saccharides of the same molar mass and nearly identical structure but exhibiting different affinity to the adsorbents. The only structural difference between them is the orientation of hydroxyl group at C #4. One possible elucidation could lie in a higher affinity of galactose to so called unfreezable pore water compared to glucose which preferably partitions to unbound freezable pore water (Vaňková et al. 2010b).

Another reason could be conformational dissimilarity in hydroxyl groups arrangement favouring complexation of galactose over glucose. Nonetheless, the deprotonation of −OH group is low at the pH close to neutral so the ability of these groups to substitute water molecules hydrating metal ion is poor which results in unstable, weak complexes (Gyurcsik and Nagy 2000). The distinction between the adsorption affinities of glucose and galactose is emphasized in the case of the calcium form of the ion exchanger. The selectivity \( \alpha_{Gal/Glc} \) reached a value of 1.27, which was more than 10 % higher than this selectivity for the Na+ form (the lowest). One may assume that bidentate interactions enabled by bivalent calcium ions are strongly favourable for spatial hydroxyl orientation to fulfill axial–equatorial–axial rule and to form a more stable complex (Gyurcsik and Nagy 2000; Whitfield et al. 1993). Distinct interactions take place in the case of adsorbent H+-form and saccharides. In this particular instance, interactions between the sulfonic acid functional group of the resin and positively charged hydrogen of the −OH group may create weak hydrogen bonds (Pedruzzi et al. 2008).

Table 2 further presents the influence of ionic form of the resin on the sorption capacity. For monovalent cations, the sorption capacity seems to be proportional to the cation radius. The highest affinity was observed for the potassium form, in agreement with observations of other researchers (Vente 2004; Nobre et al. 2009; Rabelo et al. 2012). The lower capacity for the Ca2+-form compared to that of the K+-form confirms the observation of Vente that monovalent ions offer higher sorption capacity than divalent ones (Vente 2004). The potential of the potassium form to yield such high capacity may be explained in at least two ways. Relatively high affinity between the potassium ion and a saccharide molecule can be elucidated by marked electrostatic interactions of the positively charged large ion and free electrons of hydroxyl groups of saccharides.

Another explanation can be based on the hydration number of the cation. In comparison to Na+ and Ca2+, K+ is characterized by the lowest hydration number. It means that the amount of unbound water in the pores is the biggest what favours partitioning of saccharides into the pores (Glueckauf and Kitt 1955). Discussing the influence of ionic form on the sorption capacity, the ratio of solid to liquid phase must also be taken into account (Table 3).

It is a well-known property of ion-exchange resins to swell or shrink when a counter-ion is being changed. Table 3 presents the changes of bed voidage and respective values of phase ratios, \( F = \frac{1 - \in }{\varepsilon } \). For smaller molecules such as glucose or galactose, a clear dependence between the phase ratio and sorption capacity is expected. The expected trend was partly confirmed. Table 2 shows that the lowest sorption capacity was determined for the hydrogen form (F = 2.17). It was higher for the calcium form (F = 2.46) and reached the highest values for the alkali cation forms (F = 2.64 and 2.89). Surprisingly, the highest capacity was observed for the potassium form even though the sodium form bed had a higher phase ratio. This observation emphasizes the complexity of distribution of saccharides between liquid and cation-exchange solid phase discussed above. No straightforward predictions are possible.

Table 3 further displays two crucial parameters that were taken as decisive factors for the selection of ionic form for a deeper study: selectivity and bed efficiency. Considering the use of SMB chromatography in further process development, such an ionic form should be selected which deals best with the separation of galactotriose from lactose in order to collect non-prebiotic saccharides in one stream (extract) and prebiotic GOS in another one (raffinate). For that reason, the selectivity between these two key saccharides was chosen as the decisive parameter. The H+-form of the adsorbent provided a value of \( \alpha_{GOS3/Lac} \) = 1.419 which was by 6–8 % higher than those for the other ionic forms of the adsorbent.

Table 3 shows that, regarding the bed efficiency expressed by the number of theoretical plates for glucose N Glc, each bed surpassed the threshold value of 30 suggested by Juza as a minimum for industrial application to an SMB system (Juza 1999). The hydrogen ionic form of the adsorbent proved its superiority over the other ionic forms in this parameter too. Concluding, the H+-form was designated as the best candidate for separation of prebiotic galacto-oligosaccharides from non-prebiotic saccharides what concedes research of authors dealing with other oligosaccharides (Rabelo et al. 2012; Moravčík et al. 2012).

4.2 Performance of adsorbent hydrogen ionic form

The selected H+-form was subjected to further investigations. A dynamic model was built that incorporated the values of distribution coefficient K i obtained by preparative pulse experiments of single-component solutions presented in Sect. 4.1 In order to validate the model for real separations, several mixtures were tested.

The first step in the validation of the proposed model described in Sect. 3 was to fit the elution profiles of single-component saccharide solutions. Both the output concentration from the model in gProms and the signal from RI detector were normalized through a residence time distribution function E(t):

Figure 1a–c depicts a very good agreement between the experimental and simulated elution profiles for a monosaccharide (glucose), disaccharide (lactose) and galacto-oligosaccharide (galactotetraose). A similarly good match was achieved for galactose and galactotriose elution profiles, which are not shown for brevity.

Breakthrough curves were measured in two ways, step series (GOS syrup) and staircase method (monosaccharides and lactose solutions). The feed concentration of individual carbohydrates during the pulse experiment and breakthrough curves measurements covered the same range, in order to maintain adsorption constants validity. Continuous bed saturation with highly concentrated solution provides useful insight into bed capability to deal with high osmotic pressure and elevated viscosity.

Single-component breakthrough curves are shown in Fig. 2. The proposed model with the used parameters fitted the experimental data very well throughout the entire concentration range for all saccharides but lactose in third saturation step. Here, the true adsorbed amount of lactose was a few per cent lower than the value predicted from the linear isotherm obtained from the pulse experiments. This implies a slightly concave character of the isotherm at the concentrations approaching 200 g/L. Breakthrough curves of lactose-glucose binary mixtures were measured so that the concentrations of single saccharides in individual steps were the same as in the single-component experiments (Fig. 3). A small bed shrinkage by about 1 % was observed in the third step when the resin was exposed to a highly concentrated solution with the total saccharide concentration of 300 g/L. This change was taken into account in the mathematical model. The experimental data were reproduced by the model with a fair accuracy as shown in Fig. 3.

It may look surprising at the first glance that the model worked so well with the concentration-independent parameters. Parametric sensitivity simulations showed that the breakthrough curve broadening was controlled solely by axial dispersion when mass transfer resistance effect was almost negligible. This observation can be supported by the results of a previous study where an industrial-grade ion exchanger was used for the characterization of adsorption kinetics of fructooligosaccharides (Vaňková et al. 2010b). The analysis of adsorption zone broadening effects showed that the contribution of mass transfer resistance was from 15 to 60 %. The particle mean size of the industrial-grade ion exchanger was however about fivefold larger than the particle mean size of the resin used in this study. As follows from Eq. (9), the corresponding mass transfer coefficient values for the adsorbent used in this study should be about 25 times lower.

This explanation must be completed by that why the saccharide concentration did not affect axial dispersion coefficient either. The superficial velocity had the value of 1.6 × 10−4 m/s so the order of magnitude of the Reynolds number values for different saccharide types and concentrations was 10−2. At such low Reynolds number values, the Péclet number becomes essentially constant and independent of the density and viscosity of the solutions (Vaňková et al. 2010b). For a specific fixed-bed, the axial dispersion coefficient is only a function of the flow velocity.

Again, the extrapolation of equilibrium data from the pulse experiments, in which the outlet concentrations were only several g/L, was successful up to the concentration of 200 g/L. In the last step, the adsorbed amounts of both lactose and glucose were overestimated by the model at the total feed concentration of 300 g/L.

It can thus be concluded that preparative pulse experiments of single-component solutions provided reliable values of adsorption isotherm parameters of saccharides on cation exchange resins till moderately high concentrations. The application of this material-saving method was essential for tri- and tetraoligosaccharides which are too expensive to be used in breakthrough experiments.

Figure 4 presents the breakthrough curves of individual saccharides for one of the duplicated runs when the GOS syrup was fed into the bed formed by the H+-form of the resin. Considering the complex composition of the mixture, the model fits can be considered quite satisfactory. All simulated breakthrough curves have the same shape as the corresponding experimental ones but they are slightly shifted to shorter breakthrough times. This implies that the model predicted the dispersion phenomena very well but the deviation is in the equilibrium data. The experimental adsorbed amounts were for each saccharide approximately 10 % larger than the model ones. Only few authors dealt with multi-component adsorption of saccharides on this type of resin. They noticed competitive and cooperative effects depending on the type of saccharides, their concentrations or mutual ratio but the behaviour described above has not been observed (Chilamkurthi et al. 2012; Nowak et al. 2007; Vaňková et al. 2010a; Gramblička and Polakovič 2007). Its unequivocal explanation is not easy because the complete specification of this commercial syrup is unknown. The equilibrium may have been influenced by the presence of small amounts of citric acid, which is added as a preservative, and milk proteins.

5 Conclusions

A simple but reliable preparative pulse method was used to determine adsorption isotherms of all major saccharides contained in a post-reaction mixture of GOS: galactose, glucose, lactose, galactotriose and galactotetraose. From the four investigated adsorbents differing by the counter ions (H+, Na+, K+ and Ca2+), the hydrogen ionic form of a strong cation exchanger manifested the best selectivity for the two key saccharides, galactotriose and lactose, as well as the best bed efficiency expressed by the number of theoretical plates.

A multitude of breakthrough curves was measured for the selected H+-form of the resin. They were fitted with the axial dispersive flow model with the LDF approximation incorporated into the software gProms. The values of the model crucial parameter—adsorption equilibrium constant—were adopted from the pulse experiments in order to examine their validity for adsorption of binary and multicomponent mixtures at overloading conditions. In general, a very good agreement between experimental and simulated data was achieved. This proved the reliability of preparative pulse methodology in providing accurate data on adsorption isotherms of the saccharides for the type of adsorbent investigated. The validated model can be a useful tool for a future design and optimization of SMB separation of these prebiotic galacto-oligosaccharides from remaining non-prebiotic saccharides.

Abbreviations

- C 0,i :

-

Equilibrium liquid phase concentration component i (kg m−3)

- D a :

-

Axial dispersion coefficient (m2 s−1)

- D m,i :

-

Molecular diffusivity (m2 s−1)

- F :

-

Solid-liquid phase ratio (–)

- k h,i :

-

Mass transfer coefficients for the homogeneous particle (s−1)

- K i :

-

Adsorption equilibrium constant of component i (–)

- L :

-

Bed length (m)

- N i :

-

Plate number of component i (–)

- Pe :

-

Peclet number (–)

- Q :

-

Volumetric flow rate (m3 s−1)

- \( \bar{q}_{i} \) :

-

Average adsorbed solid-phase concentrations of the component i (kg m−3)

- \( q_{i}^{*} \) :

-

Equilibrium solid phase concentration

- R p :

-

Particle radius (m)

- t R :

-

Retention time (first statistical moment of peak) (s)

- t 0 :

-

Retention time of unretained tracer (s)

- u int :

-

Interstitial velocity (m s−1)

- V C :

-

Bed volume (m3)

- z :

-

Axial coordinate (m)

- α:

-

Selectivity (–)

- ε:

-

Bed voidage (–)

- σ2 :

-

Variance (s2)

- τ:

-

Tortuosity (–)

- Gal:

-

Galactose

- Glc:

-

Glucose

- Lac:

-

Lactose

- GOS3:

-

Galactotriose

- GOS4:

-

Galactotetraose

- GOS5:

-

Galactopentaose

References

Antošová, M., Polakovič, M., Báleš, V.: Separation of fructooligosaccharides on a cation-exchange HPLC column in silver form with refractometric detection. Biotechnol. Tech. 13, 889–892 (1999)

Bensley, R.R.: Physical chemistry of cells and tissues, Philadelphia and Toronto. Anat. Rec. 95, 75–76 (1946)

Brereton, K.R., Green, D.B.: Isolation of saccharides in dairy and soy products by solid-phase extraction coupled with analysis by ligand-exchange chromatography. Talanta 100, 384–390 (2012)

Chilamkurthi, S., Willemsen, J.H., van der Wielen, L.A.M., Poiesz, E., Ottens, M.: High-throughput determination of adsorption equilibria for chromatographic oligosaccharide separations. J. Chromatogr. A 1239, 22–34 (2012)

Cho, S.S., Finocchiaro, T.: Handbook of prebiotics and probiotics ingredients: health benefits and food applications. CRC Press. (2009)

Coulier, L., Timmermans, J., Bas, R., van den Dool, R., Haaksman, I., Klarenbeek, B., Slaghek, T., van Dongen, W.: In-depth characterization of prebiotic galacto-oligosaccharides by a combination of analytical techniques. J. Agric. Food Chem. 57, 8488–8495 (2009)

Dembczynski, R., Jankowski, K.: Characterisation of small molecules diffusion in hydrogel-membrane liquid-core capsules. Biochem. Eng. J. 6, 41–44 (2000)

Glueckauf, E., Coates, J.I.: Theory of chromatography. Part 4. The influence of incomplete equilibrium on the front boundary of chromatogram and on the effectiveness of separation. J. Chem. Soc. 1315–1321 (1947)

Glueckauf, E., Kitt, G.P.: A theoretical treatment of cation exchangers. III. The hydration of cations in polystyrene sulphonates. Proc. R. Soc. Lond. A 228, 322–341 (1955)

Goulding, R.W.: Liquid chromatography of sugars and related polyhydric alcohols on cation exchangers: the effect of cation variation. J. Chromatogr. A 103, 229–239 (1975)

Gramblička, M., Polakovič, M.: Adsorption equilibria of glucose, fructose, sucrose, and fructooligosaccharides on cation exchange resins. J. Chem. Eng. Data 52, 345–350 (2007)

Gyurcsik, B., Nagy, L.: Carbohydrates as ligands: coordination equilibria and structure of the metal complexes. Coord. Chem. Rev. 203, 81–149 (2000)

Hernández, O., Ruiz-Matute, A.I., Olano, A., Moreno, F.J., Luz Sanz, M.: Comparison of fractionation techniques to obtain prebiotic galactooligosaccharides. Int. Dairy J. 19, 531–536 (2009)

Juza, M.: Development of an high-performance liquid chromatographic simulated moving bed separation from an industrial perspective. J. Chromatogr. A 865, 35–49 (1999)

Laatikainen, M., Heinonen, J., Sainio, T.: Modeling of chromatographic separation of concentrated-acid hydrolysates. Sep. Purif. Technol. 80, 610–619 (2011)

Lee, J.W., Kwon, T.O., Moon, I.S.: Adsorption of monosaccharides, disaccharides, and maltooligosaccharides on activated carbon for separation of maltopentaose. Carbon 42, 371–380 (2004)

Luz, D.A., Rodrigues, A.K.O., Silva, F.R.C., Torres, A.E.B., Cavalcante Jr, C.L., Brito, E.S., Azevedo, D.C.S.: Adsorptive separation of fructose and glucose from an agroindustrial waste of cashew industry. Bioresour. Technol. 99, 2455–2465 (2008)

Martinsson, E., Samuelson, O.: Partition chromatography of sugars on ion-exchange resins. J. Chromatogr. A 50, 429–435 (1970)

Moravčík, J., Gramblička, M., Wiśniewski, Ł., Vaňková, K., Polakovič, M.: Influence of the ionic form of a cation-exchange adsorbent on chromatographic separation of galactooligosaccharides. Chem. Pap. 66, 583–588 (2012)

Nobre, C., Santos, M.J., Dominguez, A., Torres, D., Rocha, O., Peres, A.M., Rocha, I., Ferreira, E.C., Teixeira, J.A., Rodrigues, L.R.: Comparison of adsorption equilibrium of fructose, glucose and sucrose on potassium gel-type and macroporous sodium ion-exchange resins. Anal. Chim. Acta 654, 71–76 (2009)

Nowak, J., Gedicke, K., Antos, D., Piątkowski, W., Seidel-Morgenstern, A.: Synergistic effects in competitive adsorption of carbohydrates on an ion-exchange resin. J. Chromatogr. A 1164, 224–234 (2007)

Otero, M., Zabkova, M., Rodrigues, A.E.: Comparative study of the adsorption of phenol and salicylic acid from aqueous solution onto nonionic polymeric resins. Sep. Purif. Technol. 45, 86–95 (2005)

Pedruzzi, I., Borges da Silva, E.A., Rodrigues, A.E., et al.: Selection of resins, equilibrium and sorption kinetics of lactobionic acid, fructose, lactose and sorbitol. Sep. Purif. Technol. 63, 600–611 (2008)

Rabelo, M., Pereira, C., Rodrigues, S., Rodrigues, A., Azevedo, D.: Chromatographic separation of isomaltooligosaccharides on ion-exchange resins: effect of the cationic form. Adsorpt. Sci. Technol. 30, 773–784 (2012)

Rajendran, A., Paredes, G., Mazzotti, M.: Simulated moving bed chromatography for the separation of enantiomers. J. Chromatogr. A 1216, 709–738 (2009)

Stefansson, M., Westerlund, D.: Ligand-exchange chromatography of carbohydrates and glycoconjugates. J. Chromatogr. A 720, 127–136 (1996)

Tiihonen, J., Peuha, E.L., Latva-Kokko, M., Silander, S., Paatero, E.: Subcritical water as eluent for chromatographic separation of carbohydrates using cation-exchange resins. Sep. Purif. Technol. 44, 166–174 (2005)

Vaňková, K., Gramblička, M., Polakovič, M.: Single-component and binary adsorption equilibria of fructooligosaccharides, glucose, fructose, and sucrose on a Ca-form cation exchanger. J. Chem. Eng. Data 55, 405–410 (2010a)

Vaňková, K., Ačai, P., Polakovič, M.: Modelling of fixed-bed adsorption of mono-, di-, and fructooligosaccharides on a cation-exchange resin. Biochem. Eng. J. 49, 84–88 (2010b)

Vente, J.A., Bosch, H., de Haan, A.B., Bussmann, P.J.T.: Evaluation of sugar sorption isotherm measurement by frontal analysis under industrial processing conditions. J. Chromatogr. A 1066, 71–79 (2005)

Vente, J.A.: Adsorbent functionality in relation to selectivity and capacity in oligosaccharide separations. Febodruk, (2004)

Vera, C., Guerrero, C., Conejeros, R., Illanes, A.: Synthesis of galacto-oligosaccharides by Β-galactosidase from Aspergillus Oryzae using partially dissolved and supersaturated solution of lactose. Enzyme Microb. Technol. 50, 188–194 (2012)

Whitfield, D.M., Stojkovski, S., Sarkar, B.: Metal coordination to carbohydrates. Structures and function. Coord. Chem. Rev. 122, 171–225 (1993)

Acknowledgments

The authors would like kindly thank to FrieslandCampina for providing the Vivinal® GOS syrup. Carla Pereira gratefully acknowledges financial support from Fundação para a Ciência e a Tecnologia, Postdoctoral Research Fellowship SFRH/BPD/71358/2010. The Slovak side was partly supported by the grant of Slovak Agency for Science (VEGA 1/0531/13).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wiśniewski, Ł., Pereira, C.S.M., Polakovič, M. et al. Chromatographic separation of prebiotic oligosaccharides. Case study: separation of galacto-oligosaccharides on a cation exchanger. Adsorption 20, 483–492 (2014). https://doi.org/10.1007/s10450-013-9587-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10450-013-9587-3