Abstract

The objective of this study was to test the hypothesis that enzymatic degradation by collagenase significantly reduces dynamic moduli and increases compressive strains of bovine articular cartilage under physiological compressive stress levels and loading frequencies. Twenty-seven distal femoral cartilage plugs (3 mm diameter) were loaded in a custom apparatus under load control, with a load up to 40 N and loading frequencies of 0.1, 1, 10, and 40 Hz, before and after incubation in physiological buffered saline containing various concentrations of collagenase (0, 2, and 10 U/mL). Collagenase digestion reduced the equilibrium Young’s modulus by 49% with 2 U/mL and 61% with 10 U/mL, while the decrease in dynamic modulus at 40 Hz was in the range of 13–20% with 2 U/mL and 24–33% with 10 U/mL, relative to respective controls. The amplitudes of dynamic compressive strains increased from 22 ± 6% to 26 ± 8% at 0.1 Hz and 9.6 ± 3.3% to 13.5 ± 3.2% at 40 Hz, with 10 U/mL collagenase. This experimental study serves to confirm that collagen contributes significantly to the dynamic compressive properties of cartilage, by demonstrating that collagenase digestion impairs these properties, under stress amplitudes and frequencies which are representative of physiological loading conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The compressive properties of articular cartilage at physiological load levels following enzymatic digestion are poorly understood and the magnitudes of in situ compressive strains remain unclear. Contact stresses in healthy joints typically range from 1 to 6 MPa for light to moderate activities of daily living;11,14 under more strenuous activities, peak contact stresses in natural joints have been estimated in the range of 12 Mpa;20 and in a classical study by Hodge et al.,12 the contact stress measured in vivo using an instrumented hip endoprosthesis was found to reach 18 MPa while rising from a chair. Typical physiological loading frequencies are in the range of 0.1–2 Hz, and higher under impact loading. In unconfined compression cyclical loading, the dynamic modulus of bovine articular cartilage at 1 Hz has been measured at 13–37 MPa under applied strain amplitudes of 0.5–2.5%,5,16,26 corresponding to compressive stresses up to 1 MPa. In our previous study of dynamic loading of bovine articular cartilage under physiological loading conditions,24 the frequency- and stress-dependent dynamic modulus was investigated at 4 MPa of applied stress, showing an increase from ∼48 MPa at 0.1 Hz to ∼65 MPa at 40 Hz, while the peak compressive strain amplitudes decreased from ∼16% at 0.1 Hz to ∼9% at 40 Hz. Theoretical analyses suggest that unconfined compression moduli at high loading frequencies are proportional to the tensile properties of the collagen–proteoglycan structure of articular cartilage,6,13,28,29 because axial compression produces tensile radial and circumferential strains.1

Enzymatic digestion has previously been shown to severely alter the functional properties of articular cartilage. Stromelysin treatment, with its concomitant loss of proteoglycan (PG), causes a significant reduction in equilibrium modulus, dynamic modulus, and streaming potential of articular cartilage compared to controls.4 Trypsin treatment causes a significant decrease in the compressive stiffness of articular cartilage,7,35 while glycosidase treatment (chondroitinase ABC and hyaluronidase) gives rise to a significant decrease in the dynamic shear modulus, equilibrium compressive modulus, and equilibrium tensile modulus.17,27,31,36 Regarding collagenase treatment, Laasanen et al. have reported ∼70% decrease in equilibrium compressive modulus and ∼45% in instantaneous dynamic compressive modulus of articular cartilage.17 Significant reductions have been reported in tensile stiffness with articular cartilage degeneration resulting from type XI collagen mutations in mice,34 and in Young’s modulus from indentation testing, with the degradation of the collagen fibril network by collagenase treatment.31

These studies with enzymatic digestion investigated material properties of articular cartilage under various loading conditions, and determination of whether or not the loading environment falls within physiologic bounds would facilitate interpretation of the results. Knowledge of mechanical properties with cartilage degeneration by collagenase treatment in a physiological loading environment will provide valuable insight for cartilage tissue engineering.9,10,19,21,33 The present study extends the previous dynamic loading study of our own group24 to include enzymatic digestion by collagenase treatment. To the best of our knowledge, the effect of enzymatic degradation by collagenase treatment on the functional dynamic modulus and compressive strain has not been well characterized under physiological loading conditions. Therefore, the objective of this study was to test the hypothesis that enzymatic degradation by collagenase significantly reduces the dynamic compressive modulus and increases the compressive strains of articular cartilage. Measurements of the mechanical properties were performed under dynamic unconfined compression, under load control, at engineering compressive stresses up to 5.7 MPa and loading frequencies of 0.1, 1, 10, and 40 Hz.

Materials And Methods

Sample Preparation

Twenty-seven cylindrical cartilage plugs, 3 mm in diameter, were harvested from the trochlea and condyles of the distal femoral articular layer of four fresh frozen bovine knee joints (3 years old) obtained from a local abattoir. Using a sledge microtome (Model 1400; Leiz, Rockleigh, NJ), approximately 0.5 mm of tissue was microtomed from the deep zone to remove remnants of subchondral bone, and to produce a surface parallel to the articular side, leaving the articular surface intact.

Testing Apparatus

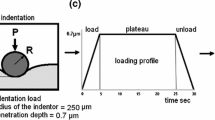

The custom-designed testing apparatus24 consisted of a voice-coil force actuator (Model LA17-28-000A; BEI Kimco Magnetics Division, San Marcos, CA, 71N peak force), connected in series with a linear variable differential transformer (LVDT) for displacement measurements (Model PR812-200, Schaeviz Sensors, Hamptons, VA, ±5 mm) and a loading platen whose surface was attached to 1 mm thick glass. Tissue specimens were placed in a stainless steel specimen chamber mounted on a load cell (Model 8523, Burster, Sterling Heights, MI, ±200N). The voice-coil force actuator, connected to a power supply (Model PST-040-13-DP, Copley Controls Corp., Canton, MA, +40VDC at 13A continuous) and controller box (Model TA115, Trust Automation INC., San Luis Obispo, CA, 150W continous/325W peak) was controlled via a force feedback loop using a desktop computer with a data input and output board (Model PCI-MIO-16XE-10, National Instruments, Austin, TX) using the LabView software package (Version 5.0, National Instruments, Austin, TX).

Collagenase Treatment

Specimens were divided equally into a control group incubated in PBS (0 U, n = 9), and two groups treated respectively with 2 U/mL (2 U, n = 9) and 10 U/mL (10 U, n = 9) collagenase type IV (Sigma, MO). All specimens were tested before (C-) and after (T-) treatment (14–16 h incubation at 37 °C on an orbital shaker), thus serving as their own controls.

Loading Protocol

On the day of testing, specimens were thawed at room temperature in normal phosphate buffered saline (PBS) solution for 1 h and the thickness was measured with a custom micrometer device. The thickness changed from 1.49 ± 0.41 to 1.48 ± 0.44 mm with PBS incubation (n = 9) for 14–16 h, 1.38 ± 0.26 to 1.32 ± 0.28 mm with 2 U/mL collagenase treatment (n = 9), and 1.60 ± 0.32 to 1.48 ± 0.39 mm with 10 U/mL collagenase treatment (n = 9), showing no statistically significant difference in all cases. All subsequent tests were performed in PBS at room temperature. To zero the position of the loading platen, the specimen was mounted on the device and the platen was lowered until a small load less than 0.1 N was registered; this load was removed in less than a minute. A tare load of 0.2 N (28 kPa) was initially applied to each sample to maintain proper contact between the loading platen and cylindrical cartilage specimen, and the specimen was allowed to equilibrate for 30–40 min. The reduction in thickness of the original sample height resulting from tare load application was 7.0 ± 1.9% and 8.0 ± 2.4% before and after incubating in PBS (n = 9), 7.3 ± 2.7% and 15.9 ± 7.4% before and after 2 U/mL collagenase treatment (p < 0.0001, n = 9), and 6.4 ± 2.2% and 18.6 ± 11.9% before and after 10 U/mL collagenase treatment (p < 0.0001, n = 9). The equilibrium Young’s modulus in the range of small strains (E Y) was determined from these measurements. Cyclical compressive loads were then applied to the specimen using a sinusoidal profile of the form F = F 0(1−cos 2πft)/2 (where f is the loading frequency), nominally varying in amplitude from 0 to F 0 = 40 N (equivalent to engineering stresses in the range of 0–5.7 MPa when calculated with the initial surface area of the specimen) above the initial tare load. This choice of loading profile was motivated by the desire to guarantee a full sinusoidal loading profile with no loading platen lift-off, while keeping the tare load small. Cyclical loads consisted of 40 cycles at 40 Hz, 10 cycles at 10 Hz, 2 cycles at 1 Hz, and 1 cycle at 0.1 Hz, and were applied in that given order. Because the mean applied load was equal to F 0/2, the specimen dynamic deformation was accompanied by a creep deformation; thus, the specimen was allowed to recover for 1–10 min in proportion to the duration of loading between each set of loading frequencies. At the completion of all the dynamic loading experiments, the specimen was again allowed to recover for 10 min before being refrozen at −20 °C for biochemical characterization.

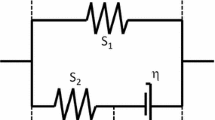

Analysis of Dynamic Modulus (|G*|)

Since physiological load magnitudes may produce strains in the finite deformation range, it is necessary to clarify the method by which material properties were evaluated. The data were evaluated as Cauchy normal stress component vs. stretch ratio (σ 33 vs. λ 3, where the 3-direction denotes the axial loading direction), assuming that the response of cartilage at these tested frequencies is nearly incompressible (λ 3 = h/h 0, σ 33 = hF/h 0 A 0, where F is the applied load, h is the sample thickness in the deformed configuration, and h 0 and A 0 are the thickness and cross-sectional area in the reference configuration, respectively). As observed in our previous dynamic loading study,24 the mechanical response was nonlinear. To capture the nonlinearity of the response, the time-varying data at each loading frequency were plotted as stress vs. strain (σ 33 vs. λ 3−1) and the data corresponding to the loading phase (i.e., when the compressive stress is increasing during the loading cycle) were fitted with a suitable function, σ 33 = A(1−exp[−B(λ 3−1)]), for the purpose of smoothing. The slope of this function (∂σ 33/∂λ 3) was then evaluated at σ 33 = 0 and 3 MPa to provide the strain- (or stress-) dependent dynamic modulus at two representative values of the applied stress, at each tested frequency.

Analysis of Phase Angle (∠G*)

The nonlinear stress–strain response precluded the use of standard Fourier transform analysis commonly used for linear responses under small strains.5,16,26 To capture the nonlinearity of the response, the same methodology as our previous dynamic loading study24 was adopted, and according to standard continuum mechanics relations valid under finite deformation,18 the phase angle ∠G* can be evaluated from tan (∠G*) = 4(W l + W u)/π(W l−W u), where W l and W u are respectively the work done (to the sample) during the loading and unloading phases of a cycle ( \( W_{{\text{l}}} = {\int_0^{\pi \mathord{\left/ {\vphantom {\pi \omega }} \right. \kern-\nulldelimiterspace} \omega } {(\sigma _{{33}}) (d\varepsilon _{3} /dt)} }dt = F(\pi \mathord{\left/ {\vphantom {\pi \omega }} \right. \kern-\nulldelimiterspace} \omega )\cdot \lambda _{3}(\pi \mathord{\left/ {\vphantom {\pi \omega }} \right. \kern-\nulldelimiterspace} \omega )/A_{0} - {\int_0^{\pi \mathord{\left/ {\vphantom {\pi \omega }} \right. \kern-\nulldelimiterspace} \omega } {(\lambda _{3})(dF/dt) /A_{0} } }dt \) and \( W_{{\text{u}}} = {\int_{\pi \mathord{\left/ {\vphantom {\pi \omega }} \right. \kern-\nulldelimiterspace} \omega }^{{2\pi } \mathord{\left/ {\vphantom {{2\pi } \omega }} \right. \kern-\nulldelimiterspace} \omega } {(\sigma _{{33}}) (d\varepsilon _{3} /dt)} }dt = - F(\pi \mathord{\left/ {\vphantom {\pi \omega }} \right. \kern-\nulldelimiterspace} \omega ) \cdot \lambda _{3}(\pi \mathord{\left/ {\vphantom {\pi \omega }} \right. \kern-\nulldelimiterspace} \omega )/A_{0} - {\int_{\pi \mathord{\left/ {\vphantom {\pi \omega }} \right. \kern-\nulldelimiterspace} \omega }^{{2\pi } \mathord{\left/ {\vphantom {{2\pi } \omega }} \right. \kern-\nulldelimiterspace} \omega } {(\lambda _{3}) (dF/dt) /A_{0} } }dt \) where λ 3 = 1 + ε 3, and ε 3 is engineering strain). For pure elastic material, W l + W u would be zero, resulting in zero phase angle, because W l has “+” sign and W u has “−” sign.

Glycosaminoglycan (GAG) and Collagen Content

To determine the GAG and collagen content of each mechanically tested cartilage explant, frozen constructs were thawed, their wet weight measured, and then lyophilized overnight. Constructs were reweighed dry, and digested for 16 h with papain (0.56 units/mL in 0.1 M sodium acetate, 10 M cysteine HCL, 0.05 M EDTA, pH 6.0) at 60 °C. GAG content of the digest was assessed using the 1,9-dimethylmethylene blue dye-binding assay scaled for microplates.8 Ortho-hydroxyproline (OHP), a measure of collagen content, was determined colorimetrically by reaction of the digest with dimethylaminobenzaldehyde and chloramine T.30 OHP content was converted to total collagen content using a 1:10 ratio of OHP:Collagen.32 GAG and collagen content are reported as a percent of the wet weight (% ww) of the tissue.

Immunohistochemical Staining of Type II Collagen

For histological analyses, specimens were fixed in acid–formalin–ethanol, dehydrated in a graded series of alcohol, and embedded in paraffin (Polysciences, Warrington, PA). Paraffin blocks were sectioned (8 μm thickness) using a rotary microtome (Leica model 2030, Germany), and the sections were affixed to glass slides. For type II collagen immunohistochemical staining, slides were deparaffinized, rehydrated, briefly digested with 0.5 mg/mL hyaluronidase for 30 min at 37 °C, and swelled for 4 h in 0.5 M acetic acid at 4 °C. The slides were then rinsed with PBS, treated with 3% hydrogen peroxide in methanol for 10 min at room temperature to block endogenous peroxidase activity, rinsed with PBS, and incubated with blocking solution (10% horse serum in PBS) for 10 min at room temperature. After blocking, samples were incubated with a monoclonal antibody to type II collagen (II-II6B3, Developmental Studies Hybridoma Bank, University of Iowa) at a 1:3 dilution of supernatant overnight at 4 °C. Slides were then incubated with a biotin-conjugated horse-derived broad spectrum IgG secondary antibody (Vector Labs, Burlingame, CA) for 20 min at room temperature. Following a PBS rinse, the samples were visualized using streptavidin-conjugated horseradish peroxidase and 3,3′ diaminobenzidine as the substrate chromagen employing the Vectastain ABC kit (Vector Labs) as directed by the supplier. Non-immune control specimens were incubated with blocking solution (10% horse serum in PBS) in place of primary antibody. Images were captured using a Zeiss Axioskop 40 light microscope and Axiovision software.

Statistical Analysis

Two-way ANOVA with repeated measures was performed to investigate the effects of collagenase treatment and loading frequency on the dynamic modulus, phase angle, and compressive stress (SAS Institute Inc., NC) with an α = 0.05. One-way ANOVA with repeated measures was used to investigate the effect of collagenase treatment on E Y. Post hoc testing of means was performed using Bonferroni adjustments.

Results

As a result of incubation, the equilibrium Young’s modulus (E Y) evaluated from the tare load application decreased from 0.43 ± 0.12 MPa to 0.38 ± 0.11 MPa in the PBS control group, showing no statistical significance; 0.45 ± 0.21 to 0.23 ± 0.14 MPa with 2 U/mL collagenase treatment, and 0.49 ± 0.19 to 0.19 ± 0.08 MPa with 10 U/mL collagenase treatment (Fig. 1). E Y showed a statistically significant difference before and after collagenase treatment with both 2 and 10 U/mL (p < 0.0001).

The amplitudes of the dynamic compressive strains before and after treatment are summarized as a function of loading frequency in Fig. 2. These strains varied from 21.7 ± 5.6 to 26.2 ± 7.6% at 0.1 Hz loading frequency and from 9.6 ± 3.3 to 13.5 ± 3.2% at 40 Hz loading frequency with 10 U/mL collagenase treatment. No statistically significant differences in dynamic compressive strains were detected either with PBS or with collagenase treatment in all cases. However, the amplitudes of dynamic compressive strains decreased significantly with increasing loading frequencies (Fig. 2).

Effects of enzymatic digestion on dynamic compressive strain amplitudes: (a) PBS control group before (C0U) and after (T0U) incubation in PBS, (n = 9), (b) collagenase treatment group before (C2U) and after (T2U) incubation in 2 U/mL collagenase (n = 9), and (c) collagenase treatment group before (C10U) and after (T10U) incubation in 10 U/mL collagenase (n = 9). Asterisk denotes a significant statistical difference either before and after collagenase treatment or between corresponding values at applied loading frequencies (p < 0.05), respectively

The stress–strain responses of a typical specimen are presented in Fig. 3, at various loading frequencies, along with the corresponding curvefits. Consistent with our previous dynamic loading study,24 it was also found that the two-parameter function σ 33 = A(1−exp[−B (λ 3−1)]) could successfully fit the data at all frequencies, with the coefficients A, B, and corresponding R 2 values for the curvefits provided in Table 1. Differentiating these functions produces equations for the strain- or stress-dependent dynamic modulus at each loading frequency.

Frequency-dependent differences of the incremental dynamic modulus (|G*|) derived from the slope of the above stress–strain curve are indicated in Fig. 4 at selected compressive Cauchy stresses (0 and 3 MPa). A two-way ANOVA for the factors of applied loading frequency and collagenase treatment showed no statistical differences in dynamic moduli at either stress levels (0 and 3 MPa) and either collagenase concentrations (2 and 10 U/mL) at 0.1 Hz. However, significant differences (p < 0.05) were observed before and after 10 U/mL treatment, at 1, 10, and 40 Hz loading frequencies (At 3 MPa of applied stress, the corresponding change was from 39.1 ± 12.0 to 31.5 ± 9.5 MPa at 1 Hz and 43.8 ± 12.1 to 33.4 ± 11.3 MPa at 40 Hz with 10 U/mL treatment.). A two-way ANOVA for the factors of loading frequency and stress showed that the dynamic modulus increased significantly with an increase in the applied stress levels (0 and 3 MPa) at all frequencies and in all cases of treatment (p < 0.0001, data not shown).

Mean and standard deviation of the incremental dynamic modulus (|G*| = ∂σ 33/∂λ 3) at selected values of the applied compressive stress σ 33 as a function of frequency, for each treatment group. Open squares indicate data extrapolated from the experimental range, using the coefficients A, B of the curvefits, σ 33 = A (exp[B (λ 3−1)]−1). Asterisk denotes a significant statistical difference against corresponding values at 0.1 Hz (p < 0.05)

The phase angle derived from the area under the hysteresis loop of the stress vs. strain response is shown in Fig. 5. A two-way ANOVA for the factors of loading frequency and collagenase treatment indicates a significant difference in the phase angle (∠G*) before and after 10 U/mL collagenase treatment at 0.1 and 1 Hz loading frequencies (∠G* increased from 35.7 ± 2.1 to 43.8 ± 1.8° at 0.1 Hz and 20.3 ± 3.2 to 28.6 ± 2.5° at 1 Hz with 10 U/mL treatment).

Mean and standard deviation of the phase angle (∠G*) determined from the energy dissipation analysis over an entire loading cycle as a function of frequency: (a) PBS control group; (b) collagenase treatment group, and (c) collagenase treatment group before (C10U) and after (T10U) incubation in 10 U/mL collagenase (n = 9). Asterisk denotes a significant statistical difference against corresponding values at 0.1 Hz (p < 0.05)

Type II collagen staining showed clear differences in the overall staining intensity and localized pericellular deposits between PBS control group, 2, and 10 U/mL collagenase treated groups; non-immune controls without primary antibody showed no staining (Fig. 6). Although there are trends toward decreases in collagen and GAG content of the cartilage explants with collagenase treatment, no statistical differences between PBS control group, 2, and 10 U/mL collagenase treated groups were observed (Fig. 7). Unlike collagen staining, Safranin O staining revealed no marked differences in staining intensity between samples treated with collagenase and PBS controls (data not shown).

Discussion

The aim of this study was to investigate the unconfined compression dynamic modulus and range of compressive strains in bovine articular cartilage under load control, at engineering compressive stresses up to 5.7 MPa, in normal and collagenase-treated tissue samples. The objective was to test the hypothesis that enzymatic degradation by collagenase significantly reduces the dynamic moduli and increases the compressive strains under physiological loading conditions. In order to accomplish this objective, we have measured incremental dynamic moduli, compressive strains, and phase angles under physiological stress levels and loading frequencies to investigate the effect of collagenase digestion, while these quantitative values following collagenase digestion have not been reported in the literature under physiological loading conditions.

Results indicate that physiological compressive engineering stress levels of ∼3–6 MPa produce compressive strains in the range of 25–10% at physiological loading frequencies of 0.1–40 Hz under an unconfined compression testing configuration. This configuration was chosen because it is more representative of in situ contact conditions than confined compression or indentation with a porous-permeable filter.25 After collagenase treatment, the corresponding range of compressive strains increases 30 and 13% at 0.1 and 40 Hz, respectively (Fig. 2). Depending on the applied stress, the dynamic modulus was in the range of 7–44 MPa before collagenase treatment, and 6–33 MPa after collagenase treatment under physiological loading conditions (Fig. 4). These results support the hypothesis that collagenase digestion significantly compromises the dynamic unconfined compression modulus of cartilage. This important finding confirms our current understanding that the tensile properties of cartilage, which result primarily from the properties of the collagen matrix, play an important role in regulating the tissue response to dynamic compression.

Consistent with our previous dynamic loading study,24 the nonlinear stress–strain response under these high compressive stresses produces a nonlinear increase in dynamic modulus with increasing strain both before and after enzymatic digestion with collagenase. As demonstrated in Fig. 3, typical stress–strain responses for a single cycle of loading at each of the loading frequencies show that a larger hysteresis loop is evident at the lower frequencies, indicative of energy dissipation over that loading cycle. However, at the higher frequencies, the hysteresis loop diminishes in area and is eliminated at 40 Hz. As explained in the “Analysis of Phase Angle” section in Materials and Methods, the area of this hysteresis loop provides a phase angle shift (∠G*) between the applied stress input and the measured strain output at the given loading frequency under the dynamic loading experiment, and a small phase angle shift is indicative of elastic material behavior.

According to previous enzymatic digestion studies, stromelysin or trypsin treatment causes a significant reduction in the compressive stiffness of articular cartilage,4,7 while glycosidase treatment (chondroitinase ABC and hyaluronidase) gives rise to a significant decrease in the dynamic shear modulus, equilibrium compressive modulus, and equilibrium tensile modulus.17,27,36 Collagenase treatment shows a significant decrease in equilibrium and dynamic compressive stiffness17,31 and in tensile stiffness.15,34 Consistent with these findings, collagenase digestion reduced E Y by 49% with 2 U/mL and 61% with 10 U/mL, relative to respective controls in the current study (Fig. 1). As shown in Fig. 4, the reduction in the dynamic modulus before and after collagenase treatment was more significant at the lower applied stresses. For example, with 10 U/mL collagenase treatment, the reduction was 12% at 3 MPa and 30% at 0 MPa at 0.1 Hz; and 24% at 3 MPa and 33% at 0 MPa at 40 Hz.

An interesting observation is that the dynamic compressive modulus was reduced less significantly than the equilibrium compressive modulus. This result would suggest that the dynamic modulus is less sensitive to collagenase digestion than the equilibrium Young’s modulus. This finding is unexpected in light of the prediction that the dynamic modulus in unconfined compression is proportional to the tensile properties,6,13,22,28,29 whereas the equilibrium compressive modulus has no such theoretically-motivated dependence. It is believed that the destruction of collagen structure by collagenase digestion will cause a decrease in tensile strength of articular cartilage which results in a decrease in dynamic modulus, because collagen fibers play an important role in maintaining the tensile strength of articular cartilage. Another possible mechanism to change dynamic modulus might be explained related to the change in hydraulic permeability after collagenase digestion. The loss of collagen by collagenase treatment can make the interstitial fluid easy to escape out of the cartilage through an increase in hydraulic permeability, resulting in a decrease in the interstitial fluid pressurization which can support the applied load initially under unconfined compression. This decrease in the interstitial fluid load support after collagenase digestion has been investigated in the previous study of our groups,2 consistently with the result of the current study showing that a decrease in dynamic modulus at fast loading frequency (e.g., 40 Hz) is larger than that at slow loading frequency (e.g., 0.1 Hz). Though the result that the equilibrium modulus was reduced more than the dynamic modulus after collagenase treatment in the current study is unexpected, it is consistent with the finding of Laasanen et al. who reported a greater reduction in the Young’s modulus (∼70%) than in the dynamic modulus (∼45%) with collagenase treatment.17

This finding may be associated with the initial tare load application from which Young’s modulus was calculated. Though a small tare load of 0.2 N (28 kPa) was applied to the specimen before dynamic loading, a large reduction in the thickness of the original sample height by as much as ∼16% with 2 U/mL and ∼19% with 10 U/mL collagenase treatment may cause strain-dependent stiffening of the articular cartilage, potentially underestimating the reduction in dynamic modulus with collagenase treatment; in other words, this small tare load may effectively compress the digested region taking up all the slack, and this would make collagenase-digested samples appear stiffer when loaded dynamically. These results emphasize the potentially confounding effects of nonlinear material responses. Despite the best efforts of this study to account for nonlinearities, it is impossible to establish a reference configuration which produces the same tare deformation under the same tare load for all treatment groups.

Despite the histological evidence of loss of collagen staining, it was surprising that no statistical differences in collagen content of the cartilage explants were observed between samples treated with collagenase and PBS controls. One possible reason for this result is that collagenase digests the tissue nearly completely at the peripheral edges of the sample, while leaving the core (which is used for measuring collagen content) less affected. However, the relatively small reduction in thickness following collagenase digestion does not strongly favor this explanation. Another possible reason might be related to the loss of tissue structure and organization without a large loss of collagen and GAG content within the cartilage explants. The observed changes in mechanical properties, without dramatic changes in biochemical composition may point to the fact that the mechanical integrity of collagen is impaired, without it being removed from the explants. Further studies that measure collagen and GAG content in the testing media, as well as collagen and GAG content of the cartilage explants before and after dynamic loading, may help clarify this unexpected result. Another possible quantification of mechanical integrity of collagen with collagenase digestion could be performed by FTIR (Fourier Transform InfraRed) microscopy3 and can be compared with the measurements of collagen and GAG content in the testing media and cartilage explants before and after dynamic loading.

While it is generally understood that collagen imparts an elevated tensile modulus to cartilage, it has not always been evident that this structural characteristic serves the primary function of cartilage, whose mode of loading under physiological conditions in diarthrodial joints is in dynamic compression. In the previous experimental and theoretical studies of our group,2,13,23,25 it has been reported that interstitial fluid load support of articular cartilage was caused by the ratio of tensile to compressive moduli, and its interstitial fluid load support at the articular surface was decreased from ∼82 to ∼53% following collagenase digestion. These results suggest that collagenase digestion is likely to reduce tensile modulus much more than its compressive modulus resulting in a decrease in the ratio of tensile to compressive moduli. Since the same collagenase and digestion protocol as those of Basalo et al. 2 has been adopted in the current study, a reduction in the dynamic compressive modulus of articular cartilage in this study can attribute to a decrease in its tensile moduous following collagenase digestion. Moreover, the fact that compressive properties of articular cartilage are related to its tensile properties is also supported by our experimental results23 and theoretical predictions.13 From these points of view, it is now understood that the tensile properties of cartilage contribute to its dynamic compressive modulus. To the best of our knowledge, this experimental study investigates the first such comparisons of dynamic moduli, compressive strains, and phase angles before and after collagenase digestion under diverse stress amplitudes (0–3 MPa) and loading frequencies (0.1–40 Hz) which are representative of physiological loading conditions, and serves to confirm the mechanism about contribution of cartilage tensile properties to dynamic compression by demonstrating that collagenase digestion impairs the dynamic compressive properties of cartilage.

References

Ateshian G. A., W. H. Warden, J. J. Kim, R. P. Grelsamer, V. C. Mow. Finite deformation biphasic material properties of bovine articular cartilage from confined compression experiments. J. Biomech. 30:1157–1164, 1997

Basalo I. M., R. L. Mauck, T. A. Kelly, S. B. Nicoll, F. H. Chen, C. T. Hung, G. A. Ateshian. Cartilage interstitial fluid load support in unconfined compression following enzymatic digestion. J. Biomech. Eng. 126:779–786, 2004

Bi X., X. Yang, M. P. Bostrom, N. P. Camacho. Fourier transform infrared imaging spectroscopy investigations in the pathogenesis and repair of cartilage. Biochim. Biophys. Acta 1758:934–941, 2006

Bonassar L. J., E. H. Frank, J. C. Murray, C. G. Paguio, V. L. Moore, M. W. Lark, J. D. Sandy, J. J. Wu, D. R. Eyre, A. J. Grodzinsky. Changes in cartilage composition and physical properties due to stromelysin degradation. Arthritis Rheum. 38:173–183, 1995

Buschmann M. D., Y. J. Kim, M. Wong, E. Frank, E. B. Hunziker, A. J. Grodzinsky. Stimulation of aggrecan synthesis in cartilage explants by cyclic loading is localized to regions of high interstitial fluid flow. Arch. Biochem. Biophys. 366:1–7, 1999

Cohen B., W. M. Lai, V. C. Mow. A transversely isotropic biphasic model for unconfined compression of growth plate and chondroepiphysis. J. Biomech. Eng. 120:491–496, 1998

DiSilvestro M. R., J. K. Suh. Biphasic poroviscoelastic characteristics of proteoglycan-depleted articular cartilage: simulation of degeneration. Ann. Biomed. Eng. 30:792–800, 2002

Farndale R. W., C. A. Sayers, A. J. Barrett. A direct spectrophotometric microassay for sulfated glycosaminoglycans in cartilage cultures. Connect. Tissue Res. 9:247–248, 1982

Freed, L. E., I. Martin, and G. Vunjak-Novakovic. Frontiers in tissue engineering. In vitro modulation of chondrogenesis. Clin. Orthop. 367(Supplement):S46–S58, 1999

Gooch K. J., T. Blunk, D. L. Courter, A. L. Sieminski, P. M. Bursac, G. Vunjak-Novakovic, L. E. Freed. Igf-i and mechanical environment interact to modulate engineered cartilage development. Biochem. Biophys. Res. Commun. 286:909–915, 2001

Herberhold C., S. Faber, T. Stammberger, M. Steinlechner, R. Putz, K. H. Englmeier, M. Reiser, F. Eckstein. In situ measurement of articular cartilage deformation in intact femoropatellar joints under static loading. J. Biomech. 32:1287–1295, 1999

Hodge W. A., K. L. Carlson, R. S. Fijan, R. G. Burgess, P. O. Riley, W. H. Harris, R. W. Mann. Contact pressures from an instrumented hip endoprosthesis. J. Bone Joint Surg. Am. 71:1378–1386, 1989

Huang C. Y., V. C. Mow, G. A. Ateshian. The role of flow-independent viscoelasticity in the biphasic tensile and compressive responses of articular cartilage. J. Biomech. Eng. 123:410–417, 2001

Kaab M. J., K. Ito, J. M. Clark, H. P. Notzli. Deformation of articular cartilage collagen structure under static and cyclic loading. J. Orthop. Res. 16:743–751, 1998

Kempson G. E., M. A. Tuke, J. T. Dingle, A. J. Barrett, P. H. Horsfield. The effects of proteolytic enzymes on the mechanical properties of adult human articular cartilage. Biochim. Biophys. Acta. 428:741–760, 1976

Kim Y. J., L. J. Bonassar, A. J. Grodzinsky. The role of cartilage streaming potential, fluid flow and pressure in the stimulation of chondrocyte biosynthesis during dynamic compression. J. Biomech. 28:1055–1066, 1995

Laasanen M. S., J. Toyras, R. K. Korhonen, J. Rieppo, S. Saarakkala, M. T. Nieminen, J. Hirvonen, J. S. Jurvelin. Biomechanical properties of knee articular cartilage. Biorheology 40:133–140, 2003

Lai, W., D. Rubin, and E. Krempl. Introduction to Continuum Mechanics. Pergamon Press, 3rd ed., pp. 203–207, 1993

Li K. W., Y. H. Falcovitz, J. P. Nagrampa, A. C. Chen, L. M. Lottman, J. Y. Shyy, R. L. Sah. Mechanical compression modulates proliferation of transplanted chondrocytes. J. Orthop. Res. 18:374–382, 2000

Matthews L. S., D. A. Sonstegard, J. A. Henke. Load bearing characteristics of the patello-femoral joint. Acta Orthop. Scand. 48:511–516, 1977

Mauck R. L., M. A. Soltz, C. C. Wang, D. D. Wong, P. H. Chao, W. B. Valhmu, C. T. Hung, G. A. Ateshian. Functional tissue engineering of articular cartilage through dynamic loading of chondrocyte-seeded agarose gels. J. Biomech. Eng. 122:252–260, 2000

Mizrahi J., A. Maroudas, Y. Lanir, I. Ziv, T. J. Webber. The “instantaneous” deformation of cartilage: effects of collagen fiber orientation and osmotic stress. Biorheology 23:311–330, 1986

Park S., G. A. Ateshian. Dynamic response of immature bovine articular cartilage in tension and compression, and nonlinear viscoelastic modeling of the tensile response. J. Biomech. Eng. 128:623–630, 2006

Park S., C. T. Hung, G. A. Ateshian. Mechanical response of bovine articular cartilage under dynamic unconfined compression loading at physiological stress levels. Osteoarthr. Cartil. 12:65–73, 2004

Park S., R. Krishnan, S. B. Nicoll, G. A. Ateshian. Cartilage interstitial fluid load support in unconfined compression. J. Biomech. 36:1785–1796, 2003

Sah R. L., Y. J. Kim, J. Y. Doong, A. J. Grodzinsky, A. H. Plaas, J. D. Sandy. Biosynthetic response of cartilage explants to dynamic compression. J. Orthop. Res. 7:619–636, 1989

Schmidt M. B., V. C. Mow, L. E. Chun, D. R. Eyre. Effects of proteoglycan extraction on the tensile behavior of articular cartilage. J. Orthop. Res. 8:353–363, 1990

Soltz M. A., G. A. Ateshian. A conewise linear elasticity mixture model for the analysis of tension–compression nonlinearity in articular cartilage. J. Biomech. Eng. 122:576–586, 2000

Soulhat J., M. D. Buschmann, A. Shirazi-Adl. A fibril-network-reinforced biphasic model of cartilage in unconfined compression. J. Biomech. Eng. 121:340–347, 1999

Stegemann H., K. Stalder. Determination of hydroxyproline. Clin. Chim. Acta 18:267–273, 1967

Toyras J., J. Rieppo, M. T. Nieminen, H. J. Helminen, J. S. Jurvelin. Characterization of enzymatically induced degradation of articular cartilage using high frequency ultrasound. Phys. Med. Biol. 44:2723–2733, 1999

Vunjak-Novakovic G., I. Martin, B. Obradovic, S. Treppo, A. J. Grodzinsky, R. Langer, L. E. Freed. Bioreactor cultivation conditions modulate the composition and mechanical properties of tissue-engineered cartilage. J. Orthop. Res. 17:130–138, 1999

Vunjak-Novakovic G., B. Obradovic, I. Martin, L. E. Freed. Bioreactor studies of native and tissue engineered cartilage. Biorheology 39:259–268, 2002

Xu L., C. M. Flahiff, B. A. Waldman, D. Wu, B. R. Olsen, L. A. Setton, Y. Li. Osteoarthritis-like changes and decreased mechanical function of articular cartilage in the joints of mice with the chondrodysplasia gene (cho). Arthritis Rheum. 48:2509–2518, 2003

Zheng Y. P., C. X. Ding, J. Bai, A. F. Mak, L. Qin. Measurement of the layered compressive properties of trypsin-treated articular cartilage: an ultrasound investigation. Med. Biol. Eng. Comput. 39:534–541, 2001

Zhu W., V. C. Mow, T. J. Koob, D. R. Eyre. Viscoelastic shear properties of articular cartilage and the effects of glycosidase treatments. J. Orthop. Res. 11:771–781, 1993

Acknowledgments

This study was supported by funds from the National Institute of Arthritis and Musculoskeletal and Skin Diseases of the National Institutes of Health (AR-46532, AR-43628) and by the Korea Research Foundation Grant funded by the Korean Government (Basic Research Promotion Fund of MOEHRD: KRF-2007-331-D00593).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, S., Nicoll, S.B., Mauck, R.L. et al. Cartilage Mechanical Response under Dynamic Compression at Physiological Stress Levels Following Collagenase Digestion. Ann Biomed Eng 36, 425–434 (2008). https://doi.org/10.1007/s10439-007-9431-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10439-007-9431-6