Abstract

In this paper, we implement rotational flow control on a polymeric microfluidic “lab-on-a-disc” platform by combining serial siphoning and capillary valving for sequential release of a set of on-board stored liquid reagents into a common (assay) channel. The functionality of this integrated, multi-step, multi-reagent centrifugal assay platform critically depends on the capability to establish very reproducible, capillary-driven priming of the innately only weakly hydrophilic siphon microchannels made from common poly(methyl methacrylate) (PMMA) substrates. Due to the relatively high contact angle of the native PMMA substrate, it was practically impossible to ensure sequential release of on-board stored reagents using the capillary-driven serial siphon valves. In this work, we demonstrate that spin-coated hydrophilic films of poly(vinyl alcohol) (PVA) and (hydroxypropyl)methyl cellulose (HPMC) provide stable contact angles on PMMA substrates for more than 60 days. The deposited films were characterized using contact angle measurements, surface energy calculations and X-ray photoelectron spectroscopy spectra. The PVA and HPMC films reduced the water contact angle of the PMMA substrate from 68° to 22° and 27° while increasing their surface energies from 47 to 62 and 57 mN m−1, respectively. On the centrifugal microfluidic platform, the films were validated to enable the effective and reproducible priming of the serial siphon microchannels at low rotational frequencies while ensuring that the in-line capillary valves are not opened until their respective burst frequencies are passed. Furthermore, the biocompatibility of the proposed surface modification method was examined, and the platform was used to run a sandwich immunoassay for the detection of human immunoglobulin G, and its performance was proven to be comparable to dynamic coating using surfactants.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

One of the most crucial steps in biological analysis systems is the spatiotemporally controllable release of a repertoire of assay reagents. Siphon microchannels comprise attractive structures in centrifugal platforms as they can be utilized for several functions, such as valving, pumping, metering and mixing (Ducrée et al. 2007). Moreover, centrifugal forces have been shown to positively benefit active flow-through assays, especially for surface-based assays, by decreasing total assay time and increasing assay sensitivity (Peytavi et al. 2005).

On the here considered centrifugal microfluidic “lab-on-a-disc” platform, we chose serial siphoning to direct the sequential release of bioreagents (Steigert et al. 2007). Yet, the requirement of long-term hydrophilic microchannel surfaces represents major challenge of serial siphoning (Siegrist et al. 2009). A plethora of surface modification methods for wettability control has been reported in the literature (Kitsara and Ducrée 2013), among them the most commonly used are oxygen plasma treatment (Weikart and Yasuda 2000), plasma-enhanced chemical vapor deposition (PECVD) (Ozaydin-Ince et al. 2012; Riaz et al. 2012), (V)UV irradiation (Hozumi et al. 2002) and dynamic coating (Righetti et al. 2001). Oxygen plasma treatment induces the formation of hydroxyl groups, but the resulting hydrophilicity is of transient nature as the surfaces relapse to their original hydrophobic state. Films generated by PECVD are homogeneous, highly coherent and adherent to a variety of substrate types and can be prepared from monomers, which cannot be polymerized by conventional methods. Also UV and VUV irradiation can modify large areas at considerably lower costs. Yet, for PECVD as well as for short-wavelength radiation exposure, designated equipment is required. Summarizing, most of surface treatments are either of transient nature or involve rather complex process steps and equipment, which could potentially lead to low reproducibility of results. Another method to establish capillary priming on hydrophobic polymeric substrates is the dynamic coating with surface modifiers added to the buffer, which is then forced through the channel at a constant speed. However, caution must be taken to avoid structure alteration in or damage to protein analytes in the presence of the surface modifiers.

The present work proposes deposition of hydrophilic polymeric thin films onto microstructured polymeric substrates, such as poly(methyl methacrylate) (PMMA), applying the commonly used and highly available technique of spin coating. The selection of the coatings has been guided by the reduction in the contact angle with respect to native PMMA, in combination with their biocompatibility. Poly(vinyl alcohol) (PVA) is a synthetic polymer used in a wide range of industrial, medical and food applications (DeMerlis and Schoneker 2003). (Hydroxypropyl)methyl cellulose (HPMC) is a macromolecule of natural origin derived from cellulose, which also has been used extensively in the food and pharmaceutical industries. This polysaccharide exhibits hydrophobic (methyl) and hydrophilic (hydroxypropyl) groups distributed along the cellulose backbone (Machiste and Buckton 1996; Pérez et al. 2008). Both of these polymeric materials have been reportedly used on the wall coating for separations using capillary electrophoresis (Horvath and Dolník 2001; Lucy et al. 2008; Shah et al. 2006; Okada et al. 2007). Briefly, in these studies, PMMA microchannels and reservoirs were modified with hydrophilic solutions followed by a process, which includes UV/ozone treatment, filling with solution, incubating at room temperature, emptying the solution by a vacuum pump and heating (Shah et al. 2006) or just filling and heating (Okada et al. 2007).

For applications that long-term stability of these coatings under working conditions is required, coatings need to be crosslinked. Many crosslinking methods have been reported in the literature, among them the most commonly used are chemical crosslinking and irradiation (Bhattacharya et al. 2008). Chemical crosslinking can be accomplished with the addition of suitable chemical agents, for instance, by adding hexamethylene diisocyanate to PVA solution following a procedure that requires two days (Krumova et al. 2000). Also, chemical crosslinking of HPMC can be performed, for instance by using polycarboxylic acid, but the process is again time consuming as five days are required before use (Coma et al. 2003). Crosslinking with irradiation can be achieved by the addition of photosensitizer and exposure to UV light. For instance, a method for PVA crosslinking using photolithographic processes has been reported, by using polyoxometalate as the crosslinking agent and following a process for negative-tone photoresists which required exposure to deep ultraviolet (DUV) (Pavli et al. 2011). Summarizing, the crosslinking is quite time-consuming, adds complexity, and, in some cases (irradiation), specific equipment is required; then, the process starts becoming more cumbersome.

Here, the proposed method of liquid deposition on the microstructured PMMA surface prior to sealing has advantages such as the quick formation of a uniform layer (within 20 min), long-term storage stability (more than two months), low-complexity and high availability as only a common spin coater is involved. Furthermore, in the disposable sample-to-answer devices, one of the key parameters is the fast detection of the analytes, and in these cases, the proposed coatings are suitable—as demonstrated in the case of the detection of human immunoglobulin G (hIgG).

2 Materials and methods

2.1 Hydrophilic coatings formation

PVA featured a molecular weight of 31–50 kDa and a degree of hydrolysis of 87–89 %. HPMC with a methoxyl content of 19–24 % and a hydroxypropoxyl content of 7–12 % had a molecular weight of approximately 26 kDa. Both hydrophilic polymers with chemical structures illustrated in Fig. 1 were purchased from Sigma-Aldrich® and dissolved in deionized water. PVA and HPMC aqueous solutions were prepared by stirring and heating at 60 °C and at room temperature, respectively. The film formation conditions were the same for both materials: spin coating at 3,000 rpm for 30 s onto a PMMA sheet and baking on a hot plate at 60 °C for 20 min.

2.2 Surface characterization methods

For the characterization of the hydrophilic coatings onto PMMA sheet surface, contact angle measurements as well as X-ray photoelectron spectroscopy (XPS) measurements were taken. For the deposition study, plain (not milled) PMMA sheet samples were used.

The optical contact angle (CA) measuring instrument to characterize the coatings was the OCA 20 from DataPhysics Instruments GmbH with SCA 20 software. The sessile drop method was utilized, and the measurements were taken at room temperature (20 °C). The volume of the applied droplets of deionized water was 1.5 μl. The typical CA equilibrium was measured 15 s after the droplet placement on the sample surface. The CAs were obtained by averaging over several measurements in various characteristic locations of the sample surface, and the variation between individual measurements was not more than 3°. For the calculation of the surface free energy (SFE) of the samples, we used three probe liquids: deionized water, ethylene glycol with ≥99.8 % purity and diiodomethane with ≥98.5 % purity (the latter two were purchased from Sigma-Aldrich®).

The XPS analysis was performed using a Vacuum Generator (VG) single channeltron CLAM analyzer at a base pressure of 1 × 10−9 mbar. The photoelectrons were excited with a conventional Mg Kα (hν = 1,253.6 eV) X-ray source and an electron energy analyzer operating at a 50-eV pass energy, yielding an overall resolution of 1.2 eV. XPS core level spectra were curve fitted using Voigt profiles composed of Gaussian and Lorentzian line shapes in a 3:1 ratio and using a Shirley-type background.

Furthermore, the thickness of the PVA and HPMC coatings was evaluated using a stylus profilometer (Dektak 150 from Veeco). The thickness values are 80 ± 5 nm in the case of 4 % PVA and 170 ± 6 nm in the case of 4 % HPMC. Additionally, atomic force microscopy (AFM) measurements were taken using tapping mode (CP-II from Veeco) in a scanning area of 4 × 4 μm2. The surface roughness was determined using the root mean square roughness parameter (RRMS) by scanning four times on each sample. The RRMS values were very low for both coatings, in the range 0.1–0.3 nm. The above results prove that the coatings are uniform using the spin-coating method.

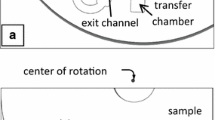

2.3 Centrifugal platform fabrication

The full, disc-shaped device is consists of three layers of PMMA sheets (Radionics, Ireland) bonded by two layers of interspersed pressure-sensitive adhesives (PSAs) (Adhesives Research, Ireland) as displayed in Fig. 2a. More specifically, it consists of: (1) top 1.5-mm-thick PMMA disc with laser-cut sample loading and venting holes, (2) knife-cut top PSA layer, (3) middle, 2-mm-thick PMMA disc exhibiting precision-milled chambers, capillary valves and siphon microchannels, (4) bottom, knife-cut PSA layer and (5) a blank, 1.5-mm-thick PMMA disc for sealing of the bottom microchannels. The basic design paradigm of the disc-based functional structures is motivated by previous publications (Siegrist et al. 2009). Each disc hosts four fluidically independent modules, each consisting of four loading chambers, capillary valves and siphon microchannels to leverage the sequential introduction of a palette of liquids to the common central channel (Fig. 2b). The microchannels are 250 μm wide and 250 μm deep; the capillary valves and the loading waste chambers are 350 μm and 1.7 mm deep, respectively. Again, it should be noted that the spin coating of the hydrophilic solutions takes place before the assembly of the device.

a Five-layer disc assembly which features four devices and b the main microfluidic layer of one module on the central disc displaying the four liquid reservoirs, which connected by the serial siphons to the common channel. The number of windings and capillary valves corresponds to the order in which the liquids are to be released to the central (assay) channel

2.4 Microfluidic platform/detection system measurement setups and immunoassay reagents

The centrifugal protocols were performed on a designated test stand (Grumann et al. 2005), which comprises of a computer-controlled spindle motor (4490 series, Faulhaber, DE), a stroboscope (Drelloscop 3244, Drello, DE) and a short exposure time CCD camera (Sensicam series, PCO, DE) for visualizing a given area on the disc, typically once per rotation.

Assay readout was eventually performed by supercritical angle fluorescence (SAF) (Siegrist et al. 2011), which selectively collects the surface-specific fluorescence emanating from surface-bound emitters while suppressing signal originating from the bulk (Kurzbuch et al. 2009, 2010). The system consists of a photomultiplier tube (PMT) (Hamamatsu, Japan) for detection, a 635-nm, 5-nW laser diode (Hitachi, Ireland) for excitation and various optical elements for collimation and focusing (ThorsLabs, USA). The laser and the PMT were controlled through a custom LabVIEW program and hardware. Surface-bound fluorescence dye molecules are excited by the laser diode with a beam diameter of about 400 μm. In a confocal optical setup, an ellipsoidal mirror (Optiforms, USA) is used for collection of SAF emission (light emitted at an angle above 61.5°), which is recorded by the photodetector. The SAF chips containing embedded optics were injection-molded in Zeonor® 1060R (Zeon, JP) at Protomold, UK (Kurzbuch et al. 2009).

HIgG was detected by a heterogeneous sandwich immunoassay (Nwankire et al. 2013). First, the SAF chips were surface functionalized with (3-aminopropyl)triethoxysilane (APTES) using PECVD which has been reported in the literature (Gubala et al. 2010, 2013). Then, the assay areas on the SAF chips were spotted with 30 μl of protein A (Piercenet, USA) at a concentration of 10 μg ml−1 and incubated at 4 °C overnight. Subsequently, the assay spots were blocked for 1 h at 37 °C with a 1 % v/v of bovine serum albumin (BSA) (Jackson ImmunoResearch Laboratories, USA) in phosphate-buffered saline (PBS) solution. PBS (150 mM, pH 7.4) was used for reagents dilution and for the wash steps (Sigma-Aldrich®). The fluorescence detection reagent was prepared by mixing 60 μl of biotinylated anti-human IgG antibody (Ab) (Gallus Immunotech Inc., USA) and 20 μl of biotin-binding, fluorescent protein conjugate, Neutravidin-Dylight 650 (Dy) (Piercenet, USA) in 1 ml of PBS. This fluorescence detection reagent (AbDy) was subsequently incubated in the dark at 37 °C for 20 min.

3 Results and discussion

3.1 Characterization of hydrophilic coatings

3.1.1 Contact angle measurements and surface free energy determination

Solution-phase-deposited hydrophilic PVA and HPMC films on PMMA sheets were characterized. It turned out that 2–4 % w/w solutions exhibit the same static contact angle with water. The images in Fig. 3a show a contact angle reduction for water from 68° ± 2.5° on the plain PMMA sheet to 22° ± 3° and 27° ± 3° after the spin coating of PVA and HPMC, respectively. The stability study of the hydrophilic coatings in Fig. 3b provides evidence that contact angles for either coating remain sufficiently stable for more than two months at room conditions; temperature 20 °C and average humidity 45 % (Fig. 3b). The absence of significant contact angle increase over time (known as hydrophobic recovery) (Nwankire and Dowling 2010) suggests that this technique is amenable for applications such as bioanalytical chips where long shelf-life is required.

The surface free energy (SFE) was determined from the experimental contact angles and known surface tensions of the probe liquids. Owens, Wendt, Rabel and Kaelble (OWRK) method was applied for the SFE calculation, which divides the SFE into two components: dispersive and polar fractions (Owens and Wendt 1969; Kaelble 1970):

where θ is the contact angle of the liquid on the solid surface, γ lv is the liquid–vapor surface free energy, γ d s and γ p s , and γ d l and γ p l are the dispersive and polar components of surface free energy of the solid and the liquid, respectively.

The surface tensions of deionized water, diiodomethane and ethylene glycol are 72.8, 50.8 and 47.7 mN m−1, respectively (Strom et al. 1987). Using the known surface tensions and experimental static contact angles of the probe liquids on the sample surfaces in Eq. (1), the so-determined SFE values (Table 1) were in good agreement with the available literature (Matsunaga and Ikada 1981; Carré 2007). As expected, it was observed that the deposition of the hydrophilic coatings resulted in an increase in SFE of the PMMA substrate. The polar components of the SFE of PVA and HPMC are higher than that of PMMA as it was anticipated. Furthermore, the SFE of the PVA coating was observed to be larger than that of the HPMC coating. This is most likely due to the higher surface density of hydroxyl (−OH) functional groups of the PVA compared to that of the HPMC (see Fig. 1).

3.1.2 XPS measurements

The curve fitted C 1 s and O 1 s spectra for plain, PVA- and HPMC-coated PMMA substrates are shown in Figs. 4 and 5, respectively. The XPS data clearly show that there are substantial differences in the chemical composition of each surface, confirming the presence of both the PVA and HPMC spin-coated films on PMMA. The C peaks have been attributed as follows: CHx bonds at ~285.5 eV, C–C bonds at ~286.3 eV, C–O bonds at ~287.0 eV and C = O bonds at ~289.5 eV (Fig. 4). The C peaks have full-width half-maximum (FWHM) between 1.9 and 2.3 eV. The O peaks have been attributed as follows: O = C bonds at ~532.2 eV and O–C bonds at ~533.6 eV, which is consistent with observing C 1 s peaks in these two chemical states. The O peaks have FWHM of between 1.8 eV and 2.4 eV (Fig. 5). The spectra recorded for all three samples agree well with the available literature (Louette et al. 2005a; Ton-That et al. 2001; Louette et al. 2005b; Nguyen and Dupraz 1997). The percentage of O and C elemental compositions for the three samples are presented in Table 2. The increased elemental oxygen content on the PVA (84.5 %)- and HPMC (84.4 %)-coated substrates, when compared with the uncoated (75.1 %) PMMA substrate, can be attributed to the presence of hydroxyl groups in PVA and HPMC chemical structures. These results further confirm the earlier observed low water contact angle and increased SFE on the functionalized surfaces.

3.2 Assay reagent release controlled by centrifugal serial siphoning

The effectiveness of the hydrophilic PVA and HPMC coatings on the precise control of liquid flow in microchannels was demonstrated by implementing a serial-siphoning-controlled assay with the disc structure in Fig. 2. Figure 6 depicts a frame sequence of successive release of deionized water containing <1 % v/v of a contrast agent (food dye) in PBS for visualization purposes, on the centrifugal platform applying the PVA coating (the same successful sequential release was observed using the HPMC coating). Each serial siphon bends radially inwards toward a crest point, which is located closer to the center of rotation than the liquid level in the loading reservoir. The abrupt widening at the start of the inbound flank creates a capillary barrier where the priming intermittently stops until a certain rotational burst frequency is reached. These passive valves thus stop the flow as long as capillary force is prevalent during priming, thus impeding unwanted continuous priming of multiple windings within a single low-frequency period.

Frame sequence of the sequential release of food dye solutions from the four loading chambers through the siphon microchannels to the common central channel: a liquid loading in the reservoirs, b high-speed/centrifugal forces, c low-speed/capillary forces, d first liquid delivery e second siphon priming, f–h second, third and fourth liquid delivery, respectively. The liquid residue in the channels that is not removed can be considered as a systematic error, which may be compensated by starting with a larger volume loaded to the reservoir

In a first step, all chambers were loaded with 30-μl aliquots of contrast agent (Fig. 6a). The disc was then spun at a frequency of 975 rpm (Fig. 6b), which is sufficiently high to introduce the liquid from their loading chambers into the outlets past the first capillary stop. The liquid halts once hydrostatic equilibrium with equal filling heights is established in the serial siphon and the reservoir. Then, the rotational frequency is lowered to 75 rpm where capillary forces prevail for priming the microchannels (Fig. 6c). In order to burst the inline capillary valve, the rotational frequency was increased again up to 975 rpm. Fig. 6d displays the successful delivery of liquid from the first siphons, and Fig. 6e shows the second siphon priming. Fig. 6f, g, h, portrays the liquid delivery of the remaining siphon channels, which occurred by repeating the same cyclic alteration in the rotational frequencies.

The hydrophilic coatings hence on the one hand support the priming of the microchannels at very low rotational frequencies (almost stopped disc); on the other hand, the coating still allows halting the flow at the capillary valves at those frequencies. The concave meniscus of the air–liquid interface in the microchannel further exhibits the significant increase in the hydrophilicity of the PMMA surface (Fig. 7).

The performance of the hydrophilic coatings was further examined using bioreagents. The HPMC coating was used for those experiments because, on the contrary to PVA, the preparation of its solution requires less time and no heating. More specifically, the detection of hIgG in a heterogeneous, sandwich assay format was performed, and the results were compared with the dynamic coating method using the surfactant Tween® 20 (Nwankire et al. 2013). It has to be noted that the concentration of Tween® 20 in (Nwankire et al. 2013) needed to be adjusted individually for each of the assay reagents in order to facilitate the function of the siphon valves, thus rendering this technique significantly more cumbersome.

The detection system was based on the same SAF detection platform as Nwankire et al. (2013). The centrifugal platform fabrication was adjusted for the detection with SAF system, by modifying the bottom PMMA sheet in order to incorporate the functionalized Zeonor® SAF chip which consists of injection-molded lenses (Fig. 8a). The bioreagents were added into their designated chambers, as depicted in Fig. 8b, and flown over the “protein A” capture spot. The spinning protocol was modified by including a step of rotational frequency at 375 rpm for each reagent delivery across the active assay area on the SAF chip. An incubation step of 2 min was included in between each assay reagent flowing over the active assay spot. The assay sequence followed includes (a) blocking of the non-specific sites with 1 % BSA in PBS, (b) sample: human IgG of various concentrations, (c) wash with PBS, (d) fluorescent detector reagent: a bio-tinylated, anti-human IgG antibody (Ab) and a biotin-binding fluorescent protein conjugate, Neutravidin-Dylight 650 (Dy) (AbDy), and (e) a final wash step with PBS, loaded manually from the central flow channel. The entire micro-fluidic assay process completes within about 20 min.

Fluorescence was measured immediately after the last wash step using the prototype SAF reader system. The excitation and emission wavelengths were 652 and 672 nm, respectively. Figure 9 presents the fluorescence intensity of four different hIgG concentrations (0.16, 0.8, 4, 20 μg ml−1) in the cases of HPMC-coated disc and dynamic coating with Tween® 20. The values reveal that there is no significant change in the assay performance due to the different surface modification methods. This result renders the proposed coating method suitable to microfluidic-based “sample-to-answer” assay system for bioprocess monitoring.

4 Conclusions

Common PMMA substrates have been hydrophilized by spin-coating polymeric solutions of PVA and HPMC. We demonstrated well-defined, long-term stable increases in contact angle and, correspondingly, in surface free energy after the deposition of the hydrophilic coatings on PMMA substrate surface. XPS spectra further corroborated the successful deposition of the coatings. Sequential release of liquids enabled by the enhanced surface wettability was successfully implemented in a serial-siphoning- and capillary-valving-based centrifugal platform used for the detection of hIgG. It was proven that the increase in surface energy of the coated PMMA disc enables the priming of the serial siphon microchannels at very low rotational frequency where capillary forces dominate. The performance of the heterogeneous hIgG assay was comparable with earlier results obtained with dynamic coating where the latter required specific tailoring of the surfactant concentration for each reagent. Also, potential interference between the surfactants and the biomolecules is avoided with our coating method. Overall, our spin-coating-based surface modification method excels by combining simplicity and cost efficiency of the film deposition process, reagent independence and long-term storage stability of the spin-coated films, making the method very attractive for the capillary flow control on centrifugal lab-on-a-disc platforms as well as of microfluidic systems in general.

References

Bhattacharya A, Rawlins JW, Ray P (2008) Polymer grafting and crosslinking. Wiley, Hoboken

Carré A (2007) Polar interactions at liquid/polymer interfaces. J Adhes Sci Technol 21:961–981. doi:10.1163/156856107781393875

Coma V, Sebti I, Pardon P et al (2003) Film properties from crosslinking of cellulosic derivatives with a polyfunctional carboxylic acid. Carbohydr Polym 51:265–271. doi:10.1016/S0144-8617(02)00191-1

DeMerlis CC, Schoneker DR (2003) Review of the oral toxicity of polyvinyl alcohol (PVA). Food Chem Toxicol 41:319–326

Ducrée J, Haeberle S, Lutz S et al (2007) The centrifugal microfluidic bio-disk platform. J Micromech Microeng 17:S103–S115. doi:10.1088/0960-1317/17/7/S07

Grumann M, Brenner T, Beer C et al (2005) Visualization of flow patterning in high-speed centrifugal microfluidics. Rev Sci Instrum 76:025101. doi:10.1063/1.1834703

Gubala V, Gandhiraman RP, Volcke C et al (2010) Functionalization of cycloolefin polymer surfaces by plasma-enhanced chemical vapour deposition: comprehensive characterization and analysis of the contact surface and the bulk of aminosiloxane coatings. Analyst 135:1375–1381

Gubala V, Siegrist J, Monaghan R et al (2013) Analytica chimica acta simple approach to study biomolecule adsorption in polymeric microfluidic channels. Anal Chim Acta 760:75–82

Horvath J, Dolník V (2001) Polymer wall coatings for capillary electrophoresis. Electrophoresis 22:644–655. doi:10.1002/1522-2683(200102)22:4<644:AID-ELPS644>3.0.CO;2-3

Hozumi A, Masuda T, Hayashi K et al (2002) Spatially defined surface modification of poly(methyl methacrylate) using 172 nm vacuum ultraviolet light. Langmuir 18:9022–9027

Kaelble DH (1970) Dispersion-polar surface tension properties of organic solids. J Adhesion 2:66–81

Kitsara M, Ducrée J (2013) Integration of functional materials and surface modification for polymeric microfluidic systems. J Micromech Microeng 23:033001. doi:10.1088/0960-1317/23/3/033001

Krumova M, López D, Benavente R et al (2000) Effect of crosslinking on the mechanical and thermal properties of poly(vinyl alcohol). Polymer 41:9265–9272. doi:10.1016/S0032-3861(00)00287-1

Kurzbuch D, Bakker J, Melin J et al (2009) A biochip reader using super critical angle fluorescence. Sens Actuators B Chem 137:1–6. doi:10.1016/j.snb.2008.12.057

Kurzbuch D, Bakker JWP, Ruckstuhl T, Melin J (2010) Super critical angle fluorescence scanning system. U.P.T. Office (Ed.), United States

Louette P, Bodino F, Pireaux J–J (2005a) Poly(methyl methacrylate) (PMMA) XPS Reference Core Level and Energy Loss Spectra. Surf Sci Spectra 12:69. doi:10.1116/11.20050914

Louette P, Bodino F, Pireaux J–J (2005b) Poly(vinyl alcohol) (PVA) XPS reference core level and energy loss spectra. Surf Sci Spectra 12:106. doi:10.1116/11.20050922

Lucy CA, MacDonald AM, Gulcev MD (2008) Non-covalent capillary coatings for protein separations in capillary electrophoresis. J Chromatogr A 1184:81–105. doi:10.1016/j.chroma.2007.10.114

Machiste EO, Buckton G (1996) Dynamic surface tension studies of hydroxypropylmethylcellulose film-coating solutions. Int J Pharm 145:197–201

Matsunaga T, Ikada Y (1981) Dispersive component of surface free energy of hydrophilic polymers. J Colloid Interface Sci 84:8–13. doi:10.1016/0021-9797(81)90253-8

Nguyen T-P, Dupraz A (1997) Spectroscopic studies of a multiphasic polymer-ceramic mixture material. J Biomater Sci Polym Ed 8:141–149. doi:10.1163/156856296X00219

Nwankire CE, Dowling DP (2010) Influence of nm-thick atmospheric plasma deposited coatings on the adhesion of silicone elastomer to stainless steel. J Adhes Sci Technol 24:1291–1302. doi:10.1163/016942409X12561252292062

Nwankire CE, Donohoe GG, Zhang X et al (2013) At-line bioprocess monitoring by immunoassay with rotationally controlled serial siphoning and integrated supercritical angle fluorescence optics. Anal Chim Acta 781:54–62. doi:10.1016/j.aca.2013.04.016

Okada H, Kaji N, Tokeshi M, Baba Y (2007) Channel wall coating on a poly(methyl methacrylate) CE microchip by thermal immobilization of a cellulose derivative for size-based protein separation. Electrophoresis 28:4582–4589. doi:10.1002/elps.200700105

Owens DK, Wendt RC (1969) Estimation of the surface free energy of polymers. J Appl Polym Sci 13:1741–1747. doi:10.1592/phco.30.10.1004

Ozaydin-Ince G, Coclite AM, Gleason KK (2012) CVD of polymeric thin films: applications in sensors, biotechnology, microelectronics/organic electronics, microfluidics, MEMS, composites and membranes. Reports on Progress in Physics 75:016501 (p 40). doi:10.1088/0034-4885/75/1/016501

Pavli P, Petrou PS, Douvas AM et al (2011) Selective immobilization of proteins guided by photo-patterned poly(vinyl alcohol) structures. Procedia Eng 25:292–295. doi:10.1016/j.proeng.2011.12.072

Pérez OE, Sánchez CC, Pilosof AMR, Rodríguez Patino JM (2008) Dynamics of adsorption of hydroxypropyl methylcellulose at the air–water interface. Food Hydrocoll 22:387–402. doi:10.1016/j.foodhyd.2006.12.005

Peytavi R, Raymond FR, Gagné D et al (2005) Microfluidic device for rapid (<15 min) automated microarray hybridization. Clin Chem 51:1836–1844. doi:10.1373/clinchem.2005.052845

Riaz A, Gandhiraman RP, Dimov IK et al (2012) Reactive deposition of nano-films in deep polymeric microcavities. Lab Chip 12:4877–4883. doi:10.1039/c2lc40296c

Righetti PG, Gelfi C, Verzola B, Castelletti L (2001) The state of the art of dynamic coatings. Electrophoresis 22:603–611

Shah JJ, Geist J, Locascio LE et al (2006) Surface modification of poly(methyl methacrylate) for improved adsorption of wall coating polymers for microchip electrophoresis. Electrophoresis 27:3788–3796. doi:10.1002/elps.200600118

Siegrist J, Gorkin R, Clime L et al (2009) Serial siphon valving for centrifugal microfluidic platforms. Microfluid Nanofluid 9:55–63. doi:10.1007/s10404-009-0523-5

Siegrist J, Donohoe G, Somers M et al (2011) A centrifugo-microfluidic cartridge with integrated detection optics towards automated at-line bioprocess monitoring of immunoglobulin G. 15th International Conference on Miniaturized Systems for Chemistry and Life Sciences, pp 194–196

Steigert J, Brenner T, Grumann M et al (2007) Integrated siphon-based metering and sedimentation of whole blood on a hydrophilic lab-on-a-disk. Biomed Microdevices 9:675–679. doi:10.1007/s10544-007-9076-0

Strom GCRAN, Fredriksson M, Stenius PER (1987) Contact angles, work of adhesion, and interfacial tensions at a dissolving hydrocarbon surface. J Colloid Interface Sci 119:352–361

Ton-That C, Sharda G, Teare DOH, Bradley RH (2001) XPS and AFM surface studies of solvent-cast PS/PMMA blends. Polymer 42:1121–1129. doi:10.1016/S0032-3861(00)00448-1

Weikart CM, Yasuda HK (2000) Modification, degradation, and stability of polymeric surfaces treated with reactive plasmas. J Polym Sci, Part A: Polym Chem 38:3028–3042. doi:10.1002/1099-0518(20000901)38:17<3028:AID-POLA30>3.0.CO;2-B

Acknowledgments

This work has been supported partly by the FP-7 ENIAC programme CAJAL4EU, ERDF, Enterprise Ireland (Grant No. IR/2010/0002) and the Science Foundation of Ireland (Grant No. 10/CE/B1821). Authors would like to thank R. Monaghan for the PECVD APTES depositions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kitsara, M., Nwankire, C.E., Walsh, L. et al. Spin coating of hydrophilic polymeric films for enhanced centrifugal flow control by serial siphoning. Microfluid Nanofluid 16, 691–699 (2014). https://doi.org/10.1007/s10404-013-1266-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-013-1266-x